Wavetek 132 User manual

INSTRUCTION MANUAL

MODEL 132

VCG/NOISE GENERATOR

WARRANTY

All Wavetek instruments are warranteed against defects in material and workmanship for aperiod

of one year after date of manufacture. Wavetek agrees to repair or replace any assembly or

component (except batteries) found to be defective, under normal use, during this period.

Wavetek's obligation under this warranty is limited solely to repairing any such instrument which

in Wavetek's sole opinion proves to be defective within the scope of the warranty when returned

to the factory or to an authorized service center. Transportation to the factory or service center

is to be prepaid by purchaser. Shipment should not be made without prior authorization by

Wavetek.

This warranty does not apply to any products repaired or altered by persons not authorized by

Wavetek, or not in accordance with instructions furnished by Wavetek. If the instrument is

defective as aresult of misuse, improper repair, or abnormal conditions or operations, repairs will

be billed at cost.

Wavetek assumes no responsibility for its product being used in ahazardous or dangerous manner

either alone or in conjunction with other equipment. High voltage used in some instruments may

be dangerous if misused. Special disclaimers apply to these instruments. Wavetek assumes no

liability for secondary charges or consequential damages and, in any event, Wavetek's liability for

breach of warranty under any contract or otherwise, shall not exceed the purchase price of the

specific instrument shipped and against which aclaim is made.

Any recommendations made by Wavetek for use of its products are based upon tests believed to be

reliable, but Wavetek makes no warranty of the results to be obtained. This warranty is in lieu of

all other warranties, expressed or implied, and no representative or person is authorized to

represent or assume for Wavetek any liability in connection with the sale of our products other

than set forth herein.

ii

CONTENTS

Section One SPECIFICATIONS

Physical and Electrical Specifications 1

Section Two OPERATION

Inspection 3

Operating Controls 4

Operation 7

Section Three CIRCUIT DESCRIPTION

General Description 11

Section Four MAINTENANCE

Introduction 13

Recommended Test Equipment 13

Checkout and Calibration 13

Troubleshooting 16

Section Five DATA PACKAGE

Introduction 21

Recommended Spare Parts List 21

SCOPE OF MANUAL SCOPE OF EQUIPMENT

This manual contains instructions for operating, test- The Model 132 is asource of analog and digital noise,

ing, and maintaining the Wavetek Model 132 VCG/ as well as aprecision source of sine, triangle and square

Noise Generator. The Wavetek product-improvement waveforms. Noise outputs, or waveforms can be used

program ensures that the latest electronic developments individually, or combined to provide selectable, cal i-

are incorporated into the Wavetek instruments by the brated signal-to-noise and noise-to-signal ratios to

addition of circuit and component changes as rapidly +60 dB. Waveforms can be varied over afrequency

as development and testing permit. Due to the time re- range of 0.2 Hz to 2MHz. Length of the digital se-

quired to document and print this manual, it is not quence is selectable to amaximum of 220 —1bits,

always possible to incorporate these changes into the Clock rates, variable from 160 Hz through 1.6 MHz,

manual. Inthis case, data will be found on engineering give added versatility to the noise generator. These

change sheets at the back of the manual. If there are no clock rates allow selectable noise bandwidths variable

change sheets, the manual is correct as printed. from 10 Hz to 100 kHz.

iii REV S-9/78

SECTION 1

SPECIFICATIONS

VERSATILITY HORIZONTAL PRECISION

Waveforms

ana

Sine '\J ,square u,triangle Vwaveforms

and analog noise ,or digital noise JU~

L

Dial Accuracy

±2% of full scale, 1Hz to 2MHz

Frequency Range of Signal

0.2 Hz to 2MHz in 6decade ranges

Frequency Vernier

One turn equals 1% of full scale

Ranges

X10

X100

XI K

X10K

X100K

X1M

0.2 Hz to 20 Hz

2Hz to 200 Hz

20 Hz to 2kHz

200 Hz to 20 kHz

2kHz to 200 kHz

20 kHz to 2MHz

Time Symmetry

±1% through X100K range

VERTICAL PRECISION

Function Outputs

Sine %,square Hj ,and triangle \/ selectable,

with 60 dB step attenuator in 10 dB steps and over-

lapping calibrated vernier; 5012 output impedance,

20 Vp-p into open circuit and 10 Vp-p into 5012

load from 5012 source impedance.

Sine Wave Frequency Response

Amplitude change with frequency less than:

0.1 dB from 0.2 Hz to 200 kHz

0.5 dB from 0.2 Hz to 2MHz

PURITY

Sync Output

Greater than 1Vp-p square wave into open circuit at

60012 output impedance.

DC Offset

±5 Voffset (±2.5 Voffset into 5012 load) controlled

frr\m roar npnol -npol/ prnnl i+i trip limltprl U\i thp rl\/nor«.

iiwiii ivui f-'ui iv/i ,pCui\ Ciiii^iiiuviC hi miCo k_/ yuiC uyiiui ii

ic range of the amplifier output.

VCG —Voltage Controlled Generator

Frequency of the generator may be dc-programmed,

or ac-modulated by external 0to ±5 Vsignal. Voltage

control circuitry is capable of 1000:1 deviation. The

VCG amplifier has a100 kHz bandwidth and aslew

rate of 0.1 V/jds. The instantaneous frequency is the

result of the sum of the dial setting and the externally

applied voltage.

Stability

Short term ±0.05% for 10 minutes

Long term ±0.25% for 24 hours

Percentages apply to amplitude, frequency, and dc

offset.

Sine Wave Distortion

Less than:

0.5% on X10, X100, XI K, X10K ranges

1.0% on X100K range

All harmonics 30 dB down on XI MHz range

Square Wave Rise and Fall Time

Less than 50 ns terminated into 5012

NOISE

Outputs

Pseudo-random analog or digital noise with amaximum

of 20 Vp-p excursion (open circuit) with 60 dB step

attenuator in 10 dB steps and overlapping calibrated

vernier.

Sequence Lengths

Push buttons on the front panel provide asequence

length of 210 -1, 215 -1, or 220 -1.

1

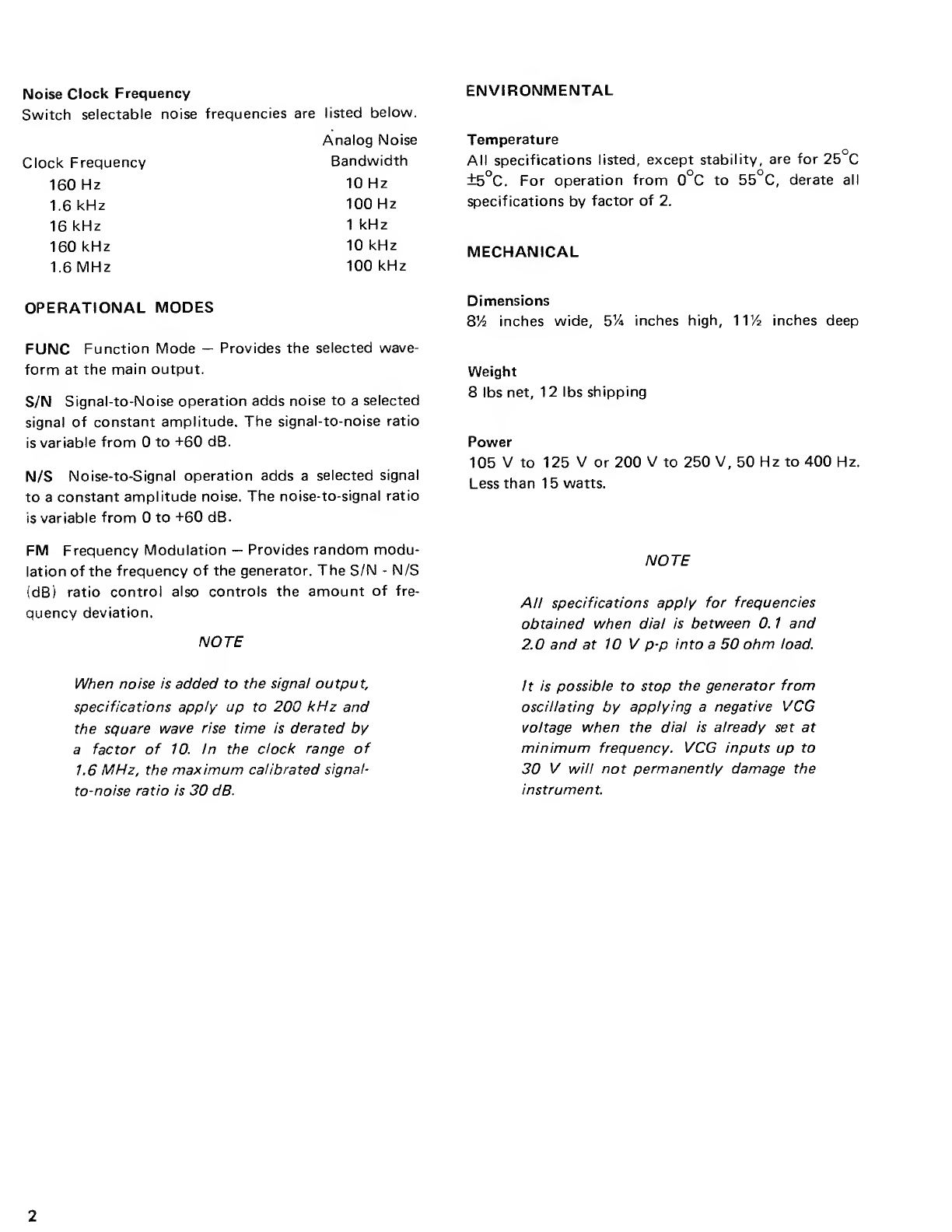

Noise Clock Frequency

Switch selectable noise frequencies are listed below.

Clock Frequency

160 Hz

1.6 kHz

16 kHz

160 kHz

1.6 MHz

Analog Noise

Bandwidth

10 Hz

100 Hz

1kHz

10 kHz

100 kHz

ENVIRONMENTAL

Temperature

All specifications listed, except stability, are for 25 C

±5°C. For operation from 0°C to 55°C, derate all

specifications by factor of 2.

MECHANICAL

OPERATIONAL MODES

FUNC Function Mode —Provides the selected wave-

form at the main output.

S/N Signal-to-Noise operation adds noise to aselected

signal of constant amplitude. The signal-to-noise ratio

is variable from 0to +60 dB.

N/S Noise-to-Signal operation adds aselected signal

to aconstant amplitude noise. The noise-to-signal ratio

is variable from 0to +60 dB.

FM Frequency Modulation —Provides random modu-

lation of the frequency of the generator. The S/N -N/S

(dB) ratio control also controls the amount of fre-

quency deviation.

NOTE

Dimensions

8V2inches wide, 5% inches high, 11

V

2inches deep

Weight

8lbs net, 12 lbs shipping

Power

105 Vto 125 Vor 200 Vto 250 V, 50 Hz to 400 Hz.

Less than 15watts.

NOTE

All specifications apply for frequencies

obtained when dial is between 0. 1and

2.0 and at 10 Vp-p into a50 ohm load.

When noise is added to the signal output,

specifications apply up to 200 kHz and

the square wave rise time is derated by

afactor of 10. In the dock range of

1.6 MHz, the maximum calibrated signal-

to-noise ratio is 30 dB.

It is possible to stop the generator from

oscillating by applying anegative VCG

voltage when the dial is already set at

minimum frequency. VCG inputs up to

30 Vwill not permanently damage the

instrument.

2

SECTION 2

OPERATION

INSPECTION 2.

3.

The following procedures should be performed to es-

sure the user that the instrument has arrived at its 4.

destination in satisfactory operating condition. Com-

plete calibration and checkout instructions are pro- 5.

vided in Section 4to determine compliance with elec- 6.

trical specifications.

Checking Visually /.

After carefully unpacking the instrument, visually in-

spect the external parts for damage to knobs, dials,

indicators, surface areas, etc. If damage is discovered,

file aclaim with the carrier who transported the in-

strument. Retain the shipping container and packing

material for use in case reshipment is required.

Checking Electrically

NOTE

8.

9.

10.

11.

Instruments are normally shipped con- 12.

nected for 115 Vpower unless 230 V

power is ordered. Refer to the end of 13.

this section for conversion instructions.

The steps in this paragraph provide aquick checkout

of the instrument operation. If electrical deficiencies

exist, refer to the WARRANTY in the front of this

manual. The following test equipment is recommended

for performing this electrical inspection: 14.

Name Required 15.

Characteristics

16.

Oscilloscope To 30 MHz

Plug-1 nDual channel

Plug-1 nPeak mV measuring

capability

17.

Counter-Timer To 2MHz with 5-digit 18.

resolution

19.

1. Turn FREQ HZ selector to the X1K position.

(This connects ac power to the unit and estab-

lishes the frequency multiplier.)

Depress MODE —FUNC push button.

Connect oscilloscope to the 50^2 OUT connec-

+v- imcfUnCZ O(/+nrrv> ino+/M'

lui vviui aici miiiai^M .

Set frequency dial to the 1.0 mark and FREQ

VERNIER to CAL position.

Set function selector to the /\j position.

Set OUTPUT ATTEN (dB) and OUTPUT VER-

NIER (dB) to maximum clockwise (cw) posi-

tion (no attenuation).

Check for 1kHz sine wave with at ieast 10 'v

p-p amplitude on oscilloscope.

AI1

Select 'and 1

]\with function selector

and check for 10 Vp-p amplitude on oscil-

loscope.

Turn frequency dial from maximum counter-

clockwise (ccw) to maximum cw position and

check for frequency change.

Step OUTPUT ATTEN (dB) selector through

its range and verify attenuation at each step.

Rotate OUTPUT VERNIER (dB) control from

maximum cw to maximum ccw position and

check for decreasing amplitude.

Rotate FREQ VERNIER control and check for

frequency change.

Set FREQ VERNIER control at maximum cw

and frequency dial at 0.02. Set frequency to

20 Hz with counter. Connect a0to +5 Vdc

input to the VCG IN connector. Slowly increase

voltage input from 0to +5 Vand check that

frequency of output waveform increases from

approximately 20 Hz to 2kHz.

Depress SEQUENCE LENGTH 210 -1push

button.

Set NOISE FREQ HZ selector to the 16K/160K

position and vernier control fully cw.

Connect aBNC cable from the NOISE SYNC

connector (rear panel) to the external trigger

input of the oscilloscope.

Rotate the function selector to Land check

to assure oscilloscope displays digital noise.

Check to assure SEQUENCE LENGTH push

buttons vary the bits in the sequence length.

Step HZ ss

!

0cto rthrouejh 'ts

range and check to assure clock frequency

changes. (Use NOISE CLOCK connector on rear

panel.)

3

20. Verify that NOISE FREQ HZ vernier control

provides approximately 10:1 variation in clock

frequency at the NOISE CLOCK connector

(rear panel).

21. Rotate function selector to /“

!

J

position and

check to assure oscilloscope displays analog

noise.

22. Check to assure SEQUENCE LENGTH push

buttons vary the length of the sequence of

analog noise. (Use NOISE SYNC connector on

rear panel.)

23. Connect oscilloscope external trigger cable to

FUNCTION SYNC connector (rear panel) and

Set iuil CttG i~i ScicClGi' tO IipGSitiGi ».

24. Set S/N —N/S (d B)selector to —10 position

and vernier control fully ccw.

25. Depress MODE —FM push button and check

to assure square waveforms are frequency modu-

lated by analog noise.

26. Release MODE —FM push button and depress

MODE —S/N push button. Check to assure

square wave and analog noise are mixed.

27. Depress MODE —N/S push button and rotate

S/N —N/S (dB) selector ccw through each

position, checking for reduction in signal level.

28. Verify that the S/N —N/S (dB) vernier attenu-

ates the signal approximately 10 dB between

each step of the S/N —N/S (dB) selector.

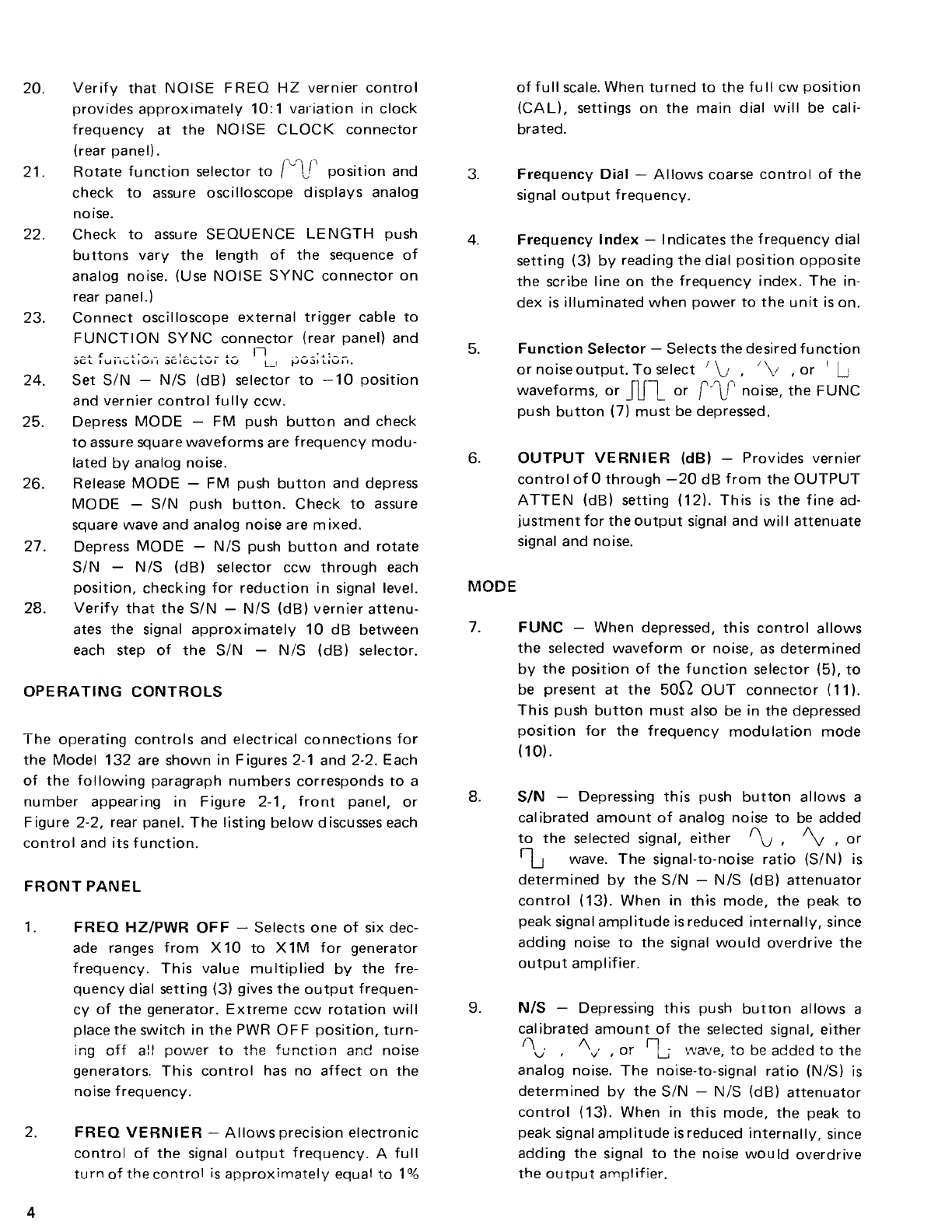

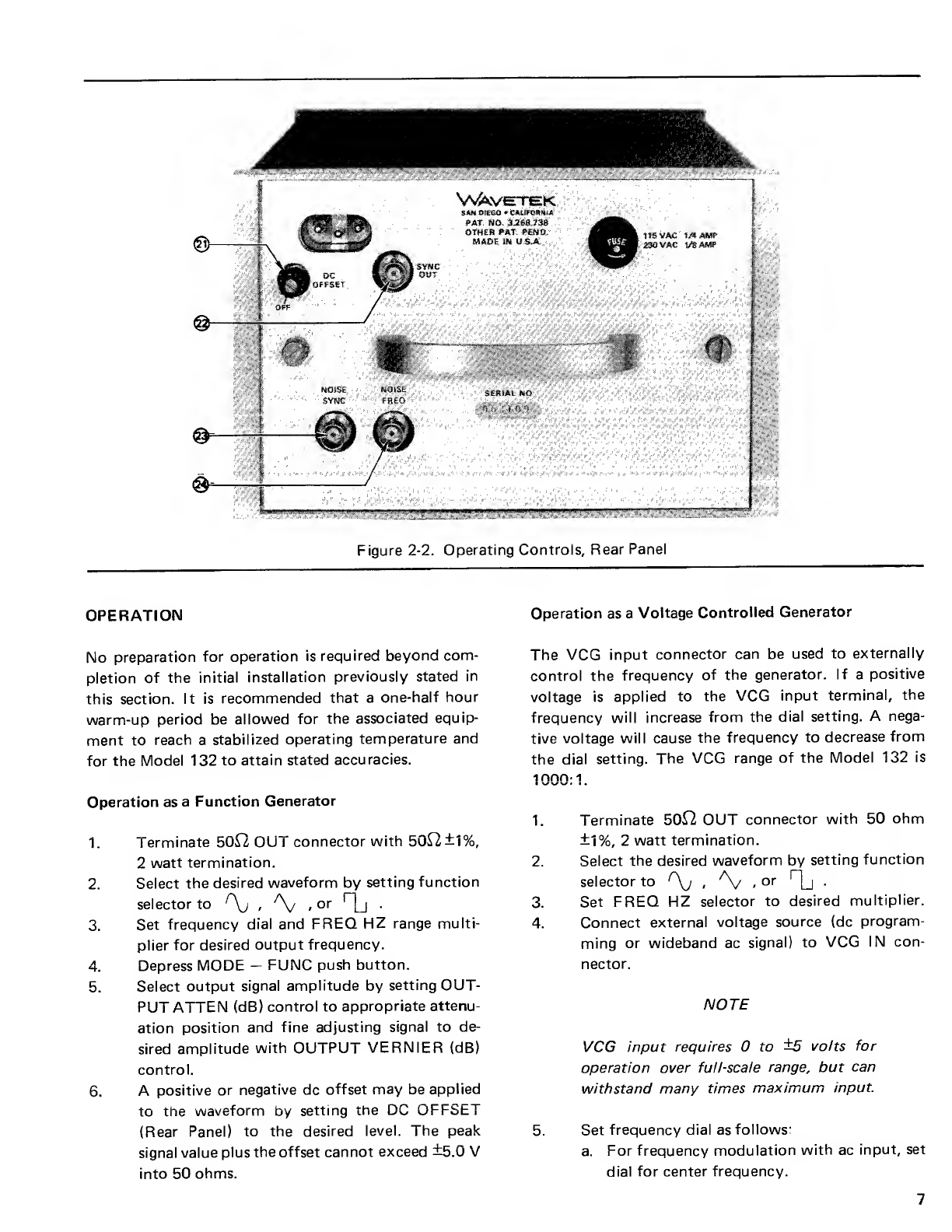

OPERATING CONTROLS

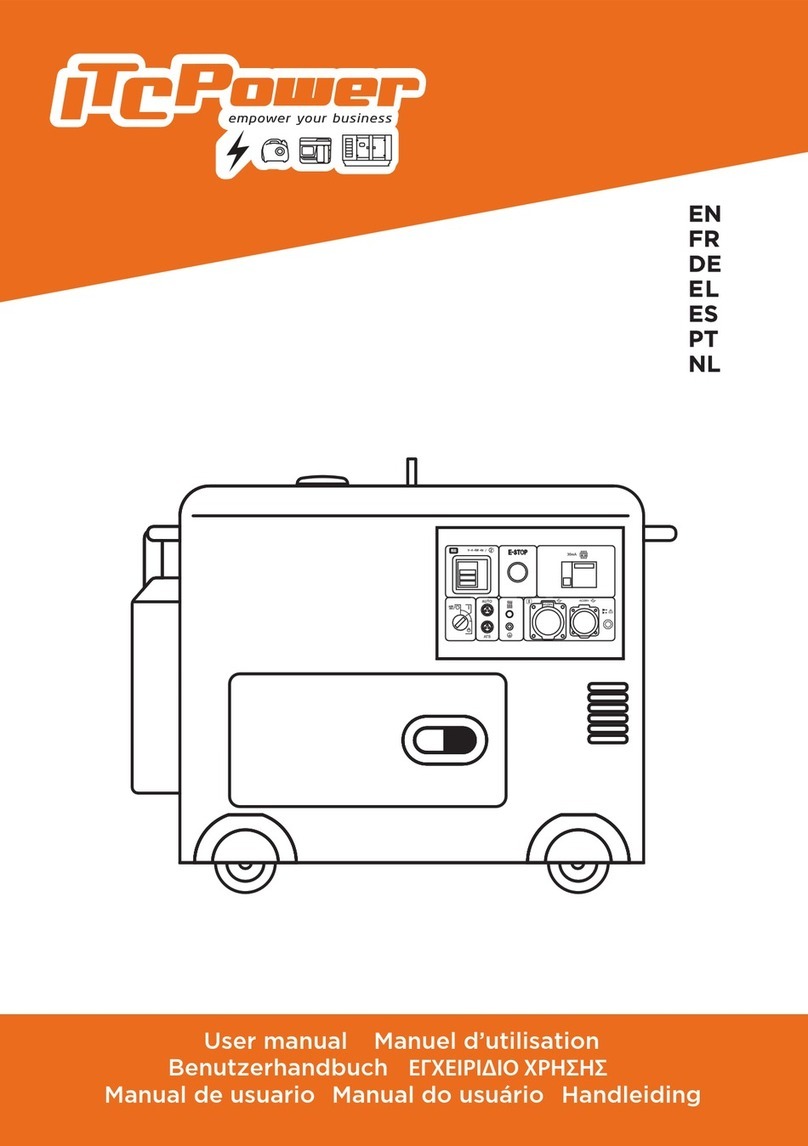

The operating controls and electrical connections for

the Model 132 are shown in Figures 2-1 and 2-2. Each

of the following paragraph numbers corresponds to a

number appearing in Figure 2-1, front panel, or

Figure 2-2, rear panel. The listing below discusses each

control and its function.

FRONT PANEL

1. FREQ HZ/PWR OFF —Selects one of six dec-

ade ranges from X10 to X1M for generator

frequency. This value multiplied by the fre-

quency dial setting (3) gives the output frequen-

cy of the generator. Extreme ccw rotation will

place the switch in the PWR OFF position, turn-

ing off all power to the function and noise

generators. This control has no affect on the

noise frequency.

2. FREQ VERNIER —Allows precision electronic

control of the signal output frequency. Afull

turn of the control is approximately equal to 1%

of full scale. When turned to the full cw position

(CAL), settings on the main dial will be cali-

brated.

3. Frequency Dial —Allows coarse control of the

signal output frequency.

4. Frequency Index —Indicates the frequency dial

setting (3) by reading the dial position opposite

the scribe line on the frequency index. The in-

dex is illuminated when power to the unit is on.

5. Function Selector —Selects the desired function

or noise output. To select !\j ,'V ,or 1

|j

waveforms, or JjJ T_ or nr noise, the FUNC

push button (7) must be depressed.

6. OUTPUT VERNIER (dB) -Provides vernier

control of 0through —20 dB from the OUTPUT

ATTEN (dB) setting (12). This is the fine ad-

justment for the output signal and will attenuate

signal and noise.

MODE

7. FUNC —When depressed, this control allows

the selected waveform or noise, as determined

by the position of the function selector (5), to

be present at the 50fi OUT connector (11).

This push button must also be in the depressed

position for the frequency modulation mode

(10).

8. S/N —Depressing this push button allows a

calibrated amount of analog noise to be added

to the selected signal, either /\j ,'v ,or

HL wave. The signal-to-noise ratio (S/N) is

determined by the S/N —N/S (dB) attenuator

control (13). When in this mode, the peak to

peak signal amplitude is reduced internally, since

adding noise to the signal would overdrive the

output amplifier.

9. N/S —Depressing this push button allows a

calibrated amount of the selected signal, either

'\y , , or r"|_j wave, to be added to the

analog noise. The noise-to-signal ratio (N/S) is

determined by the S/N —N/S (dB) attenuator

control (13). When in this mode, the peak to

peak signal amplitude is reduced internally, since

adding the signal to the noise would overdrive

the output amplifier.

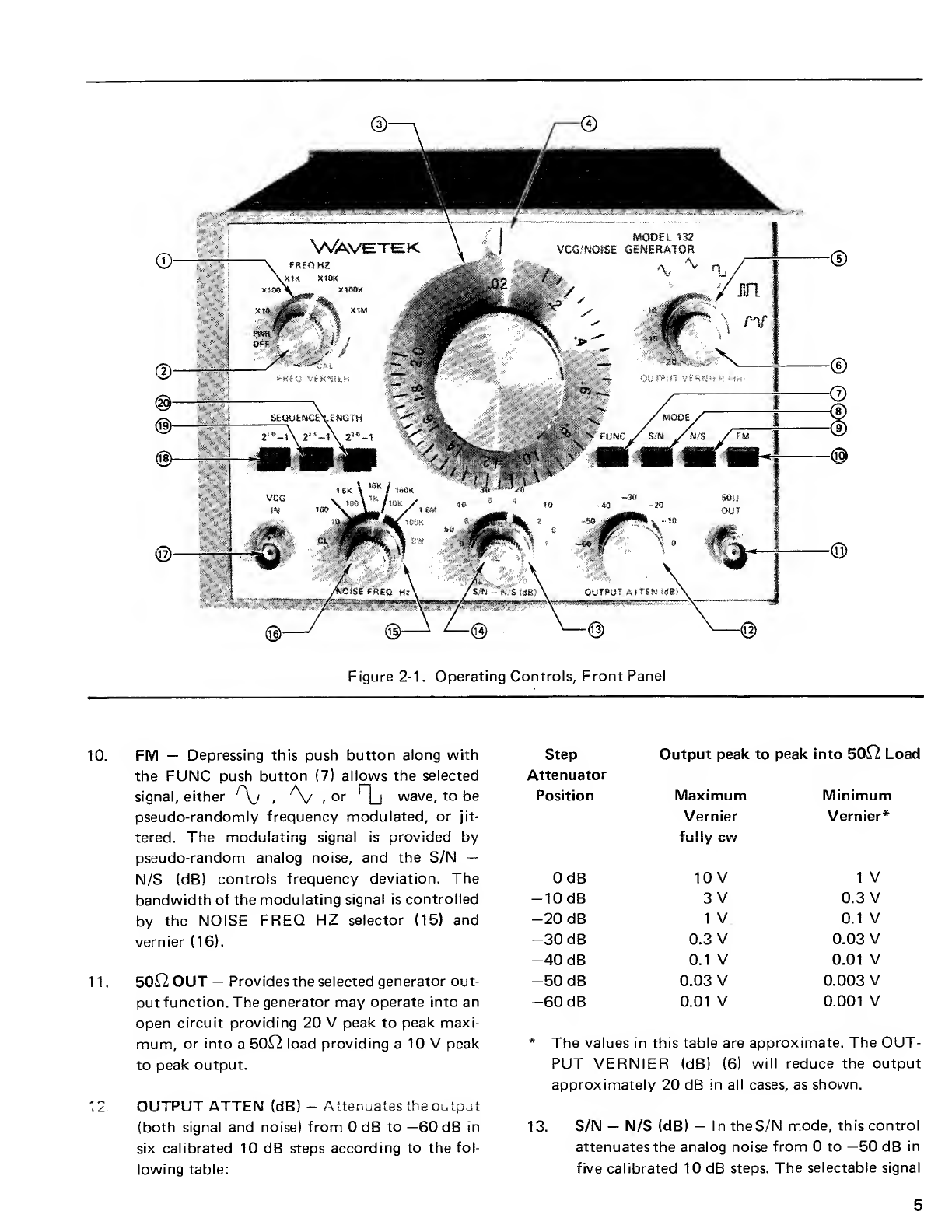

4

X100K

SEQUtMCEVENGTM

iOlSEFREO hA OUTPUT AITEN !<jb:

Figure 2-1 .Operating Controls, Front Panel

10. FM —Depressing this push button along with

the FUNC push button (7) allows the selected

signal, either Ay ,Ay ,or Oj wave, to be

pseudo-randomly frequency modulated, or jit-

tered. "The modulating signal is provided by

pseudo-random analog noise, and the S/N —

N/S (dB) controls frequency deviation. The

bandwidth of the modulating signal is controlled

by the NOISE FREQ FIZ selector (15) and

vernier (16).

11. 5012 OUT —Provides the selected generator out-

put function. The generator may operate into an

open circuit providing 20 Vpeak to peak maxi-

mum, or into a5012 load providing a10 Vpeak

to peak output.

12. OUTPUT ATTEN (dB) -Attenuates the output

(both signal and noise) from 0dB to —60 dB in

six calibrated 10 dB steps according to the fol-

lowing table:

Step Output peak to peak into 5012 Load

Attenuator

Position Maximum

Vernier

fully cvv

Minimum

Vernier*

0dB 10 V1V

—10 dB 3V0.3 V

-20 dB 1V0.1 V

-30 dB 0.3 V0.03 V

-40 dB 0.1 V0.01 V

-50 dB 0.03 V0.003 V

-60 dB 0.01 V0.001 V

*The values in this table are approximate. The OUT-

PUT VERNIER (dB) (6) will reduce the output

approximately 20 dB in all cases, as shown.

13. S/N —N/S (dB) —IntheS/N mode, this control

attenuates the analog noise from 0to —50 dB in

five calibrated 10 dB steps. The selectable signal

5

amplitude remains constant, thus giving cali-

brated 0to —50 dB signal-to-noise ratios. In the

N/S mode, the signal is attenuated with the

noise remaining unchanged, thus giving noise-

to-signal ratios from 0to —50 dB. The steps for

this control are indicated in black numerals on

the front panel.

14. S/N —N/S (dB) Vernier —Allows acalibrated

fine adjustment of the S/N —N/S (dB) step at-

tenuator (13). This control is continuously vari-

able over at least a10 dB range. When added to

the coarse control (13), this amount equals the

total S/N or N/S ratio. Approximate values ot

attenuation are indicated in red numerals on the

front panel.

15, NOISE FREQ HZ —This range control selects

the clock frequency, or bandwidth for the digi-

tal, or analog noise, respectively. When using the

digital noise function, clock frequencies from

160 Hz through 1.6 MHz (indicated in black

numerals and letters on the front panel) are

available. When using analog noise or the S/N,

N/S modes, the bandwidth of the analog noise

may be selected from 10 Hz to 100 kHz (in-

dicated in red numerals and letters on the front

panel). In the FM mode, this control establishes

the bandwidth of the analog noise used for fre-

quency modulation. There are four detent posi-

tions with an overlapping vernier control (16).

With the vernier in the full cw position, the

clock frequency, or bandwidth, is equal to the

value printed to the right of the detent mark.

16, NOISE FREQ HZ Vernier —As mentioned in

number 15, this control provides acontinuous,

fine control between the detent positions of

the coarse control. When in the full cw position,

the clock frequency, or bandwidth, is equal to

the value appearing at the right of the detent

mark. As the knob is rotated ccw, the clock

frequency, or bandwidth, is decreased. In the

full ccw position, the actual value will be at

least 10:1 (and as much as 100:1) lower than

the value to the right of the detent mark.

17. VCG IN —This connector allows external volt-

age control of function generator frequency. Up

to 1000:1 frequency change may be obtained.

Apositive voltage increases frequency and a

negative voltage decreases frequency. Refer to

"Operation as aVoltage Controlled Generator.”

SEQUENCE LENGTH

18. 210 —1—Depressing this push button will

provide 1,023 counts of the selected clock fre-

quency, or bandwidth, determined by the

NOISE FREQ HZ controls (15 and 16), for

generation of adigital, or analog noise pattern.

At the end of each sequence, the pattern is

automatically repeated.

19. 215 —1—Depressing this push button will

provide 32,767 counts of the selected clock

frequency, or bandwidth, determined by the

ni/*> «or— rnr Ii~7 .._ j. I _!Anr ir* 'f..

IwikJ liU. i i z_ ouiiu uiJ tiUi iu i\Ji ,tut

generation of adigital, or analog noise pattern.

At the end of each sequence, the pattern is

automatically repeated.

20. 220 —1—Depressing this push button will

provide 1,048,575 counts of the selected clock

frequency, or bandwidth, determined by the

NOISE FREQ HZ controls (15 and 16), for

generation of adigital, or analog noise pattern.

At the end of each sequence, the pattern is

automatically repeated.

REAR PANEL

21. DC OFFSET —This control adjusts the ±5 V

base line above or below ground (±2.5 Voffset

into 50^2 load). The OFF position gives normal

vertical symmetry. Peak amplitude is limited by

the dynamic range of the amplifier output.

22. FUNCTION SYNC —This connector provides a

synchronizing signal output at the same fre-

quency of the main generator; that is, at the

same frequency as the sine, triangle or square

wave. The amplitude is greater than 1Vpeak to

peak square wave into open circuit at 600^2

output impedance.

23. NOISE SYNC —This connector provides asyn-

chronizing output signal for monitoring the dig-

ital or analog noise. Async signal is generated at

the beginning of each repetitive cycle for the

selected sequence length of digital or analog

noise.

24. NOISE CLOCK —This connector provides an

external output of the basic clock frequency

used to generate the digital sequence and analog

noise.

6

Figure 2-2. Operating Controls, Rear Panel

OPERATION

No preparation for operation is required beyond com-

pletion of the initial installation previously stated in

this section. It is recommended that aone-half hour

warm-up period be allowed for the associated equip-

ment to reach astabilized operating temperature and

for the Model 132 to attain stated accuracies.

Operation as aFunction Generator

1. Terminate 5012 OUT connector with 5012 ±1%,

2watt termination.

2. Select the desired waveform by setting function

selector to /\j ,.or 1|j .

3. Set frequency dial and FREQ HZ range multi-

plier for desired output frequency.

4. Depress MODE —FUNC push button.

5. Select output signal amplitude by setting OUT-

PUT ATTEN (dB) control to appropriate attenu-

ation position and fine adjusting signal to de-

sired amplitude with OUTPUT VERNIER (dB)

control.

6. Apositive or negative dc offset may be applied

to the waveform by setting the DC OFFSET

(Rear Panel) to the desired level. The peak

signal value plus the offset cannot exceed ±5.0 V

into 50 ohms.

Operation as aVoltage Controlled Generator

The VCG input connector can be used to externally

control the frequency of the generator. If apositive

voltage is applied to the VCG input terminal, the

frequency will increase from the dial setting. Anega-

tive voltage will cause the frequency to decrease from

the dial setting. The VCG range of the Model 132 is

1000:

1

1. Terminate 5012 OUT connector with 50 ohm

±1%, 2watt termination.

2. Select the desired waveform by setting function

selector to ^\j ,,or Oj •

3. Set FREQ HZ selector to desired multiplier.

4. Connect external voltage source (dc program-

ming or wideband ac signal) to VCG IN con-

nector.

NOTE

VCG input requires 0to ±5 volts for

operation over full-scale range, but can

withstand many times maximum input.

5.

Set frequency dial as follows:

a. For frequency modulation with ac input, set

dial for center frequency.

7

b. For increasing frequency sweep with positive

dc input, set dial to lower frequency limit.

c. For decreasing frequency sweep with nega-

tive dc input, set dial to upper frequency

limit.

6. To sweep the audio range from 20 Hz to 20 kHz,

set the controls to 20 Hz as follows:

a. Set the main dial to 0.02.

b. Set the frequency vernier to the full ccw

position.

c. Introduce a0to +5 Vramp into the VCG

input'connector.

The maximum frequency which may be obtained, when

using the VCG input, is the range multiplier times the

value at the top of the dial (2.0). The minimum fre-

quency is the range multiplier times the value at the

bottom of the dial (0.002 —frequency vernier must

be in ccw position). Verify this using the nomograph

in Figure 2-3.

MAIN DIAL VCG IN 50HOUT

SETTING VOLTAGE FREQUENCY

Figure 2-3 -VCG Voltage-to-Frequency Nomograph

In example 1, the dial is set at 1.0 and 0 voltage is

applied to the VCG input. Extend astraight line from

1.0 (dial setting) through 0voltage (VCG voltage) and

obtain adial frequency of 1.0. For the total output

frequency, multiply the range by 1with the same dial

setting. Example 2shows the results of using aramp

from —1 volt to +2.5 volts for the VCG voltage. This

results in aswept output from 0.6 to 2.0 on the dial.

Remember to multiply the dial times the range.

Operation as aCalibrated Signal-to-Noise Source

1. Select the desired siqnal waveform bv settina

function selector to f\j ,A^ (or Tl-

2. Set frequency dial and FREQ HZ range multi-

plier for desired signal output frequency.

3. Depress MODE —S/N push button.

4. Select noise bandwidth by setting NOISE FREQ

HZ control to desired range and fine adjusting

bandwidth by turning the noise frequency Hz

vernier control.

5. Select desired SEQUENCE LENGTH by de-

pressing appropriate push button.

6. Select signal-to-noise ratio by setting S/N —N/S

(dB) control to appropriate attenuation position

and fine adjusting attenuation to desired value

with S/N —N/S vernier control.

7. Select total output amplitude by setting OUT-

PUT ATTEN (dB) control to appropriate atten-

uation position and fine adjusting signal to de-

sired amplitude with OUTPUT VERNIER (dB)

control.

Operation as aCalibrated Noise-to-Signal Source

1. Select the desired signal waveform by setting

function selector to r\j ,A^ for 1l

2. Set frequency dial and FREQ HZ range multi-

plier for desired signal output frequency.

3. Depress MODE —N/S push button.

4. Select noise bandwidth by setting NOISE FREQ

HZ control to desired range and fine adjusting

bandwidth by turning the noise frequency Hz

vernier control.

5. Select desired SEQUENCE LENGTH by depres-

sing appropriate push button.

6. Select noise-to-signal ratio by setting S/N —N/S

(dB) control to appropriate attenuation position

and fine adjusting attenuation to desired value

with S/N —N/S vernier control.

7. Select total output amplitude by setting OUT-

PUT ATTEN (dB) control to appropriate atten-

uation position and fine adjusting signal to de-

8

sired amplitude with OUTPUT VERNIER (dB)

control.

'Operation as aRandom FM Source

Before using the generator as arandom FM source,

please note the following.

4. Select desired SEQUENCE LENGTH by depres-

sing appropriate push button.

5. Select noise amplitude by setting OUTPUT

ATTEN (dB) control to appropriate attenuation

position and fine adjusting noise to desired

amplitude with OUTPUT VERNIER (dB) con-

trol.

The frequency of the generator is being varied or

modulated by achanging voltage in the same way as

described in "Operation as aVoltage Controlled Gen-

erator." However, instead of using adc ramp, or ac

signal, arandom analog voltage is used. When the FM

push button is depressed, the analog noise is injected

internally into the VCG circuit; therefore, the modu-

lation is created by random noise. The S/N —N/S (dB)

knob controls ths msximum amount of frscjusncy

deviation, since it controls the amplitude of the noise.

Bandwidth of the FM signal is controlled by the

NOISE FREQ HZ control. Using the generator in the

FM mode may be accomplished as follows:

1. Select the desired signal waveform by setting

function selector to /\y ,

/\/ ,or Hu •

2. Set frequency dial and FREQ HZ range multi-

plier for desired center output frequency.

3. Depress MODE —FUNC and FM push buttons.

4. Select the bandwidth by setting NOISE FREQ

HZ control to desired range and fine adjusting

frequency by turning the noise frequency Hz

vernier control.

5. Select desired SEQUENCE LENGTH by depres-

sing appropriate push button.

6. Select signal frequency deviation by setting

S/N —N/S (dB) controi to appropriate attenua-

tion position and fine adjusting attenuation to

desired deviation with S/N —N/S vernier control.

7. Select output signal amplitude by setting OUT-

PUT ATTEN (dB) control to appropriate atten-

uation position and fine adjusting signal to de-

sired amplitude with OUTPUT VERNIER (dB)

control.

Operation as aDigital or Analog Noise Source

1. Set function selector to digital or analog noise

position.

2. Depress MODE —FUNC push button.

3. Select clock frequency for digital or bandwidth

for analog noise by setting NOISE FREQ HZ

control to desired range and fine adjusting fre-

quency by turning the noise frequency Hz ver-

nier control.

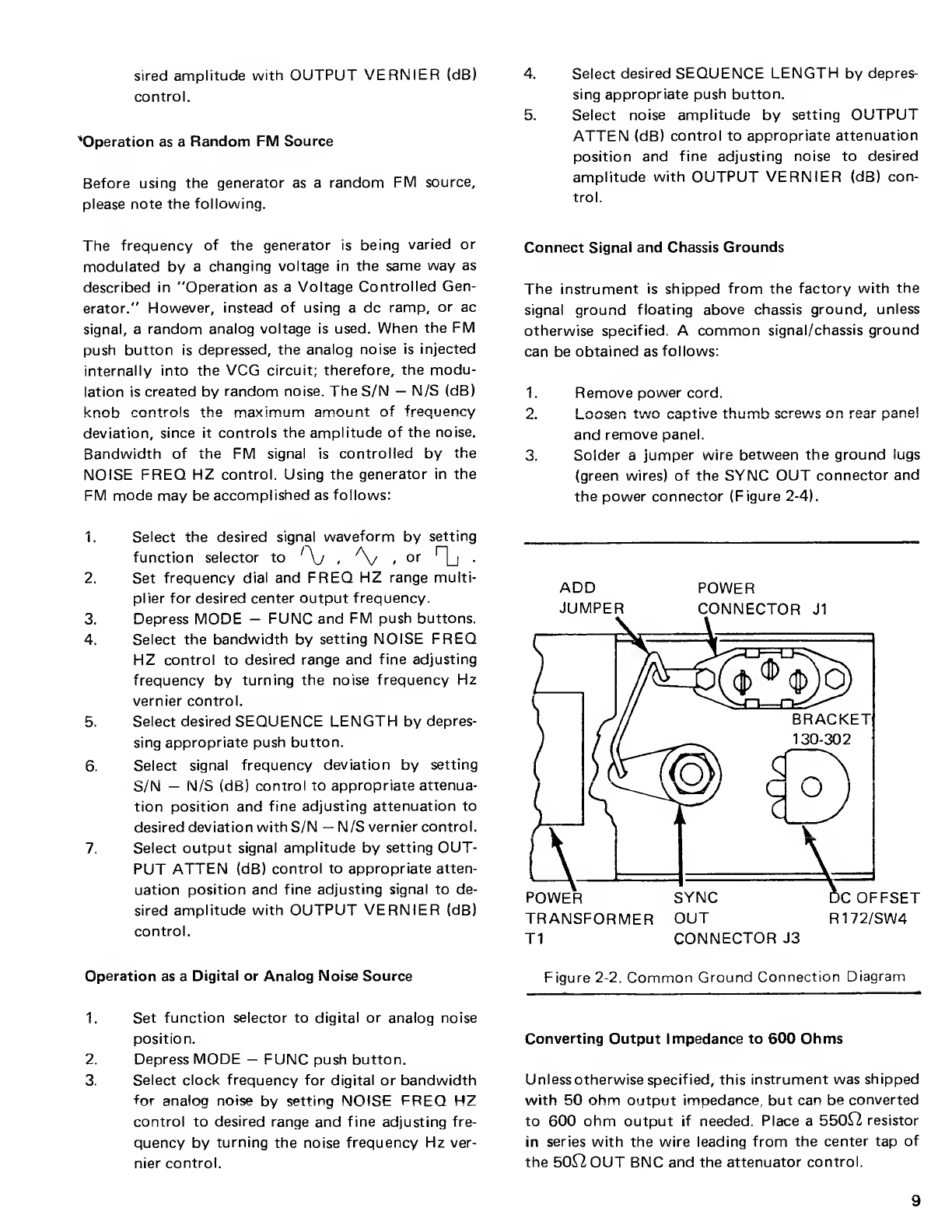

Connect Signal and Chassis Grounds

The instrument is shipped from the factory with the

signal ground floating above chassis ground, unless

otherwise specified. Acommon signal/chassis ground

can be obtained as follows:

1.

2.

3.

Remove power cord.

Ioocpn tiAirv oon+iwo thiimh coroiA/c nnroar nanol

|_WUjC II LVVWLl« VLI IUI IU Wl Ul/lIJ *-* I • IV/WI i'"

and remove panel.

Solder ajumper wire between the ground lugs

(green wires) of the SYNC OUT connector and

the power connector (Figure 2-4).

ADD POWER

JUMPER CONNECTOR J1

Figure 2-2. Common Ground Connection Diagram

Converting Output Impedance to 600 Ohms

Unless otherwise specified, this instrument was shipped

with 50 ohm output impedance, but can be converted

to 600 ohm output if needed. Place a550^2 resistor

in series with the wire leading from the center tap of

the 50^2 OUT BNC and the attenuator control.

9

Converting to 230-Volt Line Power

Instruments are shipped from the factory with the

power transformer connected for 115-volt line power,

unless ordered for 230-volt use. Converting a115-volt

unit for 230-volt operation is asimple matter.

1.

Remove power cord.

2. Loosen two captive thumb screws on rear panel

and remove panel.

3. The conversion switch is located on the chassis.

Use athin-bladed screwdriver to move the 115-

230 switch to the 230 position.

4. Replace 1/4-ampere fuse with a1/8-ampere fuse

of the same type.

10

SECTION 3

CIRCUIT DESCRIPTION

GENERAL DESCRIPTION

di3Qf*3i 1

1

Noise Generator, Figure 3-1.

Basically, asquare wave is applied to the input of an

integrator composed of awide-band differential dc

amplifier, integrating resistor and capacitor. Output

of the integrator is fed into the hysteresis switch.

The hysteresis and output switches function like a

Schmitt trigger with the limit points set at the wave-

form extremes, firing when the triangle wave reaches

+1.25 volts and —1.25 volts. When firing occurs, the

hysteresis and output switches are set, reversing the

square wave fed into the integrator. Reversal of the

square wave causes the triangle wave to reverse direc-

VCG

11

tion. The result is simultaneous generation of asquare

wave and triangle wave of the same frequency with

the positive half cycle of the square wave coincident

with the negative slope of the triangle wave.

The magnitude of the capacitor across the integrator

and amplitude of the current into the integrator deter-

mine the frequency of oscillation. Capacitance across

the integrator is changed by rotating the frequency Hz

selector. Amplitude of the current into the integrator

is determined by four parameters which are summed

in the VCG circuit: (1) hysteresis switch output, (2)

the frequency dial voltage, (3) the frequency vernier

vouage, (hj tne vi^u analog voltage input ana tne

analog noise when in the FM mode.

The sine wave is produced by feeding the triangle

wave into ashaping network composed of resistors

and diodes. As the triangle wave voltage passes through

zero, loading of the triangle wave is minimal and thus

the slope is maximum. As the triangle voltage in-

creases, diodes with current limiting resistors conduct

and successively cause the slope of the output to be

reduced.

Since the diode break points are mathematically com-

puted and fitted to the true sine shape, the resultant

waveform resembles apure sine wave. Using acom-

plementary pair of diodes on each break point, the

circuitry is completely symmetrical about ground. The

sine wave, produced by shaping, is considerably less

in amplitude than the triangle wave input and is thus

amplified to be equal to the triangle wave.

Either square, triangle, or sine waveforms can be se-

lected as asignal source. The noise source is derived

from adigital filter. Aclock oscillator of 160 Hz to

1.6 MHz range functions as atrigger source for the

digital pseudo-random sequence generator (PRSG).

Output of the PRSG is arandom binary signal that

can function as digital noise. The number of bits in

each sequence can be selected by the SEQUENCE

LENGTH controls. Parallel data is fed from the PRSG

to the digital-to-analog converter where the informa-

tion is summed and filtered to provide arandom

analog noise signal.

The selected sine, triangle, square, analog noise, or

digital noise signal is routed to the mode control

circuitry where one of the following modes of opera-

tion is selected: Function (FUNC); frequency modula-

tion (FM); signal-to-noise (S/N); or noise-to-signal

(N/S). In the signal-to-noise and noise-to-signal modes,

one signal is fed to the S/N attenuator and then mixed

with the other signal in the S/N summing amplifier in

aknown dB ratio selected by the S/N attenuator. Out-

put of the mode switching circuit is coupled to the

output amplifier. From the output amplifier the signal

is fed to the precision output attenuator and finally to

a500 output connector.

Ail circuits, except for the hysteresis switch, output

amplifier, and PRSG, operate from ±15 volt supplies.

The hysteresis switch and power amplifier require

±6 volts and ±22 volts, respectively. Operation of the

PRSG requires a+5 Vsupply.

12

SECTION 4

MAINTENANCE

INTRODUCTION

This section provides instructions for testing, calihrat-

ing, troubleshooting, and repairing the Model 132. The

instructions are concise and for the experienced elec-

tronics technician or field engineer. Wavetek main-

tains afactory-repair department for those customers

not possessing the necessary personnel or test equip-

ment to maintain the instrument. If an instrument is

returned to the factory for calibration or repair, a

detailed description of the specific problem should be

attached to facilitate the turn around time. Test point

and adjustment locations are illustrated in Section 5.

(v/ )following the procedure title. Aquick checkout

of the instrument can be performed by comparing the

indicated parameters with the tolerances given in the

Specifications of Section 1.

NOTE

The entire calibration procedure must be

read first to determine initial control

settings and test equipment connections

before attempting checkout.

Preliminary Procedures

RECOMMENDED TEST EQUIPMENT

Table 4-1 contains alist of recommended test equip-

ment. Any test equipment having equivalent accuracies

may be substituted for those listed.

Table 4-1. TEST EQUIPMENT

Name Required

Characteristics

Oscilloscope

Plug-in

Plug-in

Distortion Anaiyzer

Spectrum Analyzer

Display

IFSection

RF Section

Voltmeter

To 30 MHz

Dual Channel

Peak mV measuring

capability

To 600 kHz

To 50 MHz

Millivolt dc measurement

(10 millivolt resolution)

1. Set FREQ HZ selector to XI Kposition.

2. Depress MODE —FUNC push button.

3. Set OUTPUT ATTEN (dB) selector to 0position.

4. Allow one-half hour for warm-up.

j?. dc crnc'r (_X>c TE>Jt)

Power Supply Regulation

1. Connect voltmeter between TP1 (common) and

TP2 (+) on main board. Adjust R104 for

+15 Vdc ±100 mV.

2. Connect voltmeter between TP1 (common) and

TP3 (—). Since the negative supply is referenced

to the +15 Vsupply, the voltmeter should

indicate —15 Vdc ±100 mV.

3. Connect voltmgtgr^etween +5 Vand location

DG on ^r^Jgfeoard. Verify that voltage is +4.75

to +5.25 volts.

Square Wave Amplitude Symmetry

1. Set function selector to .

2. Connect oscilloscope, with peak mV plug-in, to

tab of switch SW3B, as illustrated below.

Counter To 10 MHz

Scope Probe XI Attenuation

CHECKOUT AND CALIBRATION

The following paragraphs provide complete sequential

calibration procedures for the Model 132. Instrument

checkout procedures are indicated by acheck mark WAVEFORM SELECTOR

13

3, Using acomparator, set the positive peak to the

center of the scope. Switch the comparator to

the negative peak and adjust R121 so that the

negative peak equals the positive peak.

Triangle Amplitude

1. Set frequency dial for 2.0 (XI Krange) and

function selector to •

2. Connect oscilloscope, with peak mV plug-in, to

tab of switch SW3B, as illustrated under “Square

Wave Amplitude Symmetry."

3. Adjust R56 on main board for positive peak at

'-i or..- 14. --f-rr \rt,„.. .t,.*.i_ t

•«V\J ILD —%J |||V \3CC onciu t/

.

4. Adjust R59 for negative peak at —1 .25 V±5 mV.

Negative Peak Positive Peak

Output Amplifier y/

1. Connect oscilloscope to 50^2 OUT connector

with 50^2 terminator loaded at oscilloscope

(

1

j_j function).

2. Set FREQ HZ selector for X1K (FREQ VER-

NIER fully cw) and frequency dial at 2.0.

3. Turn OUTPUT VERNIER (dB) fully ccw.

4. Adjust R150 for amplitude symmetry about

ground.

5. Set FREQ HZ selector for XI M(2.0 dial

setting).

6. Turn OUTPUT VERNIER (dB) fully cw.

7. Adjust C64 to provide aflat square wave with

100 nanosecond rise time.

First VCG Null y/

1. Connect oscilloscope to 50&2 OUT connector.

2. Set FREQ HZ selector to XI K. Set frequency

dial to 0.02 and turn FREQ VERNIER to CAL

position.

3. Short and open VCG IN to signal ground (out-

side of BNC connector) while monitoring out-

put frequency variation. Adjust R11 for mini-

mum frequency change using X20 horizontal

magnification on oscilloscope.

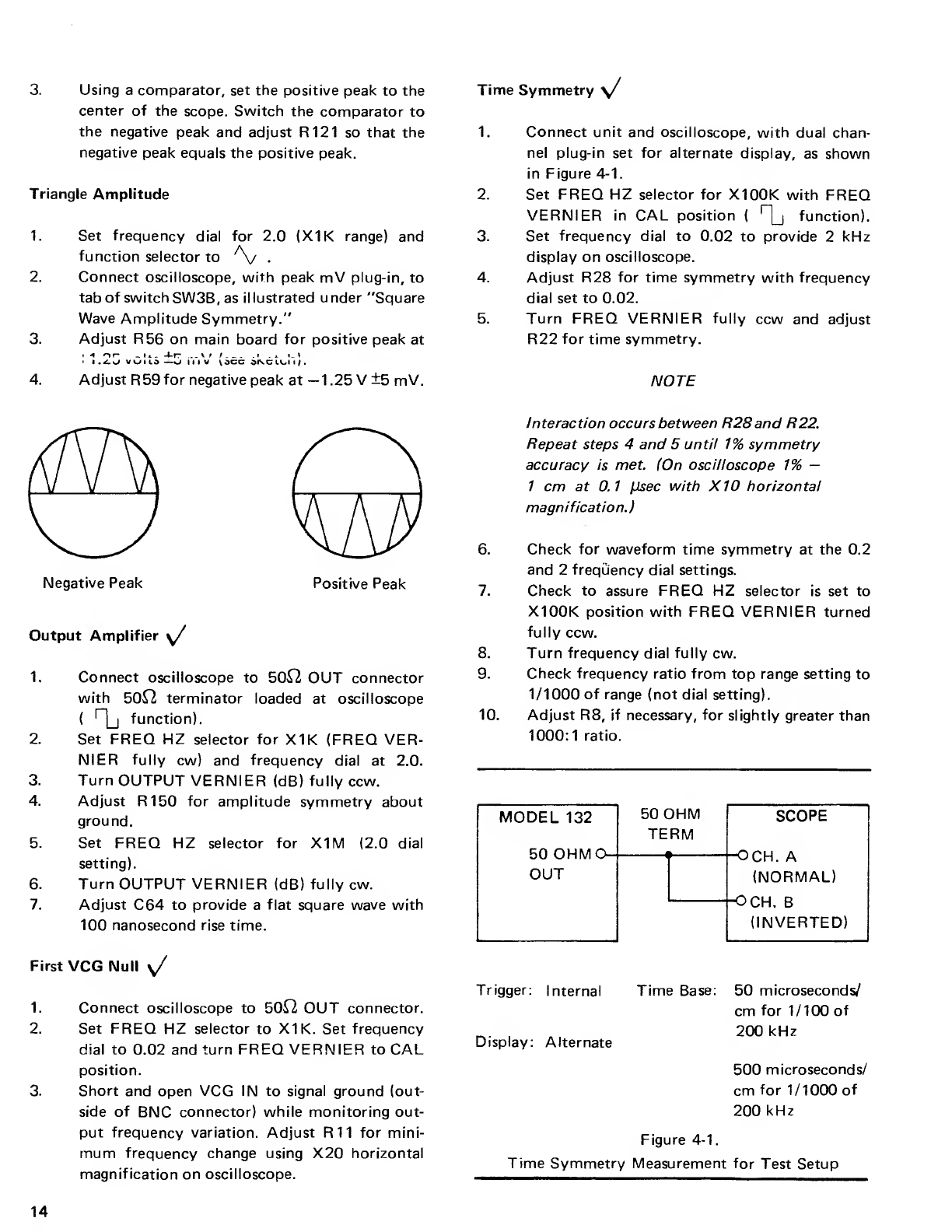

Time Symmetry y/

1. Connect unit and oscilloscope, with dual chan-

nel plug-in set for alternate display, as shown

in Figure 4-1

.

2. Set FREQ HZ selector for X100K with FREQ

VERNIER in CAL position (r|_j function).

3. Set frequency dial to 0.02 to provide 2kHz

display on oscilloscope.

4. Adjust R28 for time symmetry with frequency

dial set to 0.02.

5. Turn FREQ VERNIER fully ccw and adjust

R22 for time symmetry.

NOTE

Interaction occurs between R28 and R22.

Repeat steps 4and 5until 1% symmetry

accuracy is met. (On oscilloscope 1% —

1cm at 0.1 (isec with X10 horizontal

magnification.

)

6. Check for waveform time symmetry at the 0.2

and 2frequency dial settings.

7. Check to assure FREQ HZ selector is set to

X100K position with FREQ VERNIER turned

fully ccw.

8. Turn frequency dial fully cw.

9. Check frequency ratio from top range setting to

1/1000 of range (not dial setting).

10. Adjust R8, if necessary, for slightly greater than

1000:1 ratio.

MODEL 132 50 OHM SCOPE

TERM

50 OHM O— —

i

6oX>

OUT (NORMAL)

-OCH. B

(INVERTED)

Trigger: Internal Time Base:

Display: Alternate

50 microseconds/

cm for 1/100 of

200 kHz

500 microseconds/

cm for 1/1000 of

200 kHz

Figure 4-1

.

Time Symmetry Measurement for Test Setup

14

Frequency Calibration

1. Connect counter to 50f2 OUT connector.

2. Set FREQ HZ selector to X10K and FREQ

VERNIER fully cw.

3. Align 2.0 dial mark with the dial indicator

index and alternately switch from X10K to X1K

range while adjusting R4 for abalanced error

between the two positions of less than 2%.

4. Set FREQ HZ selector to X100K and dial at 2.0.

5. Adjust Cl 6to obtain 200.0 kHz on counter

display.

6. Set FREQ HZ selector to X1M. Adjust Cl 2to

obtain 2.00 MHz on counter display.

7. Dial alignment —No alignment is necessary if

the dial is the push-on type. If it has aset screw,

consult the factory for CAL procedure.

Sine Distortion, Amplitude, and Balance yj

1. Set FREQ HZ selector for X1K, FREQ VER-

NIER fully cw, function selector to !\j ,and

frequency dial at 2.0.

2. Connect oscilloscope, with peak mV plug-in, to

orange wire on function switch.

3. Adjust R133 to obtain 2.5 Vp-p ±25 mV

output.

4. Adjust R128 to balance output.

5. Connect the unit, distortion analyzer, and oscil-

loscope as shown in Figure 4-2.

6. Adjust R126 and R127 for less than 0.5% sine

distortion (see photo).

7. Set FREQ HZ selector to X10K.

Figure 4-2. Distortion Analysis Test Setup

8. Repeat step 6for steps 1and 7to obtain less

than 0.5% distortion at both XI Kand X10K

ranges.

9. Repeat steps 2, 3and 4.

10. Connect spectrum analyzer and check sine dis-

tortion at 2MHz.

/

Clock Frequency Calibration \/

1. Remove power from unit.

2. Remove two Phillips head screws from logic

board (one from left side of board, one from

right side).

3. Remove two 2%" standoff screws at rear of logic

board.

4. Lift front edge of logic board until board is

standing upright. (Right rear edge of logic board

will now be resting on sine module.

5. Place at least V' of styrofoam, or other suitable

insulating material, between BNC connectors

and main board. (BNC connectors are located

near left rear edge of logic board.)

CAUTION

Failure to adequately insulate BNC con-

nectors from main board may result in

electrical damage.

6. Apply power to unit.

7. Set function selector to J1T”L position.

8. Set NOISE FREQ HZ selector to 1.6M position

and NOISE FREQ HZ vernier fully cw.

9. Connect counter to NOISE CLOCK connector

(rear panel).

10. Adjust C6 on digital board for 1.6 MHz (ideally

1.62 MHz).

11. Turn NOISE FREQ HZ vernier fully ccw and

adjust R2 for 150 kHz ±1 kHz.

15

Digital Noise Amplitude Symmetry \/

1. Set function selector to _JU [_, NOISE FREQ HZ

selector to 160 kHz, and depress SEQUENCE

LENGTH -215 -1push button.

2. Connect oscilloscope, with peak mV plug-in, to

location DN on digital board.

3. Adjust R36, using comparator, to provide a

positive peak of +1.25 V±10 mV.

4. Adjust R39, using comparator, to provide a

negative peak of —1.25 V±10 mV.

Analog Noise Amplitude Symmetry

1. Connect BNC cable to NOISE SYNC connector

(rear panel) and sync connector on oscilloscope.

2. Depress SEQUENCE LENGTH -21S -1push

button.

3. Connect oscilloscope to location AN on digital

board.

4. Adjust R22 (gain) and R23 (balance) to provide

a2.5 Vp-p signal centered about ground.

S/N Frequency Compensation \/

1. Set function selector to Hj .

2. Depress MODE —S/N push button.

3. Set frequency dial to 1.0 and FREQ HZ selector

to X100K (100 kHz).

4. Set S/N —N/S (dB) selector to +50 position

and turn vernier to +9 position to provide ap-

proximately +59 dB.

5. Turn OUTPUT VERNIER (dB) full cw.

6. Connect oscilloscope to 50^2 OUT connector

with 5012 terminator (nufunction).

7. Adjust C5 on analog board for aslightly peaked

square wave response, as illustrated below.

8. Remove power from unit.

9. Remove material insulating BNC connectors

from main board.

10. Lower logic board and align holes in side of

board with screw holes.

11. Install two side screws to secure logic board.

12. Install both 2y2”standoff screws at rear of logic

board.

13. Install cover on unit.

TROUBLESHOOTING

Basic Techniques

Troubleshooting the Model 132 requires no special

technique. Listed below are afew reminders of basic

electronics fault isolation.

1. Check control settings carefully. Many times an

incorrect control setting, or aknob that has

loosened on its shaft, will cause a false indication

of amalfunction.

2. Check associated equipment connections. Make

sure that all connections are securely connected

to the correct connector.

3. Perform the checkout procedure. Many out-of-

specification indications can be corrected by

performing specific calibration procedures.

4. Visually check the interior of the instrument.

Look for such indications as broken wires,

charred components, loose leads, etc.

Troubleshooting Chart

Table 4-2 provides alist of possible malfunction symp-

toms, their probable causes, and the prescribed reme-

dies. Also listed in this table are the test points at

which measurements are to be made and the para-

meter tolerances at these points. To use the trouble-

shooting chart, locate the symptom listed in Column 1

and follow the corresponding procedures. Localize the

fault to aspecific stage by checking the parameters

given for the major test points. Then check the dc

operating voltages at the pins of solid-state devices.

Check associated passive elements with ahigh input

impedance ohmmeter (power off) before replacing a

suspected semiconductor element.

Troubleshooting Hints

The interactive nature of aclosed loop presents a

somewhat special problem when approached from a

troubleshooting standpoint. The simplest way to reduce

problem complexity is to open the loop, thereby re-

moving the interaction. The basic units of the loop

can then be tested individually. The following step-bv-

step procedure describes how this is done. (The genera-

tor loop is all contained on the main board.) Consult

the next paragraph for removal of cover and panels.

1. Set instrument controls for 20 Vp-p, 2kHz

sine-wave output.

16

Table 4-2. TROUBLESHOOTING CHART

Symptom Probable Cause Corrective Procedures

No outputs at 50&2 OUT connector Blown Fuse Replace FI.

a. 1/4A —115 Vac

b. 1/8A-220 Vac

Power Supply Check TP 1/TP2for +15 V; +5 V/DG for +5 V;

TP1/TP3 for -15 V; TP 1/TP5for +6 V; TP1/

TP6 for -6 V.

Troubleshoot associated regulator.

Output Amplifier Check at PH for waveform as selected by posi-

tion of waveform switch.

a. If waveform is present, troubleshoot output

amplifier.

h. If no waveforms are present, refer to Trouble-

shooting Hints.

50^2 Attenuator Check to see that output is present at switch. If

it is, the switch is defective.

No sine wave output Sine Amplifier Check for 260 mV p-p sine wave at pin 4of ICS.

a. If present, check IC8 circuit.

NOTE: Triangle wave must be present at pin 2

of A1to obtain sine wave output.

b. If not present, check A1 circuit.

No triangle, sine, or square wave Generator Loop Refer to Troubleshooting Hints.

No JUT Power Supply Check for correct voltages.

Clock Oscillator Check Q1 —Q8 circuit.

Faulty 1C Refer to Troubleshooting Hints.

Shaping Amplifier Check Q12 —Q14 circuit.

no nr No J1R (See above.)

Faulty Summing

Amplifier

Check Q9 —Q1 1circuit.

Faulty Low Pass

Filter

Check IC1 circuit.

No output in S/N or N/S Faulty Summing

Amplifier

Check IC2 circuit.

No noise in S/N mode Faulty Attenuator Check Test Point AW for noise. If not present

and controllable by S/N —N/S (dB) switch, the

switch is defective. If present, check IC1 and

IC2 circuits.

17

Other manuals for 132

2

Table of contents

Other Wavetek Portable Generator manuals

Wavetek

Wavetek 150 User manual

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 1001A User manual

Wavetek

Wavetek 1370 Installation instructions

Wavetek

Wavetek 182A User manual

Wavetek

Wavetek 3000 User manual

Wavetek

Wavetek 148A User manual

Wavetek

Wavetek 3510 User manual

Wavetek

Wavetek 188 User manual

Wavetek

Wavetek 144 User manual