Weider PROLINE D700 User manual

Other Weider Home Gym manuals

Weider

Weider 8275hard Drive Sys User manual

Weider

Weider Pro 330 Bench User guide

Weider

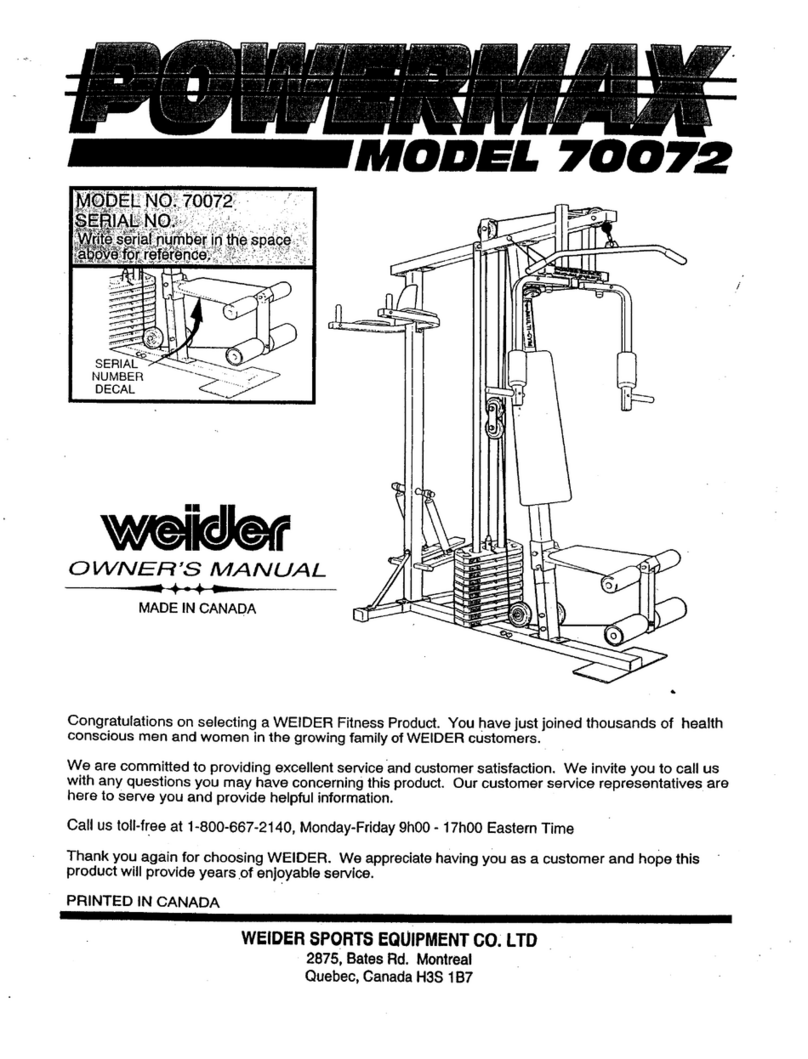

Weider Powermax 70072 User manual

Weider

Weider PRO 270 L User manual

Weider

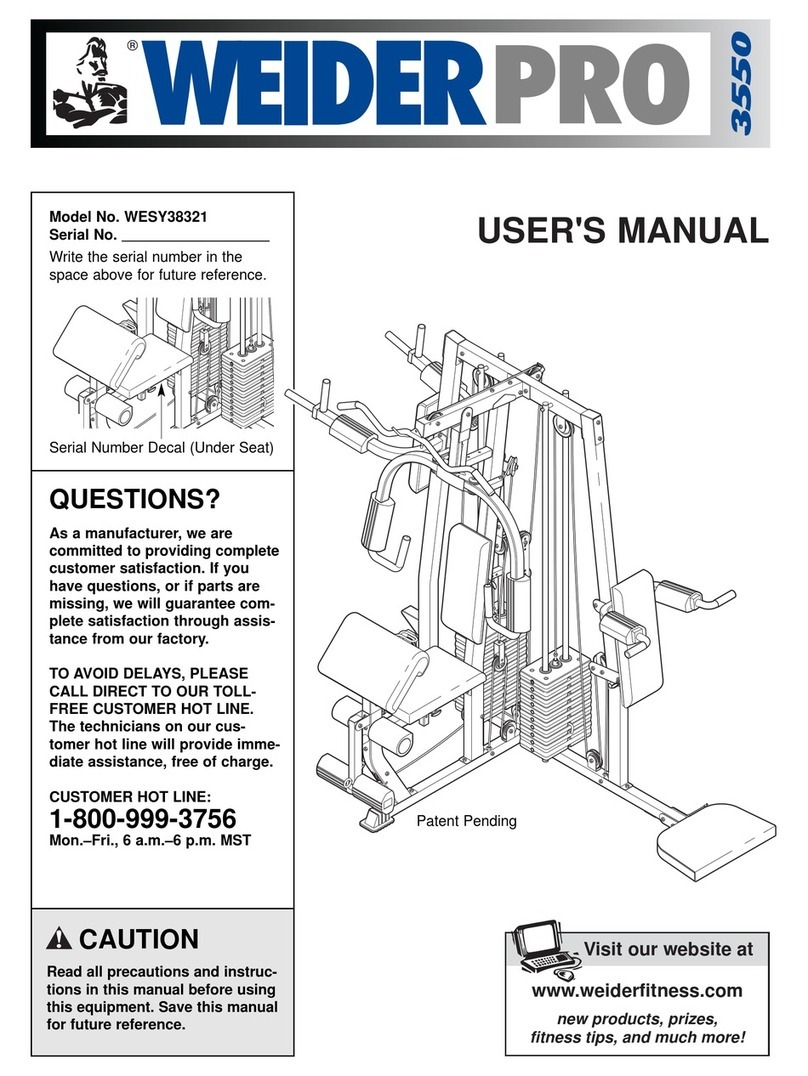

Weider WESY38321 User manual

Weider

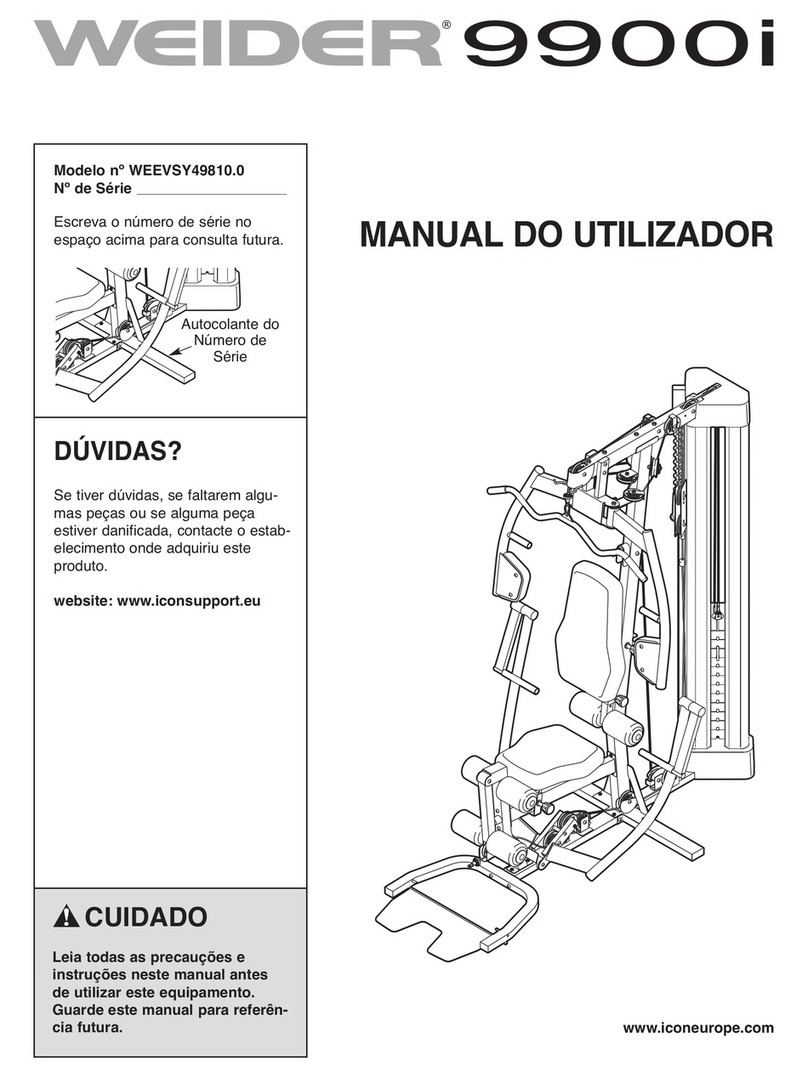

Weider 9900i User manual

Weider

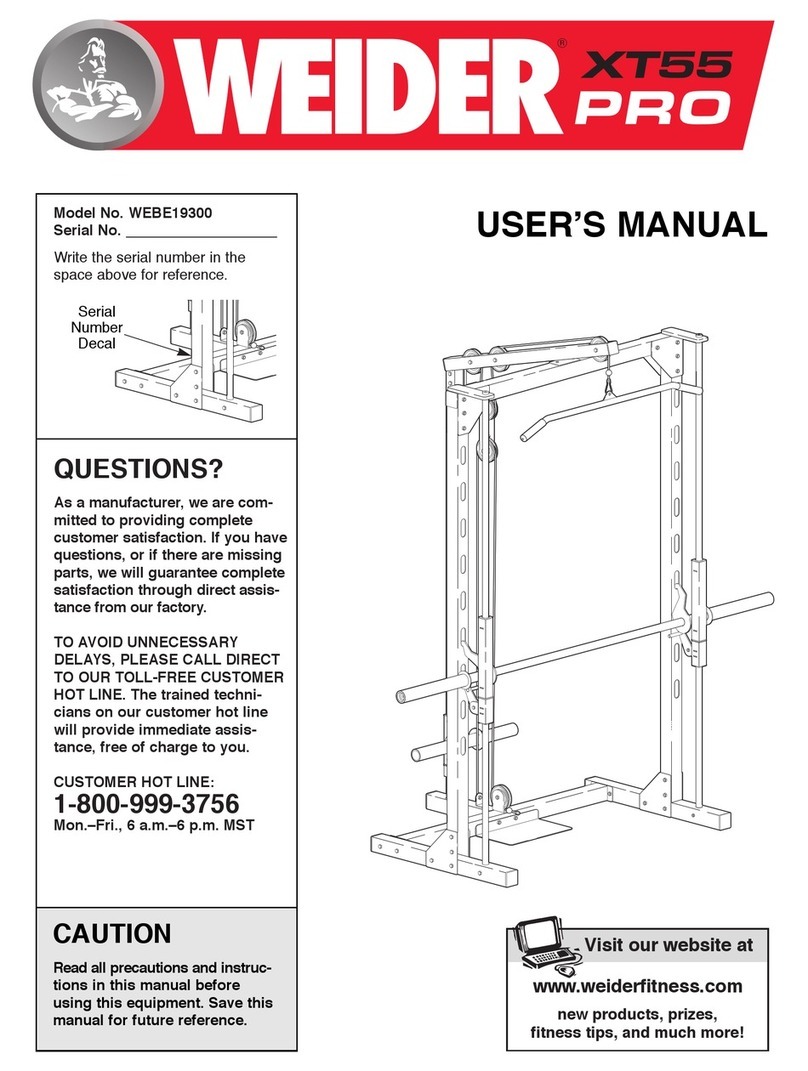

Weider WEBE19300 User manual

Weider

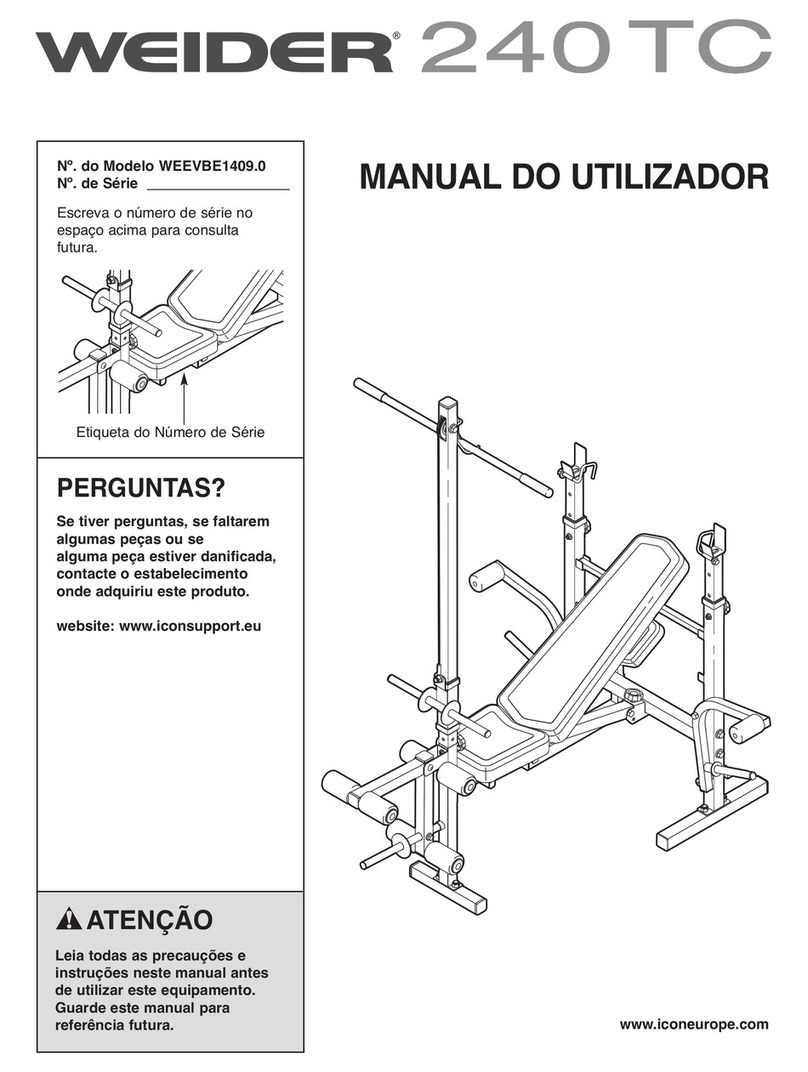

Weider 240 Tc Bench Setup guide

Weider

Weider PRO 4250 User manual

Weider

Weider D630S 354.156340 User manual

Weider

Weider 190 Tc Bench User manual

Weider

Weider Pro 305 User manual

Weider

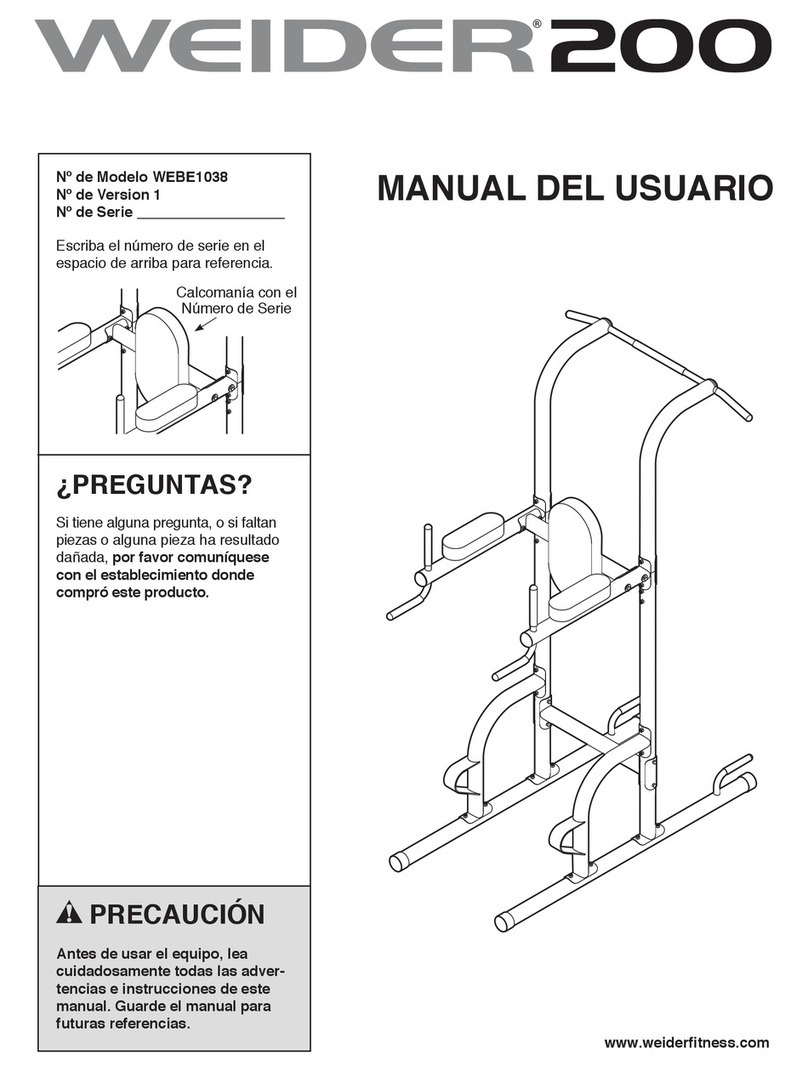

Weider 200 Bench User guide

Weider

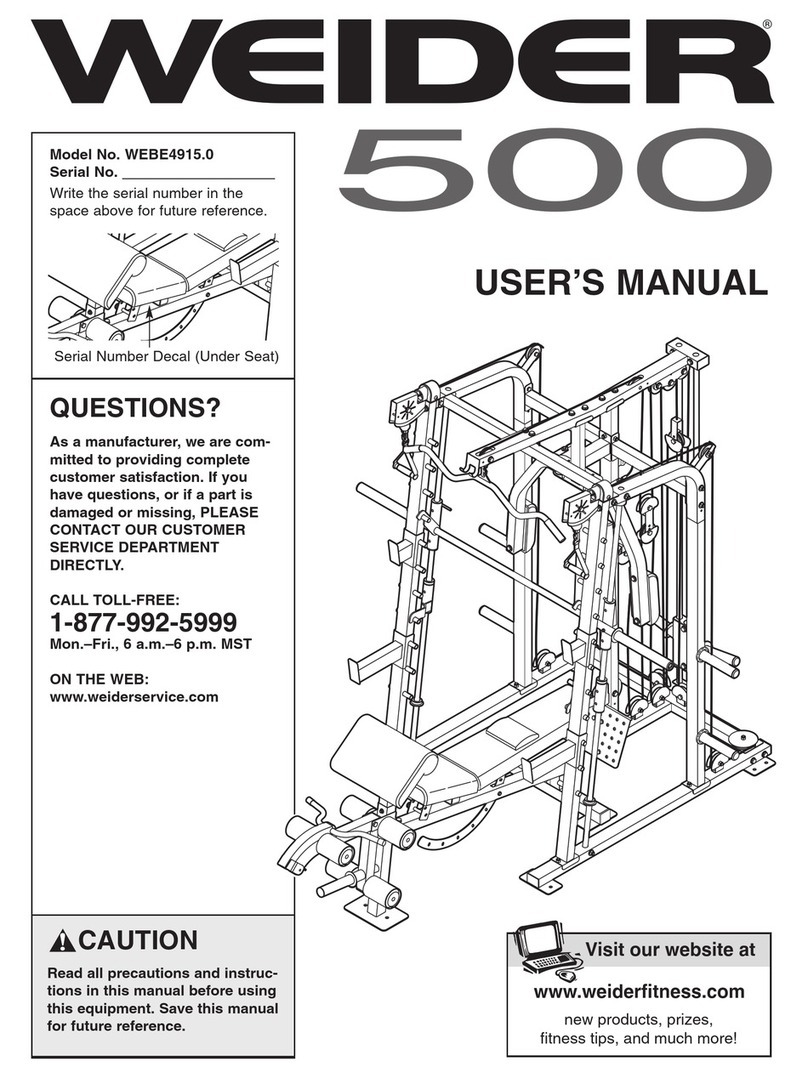

Weider WEBE4915.0 User manual

Weider

Weider Body Works Pro 2.0 Bench Manual

Weider

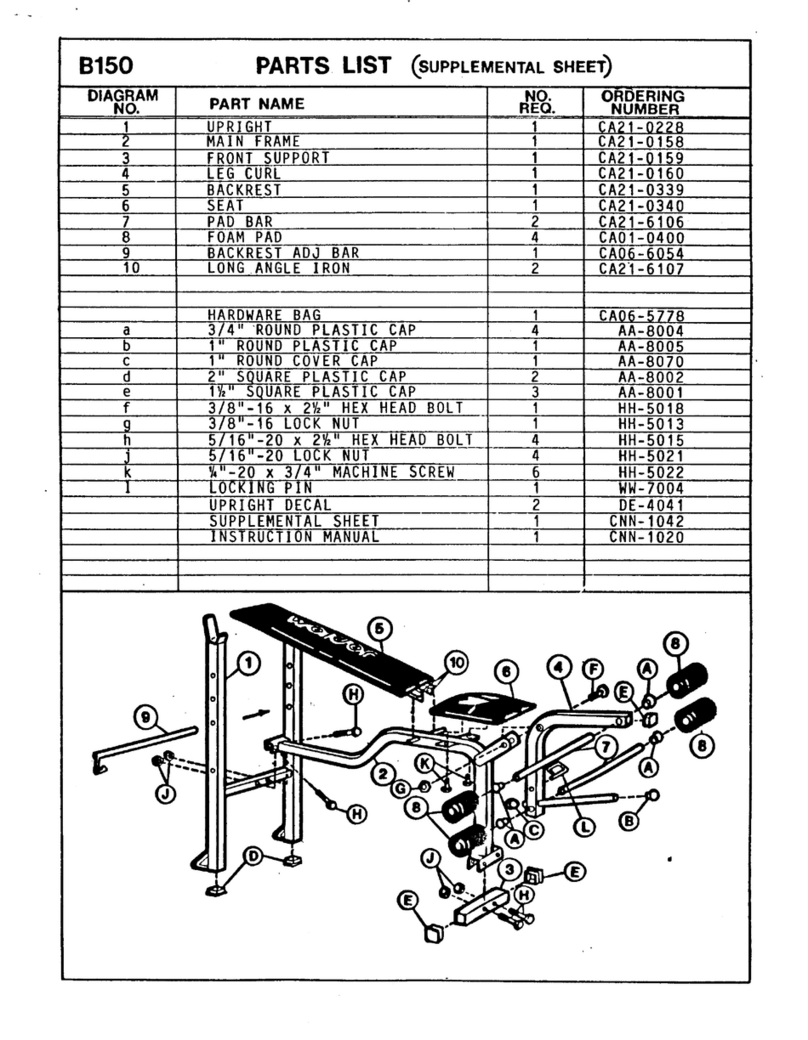

Weider B150 Gym User manual

Weider

Weider 214 Bench Quick start guide

Weider

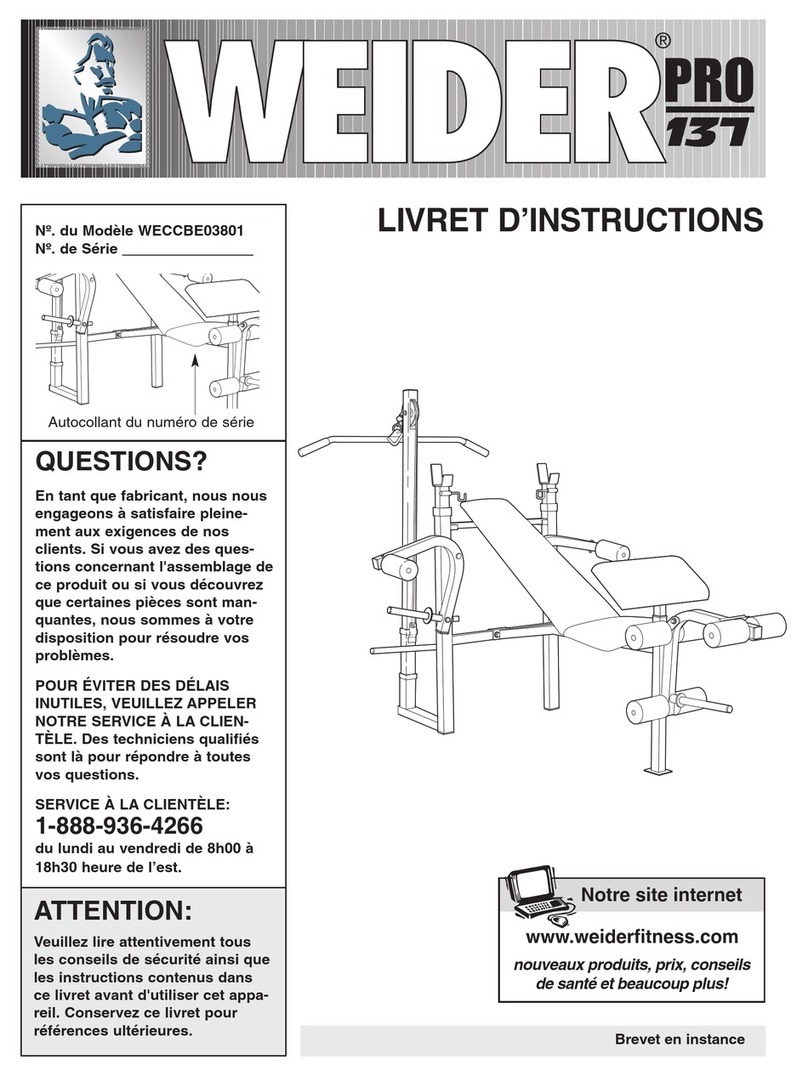

Weider Pro 137 Bench User manual

Weider

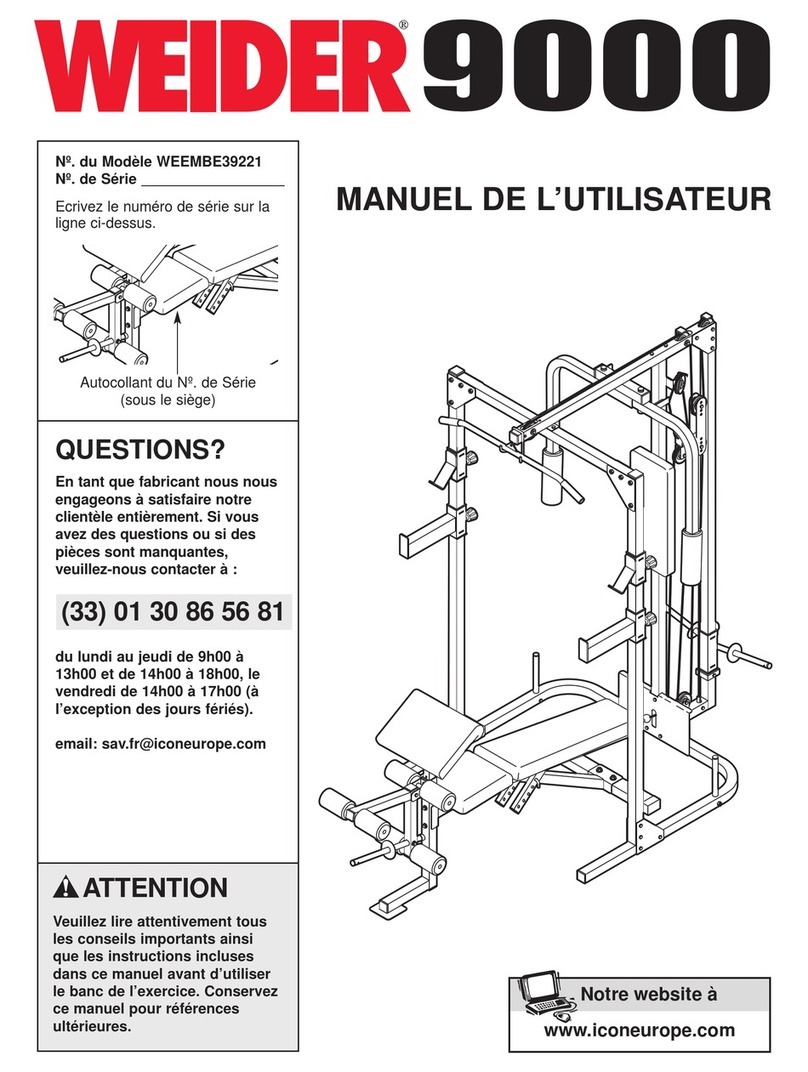

Weider 9000 Bench User manual

Weider

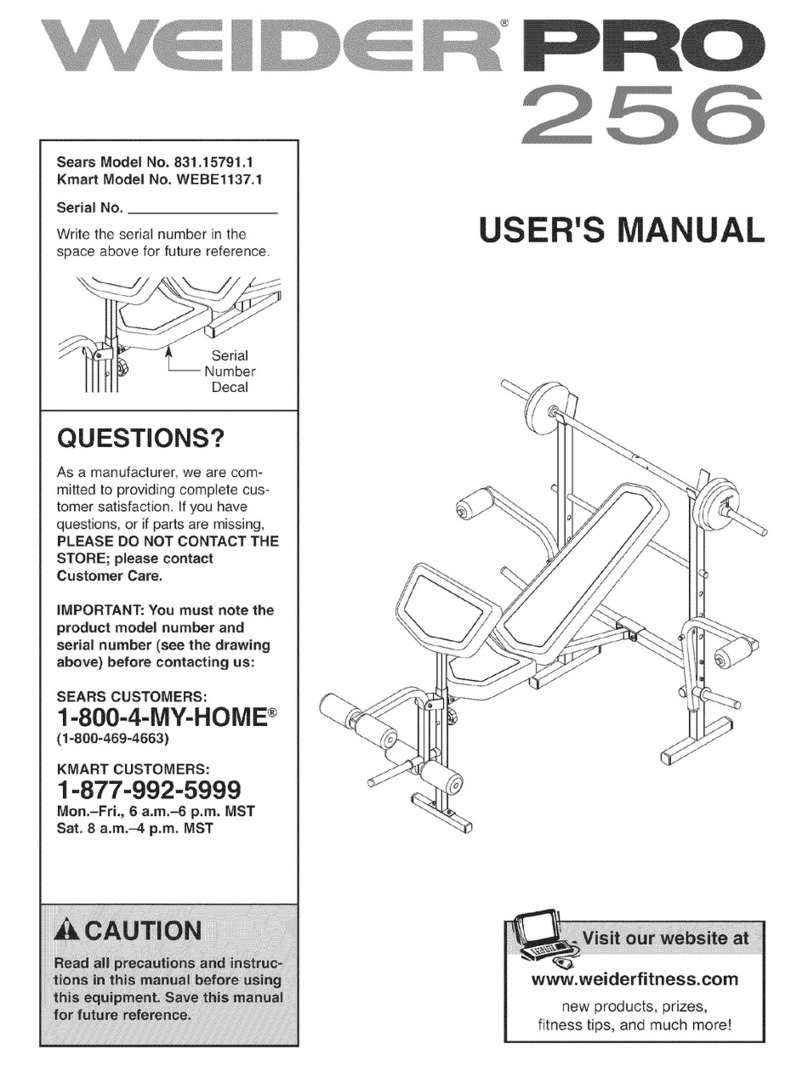

Weider Pro 256 User manual