5

ASSEMBLY

1

8

11

51

27

1

4

3

1

51

5

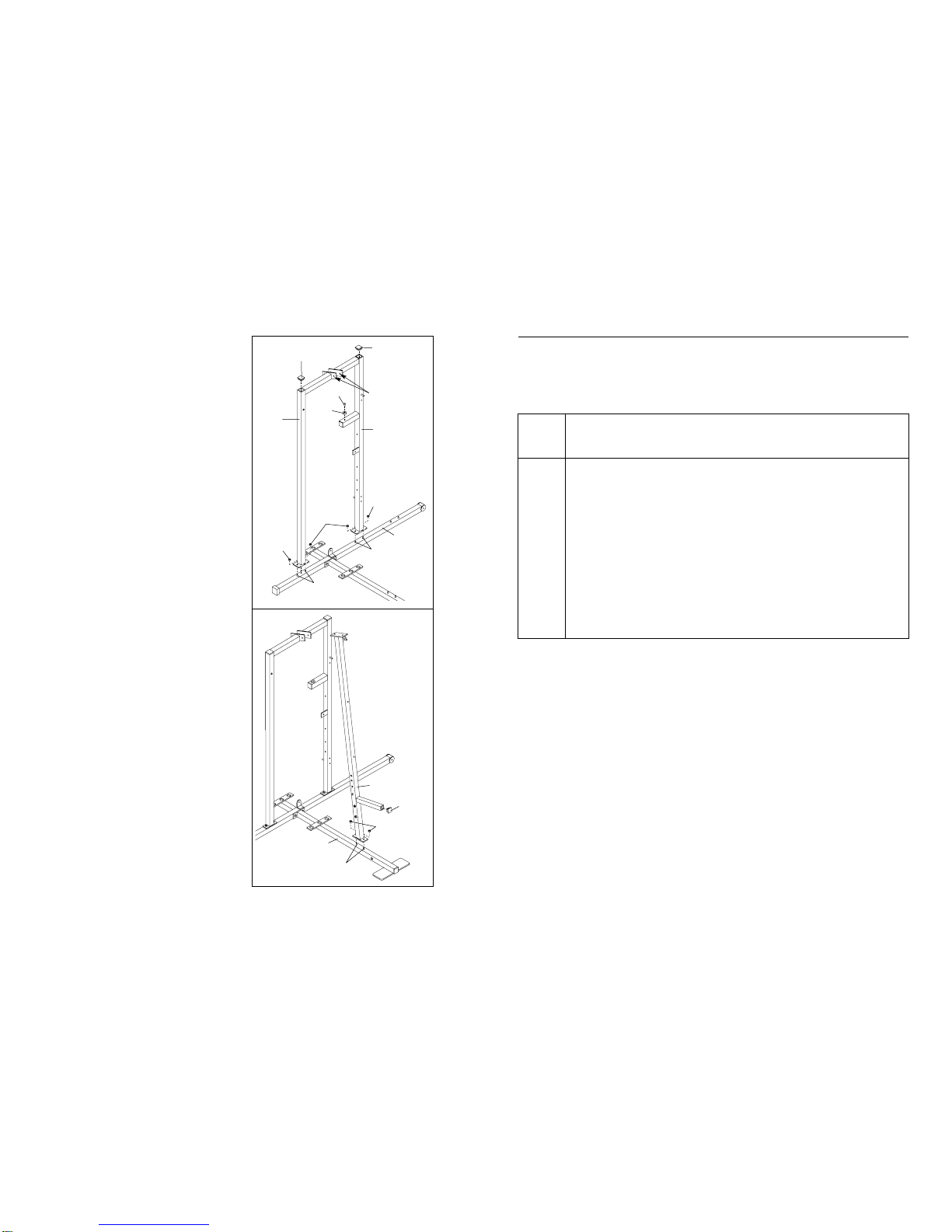

1. Before beginning, make sure that you have read

and understand the information in the box above.

Locate and open the parts bag labelled “FRAME

ASSEMBLY.”

Press two 2” Square Outer Caps (51) onto the

Stabiliser (5) in the indicated locations. Press a 2”

Square Inner Cap (27) into the end of the Base (4).

Insert six 5/16” x 2 1/2” Carriage Bolts (1) up through

the Stabiliser (5). Insert two 5/16” x 2 1/2” Carriage

Bolts up through the Base (4).

Attach the Base (4) to the Stabiliser (5) with two

5/16” x 2 3/4” Bolts (11), two 5/16” Washers (8), and

two 5/16” Nylon Locknuts (3). Do not tighten the

Nylon Locknuts yet.

Before beginning assembly, carefully read the

following information and instructions:

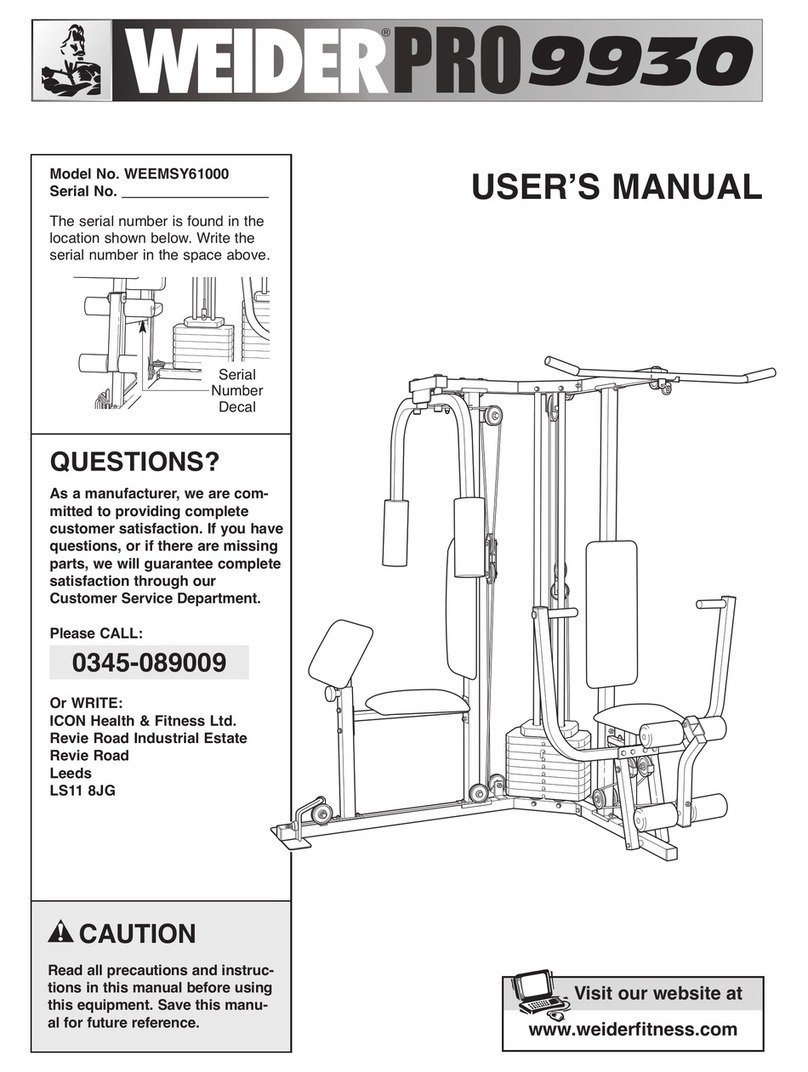

•Due to the many features of the weight system,

assembly will require several hours. By setting

aside plenty of time and by deciding to make the

task enjoyable, assembly will go smoothly. You

may want to assemble the weight system over a

couple of evenings.

•Assembly requires two people.

•Place all parts of the weight system in a cleared

area and remove the packing materials; do not

dispose of the packing materials until assembly is

completed.

• Assembly is divided into four stages: 1) frame

assembly, 2) arm assembly, 3) cable assembly,

and 4) seat assembly. The hardware for each

stage is packaged separately.

• Wait until you begin each assembly stage to open

the parts bag labelled for that assembly stage.

•As you assemble the weight system, be sure that

all parts are oriented as shown in the drawings.

•Tighten all parts as you assemble them, unless

instructed to do otherwise.

•For help identifying the small parts used in

assembly, use the PART IDENTIFICATION

CHART located in the centre of this manual.

Note: Some small parts may have been pre-

attached for shipping. If a part is not in the parts

bag, check to see if it has been pre-attached.

THE FOLLOWING TOOLS (NOT INCLUDED) ARE

REQUIRED FOR ASSEMBLY:

• two adjustable wrenches

• one standard screwdriver

• one phillips screwdriver

• one rubber mallet

• lubricant, such as grease or petroleum jelly,

and soapy water will also be needed.

•Assembly will be more convenient if you have the

following tools: A socket set, a set of open-end or

closed-end wrenches, or a set of ratchet wrenches.

1

24

TROUBLESHOOTING AND MAINTENANCE

TIGHTENING THE CABLES

Woven cable, the type of cable used on the weight system, can stretch slightly when it is first used. If there is

slack in the cables before resistance is felt, the cables should be tightened. If any slack is felt when using the

front weight stack, both the High Cable (58) and the Low Cable (23) will need to be tightened. If any slack is felt

when using the rear weight stack, both the Military Press Cable (72) and the Leg Press Cable (78) will need to

be tightened.

To tighten the cables, insert the weight pin into the middle of the weight stack. Slack can be removed from these

cables several ways:

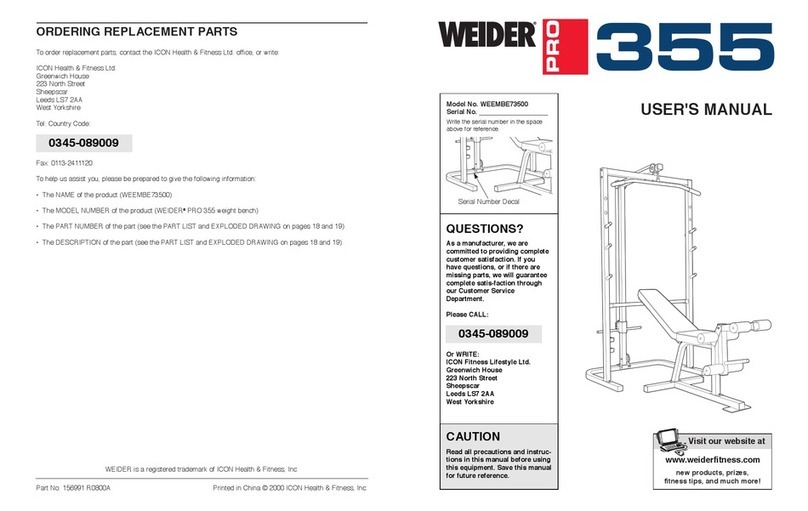

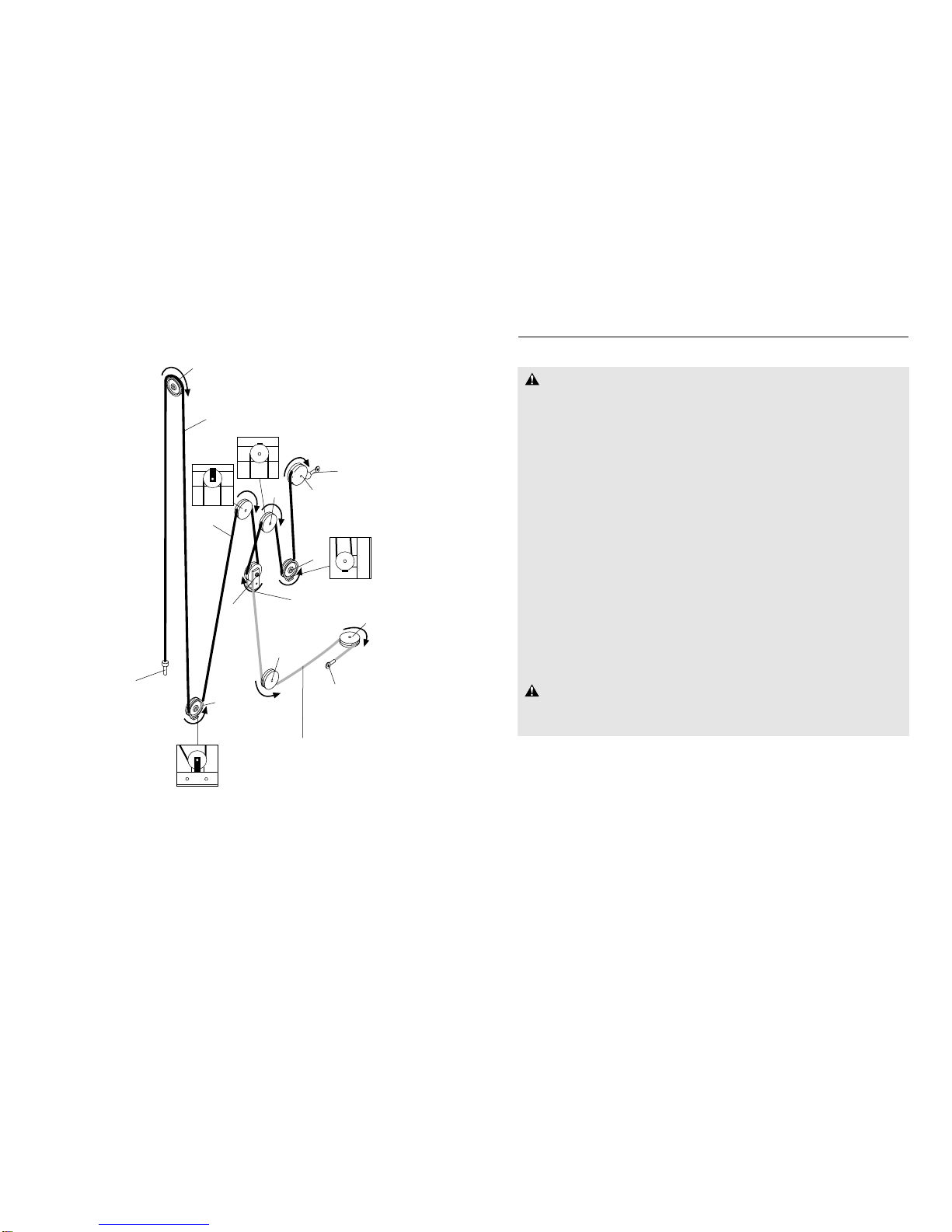

See drawing 1. Tighten the 1/4” Nylon Locknut (2) that con-

nects the end of the Low Cable (23) to the Long “U”-Bracket

(57).

The Leg Press Cable (78) can be tightened in the same man-

ner.

See drawing 1. Remove the 3/8” Nylon Locknut (21) and the

3/8” x 2” Bolt (12) from the Pulley Covers (77), 3 1/2” Pulley

(15), and Long “U”-Bracket (57). Re-attach the Pulley and

Pulley Covers to the lower hole in the Long “U”-Bracket. Be

sure that the small tab on the Pulley Cover is facing up, and

that the Cable and Pulley move smoothly.

The other Long “U”-Bracket (57) can be adjusted in the same

manner.

See drawing 2. Tighten the 1/4” Nylon Locknut (2) that con-

nects the end of the High Cable (58) to the Small “U”-Bracket

(71).

The Military Press Cable (72) can be tightened in the same

manner.

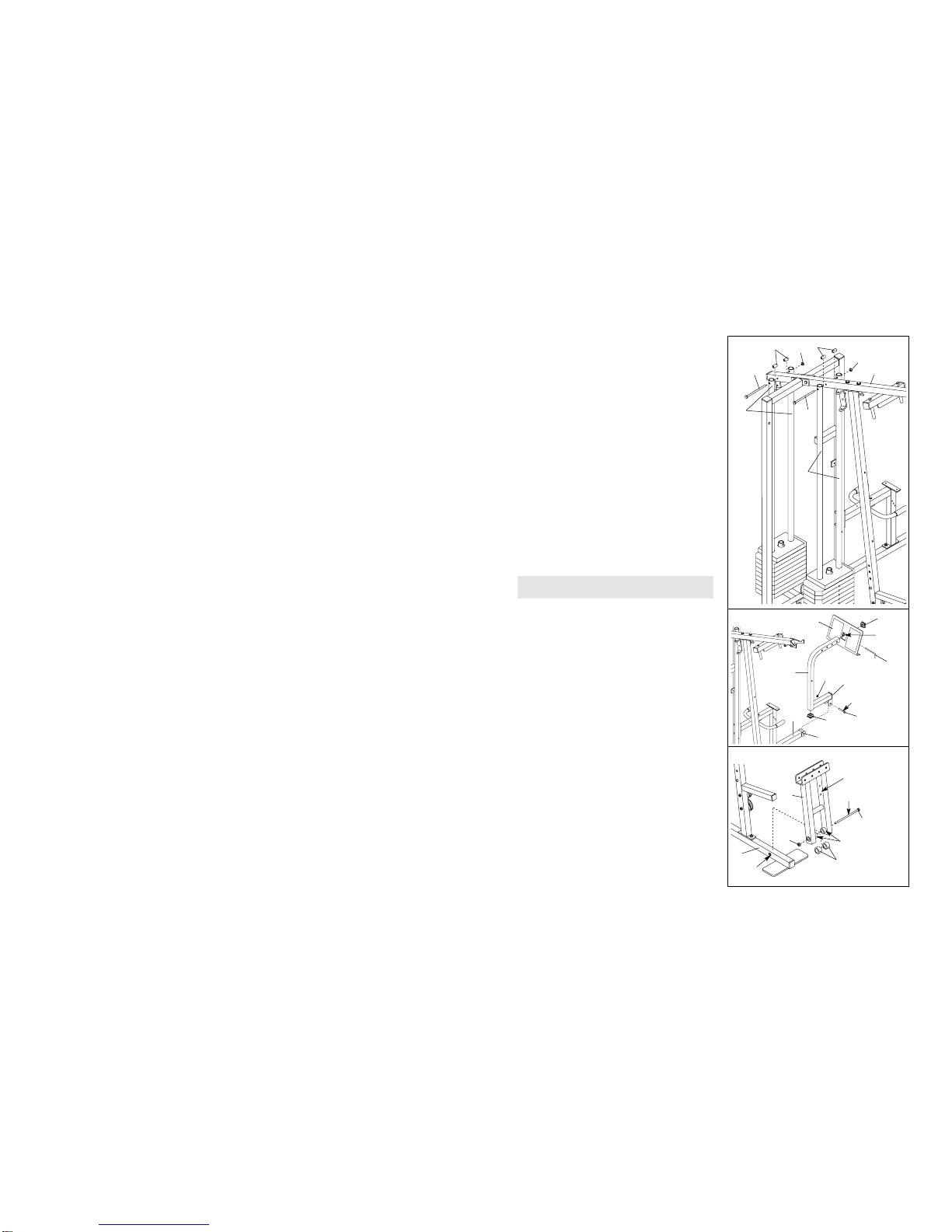

See Drawing 3. If additional slack is felt whilst using the Leg

Press Arm (96), then the end of the Leg Press Cable (78)

must be moved to the next hole in the Leg Press Seat Frame

(79). Remove the 5/16” x 2 3/4” Bolt (11), the two 5/16”

Washers (8), the end of the Cable, and both 5/16” Nylon Jam

Nuts (93) from the Leg Press Seat Frame. Re-attach the Bolt,

the Washers, the end of the Cable, and the Nylon Jam Nuts

to the next hole in the Leg Press Seat Frame.

Do not over tighten the cables. The top weight will be lift-

ed off the weight stack.

If a cable tends to slip off the pulleys often, it may have

become twisted. Remove the cable and re-install it.

If the cables need to be replaced, see ORDERING REPLACEMENT PARTS on the back cover of this manual.

71

71

2

2

58

72

2

FRAME ASSEMBLY

57

77 77

15

223 or 78

21

1

12

96

78

79

11 8

893

93

3