2

TABLE OF CONTENTS

Thank You For your Purchase..................................................................................................................................................... 3

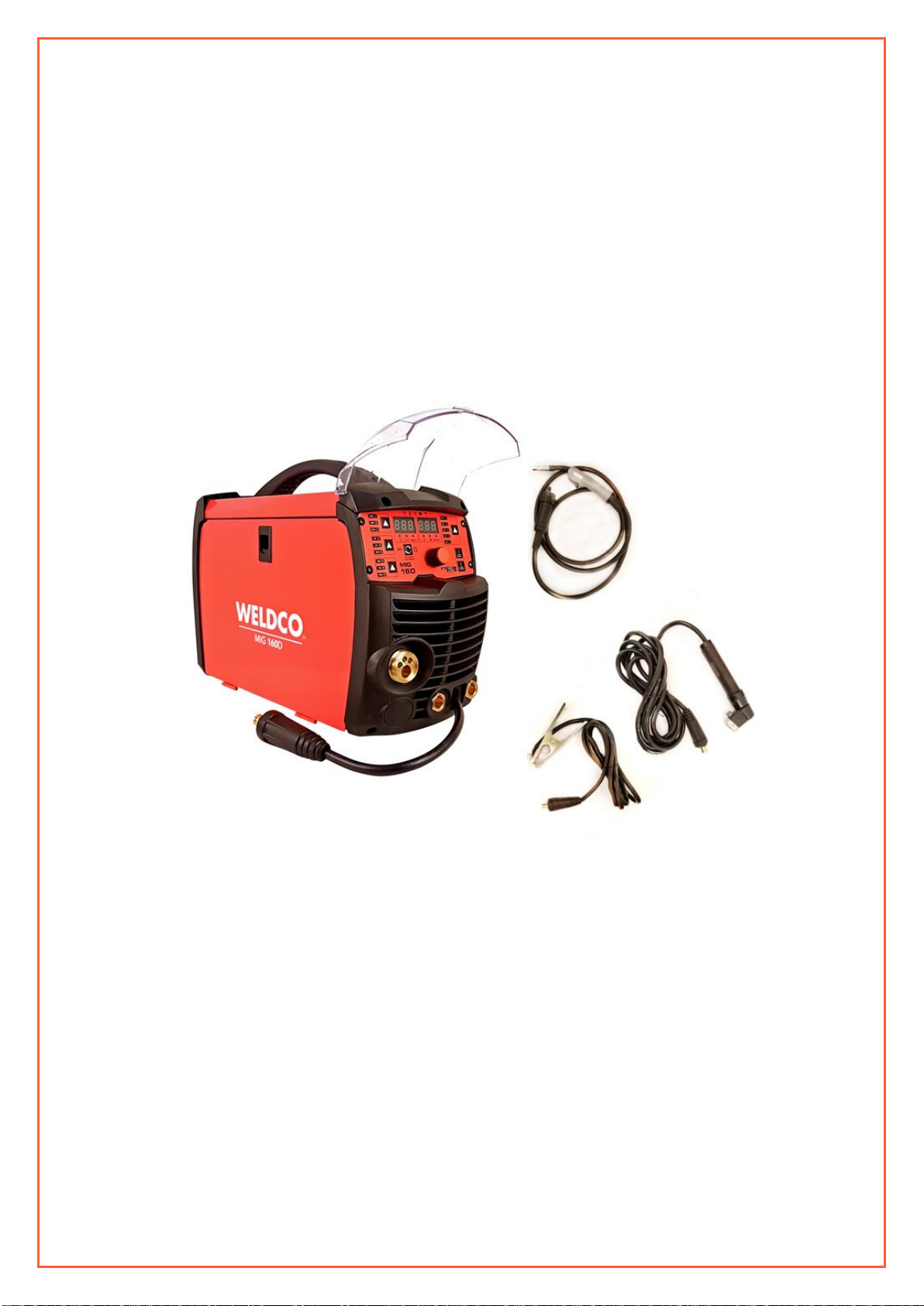

Unpacking Your New Welder ......................................................................................................................................................... 3

Welding Hazards and Safety....................................................................................................................................................... 4

Work Area ...................................................................................................................................................................................... 4

Personal Protective Equipment and Clothing (PPE) ....................................................................................................................... 4

Electromagnetic and Radio Frequencies –“PACEMAKERS”........................................................................................................... 5

Pre-Checks...................................................................................................................................................................................... 5

Warning.......................................................................................................................................................................................... 5

Storage and Transportation ........................................................................................................................................................... 5

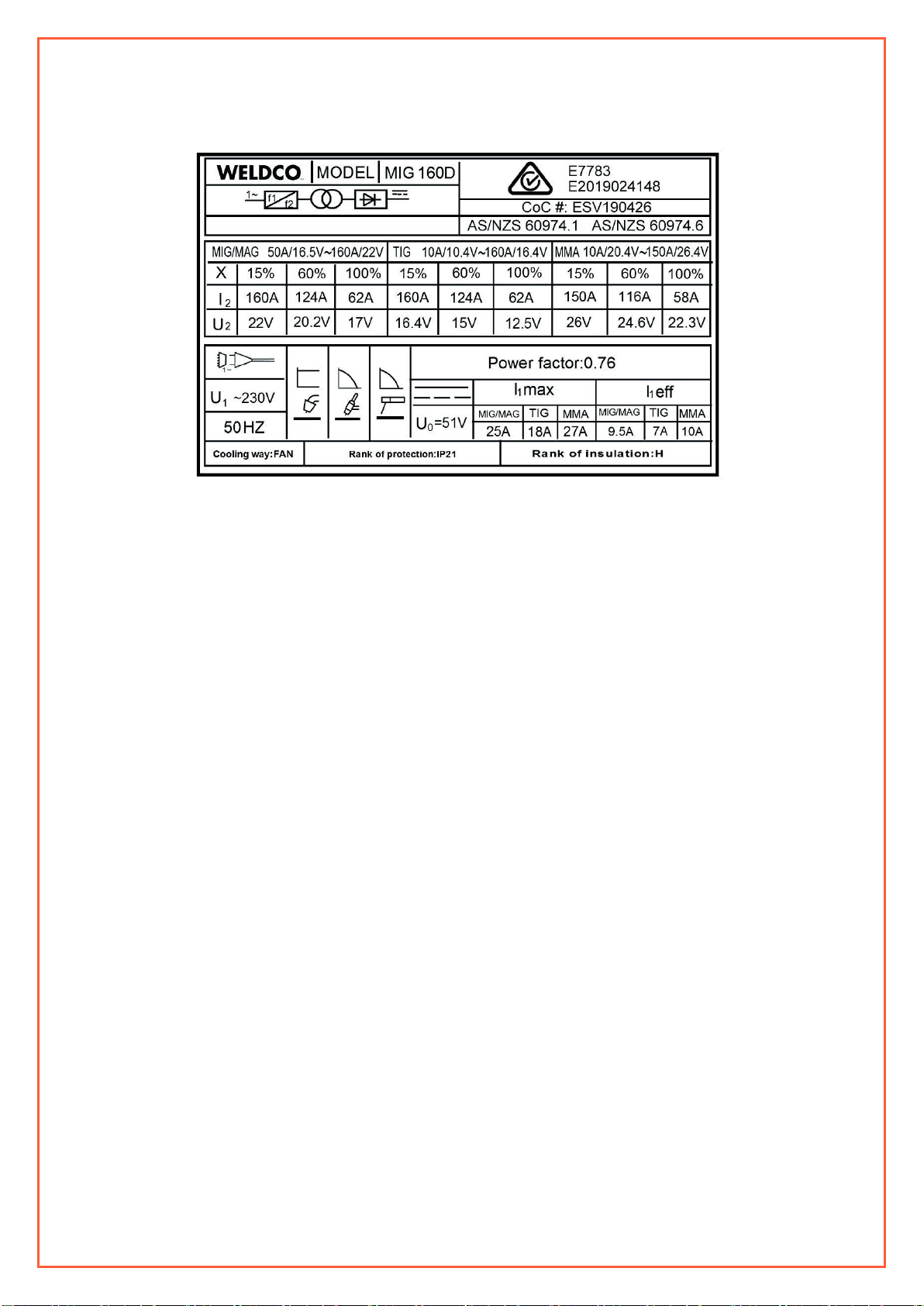

Technical Description ................................................................................................................................................................. 6

Compliance Plate............................................................................................................................................................................ 6

Duty Cycle....................................................................................................................................................................................... 6

Input Plug ....................................................................................................................................................................................... 6

Operating Environment.................................................................................................................................................................. 6

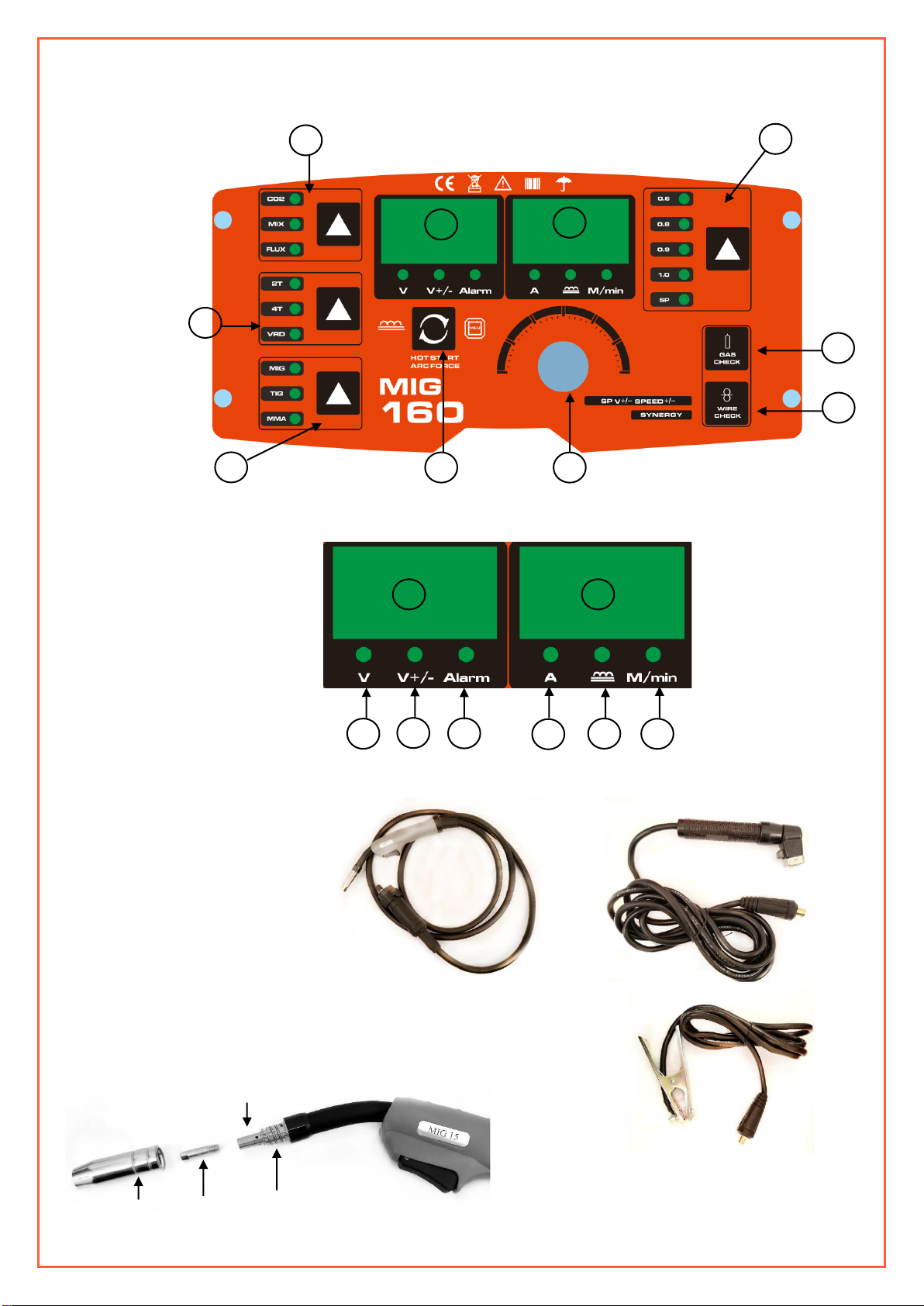

Machine Layout ......................................................................................................................................................................... 7

MIG Welding Setup .................................................................................................................................................................... 9

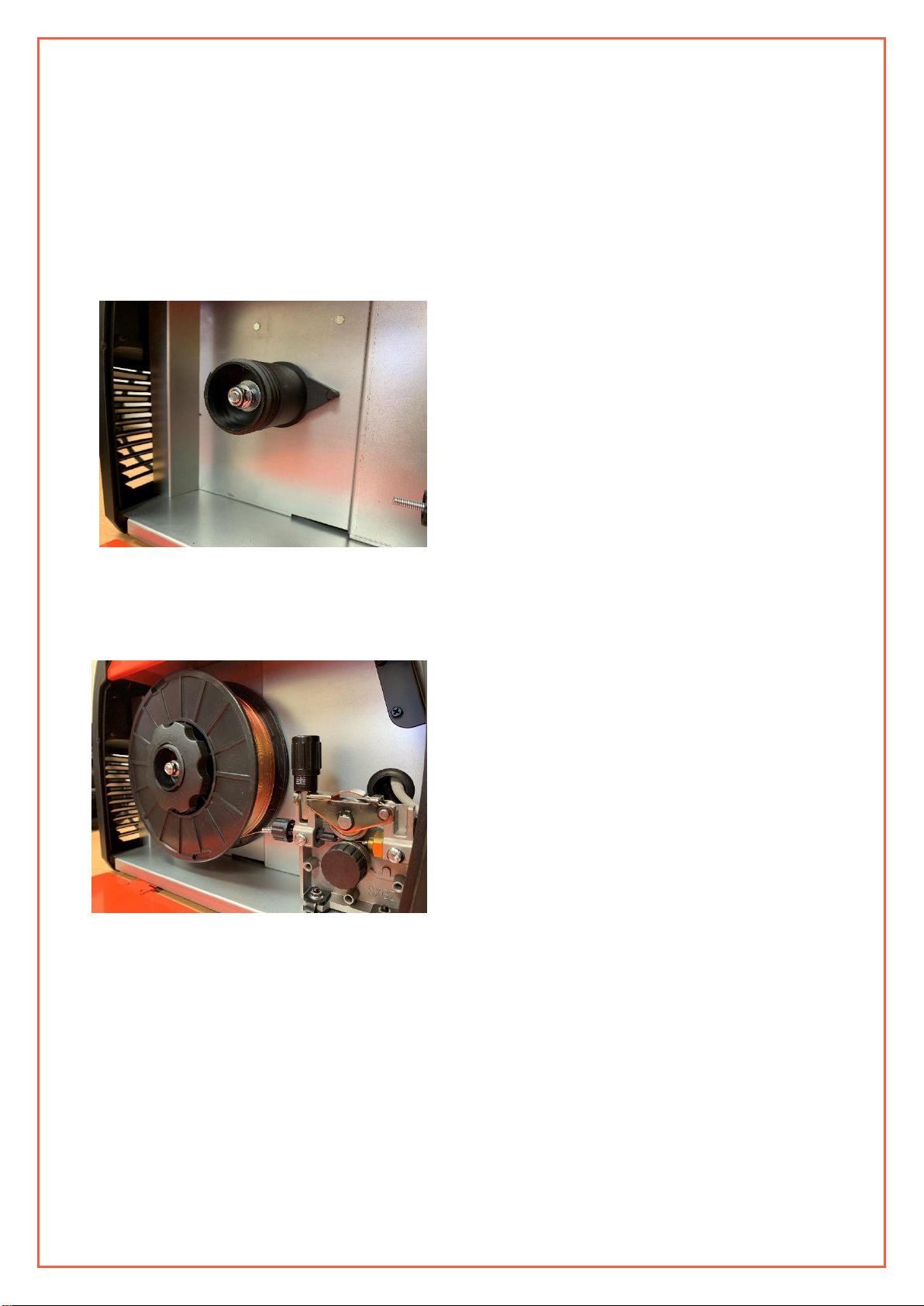

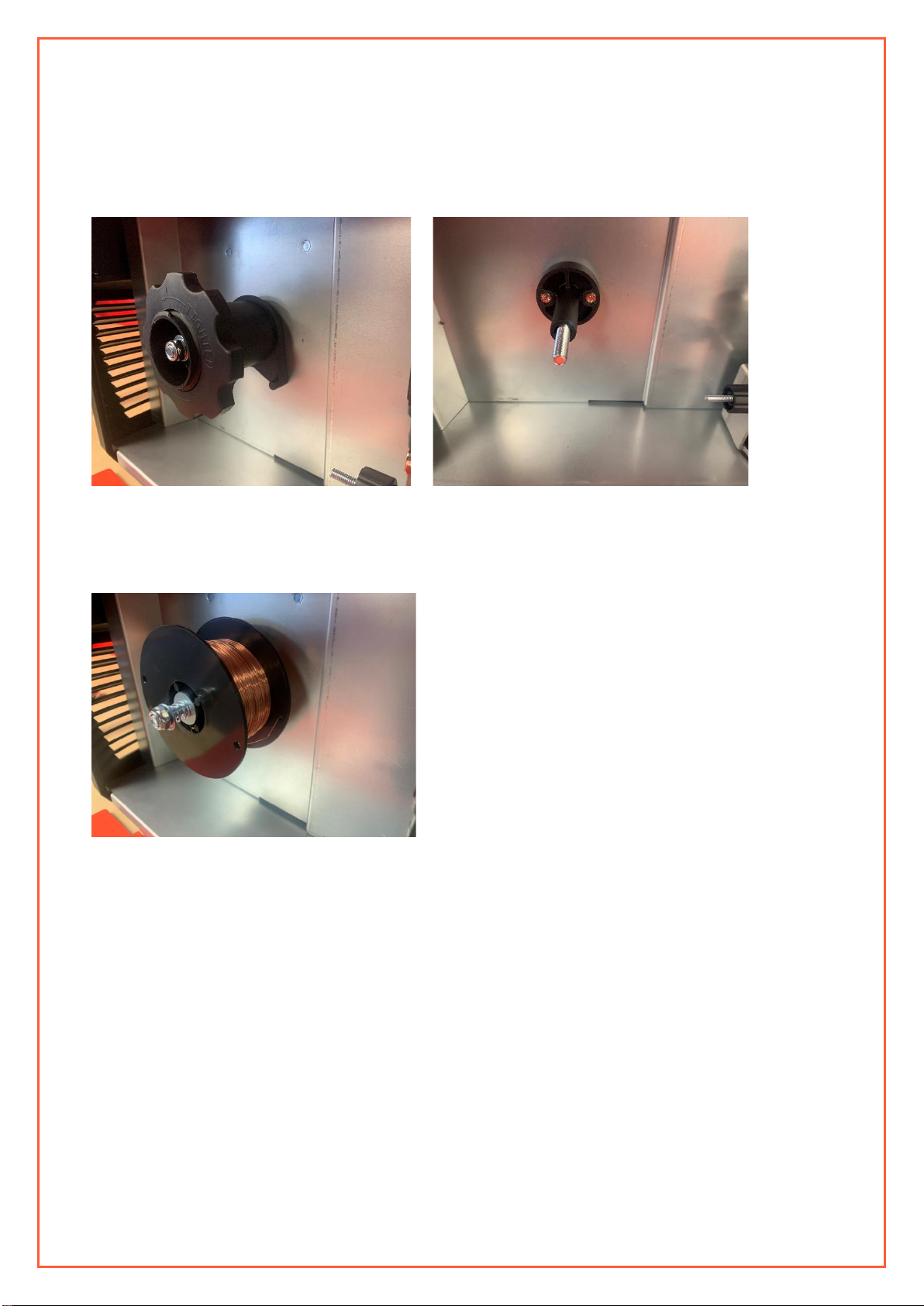

Fitting the Wire .............................................................................................................................................................................. 9

Gasless MIG Welding Setup ......................................................................................................................................................... 12

Gas MIG Welding Setup ............................................................................................................................................................... 15

MMA (Stick) Welding Setup ..................................................................................................................................................... 18

DC Lift TIG Welding Setup ........................................................................................................................................................ 20

Maintenance............................................................................................................................................................................ 22

Warranty.................................................................................................................................................................................. 22

Troubleshooting....................................................................................................................................................................... 23

Power Supply................................................................................................................................................................................ 23

Welding Torch .............................................................................................................................................................................. 23

Wire Feeder.................................................................................................................................................................................. 24

Cables ........................................................................................................................................................................................... 24