6

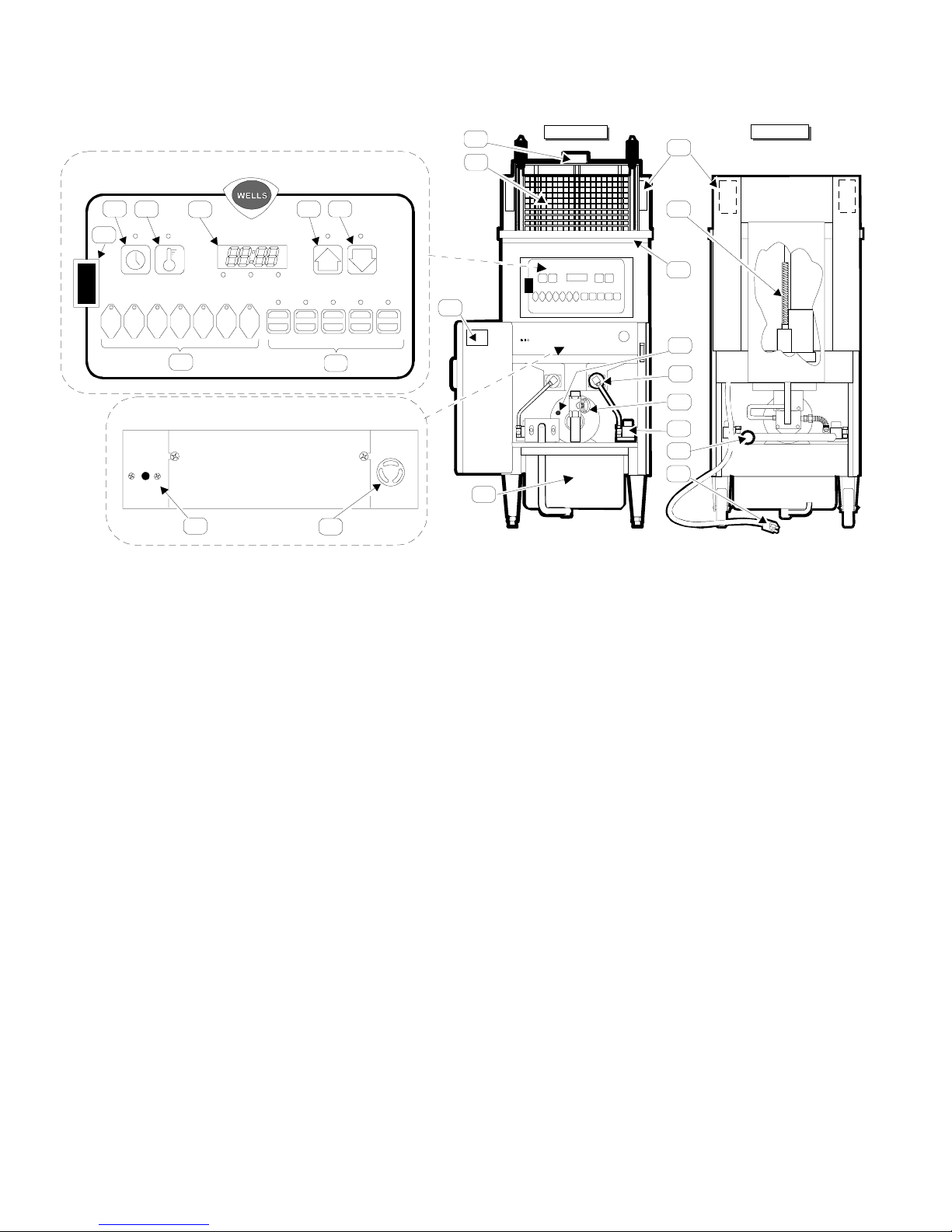

C. GAS PLUMBING INSTALLATION AND SET-UP

1. The installation of this fryer must conform to local codes. In the absence of local codes, the

installation of this fryer must conform with the National Fuel Gas Code (ANSI Z223.1).

In Canada, the National Gas Installation Code (CAN/CGAB149.2) is applicable.

2. The fryer must be isolated from municipal gas pressure or

LP/propane tank pressure by a gas pressure regulator.

In any instance where gas line pressure is in excess

of 15” of water column (1/2 psi or 3.45kP), as during

gas line testing or regulator maintenance, the fryer must

be isolated from the supply piping by closing its two

individual manual shut-off valves (item 20).

IMPORTANT: Failure to isolate the fryer from excessive

pressure will damage the gas valves and allow raw gas

to leak into the room.

3. This fryer requires specific gas pressure (at the burner orifice) for proper operation:

Natural gas @ 3.5” of water column; or,

LP/propane @ 10” of water column.

The gas valve is rated for a maximum of 15” of water column incoming line pressure.

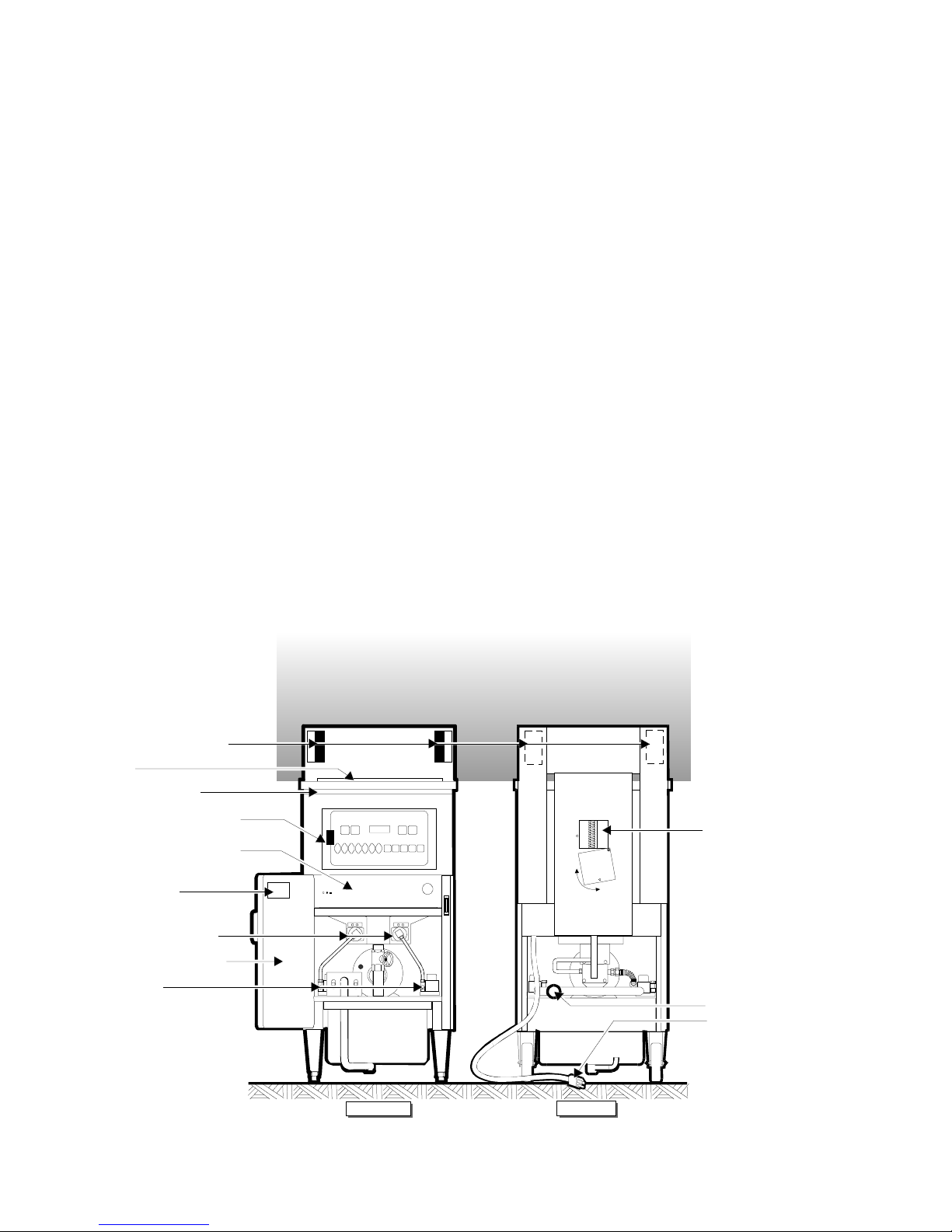

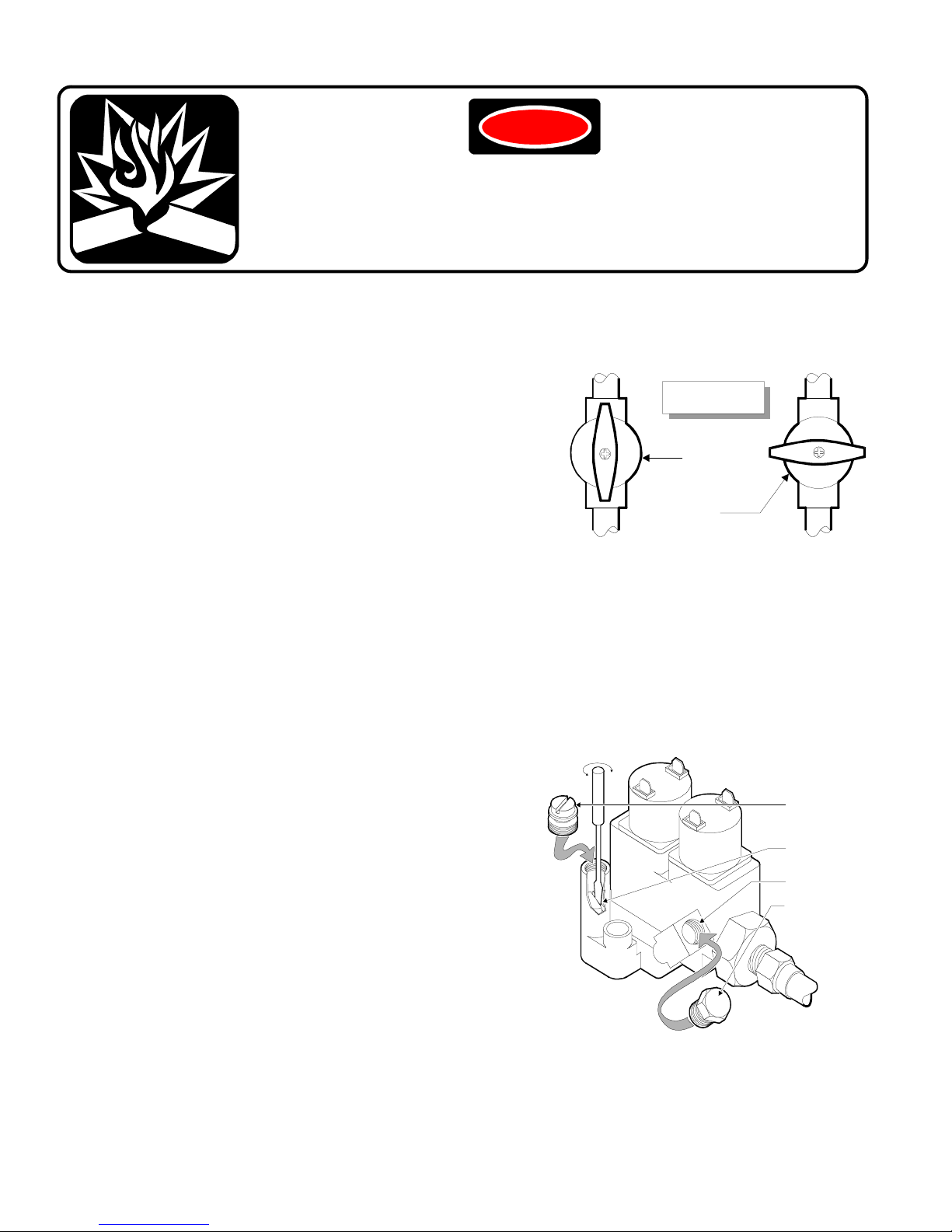

4. Gas pressure must be checked for BOTH burner systems,

while the fryer is in operation. This pressure is measured

by connecting a manometer to the pressure tap on the

gas control valve (pressure tap is threaded 1/8” NPT) :

a. Press the power switch to OFF. Turn the gas

shut-off valve for that side OFF.

b. Remove the pressure tap plug and insert an

appropriate manometer.

c. Turn the gas shut-off valve ON, and press the

power switch to FRYER.

d. Read the manometer while the gas control valve

is energized.

5. If adjustment is necessary, remove the regulator seal

screw and, using a small, flat-blade screw driver, turn

the adjusting screw (inside).

6. Be sure to turn the gas shut-off valve OFF prior to removing the

manometer. Replace the regulator seal screws and pressure tap

plugs for BOTH gas valves before turning the gas shut-off valves ON.

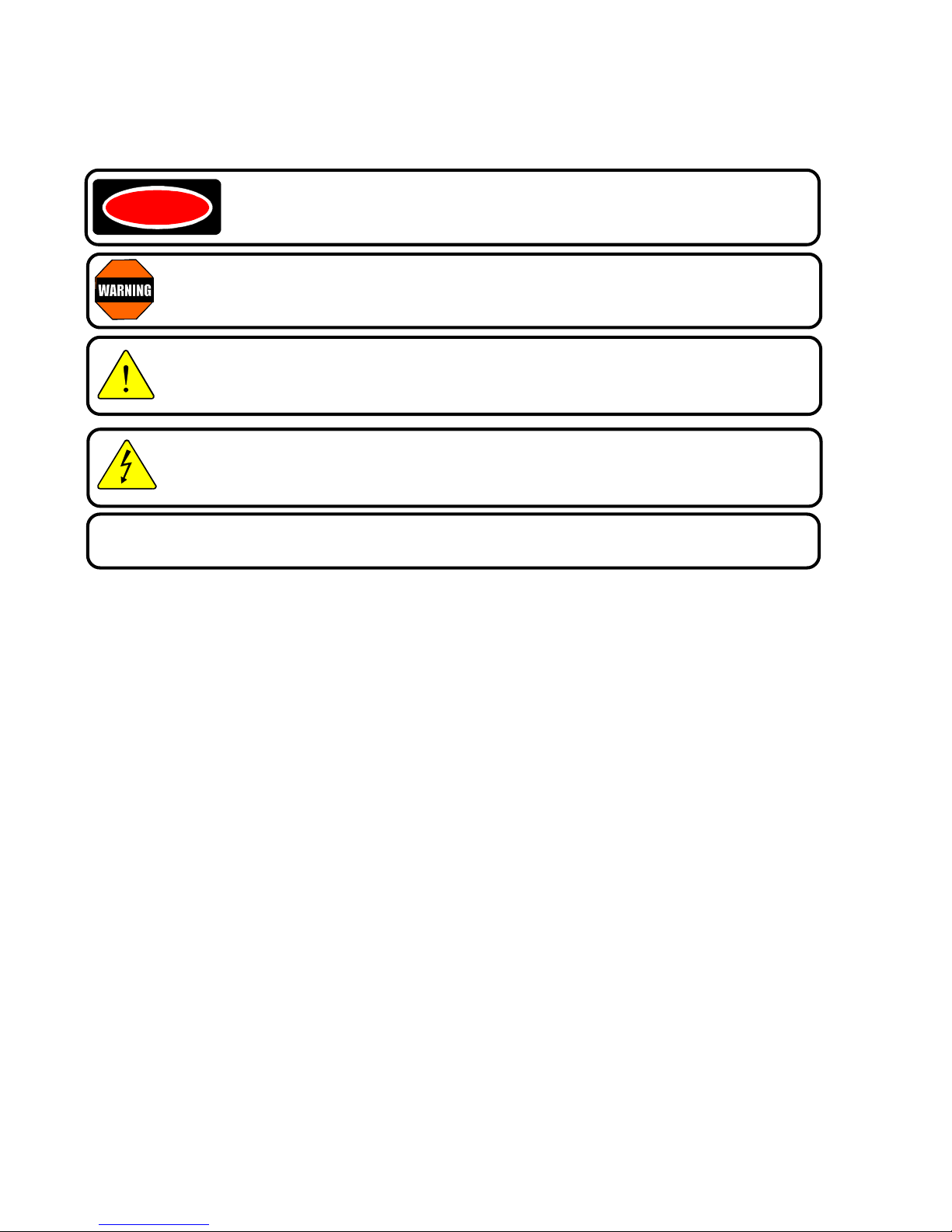

DANGER

FIRE AND EXPLOSION HAZARD

GAS CONNECTIONS AND GAS ADJUSTMENTS MUST BE MADE BY

A LICENSED PLUMBER, CERTIFIED IN GAS INSTALLATION

A gas explosion will cause death or serious injury.

PRESSURE TAP

PRESSURE TAP

PLUG

PRESSURE

REGULATOR

ADJUSTMENT

REGULATOR

SEAL SCREW

GAS SHUT-OFF

VALVE

OPEN POSITION

()ON

CLOSED POSITION

()OFF