EN

2

Table of Contents

1. Introduction......................................................................................................... 4

1.1 General Information Regarding this Document ....................................................................... 4

1.2 Function and Use for Intended Purpose .................................................................................. 4

1.3 Brief Explanation of Function- and Operating Modes............................................................... 4

1.4 Explanation of symbols ............................................................................................................ 5

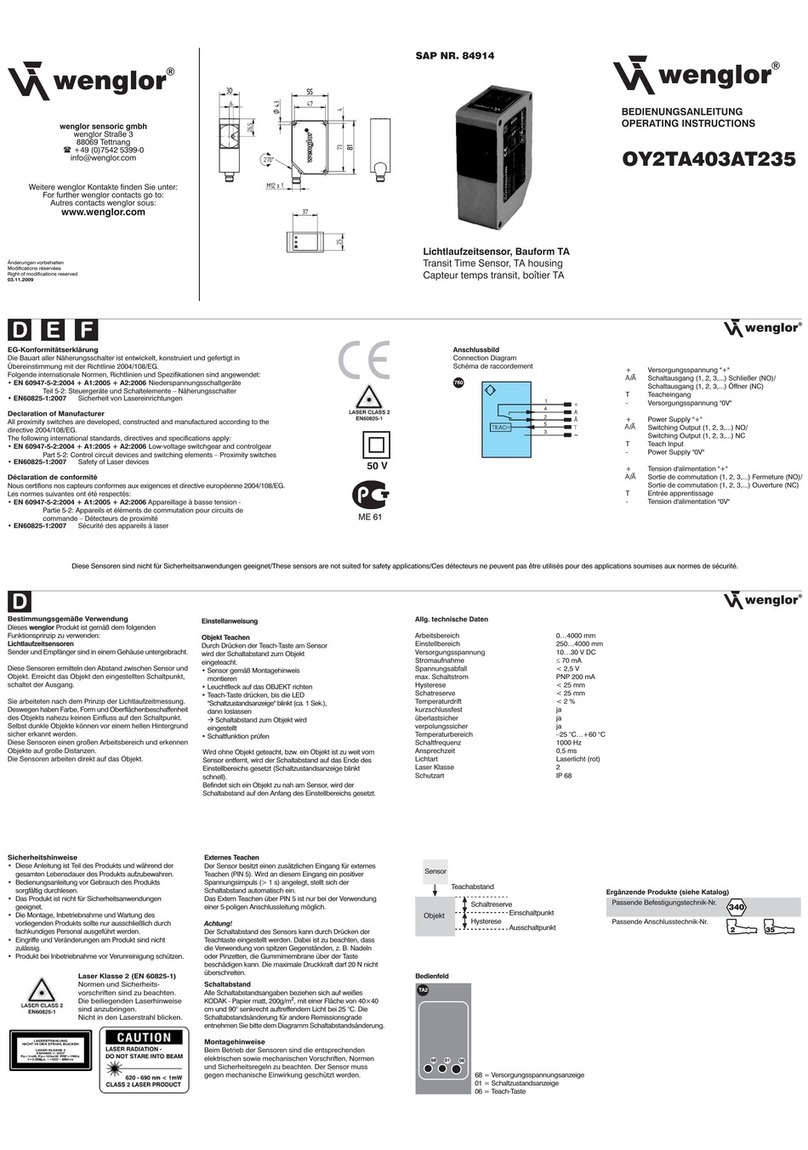

2. Description of the Safety Device........................................................................ 6

2.1 General ..................................................................................................................................... 6

2.2 Features ................................................................................................................................... 6

2.3 Layout ........................................................................................................................................ 7

2.4 Control and Display Elements................................................................................................... 7

2.5 Applications Examples .............................................................................................................. 8

3. Instructions for Use and Safety Precautions .................................................... 9

3.1 General Instructions for Use and Safety Precautions ............................................................... 9

3.2 Securing the Danger Zone ...................................................................................................... 10

3.3 Calculating Safety Clearance .................................................................................................. 10

3.4 Minimum Clearance to Reflective Surfaces............................................................................. 12

3.5 Avoidance of Reciprocal Influence Amongst Several Light Barrier Systems ......................... 13

4. Connection and Installation to the Machine ................................................... 14

4.1 Installation................................................................................................................................ 14

4.2 Connection to the Machine .................................................................................................... 15

4.3 Default Settings........................................................................................................................ 16

5. Light Array Operation ....................................................................................... 17

5.1 Settings .................................................................................................................................... 17

5.1.1 Using the Aligning Tool RF................................................................................................ 17

5.1.2 Using the SZ0-LAH1 Aligning Tool.................................................................................... 18

5.1.3 Adjustment Procedure ..................................................................................................... 18

5.2 Function Modes ...................................................................................................................... 19

5.2.1 Safety Operating Mode .................................................................................................... 19

5.2.2 Restart Inhibit and start-up inhibit..................................................................................... 20

5.2.3 Contactor Monitoring ........................................................................................................ 23

5.3 Functions ................................................................................................................................. 26

5.3.1 Fix Blanking....................................................................................................................... 26

5.3.0.2 Principle ...................................................................................................................... 26

5.3.0.3 Fix Blanking Procedure .............................................................................................. 29

5.3.0.4 Calculating Safety Clearance ..................................................................................... 30

5.3.5 Reduced Resolution.......................................................................................................... 30

5.3.0.6 Principle ...................................................................................................................... 30

5.3.0.7 Reduced Resolution Procedure ................................................................................. 32

5.3.0.8 Calculating Safety Clearance ..................................................................................... 33

5.4 Cascading................................................................................................................................ 33

5.4.1 Principle............................................................................................................................. 33

5.4.2 Cascading Procedure ....................................................................................................... 34

5.4.3 Functions........................................................................................................................... 36

5.4.4 Coding............................................................................................................................... 37

Table of Contents