!disconnection.

!· It is forbidden to use a combination of equipment where function of any one item is affected

by, or interferes with the function of any other.

!· before each use of personal fall protection equipment carry out a detailed inspection to

ensure that the device is operable and operates correctly.

!· In particular, before use inspect all accessible elements of the equipment for any damages,

excessive wear, corrosion, abrasion, cutting or improper function. On individual devices pay

particular attention to:

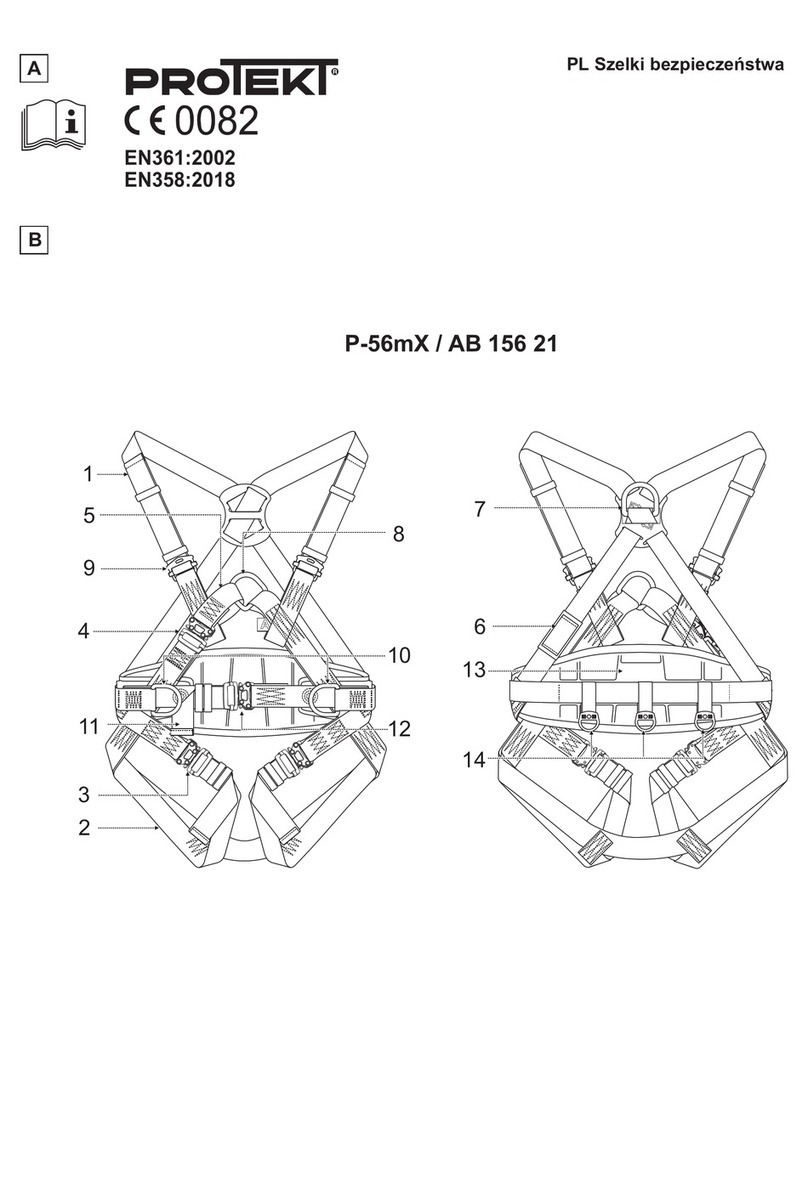

!· in full body harness, sit harnesses and work positioning devices: buckles, regulating

elements, attachment points (buckles), webbing, seams, belt loops;

!· in energy absorbers: attachment loops, webbing, seams, housing, connectors;

!· in lanyards and textile guides: rope, loops, thimbles, connectors, regulating parts, splices;

!· in lanyards and steel guides: rope, wires, clamps, loops, thimbles, connectors, regulating

parts;

!· in retractable type fall arresters: lanyard or webbing, retractor and locking mechanism for

proper operation, housing, energy absorber, connectors;

!· in guided type fall arresters: body, proper guiding, locking mechanism for proper operation,

rollers, bolts and rivets, connectors, energy absorber; in metal parts (connectors, hooks,

attachment points): load-bearing body, rivets, main pawl, function of locking gear.

!· at least once a year, after every12 months of use, personal protective equipment must be

withdrawn from use to carry out periodic detailed inspection. Periodic inspection may be

carried out by a properly qualified and skilled person. Also periodic inspection may be carried

by manufacturer of the equipment or his authorized representative.

!· in some cases, if the fall protection equipment has a complex design (e.g. fall arresters),

periodic inspections may be carried out by the equipment manufacturer, or his authorized

representative only. After the periodic inspection, date of the next inspection should be

arranged.

!· Regular periodic inspections are essential in respect of the equipment condition and safety

of users which is dependant on the equipment functionality and durability.

!· During periodic inspection it is necessary to check the legibility of all the equipment

markings (identity label of the device.) Do not use the equipment if marking is illegible.

!· it is essential for the user's safety that the product is re-sold outside the original country of

destination the reseller must provide instructions for use, for maintenance, for periodic

inspection and for repair in language of the country where the product is to be used.

!· personal fall protection equipment must be withdrawn from use and discarded immediately

(or other procedures based on instruction manual should be applied) if it has been used to

arrest a fall.

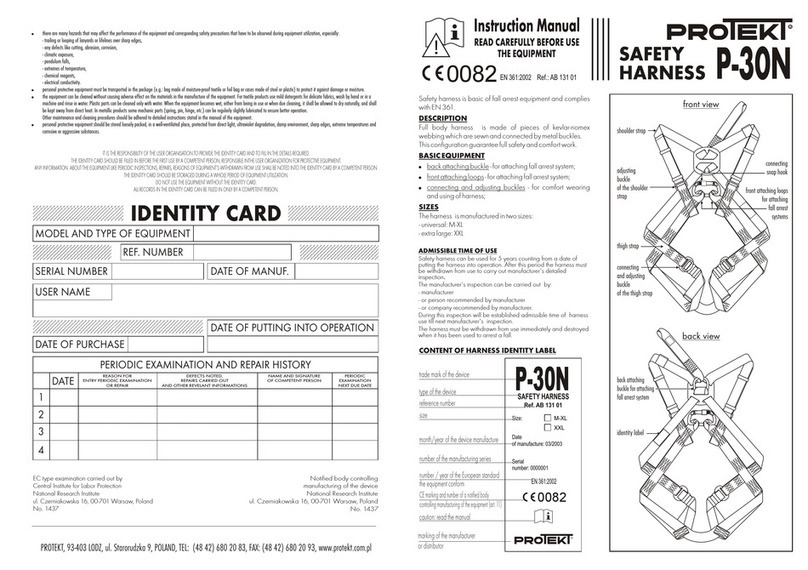

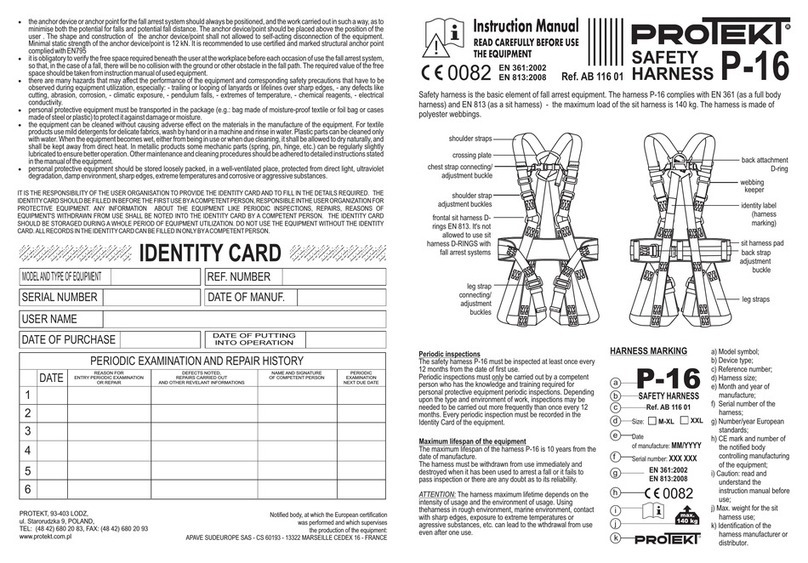

!· full body harness compliant with EN 361 is the only device supporting user's body in fall

arrest systems.

!· fall arrest system can be connected to attachment points (buckles, loops) on full body

harness marked with capital letter “A”

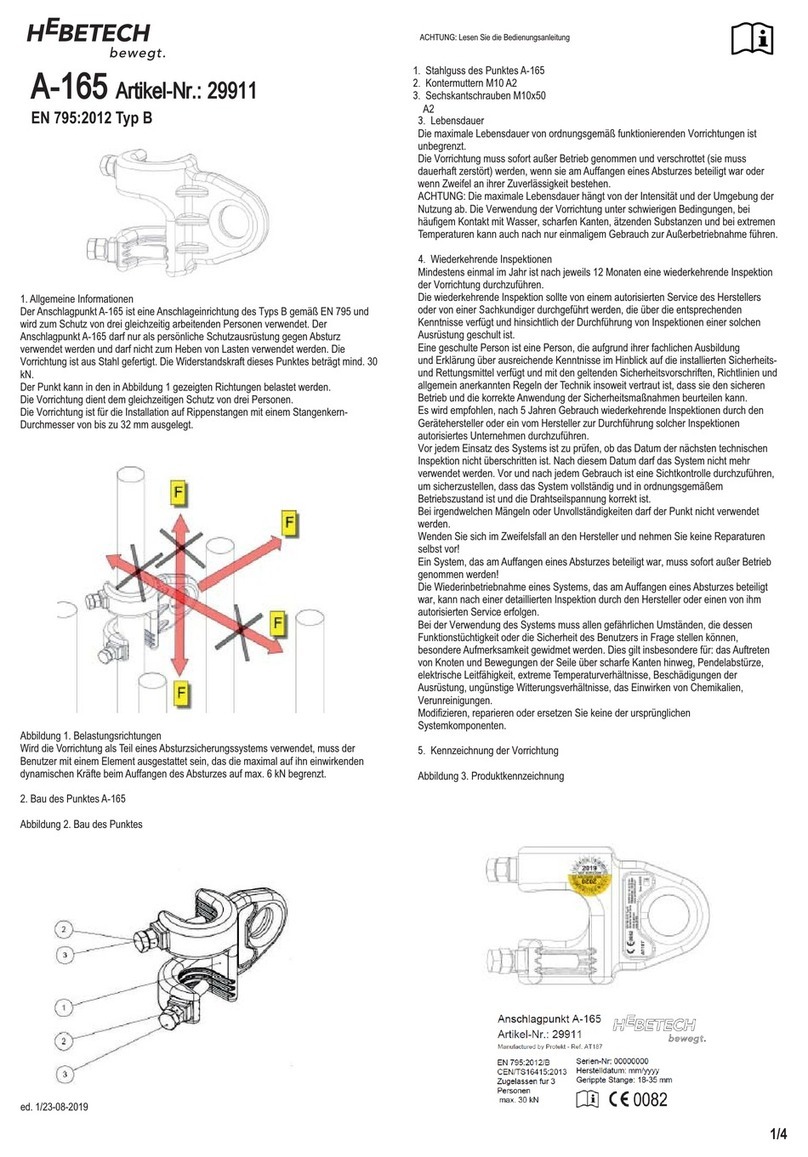

!· Anchor point (device) of the fall protection equipment should have a stable structure and

position so as to prevent a possibility of the load fall and minimize a free fall distance. Anchor

point of the equipment should be located above the user's work station. The shape and

construction of the anchor device/point shall not allow for a self-acting disconnection of the

equipment. Minimal strength of the equipment anchor point should be 12kN. It is

recommended to use certified and marked anchor points of the equipment compliant with EN

795.

!· It is obligatory to verify the free space required under the user at workplace before each

occasion of using the fall protection system, so that, in case of a fall, there is no collision with

the ground or other obstacle in the fall path. The required free space should be determined

on basis of the data given in the instruction manual of the equipment to be used.

!· when using the equipment, pay special attention to risks affecting operation of the

equipment and the user's safety, and in particular to kinks and rope movement on sharp

edges, oscillatory falls, electrical conductivity, any damages such as cuts, abrasions,

corrosion, influence of extreme temperatures, negative influence of environmental factors,

chemical substances.

!· Personal protective equipment must be transported in a package (e.g.: bag made of

moisture-proof textile or foil bag or cases made of steel or plastic) to protect it against

damage or moisture.

!· Personal fall protection equipment should be cleaned without causing adverse effect on

the materials used in the production of the equipment. For textile materials (webbings, ropes)

use agents suitable for delicate fabrics. Rinse thoroughly. Clean energy absorbers using

damp cloth only. Do not immerse energy absorber in water. Wash textile products with water

only. When the equipment becomes wet, either from being in use or after cleaning, allow it to

dry naturally, and keep it away from sources of heat. In metallic products lubricate slightly

some mechanical parts (springs, hinges, pawls, etc.) regularly to ensure their better

operation.

!· Personal protective equipment should be stored loosely packed in well-ventilated rooms,

protected from direct light, UV degradation, dust, sharp edges, extreme temperatures and

aggressive chemical substances.

!· all parts of a fall protection equipment must conform to instruction manuals for the

equipment and standards in force:

!- EN 353-1, EN 353-2, EN 354, EN 355, EN 360 - Fall arrest systems;

!- EN 362 - Connectors

!- EN341, EN1496, EN1497, EN1498 - Rescue equipment

!- EN 361 - Full body harness;

!- EN 813 - Sit harness;

!- EN 358 - Work positioning systems;

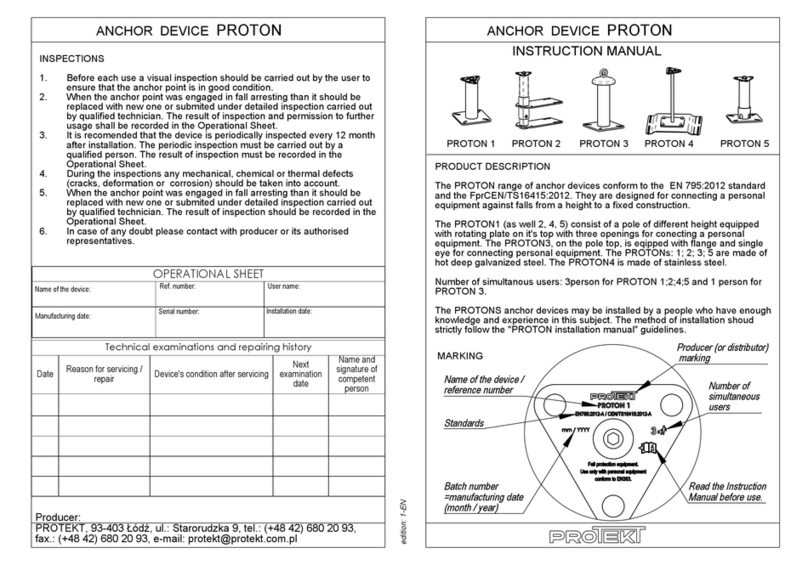

!- EN 795 - Anchor devices.

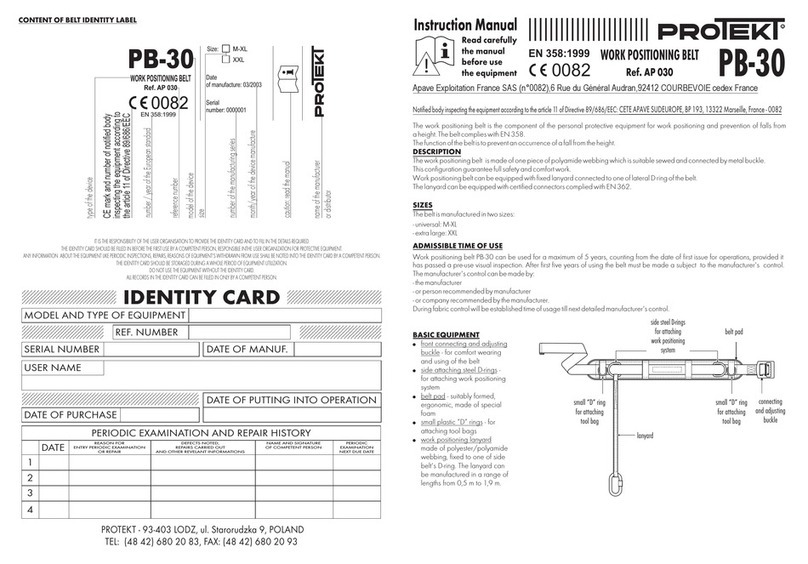

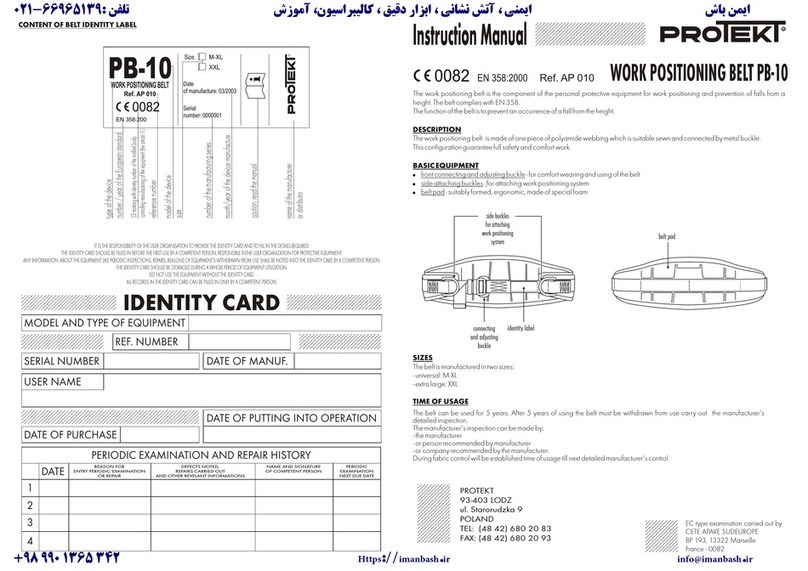

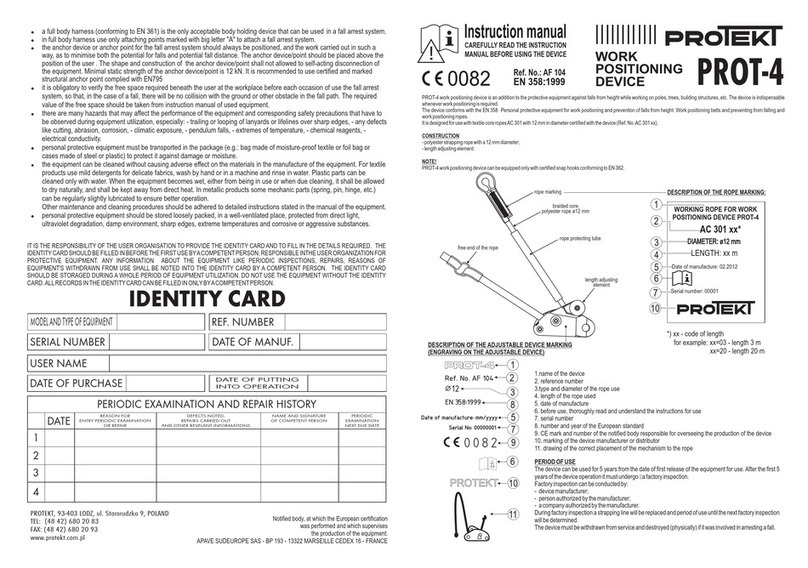

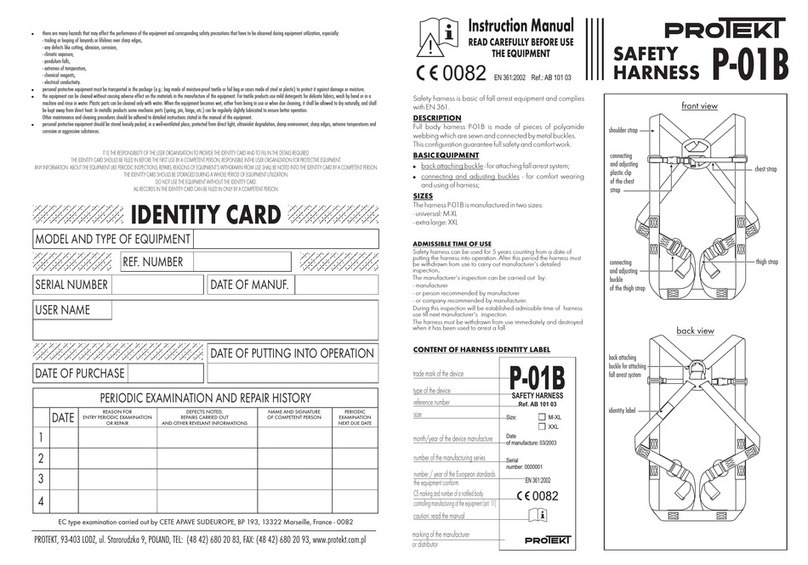

IDENTITY CARD

TECHNICAL INSPECTIONS

1

SIGNATURE OF

AUTHORIZED

PERSON

DEVICE NUMBER

USER NAME

REFERENCE NO.

DATE OF MANUFACTURE

DATE OF FIRST USE

DATE OF PURCHASE

2

3

4

5

DATE OF NEXT INSPECTIONDATE

OF INSPECTION

REASONS FOR

INSPECTION OR REPAIR

NOTICED DAMAGES,

COMPLETED REPAIRS, OTHER REMARKS

NAME OF DEVICE

MODEL

It is the responsibility of the user organisation to provide the Identity Card and to fill in the required details. The Identity Card should be filled in before the first usage of the equipment. All

information on fall protection equipment (name, serial no., purchase date and date of first use, name of user, information on repairs and inspections and withdrawal from use) must be provided

in the identity card of the device. The Identity Card should be filled in by a person responsible for fall protection equipment in an organisation. It is forbidden to use personal fall protection

equipment if the Identity Card is not filled in.

PROTEKT ul. Starorudzka 9, 93-403 Łódź , POLAND

Tel. + 48 42 6802083, Fax +48 42 6802093

European Certificate issued by

CENTRAL INSTITUTE FOR LABOUR PROTECTION

ul. Czerniakowska 16, 00-701 Warsaw, Poland, no. 1437

4/4

Declaration of Conformity EU for this product is delivered with the product.

If needed it is also available at the manufacturer's website: www.protekt.com.pl.