Westfalia DD-HT33/18 User manual

Other Westfalia Drill manuals

Westfalia

Westfalia 77 49 01 User manual

Westfalia

Westfalia BMH 900 User guide

Westfalia

Westfalia 80 03 78 User manual

Westfalia

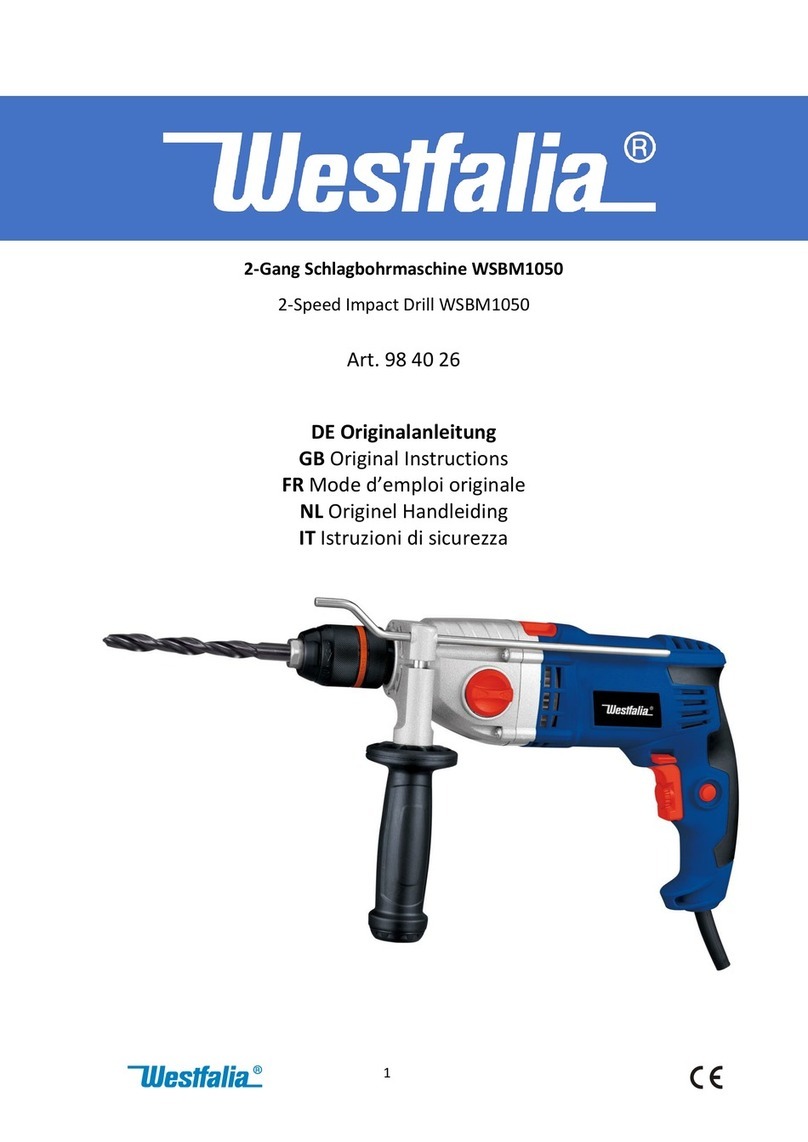

Westfalia WSBM1050 User manual

Westfalia

Westfalia WASB18BL User manual

Westfalia

Westfalia 81 84 55 User manual

Westfalia

Westfalia 65 58 86 User manual

Westfalia

Westfalia 85 93 08 User manual

Westfalia

Westfalia 28 31 19 User manual

Westfalia

Westfalia PBH 800 User guide

Westfalia

Westfalia 85 93 09 User manual

Westfalia

Westfalia SN-2010 User manual

Westfalia

Westfalia 67 64 60 User manual

Westfalia

Westfalia CT 2408 User manual

Westfalia

Westfalia WBS300 User manual

Westfalia

Westfalia 88 35 80 User manual

Westfalia

Westfalia SBMB 600 User manual

Westfalia

Westfalia TMK 008 User manual

Westfalia

Westfalia SI-92 User manual

Westfalia

Westfalia 93 56 33 User manual