2

Make sure the voltage corresponds to the type label on the

device.

Persons with limited physical, sensorial or mental abilities are

not allowed to use the device, unless they are supervised and

briefed for their safety by a qualified person.

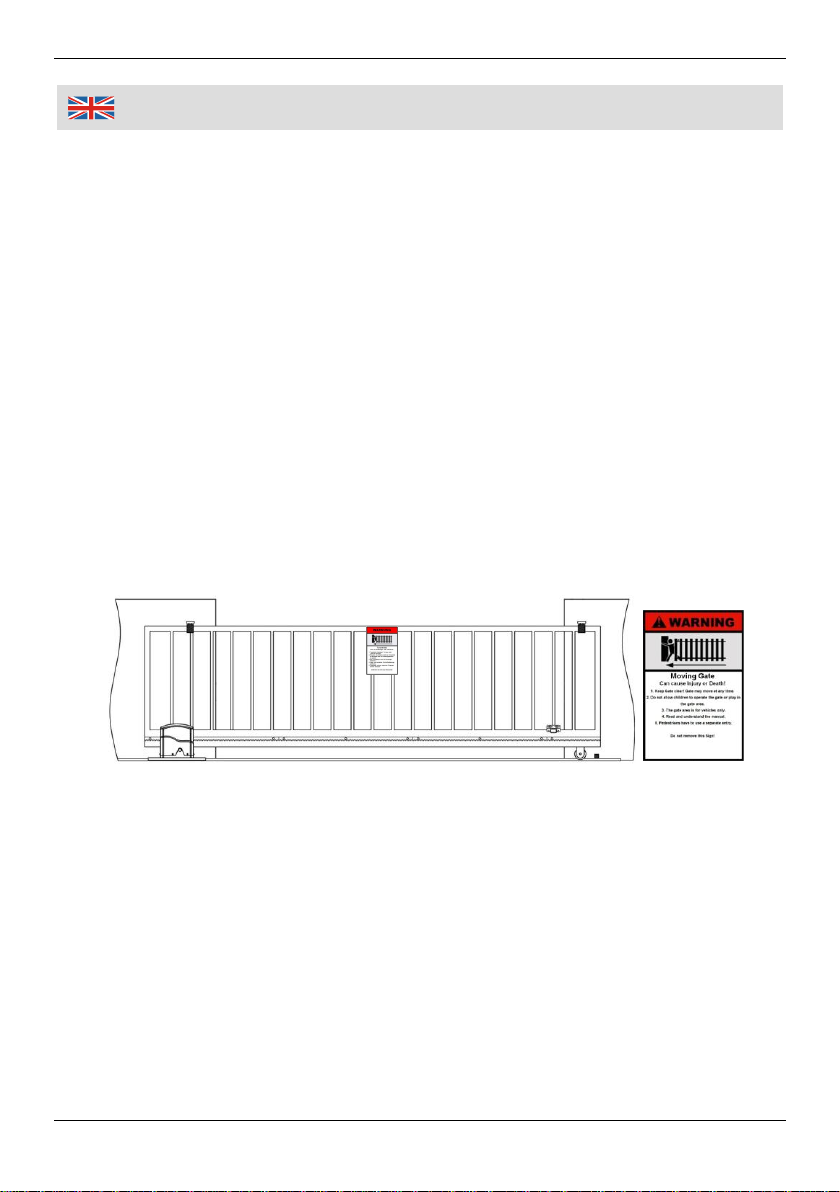

The sliding gate opener is designed for opening and closing

light-weighted sliding gates only. The sliding gate opener is

designed for private use only.

Mounting, maintenance and repairs of the sliding gate opener

must be performed by a qualified person. According to EN

12635, a qualified person is a person with suitable training,

specialist knowledge and practical experience sufficient to

correctly and safely fit, test and maintain the gate system. In

case of failure of the sliding gate opener, a qualified person must

be commissioned immediately for the inspection or repair work.

Observe the local safety regulations to prevent accidents while

mounting the sliding gate opener. Westfalia assumes no liability

for improper installation of the sliding gate opener.

WARNING. There is risk on injuries if the sliding gate opener is

not mounted and operated correctly. Incorrect mounting and

operation of the sliding gate opener may trigger unexpected gate

travel. Thus persons or objects can be trapped.

Electrical installation has to be carried out by a qualified

professional only. Power supply of the sliding gate opener is

provided by means of 230 V~ 50 Hz. Electrical power should be

reserved only for the sliding gate opener and should be protect-

ed by a 10 A fuse.

Check the whole sliding gate system (joints mounting material

etc.) for any signs of wear or damages and do not use the sliding

gate opener with a damaged sliding gate system resp. with signs

of rust, fractures or corrosion. Do not use the sliding gate opener

Please note the following safety notes to avoid

malfunctions, damage or physical injury