10

5.8 Connection Diagrams

5.

8.1

RELAY

CONNECTIONS

A simple block diagram

is

provided in Fig.

11

to illus-

trate the internal functional circuits

of

the type GFR

Relay. Complete external connections are a function

of

the associated devices used with the relay along with the

complexity

of

the system in which the components are

applied. The terminals on the

GFR

relay are suitable for

#18 through

#14

AWG

copper conductors. A maximum

of

two per terminal are permitted.

5.8.2 TYPICAL SYSTEMDIAGRAMS

Basic, typical radial distribution system diagrams are pro-

vided

in

this leaflet for guidance; refer to Figs. l

lA,

118,

llC,

llDand

llE.

Two multiple source distribution systems are illus-

trated in Figs.

11

F and l

lH.

Fig.

11

F illustrates a dual

source distribution system with center point grounding

as

allowed in the National Electrical Code under Article

250-23a, Exception No. 4 Fig.

11

H illustrates a multiple

source, multiple ground distribution system with zone dif-

ferential ground fault sensing methods employed.

5.8.3 ZONE DIFFERENTIAL GFR OPERATION

PRINCIPLES -SEE

FIG.

l JH

5.8.3.1 In general,

G~~

will operate only for ground

faults within Zone 1 and

G~~

for Zone 2. This includes

ground faults for feeders located in these respective zones.

5.8.3.2 With

"Ml"

and

"T"

closed and "M2" open and

with a ground fault in Zone

2,

G~~

will not operate

to

trip

"Ml"

but,

G:~

will

to

trip

"T".

5.8.3.3 Conversely, with "M2" and

"T"

closed and

"Ml"

open and with a ground fault in Zone 1,

G:~

will not op-

.

"M2"

b GFR

·11

.

"T"

erate

to

tnp

ut

M2

w1

to

tnp

.

5.8.3.4 For properly co-ordinated main, tie and feeder

interrupting devices, the feeder relays will always react

to clear a downstream ground fault prior

to

operation

of

either the main or tie devices.

5.8.3.5 Zone interlock wiring between upstream and

downstream devices can be included

as

shown. For this

scheme, no cross interlocking with

"T"

auxiliary contacts

is

required.

5.8.3.6 This scheme may be expanded to additional alter-

nate sources

as

long

as

interrupting devices are available

to

isolate any potential ground fault on each side

of

the

fault.

6.0

GROUND FAULT CURRENT SENSORS

(See Table 6, Page 24)

6

.1

General Description

As

indicated in Table 6 (Page 24), Ground Fault Current

Sensors (GFS) are available in a variety

of

physical sizes

and current ratings to match the application requirements

of

the distribution system. Sensors should be selected to

match the ampere rating

of

the specified

GFR

Relay. The

physical size should be selected to properly encompass the

required conductor configuration with space allowed for

minimum clearances

as

shown

in

the applicable outline

mounting figure. Outline references

are

given

in

Table 6.

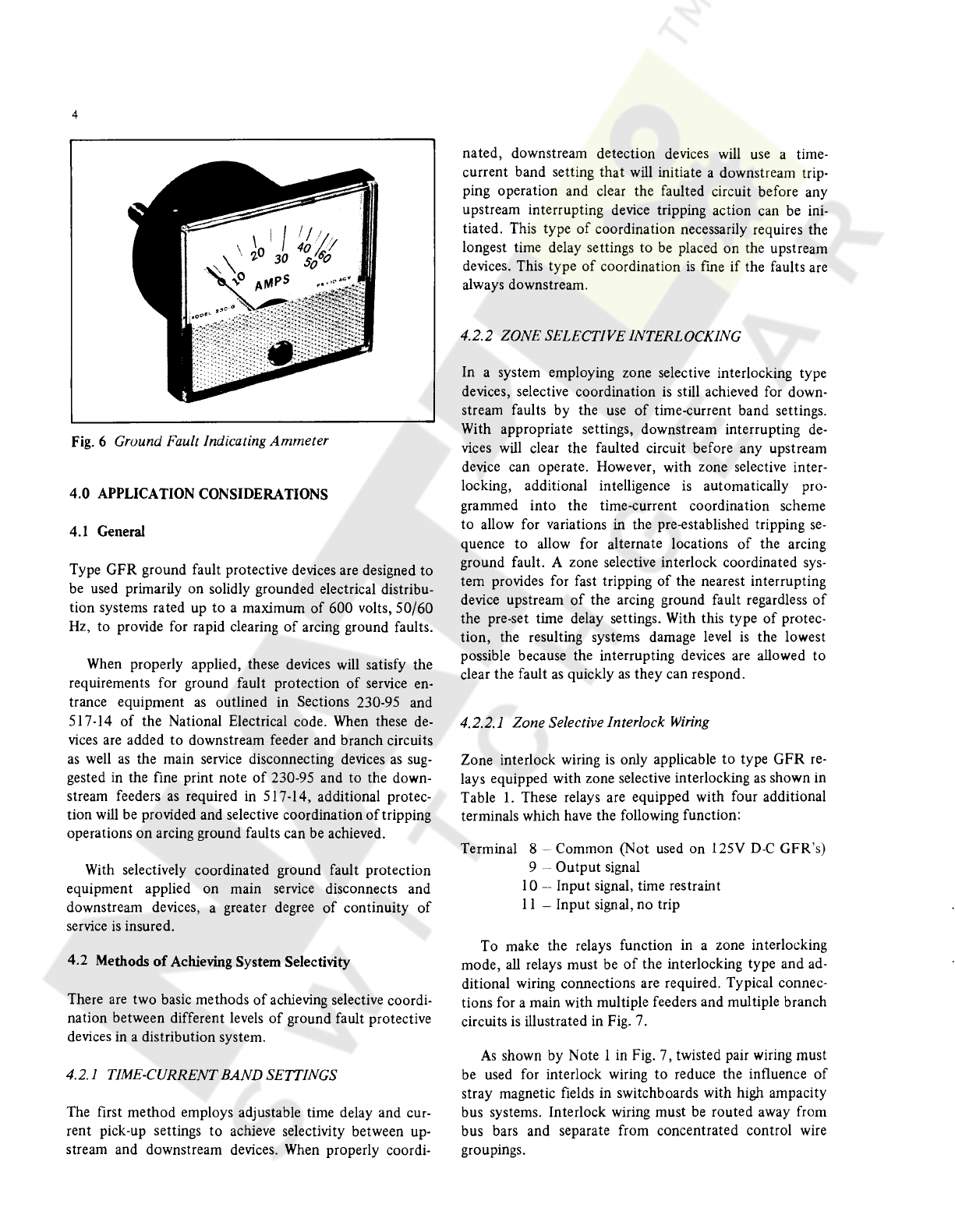

Sensors are available with solid cores having round con-

ductor openings and in split core designs with various size

rectangular openings. On the split core designs, one core

leg

is

removable

to

permit ease

of

installation around

existing conductor assemblies.

Ground Fault Current Sensors are special rated current

transformers and must be applied only with type GFR

Relays shown in Table

1.

Sensors cannot be used with any

other equipment.

Sensors are insulated with cast apoxy and can be

mounted directly to enclosure surfaces. Ideally, they

should be installed

so

that all conductors passing through

the sensor opening are physically centered in the window

opening. Minimum clearances are specified in the applica-

ble outline,

but

greater clearances will help reduce any

possible error signals. Rectangular configurations are pro-

vided with compensating windings to reduce potential

error signals.

All

sensors are provided with integral test winding for

use under simulated ground fault test conditions. With

an input

of

1.2 Amps into terminals 2-3, a rated

output

of

240 M.A. should be produced in terminals

1-3

with a

tolerance

of

±15%. For information purposes, the turns

ra-

tio and saturation levels

of

all sensors

is

provided

in

Table 6.

Courtesy of NationalSwitchgear.com