Page 5

This section will outline the operation of the siren in the factory

default configuration. Refer to the Scan-Lock™ section on the

following page for information and procedures on how to

customize the operation of this siren.

RAD (Radio Repeat) - When the rotary knob is in the RAD

position, any signal that is received by the vehicle’s two-way

radio will be simultaneously broadcast over the vehicle’s

loudspeaker (the unit must be connected to the two-way radio as

outlined in this manual).

With the Rotary Switch in this Position:

• Pressing the MAN button will produce the AIRHORN

tone until the MAN switch is released.

• Activating the HORN RING input will produce the

AIRHORN tone until the MAN switch is released.

• Activating the AUX ENABLE input has no effect.

MAN 1 (Manual Siren #1) - When the rotary switch is in this

position the siren is in a standby state where no tones have been

activated, but is waiting for another action to be taken by the

operator.

With the Rotary Switch in this Position:

• Pressing the MAN button will produce the AIRHORN

tone until the MAN switch is released.

• Activating the HORN RING input will produce the

AIRHORN tone until the HORN RING input is released.

• Activating the AUX enable input will produce a

repeating WAIL tone.

MAN 2 (Manual Siren #2) - When the rotary switch is in this

position the siren is in a standby state. No tones will be activated

until another action is taken by the operator.

With the Rotary Switch in this Position:

• Pressing the MAN switch will produce a WAIL tone. This

tone will ramp up to peak frequency and stop when the

MAN switch is released.

• Activating the HORN RING input will produce a WAIL

tone. This tone will ramp up to peak frequency and stop

when the HORN RING input is released.

• Activating the AUX enable input will produce a

repeating WAIL tone.

HF (Hands-Free Operation) - When the rotary knob is in the HF

position, the siren functions are placed in a stand-by mode. Siren

tones are activated by a single “tap” on the MAN button or on the

vehicle’s steering wheel horn ring (if the vehicle’s horn has been

wired to the HORN RING input). The first tap produces a Wail

tone (a steady rise and fall tone). A second tap produces a Yelp

tone (a fast rise and fall tone). A third tap produces a Piercer™

tone (an extremely fast rise and fall tone). The next tap returns

the siren to a Wail tone and the cycle repeats itself. Two quick

successive taps will stop the siren.

With the Rotary Switch in this Position:

• Pressing the MAN button will produce the HF cycle as

described above.

• Activating the HORN RING input will produce the HF

cycle as described above.

• Activating the AUX ENABLE input will start the HF

cycle. Releasing the AUX ENABLE will stop the cycle.

T1 (Tone #1) - When the rotary knob is in the T1 position, a

steady, rise and fall tone (WAIL) is produced.

With the Rotary Switch in this Position:

• Pressing the MAN button will change the siren tone to a

Yelp pattern (a fast rise and fall tone). Pressing the MAN

button a second time returns it back to Wail.

• Activating the HORN RING input will change the siren

tone to Yelp. Activating the HORN RING input again to

return to a Wail tone.

• Activating the AUX ENABLE input has no effect.

T2 (Tone #2) - When the rotary knob is in the T2 position, a fast,

rise and fall tone (YELP) is produced.

With the Rotary Switch in this Position:

• Pressing the MAN button will produce the Piercer™

tone. Pressing the MAN switch a second time returns it

back to Yelp.

• Activating the HORN RING input will produce the

Airhorn tone until the HORN RING input is released.

• Activating the AUX ENABLE input has no effect.

T3 (Tone #3) - When the rotary knob is in the T3 position, an

extremely fast, rise and fall tone is produced.

With the Rotary Switch in this Position:

• Pressing the MAN button will result in the AIRHORN

tone until the MAN button is released.

• Pressing the HORN RING input will result in the

AIRHORN tone until the HORN RING input is released.

• Activating the AUX ENABLE will have no effect.

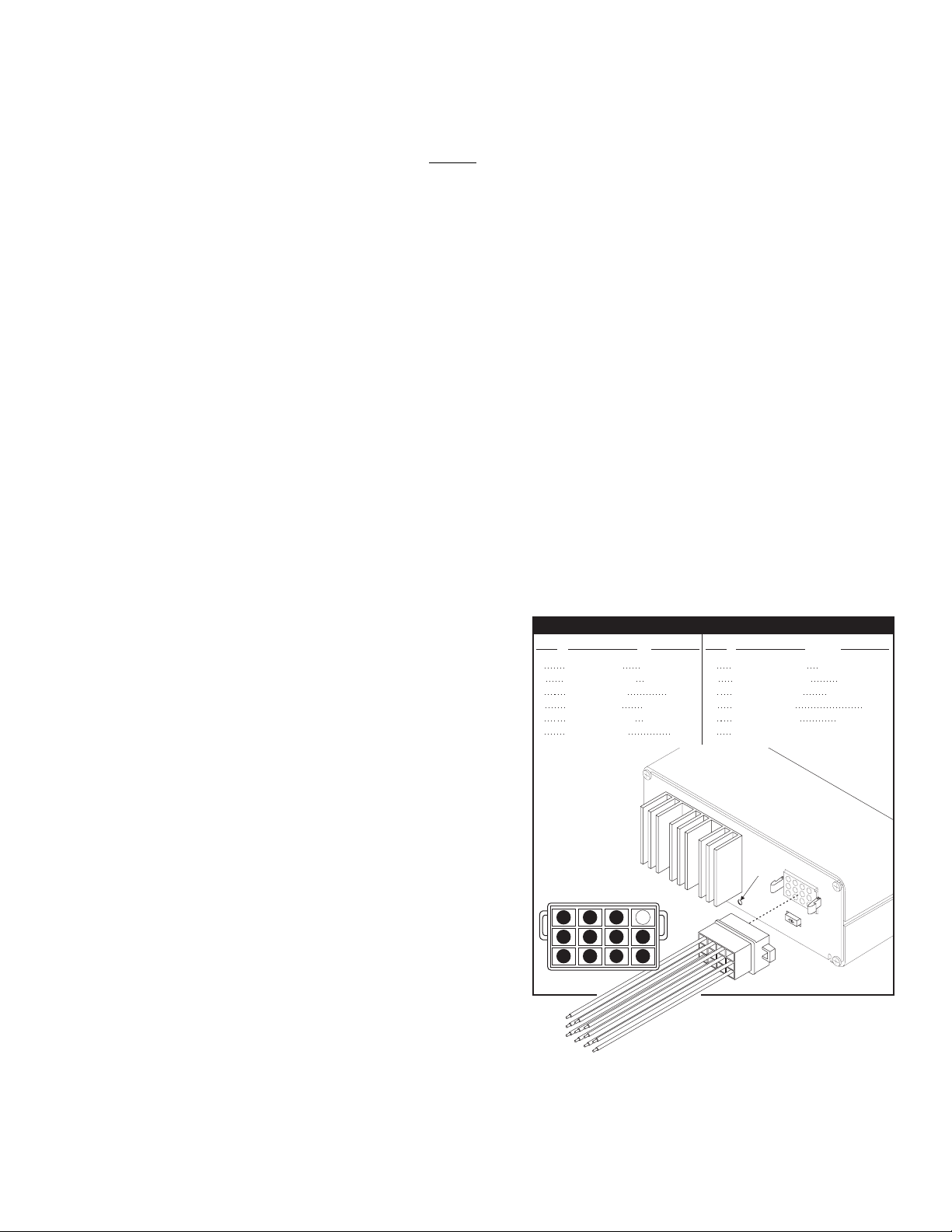

12-Volt Models 24-Volt Models

INPUT VOLTAGE . . . . . . . . . . . . . . . . . . . . 12 VDC ±20% 24 VDC ±20%

INPUT CURRENT . . . . . . . . . . . . . . . . . . . 16 AMPS (TYP.) 8 AMPS (TYP.)

INPUT FUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 AMPS 10 AMPS

SPEAKER IMPEDANCE. . . . . . . . . . . . . . . 11 OHMS MIN. 11OHMS MIN.

OPERATING TEMPERATURE . . . . . . . -30° C. TO +80° C. -30° C. TO +80° C.

STORAGE TEMPERATURE. . . . . . . . .-40° C. TO +70° C. -40° C. TO +70° C.

HUMIDITY . . . . . . . . . . . . . . . . . . . 99% (Non-Condensing) 99% (Non-Condensing)

Rotary Switch Operations

CAUTION

Loud siren noise can cause

hearing damage and/or loss.

Refer to OSHA Section 1910.95 prior

to putting ANY siren into service!

Wear

Protection!

ACTIVATION OF THIS

SIREN MAY DAMAGE

UNPROTECTED EARS!