Page 2

CAUTION! DO NOT LOOK DIRECTLY AT THESE LEDS WHILE THEY ARE ON.

MOMENTARY BLINDNESS AND/OR EYE DAMAGE COULD RESULT!

IMPORTANT WARNING!

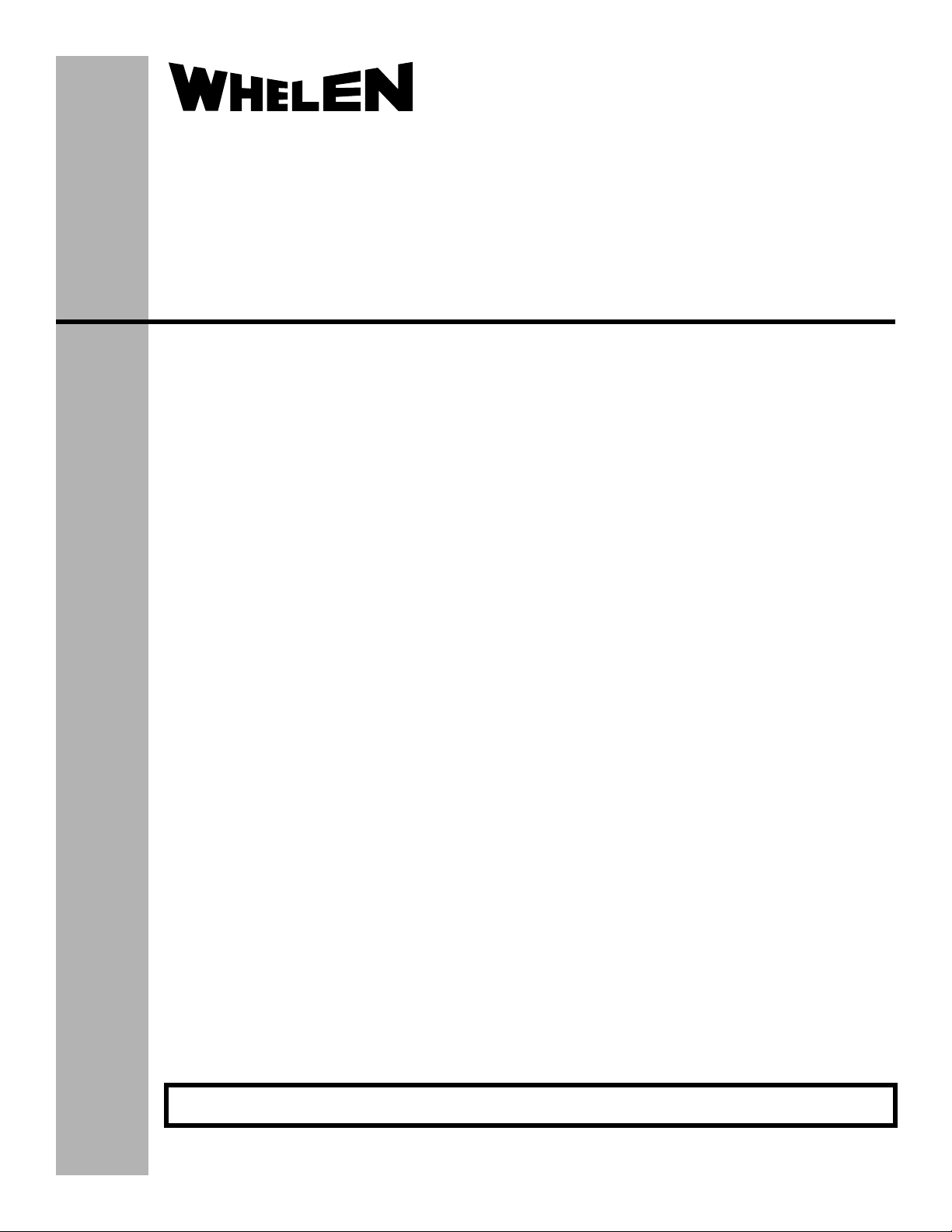

MOUNTING

SURFACE

3/8-16

HEX NUT

3/8 FLAT

WASHER

3/8 SPLIT

LOCK

WASHER

3/8-16 X 2 HEX

HEAD BOLT

3/8-16 X 2 HEX

HEAD BOLT

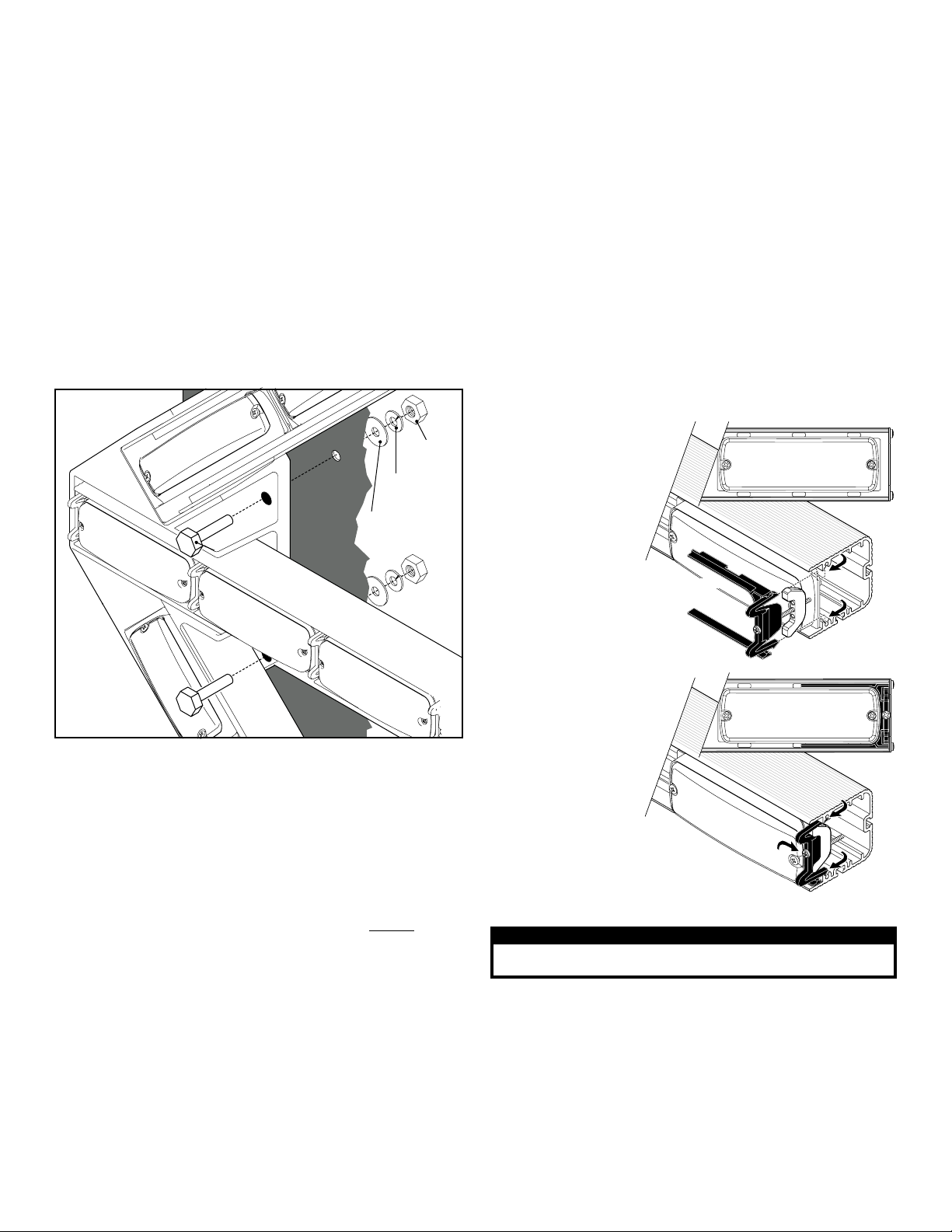

FIG. 1

Installation:

Caution: Permanent mounting of this product will require

drilling. It is absolutely necessary to make sure that no other

vehicle components could be damaged by this process. Check

both sides of the mounting surface before starting. If damage is

likely, select a different mounting location.

IMPORTANT: It is the responsibility of the installation technician

to make sure that the installation and operation of this product

will not interfere with or compromise the operation or efficiency

of any vehicle equipment!

1. Place the Traffic Advisor™ in its mounting position on the

mounting surface, making sure the arrow is level. Mark the 4 bolt

locations off onto the mounting surface (2 bolts per side).

2. Remove the Traffic Advisor from the mounting surface and drill

the 4 mounting holes using a drill sized for the 3/8” bolts.

3. Install the mounting hardware onto the bolts in the order shown

and mount the Traffic Advisor to the vehicle (Fig. 1).

IMPORTANT: When you are routing wires, the existing, factory

wire harness should be followed whenever possible. The

existing harness has been positioned so no wires will be

damaged by vehicle operation. The factory harness may include

a service loop that will keep the wires from being damaged or

broken by the movement of the dump body.

Wiring:

WARNING! All customer supplied wires that connect to the

positive terminal of the battery must be sized to supply at least

125% of the maximum operating current and FUSED at the

battery to carry that load. DO NOT USE CIRCUIT BREAKERS

WITH THIS PRODUCT!

Wire Connections:

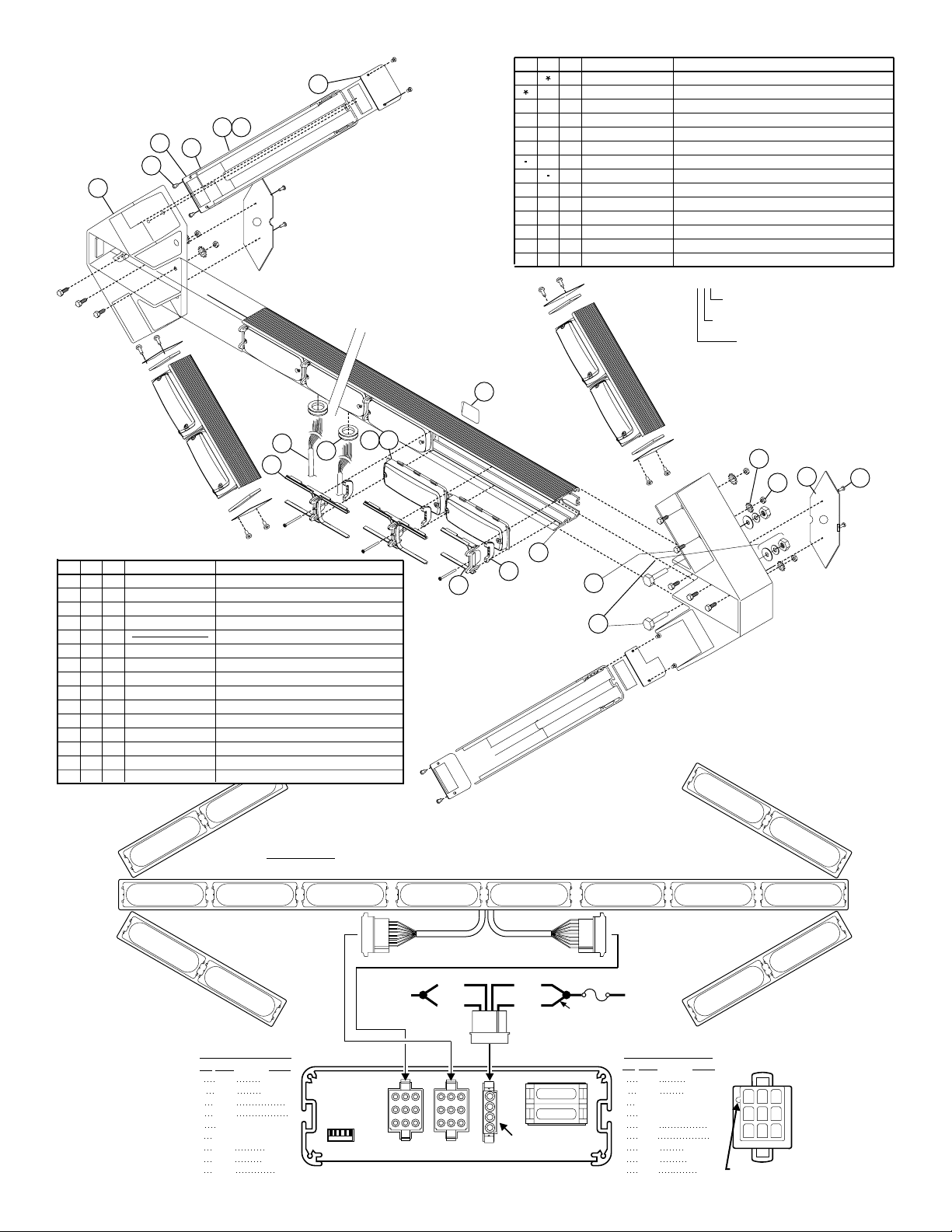

1. Splice the 2 RED wires together, then extend this single wire to

the battery and install a 15 amp fuse block (customer supplied) to

the end of the wire. (remove the fuse before connecting any

wires to the battery) Connect the wire to the POSITIVE (+)

battery terminal. Refer to the wiring diagram on the next page.

IMPORTANT: There must not be more than 2 feet of wire between

fuse block and battery. The wire between fuse and battery is

unprotected, do not allow this wire to come in contact with any

other wires.

2. Splice the 2 BLACK wires together, then extend this single wire

to the battery and connect it to the battery ground. If your vehicle

has a cable extending from the negative terminal of the battery to

the chassis, it is best to attach the BLACK wire at the chassis

connection.

Operation:

The operation of this TA is controlled by the TACTL3A Traffic

Advisor control head. Refer to the instructions that come with

the control head for operation.

Service:

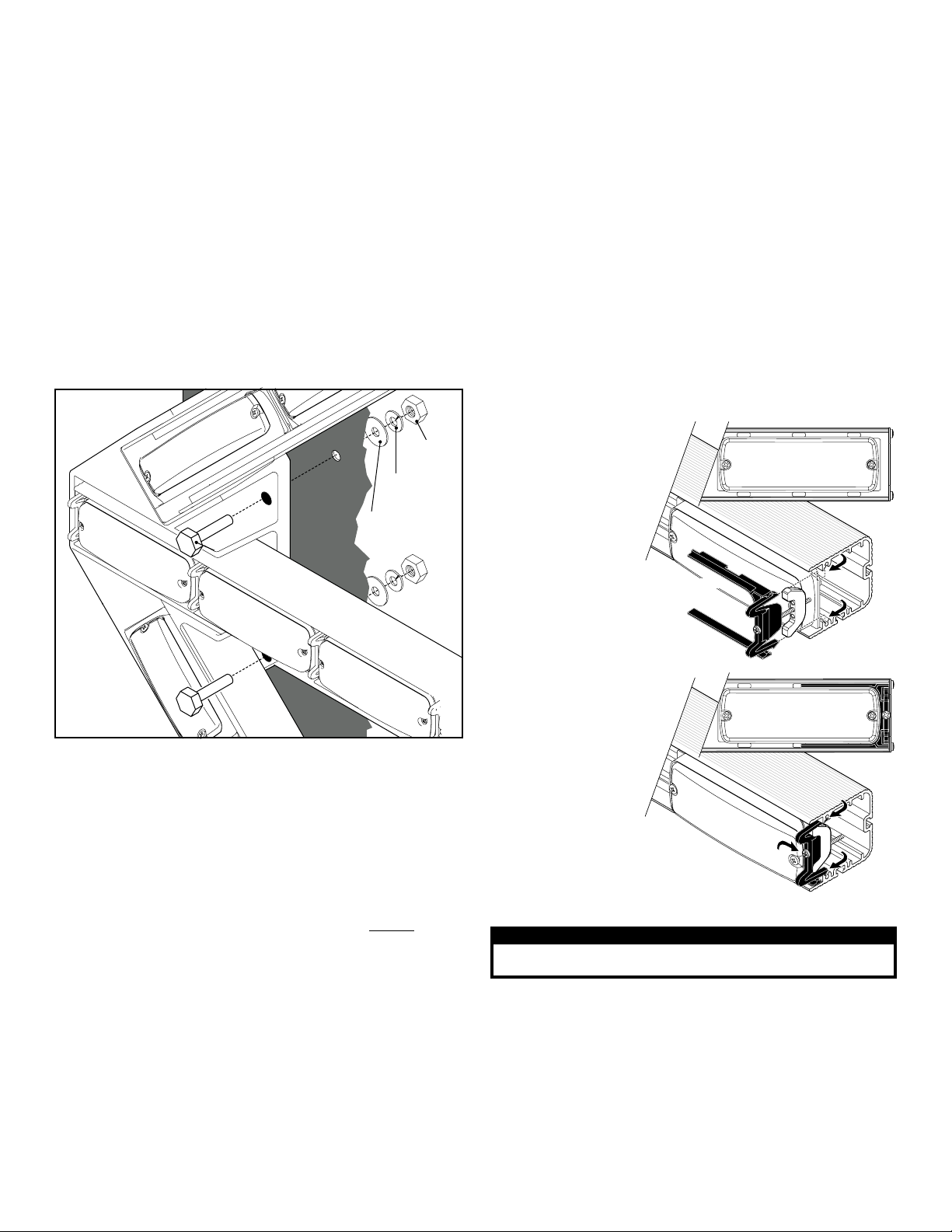

This section shows you

how to access the

lightbar for service or

lighthead replacement.

To replace a lighthead,

first loosen the set

screw(s) on the bracket.

Now squeeze the clip

together so that it

disengages from the

extrusion and pull the

bracket straight out.

With the bracket

removed the lighthead

lifts out and can be

unplugged from the

harness and removed

from the lightbar.

IMPORTANT! Before

returning the vehicle

to active service,

visually confirm the

proper operation of

this product, as well as

all vehicle

components/

equipment.

Snap the

bracket into

the extrusion.

The bracket mounts

as shown. Tighten the set

screw on the bracket to secure it.

FRONT VIEW

FRONT VIEW

Place lighthead

into extrusion

Snap-InSnap-In

Snap-InSnap-In

Tighten Set Screw