Page 10 2010 Edition 1

WHYTE Service Manual

3.3: SET UP OF FORK

Tools Required: Good Quality Shock Pump.

Small Ruler

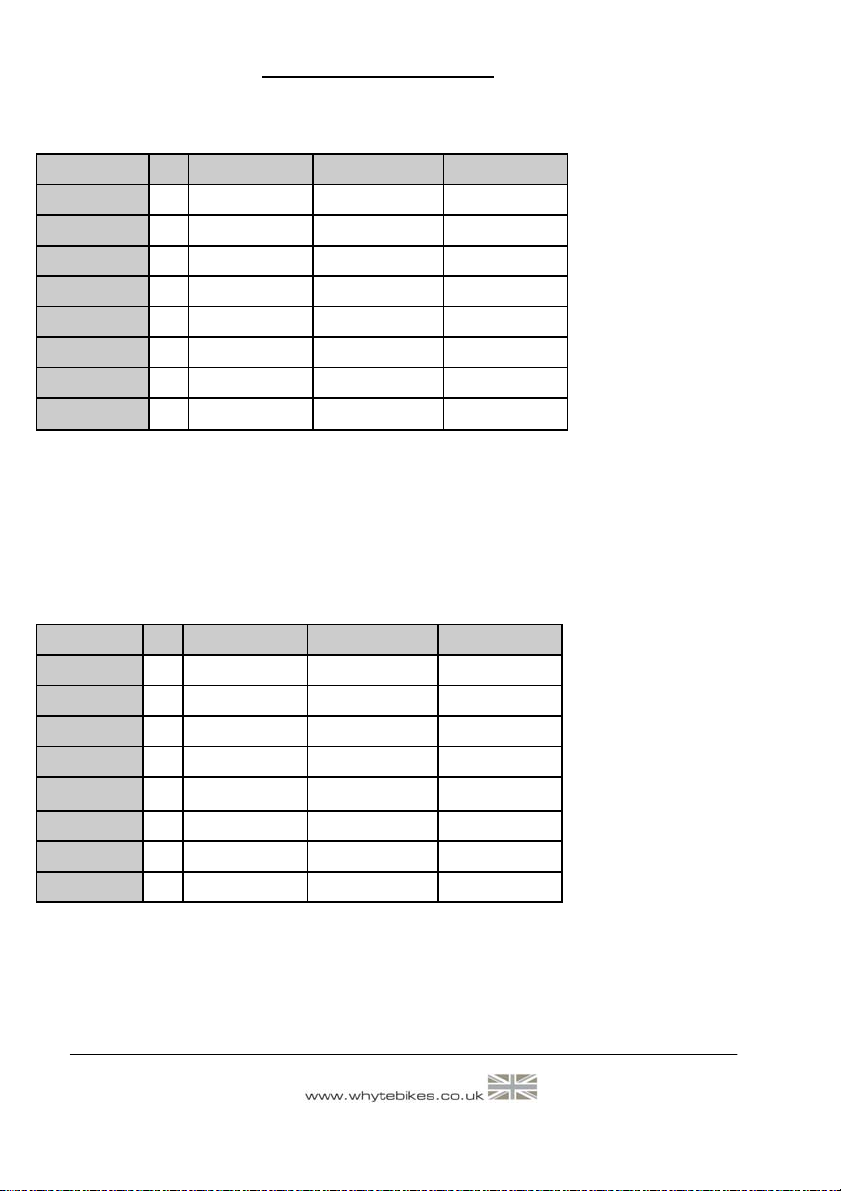

The ront suspension ork itted to your Whyte bike will be pre-set with the standard set-

tings. Be ore riding, you may need to adjust these setting. First is the Sag setting on the

ork. This is to ensure the orks are set-up correctly or your own body weight, so the ork

will per orm as intended.

To set Sag on the ront ork, you need to measure the amount the

ork compresses when you sit on the bike in the normal riding

position. See the table on the right or our recommendation o

ront ork sag on your Whyte bike. To achieve this you will need to

adjust the air spring pressure inside the ork.

Re er to the speci ication tables in this manual, and then to the relevant ork manu actur-

ers set up instructions to ind how to adjust the air spring pressure in the ork. Using a

shock pump, either add or remove air until Sag is correctly set.

Please note that or the detailed instructions or servicing and all matters relating to the

orks itted to your Whyte bike, please re er to the manu acturers instructions.

Rebound Damping adjustment:

This adjustment ine-tunes the speed at which the wheel returns to its normal ride height

a ter hitting a bump. Re er to the relevant manu acturers instructions to ind out how to

adjust the rebound damping. To demonstrate the e ect o this unction, turn the adjuster

to its slowest setting. Press down on the handlebars to compress the orks, then release

the load. The suspension recovers very slowly to its original position.

Repeat the above with the adjuster turned to the astest setting and the di erence will be

seen immediately the load is released. We recommend the optimum setting is to adjust the

re-bound damping to be as slow as possible, but not so slow that the normal ride height is

not recovered. On very rough terrain, i the bike becomes progressively lower as more

bumps are hit then the re-bound damping is set too slow. On the other hand i the bike

eels choppy and not plush then the re-bound damping is too ast. A bit o trial and error is

needed to get the exact setting.

IMPORTANT SAFETY NOTE:

Always stop riding when making adjustments o any kind to the bicycle!

3.4: SET UP OF REAR DAMPER

Tools Required: Good Quality Shock Pump.

Small Ruler

Your Whyte bike is itted with and air spring rear shock absorber. This means that the air

Model Sag

E-120

T-120

20mm (16%)

146 30mm (20%)