2010 Edition 1 Page 8

WHYTE Service Manual

3.0: PREPARATIONS FOR RIDING

3.1: MAKING ADJUSTMENTS

Please refer to the specific component manufac-

turers manual or published technical information

about adjusting the components on your Whyte

bike. Instructions may be downloaded from the

relevant manufacturer’s internet site as shown in

the table to the right.

If you are uncertain in any way about making

adjustments to any components on you Whyte

bike then DO NOT RIDE YOUR BIKE. Contact

your Whyte dealer who will be able to advise you

on how to go about setting up you Whyte for rid-

ing and or making adjustments to the compo-

nents fitted to your Whyte.

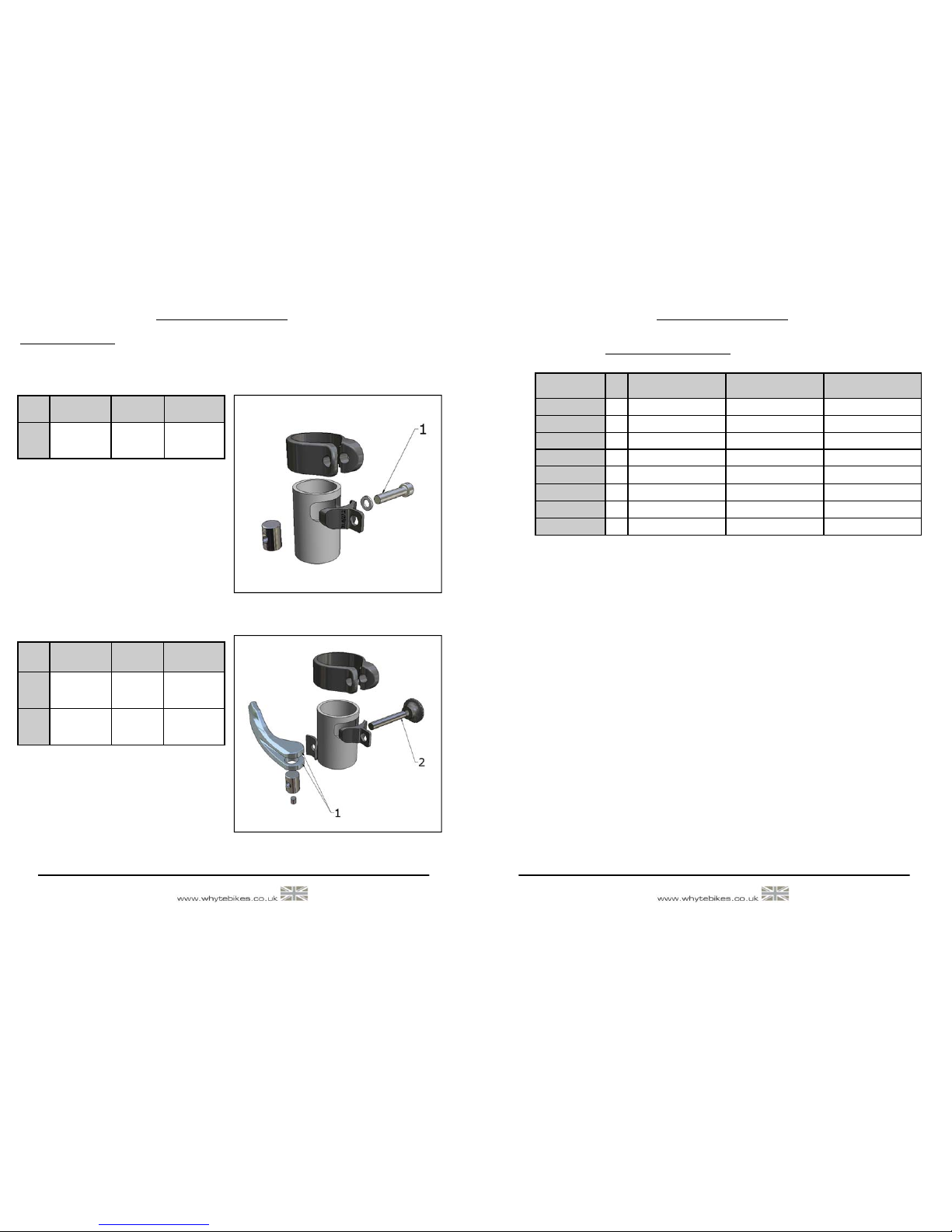

3.2: WHYTE GETTA-GRIP SEAT CLAMP

The Getta Grip seat clamp design is a patented design to allow adjustment of the saddle

height by either the use of a QR Lever or bolt-up method. This manual covers both styles

of clamps.

Alex Rims www.alexrims.com

Continental www.conti-online.com

CST www.csttires.com

DT www.dtswiss.com

Easton www.eastonbike.com

Fi:zik www.fizik.it

FSA www.fullspeedahead.com

Fulcrum www.fulcrumwheels.com

Formula www.formulahubs.com

Fox www.foxracingshox.com

Hayes www.hayesdiscbrake.com

Hope www.hopetech.com

Mavic www.mavic.com

Maxxis www.maxxis.com

Shimano www.shimano.com

SRAM www.sram.com

Sun Ringle www.sun-ringle.com

Tektro www.tektro.com

Thomson www.lhthomson.com

VP www.vpcomponents.com

WTB www.wtb.com

TH www.thindustries.com.tw

2010 Edition 1 Page 13

WHYTE Service Manual

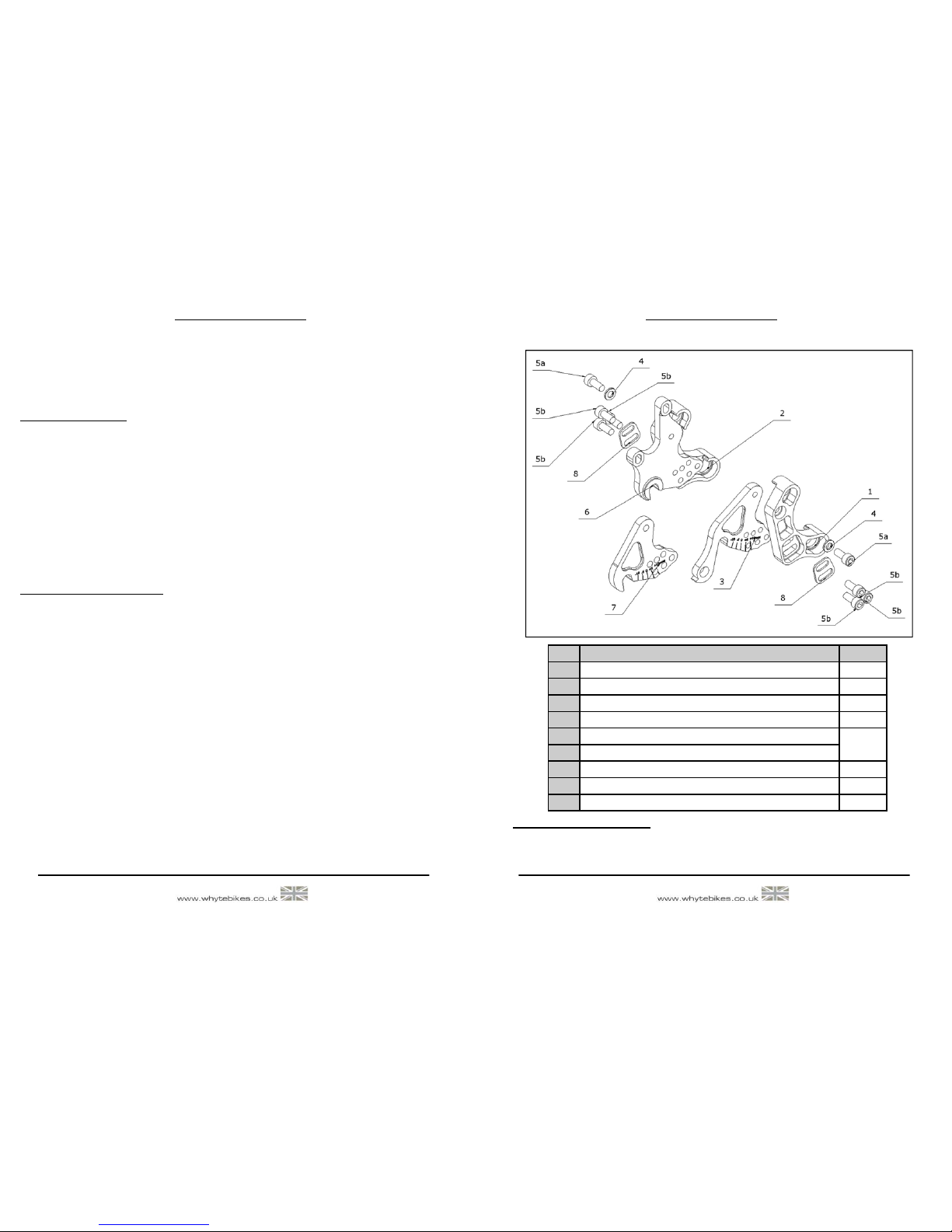

ADJUSTING THE WHYTE 19 TRAIL DROPOUT SYSTEM (Continue ).

To adjust the Dropout Plates (3 6 7) first secure the bike into a work stand. Next using

the 5mm Allen Key loosen off the RH and LH top M6x14mm Socket head Cap Screws (5a)

by one turn only. Next Remove the three RH and three LH lower M6 x 14 Screws (5b) from

the bike taking care to collect both Dropout M6 Washer Plates (8). You will now be able to

rotate both the RH and LH Dropout Plates (3 6 7) around the top pivot screw (5a) to adjust

the chain stay lengths. Align the chosen Laser Etch marks on the Dropout Plates (3 6 7)

with the edge of the mainframe dropouts (1 2) and re-assemble the Dropout M6 Washer

Plates (8) and the three M6 x 14mm Socket Head Screws (5b). Before finally tightening all

M6 Fasteners double check the LH and RH dropout plate (3 6 7) Laser Etch marks corre-

spond correctly to each other and that the rear wheel is aligned properly in the frame.

Finally tighten Screws (5a and 5b) to the torque setting described in Section 6.0

4.0: SAFETY

IMPORTANT: The following are intended to be advisory notes on the safe use of your

Whyte bike. You should also read thoroughly the General Instruction Manual also supplied

with your new bike. If at any stage you are uncertain about the safety or safe operation of

the bike as a whole or any specific component then DO NOT RIDE YOUR WHYTE and

instead please consult the specific component manufacturers instruction manual or your

Whyte Dealer for advice.

Maximum Ri er Weight Limit for Whyte Har tail MTB Series’:

19 Stone/120kg

WARNING: As is the case with all mechanical components the bicycle is subjected

to wear and high stresses. Different materials and components may react to wear

and stress fatigue in different ways. If the design life of a component has been ex-

ceeded it may fail suddenly causing possible injury to the rider. Any form of crack

scratches and decolouring in highly stresses areas are showing that the component

has exhausted its life time and has to be replaced. If you are in any doubt about one

or more components on your Whyte DO NOT RIDE YOUR BIKE. Consult the spe-

cific component manufacturers literature or take your bike to your local Whyte

Dealer.

Designe for the following use:

All bicycles in the Whyte Hardtail MTB series’ have all been designed tested and comply

with BS EN 14766 Standard for typical cross country mountain biking use. They have not

been designed or tested for extreme down-hilling or free-riding.