Whyte G-160 Works Manual

MTB Full Suspension Range

G-160 Works & G-160 RS

T-130-C Works & T-130-C RS

T-130 RS, T-130 S & T-130 SX Women s Spec

T-129 SCR, T-129 RS & T-129 S

Supplementary Service Manual

2016 Edition 1

Page 3 2016 Edition 1

Table of Contents

1.0 Introduction

2.0 Geometry:

2.1 G-160 Works & G-160 R

2.2 T-130-C Works & T-130-C R . T-130 R , T-130 & T-130 X

Women’s pec

2.3 T-129 CR, T-129 R & T-129

3.0 Preparations for riding:

3.1 Making Adjustments

3.2 Whyte Inter Grip eat Clamp Adjustment

3.3 et up of Fork

3.4 et up of Rear Damper

3.5 uspension Tuning Log

4.0 afety.

5.0 Lubrication:

5.1 Whyte Inter Grip eat Clamp

5.2 General Lubrication

6.0 ervicing the Rear uspension:

6.1 Removing the Rear hock and winging Arm

6.1.1 From G-160

6.1.1.1 Remove the Rear hock only.

6.1.1.2 Remove the other rear suspension parts.

6.1.2 From T-130-C, T-130 or T-129

6.1.2.1 Remove the Rear hock only.

6.1.2.2 Remove the other rear suspension parts.

6.2 tripping and Re-assembling Rear uspension Bearings

6.2.1 Extraction of Bearings

6.2.2 Insertion of Bearings

6.2.3 Re-Assembly of hield Washers / pacers

6.3 Re-assembling the Rear uspension

6.3.1 Re-Assembly of the Rear uspension (G-160)

6.3.1.1 Re-assemble the other rear suspension parts.

6.3.1.2 Re-assemble the Rear hock into the Frameset.

6.3.2 Re-Assembly of Rear uspension (T-130-C, T-130 or T-

129)

6.3.2.1 Re-assemble the other rear suspension parts.

6.3.2.2 Re-assemble the Rear hock into the Frameset.

Page 4 2016 Edition 1

1.0: INTRODUCTION

Thanks for choosing to purchase this Whyte product. We hope you will enjoy all the benefits

its advanced design and engineering will bring to your riding experience.

This manual will guide you through the set-up, safety and maintenance procedures that are

specific to your Whyte bike. For other more general information, we strongly advise that

you also read thoroughly the General Instruction Manual that is also supplied with your new

bike.

Also, please note that the specification of all the components that are fitted to your bike as

standard may be obtained from the Whyte Bikes Brochure or alternatively from the Whyte

Bikes website www.whytebikes.co.uk

Please remember, if you are in any doubt about your ability to safely service or repair your

Whyte bike, do not ride it and instead arrange for a professional bicycle mechanic at your

local Whyte dealer to do the job correctly.

Bundled with this manual, are the respective manufacturers instructions and manuals for

the branded parts that are fitted to your Whyte bike. Please take time to study all the rele-

vant instruction manuals to ensure you have a continually safe and well set-up bike before

every ride, and to help you build up a relationship of knowledge between you and your

Whyte Dealer.

Happy and safe riding,

Whyte design team. May 2015.

WHYTE Service Manual

7.0 ervicing the Whyte Modular Dropout ystems:

7.1 Disassembly of Modular Rear Dropouts

7.1.1 himano E-Thru

7.1.2 RAM Maxle 142mm

7.2 Reassembly of Modular Rear Dropouts

7.2.1 himano E-Thru

7.2.2 RAM Maxle 142mm

7.3 Rear Derailleur et-up

8.0 ervicing the Whyte Inter Grip eat Clamp

9.0 Fitting Internal Cables & Hoses.

9.1 To replace cable or hose outers.

9.2 To fit a “Dropper” seat-post with internal hose.

10.0 Torque ettings.

11.0 Owner’s Notes

Table of Contents (continued)

Page 5 2016 Edition 1

WHYTE Service Manual

2.0: GEOMETRY

Figure1: Geometry

Page 6 2016 Edition 1

WHYTE Service Manual

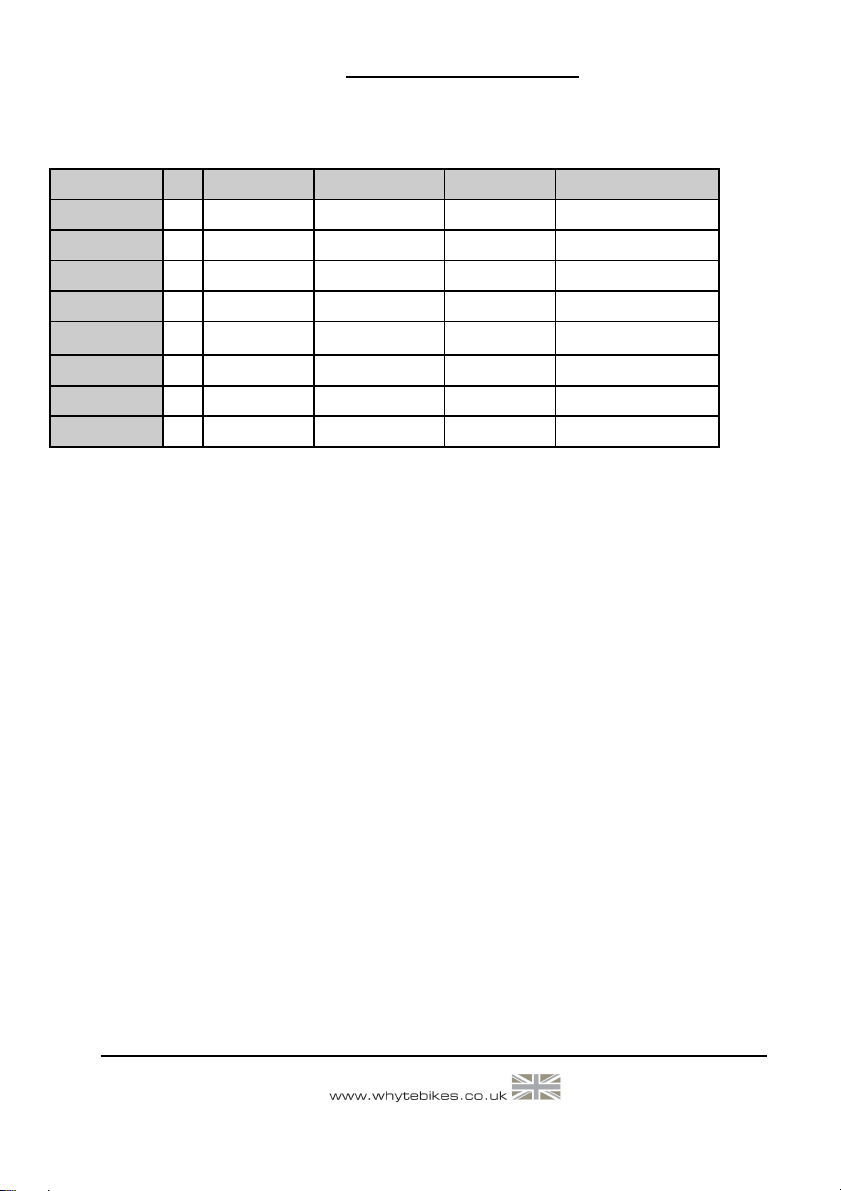

Frame Size X Small Medium Large

Head Angle A 65.5° 65.5° 65.5°

Seat Angle* B 74.7° 74.5° 74.3°

Top Tube C 607.6mm 636.6mm 655.9mm

BB Height** D 342.5mm 342.5mm 342.5mm

Stand Over E 808mm 816mm 822mm

Wheel Base F 1181.7mm 1211.7mm 1231.7mm

Chain Stay G 425mm 425mm 425mm

Seat Post H 30.9mm 30.9mm 30.9mm

2.1: Whyte G-160 Geometry

Notes:

Geometry shown here is ’ howroom’ i.e. without rider aboard the bicycle. ’With ag’ geometry is with rider after correct

sag is set at front and rear. Please refer to suspension set up for information on how to achieve the correct sag of the

fork and rear damper.

* Effective seat angle, from wheel centres horizontal to line from BB to seat post axis @ top of saddle.

** BB height with Ø717mm tyres fitted (2.25” / 54-584)

Frame Size X Small Medium Extra-Large

Head Angle A 66.5° 66.5° 66.5°

Seat Angle* B 73.7° 73.5° 73.2°

Top Tube C 591.4mm 611.1mm 650.7mm

BB Height** D 331.0mm 331.0mm 331.0mm

Stand Over E 763mm 766mm 776mm

Wheel Base F 1136.5mm 1156.5mm 1196.5mm

Chain Stay G 420mm 420mm 420mm

Seat Post H 30.9mm 30.9mm 30.9mm

Extra Small

66.5°

74.0°

571.7mm

331.0mm

761mm

1118.5mm

420mm

30.9mm

Large

66.5°

73.3°

631.0mm

331.0mm

776mm

1176.5mm

420mm

30.9mm

2.2: Whyte T-130-C & T-130 Geometry

Notes:

Geometry shown here is ’ howroom’ i.e. without rider aboard the bicycle. ’With ag’ geometry is with rider after correct

sag is set at front and rear. Please refer to suspension set up for information on how to achieve the correct sag of the

fork and rear damper.

* Effective seat angle, from wheel centres horizontal to line from BB to seat post axis @ top of saddle.

** BB height with Ø717mm tyres fitted (2.25” / 54-584)

Page 7 2016 Edition 1

2.3: Whyte T-129 Geometry

WHYTE Service Manual

Notes:

Geometry shown here is ’ howroom’ i.e. without rider aboard the bicycle. ’With ag’ geometry is with rider after correct

sag is set at front and rear. Please refer to suspension set up for information on how to achieve the correct sag of the

fork and rear damper.

* Effective seat angle, from wheel centres horizontal to line from BB to seat post axis @ top of saddle.

** BB height with Ø748mm tyres fitted (29” x 2.25” / 54/56-622)

Frame Size X Small Medium Large

Head Angle A 66.5° 66.5° 66.5°

Seat Angle* B 74.2° 74.0° 73.8°

Top Tube C 593.4mm 613.4mm 633.1mm

BB Height** D 335mm 335mm 335mm

Stand Over E 800mm 805mm 810mm

Wheel Base F 1156.1mm 1176.1mm 1196.1mm

Chain Stay G 431mm 431mm 431mm

Seat Post H 30.9mm 30.9mm 30.9mm

Extra—Large

66.5°

73.6°

652.8mm

335mm

815mm

1216.1mm

431mm

30.9mm

Page 8 2016 Edition 1

WHYTE Service Manual

3.0: PREPARATIONS FOR RIDING

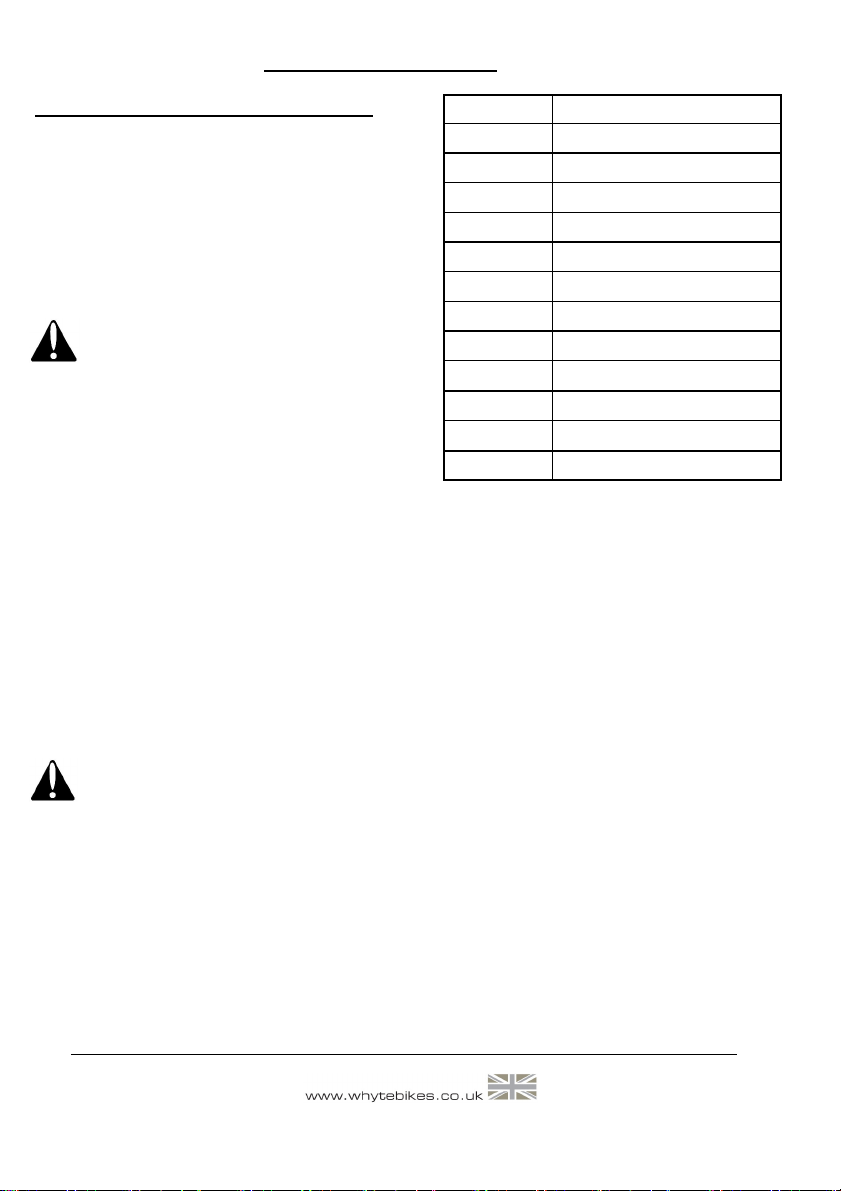

3.1: MAKING ADJUSTMENTS

Please refer to the specific component manufac-

turers manual or published technical information

about adjusting the components on your Whyte

bike. Instructions may be downloaded from the

relevant manufacturer’s internet site, as shown

in the table to the right.

CAUTION! If you are uncertain in any

way, about making adjustments to any

components on you Whyte bike, then DO

NOT RIDE YOUR BIKE.

Contact your Whyte dealer who will be able to

advise you on how to go about setting up you

Whyte bike for riding, and or making adjust-

ments to the components fitted to your Whyte

bike.

3.2: WHYTE INTER GRIP SEAT CLAMP ADJUSTMENT & SERVICE

Tools Required: 5mm AF Allen Keys (2 o , 1 itted to a 3Nm to 15Nm Torque Wrench)

Small Size Flat Blade Screwdriver

SKF LGEP2 or Castrol Spheerol AP3 or Finish Line Te lon White Lithium

Complex grease

Reference figures 2 to 7. The Inter Grip seat clamp design is present on most models of

Whyte full suspension mountain bikes. It allows adjustment of the saddle height & direction.

CAUTION! Avoid over-tightening the seat clamp.

In particular, “dropper” seat-posts such as SRAM Reverb may not work correctly i the seat

clamp is over tightened.

Figure 2. To adjust the seat height and/or direction, using the 5mm Allen key, undo the M6

Capscrew (1) just enough to allow the eat Post (7) to slide freely up and down. et the

height and/or direction to the desired level.

Figure 3. Re-tighten the M6 Capscrew (1) with the 5mm Allen Key in the Torque Wrench to

the 6Nm limit, as marked on the Plain leeve (2).

Figures 4 & 5. If a “dropper” seat-post is fitted, simultaneously depress the activation trigger

DT wiss www.dtswiss.com

Easton www.eastonbike.com

Formula www.formulahubs.com

Fox www.foxracingshox.com

Hope www.hopetech.com

Jagwire www.jagwireusa.com

Maxxis www.maxxis.com

Race Face www.raceface.com

himano www.shimano.com

R untour www.srsuntour-cycling.com

RAM www.sram.com

Tektro www.tektro.com

WTB www.wtb.com

Page 9 2016 Edition 1

and press down on the saddle to compress the seat-post until it is fully down. Then release

the activation trigger and the seat-post should rise up automatically.

Figure 6. If this does not happen, gradually loosen the M6 Capscrew (1) with the 5mm Allen

Key below the 6Nm limit, until the seat-post rises automatically.

Figure 7. Then firmly twist the saddle to confirm the seat-post is still securely gripped by the

lowered torque value that allows the “dropper” seat-post to function correctly.

CAUTION! When adjusting the saddle height you MUST obey the Minimum insertion

depth requirement marked on the eat Post (7). Also consult the seat-pin manufactur-

ers instructions in conjunction with these notes.

WHYTE Service Manual

Figure 2 Figure 3

Figure 4

Figure 5

Figure 6

Figure 7

Page 10 2016 Edition 1

WHYTE Service Manual

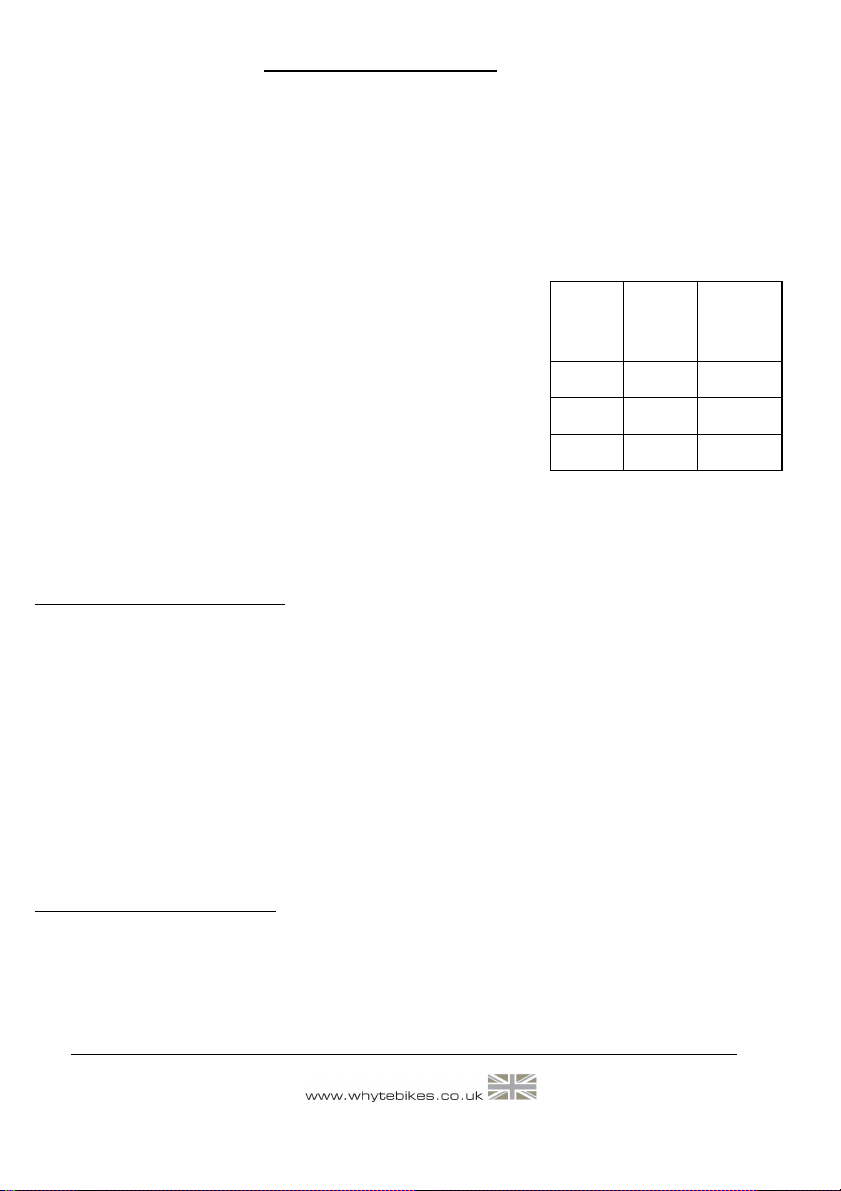

3.3: SET UP OF FORK

Tools Required: Good Quality Shock Pump.

Small Ruler

The front suspension fork fitted to your Whyte bike will be pre-set with the standard set-

tings. Before riding, you may need to adjust these setting. First is the ag setting on the

fork. This is to ensure the forks are set-up correctly for your own body weight, so the fork

will perform as intended.

To set ag on the front fork, you need to measure the

amount the fork compresses when you sit on the bike in the

normal riding position. ee the table on the right for our

recommendation of front fork sag on your Whyte bike. To

achieve this you will need to adjust the air spring pressure

inside the fork.

Refer to the specification tables in this manual, and then to

the relevant fork manufacturers set up instructions to find

how to adjust the air spring pressure in the fork. Using a

shock pump, either add or remove air until ag is correctly

set.

Please note that for the detailed instructions for servicing and all matters relating to the

forks fitted to your Whyte bike, please refer to the manufacturers instructions.

Rebound Damping adjustment:

This adjustment fine-tunes the speed at which the wheel returns to its normal ride height

after hitting a bump. Refer to the relevant manufacturers instructions to find out how to

adjust the rebound damping. To demonstrate the effect of this function, turn the adjuster to

its slowest setting. Press down on the handlebars to compress the forks, then release the

load. The suspension recovers very slowly to its original position.

Repeat the above with the adjuster turned to the fastest setting and the difference will be

seen immediately the load is released. We recommend the optimum setting is to adjust the

re-bound damping to be as slow as possible, but not so slow that the normal ride height is

not recovered. On very rough terrain, if the bike becomes progressively lower as more

bumps are hit then the re-bound damping is set too slow. On the other hand if the bike feels

choppy and not plush then the re-bound damping is too fast. A bit of trial and error is

needed to get the exact setting.

IMPORTANT SAFETY NOTE:

Always stop riding when making adjustments of any kind to the bicycle!

Model

Sag

(15% -

Firm)

Sag

(25% -

Plush)

T-129 18mm 30mm

T-130 19.5mm 32.5mm

G-160 2 mm 0mm

Page 11 2016 Edition 1

WHYTE Service Manual

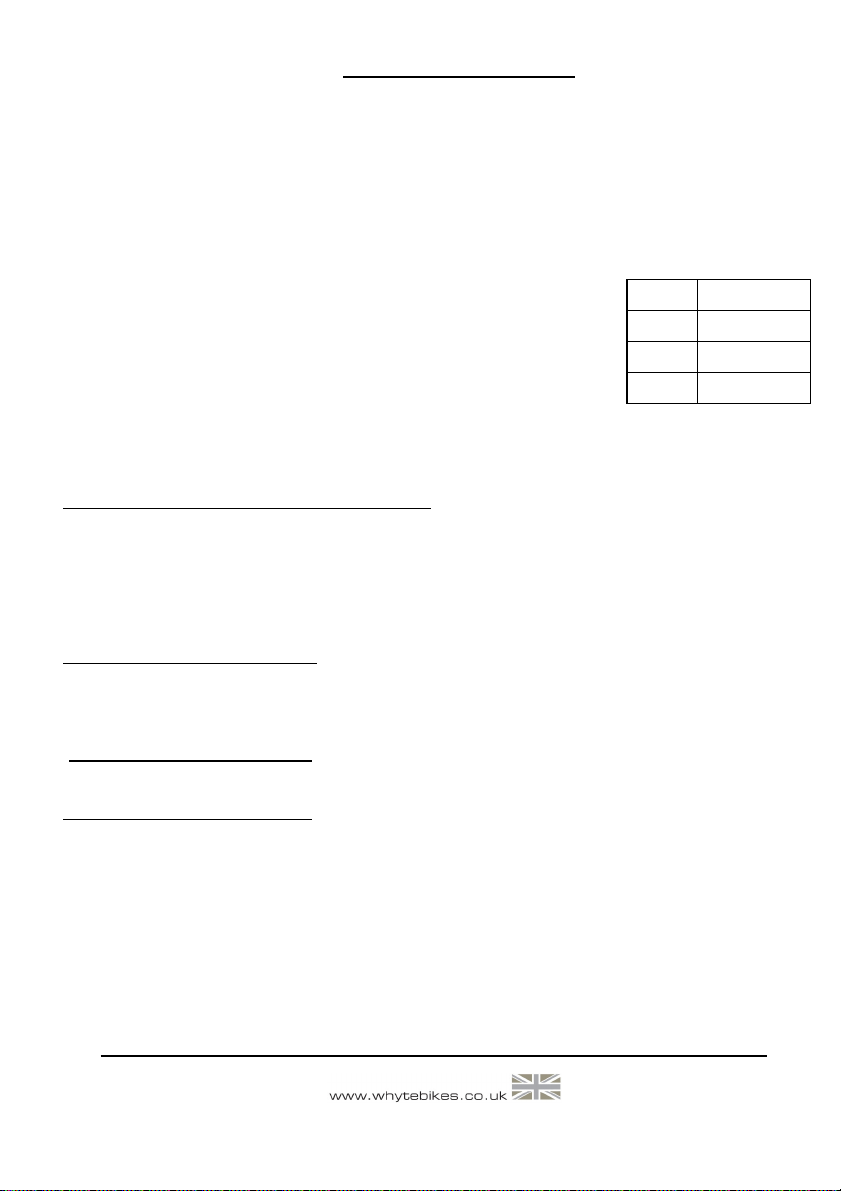

3.4: SET UP OF REAR DAMPER

Tools Required: Good Quality Shock Pump.

Small Ruler

Your Whyte bike is fitted with and air spring rear shock absorber. This means that the air

pressure in the shock absorber determines the spring rate. The correct ‘sag’ can be found

using the sliding ‘O’ ring fitted to the shaft of the shock piston. lide the ‘O’ ring against

the shock body. Then gently sit on the bike in your normal riding position and with normal

riding gear, including back pack if applicable, and also raise your

feet off the floor. Carefully dismount and measure the distance the

‘O’ ring has moved away from the shock body.

The optimum distance for the Quad-Link rear suspension system

is shown in the table to the right. If there is less than that dis-

tance fit a shock pump and release air pressure. Conversely if

there is greater than that distance, fit the shock pump and in-

crease air pressure.

Repeat the ‘sag’ test until the recommended sag distance is achieved.

Rear uspension et-up - Rebound Damping:

When the damper unit is being compressed, this is known as the compression stroke. As

the suspension unit recovers from compression back towards its full length, this is called

the re-bound stroke. All the shocks fitted as standard to the Whyte full suspension moun-

tain bikes have factory set compression damping, and manually adjustable rebound damp-

ing.

Rebound Damping Adjustment:

The advice in section 3.3 about the fork rebound damping adjustments also applies to the

rear shock.

IMPORTANT SAFETY NOTE:

Always stop riding when making adjustments of any kind to the bicycle!

Platform Damping Adjustment.

The rear hock fitted to your Whyte bike may have a “platform” facility to adjust the slow

speed compression damping, eg Fox “C.T.D.” (Climb / Trail / Descend) or RAM Rock hox

“Motion Control”. Please refer to the relevant shock manufactures technical information to

learn how to adjust these features.

Please note, that the Whyte rear suspension systems have been designed not to rely on

excessive low speed compression damping to obtain efficient pedalling performance, and

turning on too much low speed damping on the rear shock will compromise the suspen-

sions sensitivity to small bump absorption and traction.

Model Sag

T-129 17mm (25%)

T-130 17mm (25%)

G-160 19mm (30%)

Page 12 2016 Edition 1

WHYTE Service Manual

3.5: SUSPENSION TUNING LOG

Record your best suspension settings in the table below, to restore them if necessary, eg.

after dealer servicing of the suspension or if a friend has borrowed your bike.

4.0: SAFETY

IMPORTANT: The following are intended to be advisory notes on the safe use of your

Whyte bike. You should also read thoroughly the General Instruction Manual also supplied

with your new bike. If at any stage you are uncertain about the safety or safe operation of

the bike as a whole, or any specific component, then DO NOT RIDE YOUR WHYTE and

instead please consult the specific component manufacturers instruction manual or your

Whyte Dealer for advice.

Maximum Weight Limit for Whyte G-160, T-130-C, T-130 & T-129:

18st. / 114kg (including rider’s luggage)

WARNING: As is the case with all mechanical components, the bicycle is subjected

to wear and high stresses. Different materials and components may react to wear

and stress fatigue in different ways. If the design life of a component has been ex-

ceeded, it may fail suddenly causing possible injury to the rider. Any form of crack,

scratches and decolouring in highly stresses areas are showing that the component

has exhausted its life time and has to be replaced. If you are in any doubt about one

or more components on your Whyte DO NOT RIDE YOUR BIKE. Consult the specif-

ic component manufacturers literature, or take your bike to your local Whyte Dealer.

Designed for the following use:

The Whyte T-129 bicycles have all been designed, tested and comply with I O 4210-2

afety tandard, for typical cross country, marathon enduro or trail mountain biking use.

They have not been designed or tested for extreme down-hilling or free-riding.

The Whyte G-160, T-130-C & T-130 bicycles have all been designed, tested and comply

with I O 4210-2 afety tandard, for typical free-ride or gravity enduro mountain biking

use. They have not been designed or tested for extreme down-hilling.

Date

Rider Weight

(including all

riding kit)

(kg or lbs)

Fork Pressure

(bar or P.S.I)

Fork Rebound

Damping

(# of clicks from

softest setting)

Shock Pressure

(bar or P.S.I)

Shock Rebound

Damping

(# of clicks from

softest setting)

Page 13 2016 Edition 1

WHYTE Service Manual

5.0: LUBRICATION

Please refer to the Whyte General Instruction Manual for guidance about lubricating many

of the components on your Whyte bicycle.

For the range of bicycles contained in this upplementary ervice Manual, there is also the

following specific guidance:

5.1: WHYTE INTER GRIP SEAT CLAMP

5.2: GENERAL WHYTE LUBRICATION

For the correct lubrication regime and maintenance of all parts on a Whyte bicycle, please

refer to the specific component manufacturers detailed instructions bundled with this man-

ual or for further information visit the specific manufacturers website.

Figure 8: Capscrew Lubrication

Item Lubricant Lubrication

Interval

1 KF LGEP2 or Castrol pheerol AP3 or Finish

Line Teflon White Lithium Complex grease Once a Month

Description

M6 x 30mm

Capscrew

Page 14 2016 Edition 1

WHYTE Service Manual

6.0: SERVICING THE REAR SUSPENSION

6.1.1: Remove the Rear Shock, Links & Swinging Arm from the Whyte G-160

Tools Required: 4mm AF Allen Keys (2 o )

5mm AF Allen Key - ball ended (1 o )

6mm AF Allen Key (1 o )

8mm AF Allen Key (1 o )

15mm Open-ended, or adjustable spanner

T-25 Torx® Keys (2 o )

10mm AF Socket (2 o )

6.1.1.1 To remove only the rear shock absorber (6) from the frameset.

Whilst referencing figure 9, using the T-25 Torx®) Keys, undo the two M5 x 16mm long ocket-

head Capscrews (1) from the Ø8mm x 31mm long Hollow Pivot Pin (3) that passes through the

Main Frame (16) and front of the Rear hock Absorber (6). Whichever Capscrew (1) becomes un-

done first, remove it and the adjacent Collar (2), and pull the Pivot Pin (3) all the way out from the

other side.

Using the 6mm AF Allen Key and the 8mm AF Allen Key, undo and remove both the Flanged Nut

M12 x 19mm long (4) from the Flanged crew M12 x 15mm long (5), that pass through the hock

Extender (7) and the rear of the Rear hock Absorber (6). You can now remove the Rear hock

Absorber (6).

6.1.1.2 To remove the H-link (20) & swinging arm parts (17, 18 & 19) from the main

frame (16).

Again, whilst referencing figure 9, using the 15mm open ended spanner, unscrew and remove the

two M22 Bearing Caps (7) at the front of the H-link (20). Next, using the 10mm AF sockets, undo

the M8 Aerospace nuts (9) on the M8 x 71mm long stud (10) that passes through the H-link (20)

and Main Frame (16). Whichever Aerospace Nut (9) becomes undone first, remove it, and then

remove the M8 x 71mm long stud (10) from the other side.

Next, using the T-25 Torx®) Key, unscrew and remove the two M8 x 23 long Flanged crews (14)

from either side of the Chainstays (19). The eat-stays (17 & 18) together with the H-link (20)

may now be removed from the Main Frame (16) & Chainstays (19). Be careful to retain all the

shield washers (Items 2, Figure 13 & Items 2 & 3, Figure 15) ready for re-assembly.

Then, using the two 4mm AF Allen keys, undo the two M6 x 20mm long countersunk-head cap

screws (11) in the M6 x 70mm long hollow pivot pin (13). Whichever countersunk head cap screw

(11) becomes undone first, remove it and the adjacent collar (12), and then remove the M6 x

70mm long hollow pivot pin (13) from the other side. The Chainstays (19) may now be removed

from the Main Frame (16). Be careful to retain all the shield washers (Items 2, Fig 13) ready for re

-assembly.

To separate the eat-stays (17 & 18) from the H-link (20), whilst referencing figure 10, using the

15mm open ended spanner, unscrew and remove the four M22 Bearing Caps (8) at the rear of the

H-link (20). Next, using a 10mm ocket and the 5mm AF Allen Key, undo the M8 Aerospace nuts

(9) on the M8 x 20 long ocket-head Capscrews (15) that passes through the H-link (20) and seat-

stays (17 & 18). The eat-stays (17 & 18) may now be removed from the H-link (20). Be careful

to retain all the shield washers (Items 2, Fig 10) ready for re-assembly.

Page 15 2016 Edition 1

WHYTE Service Manual

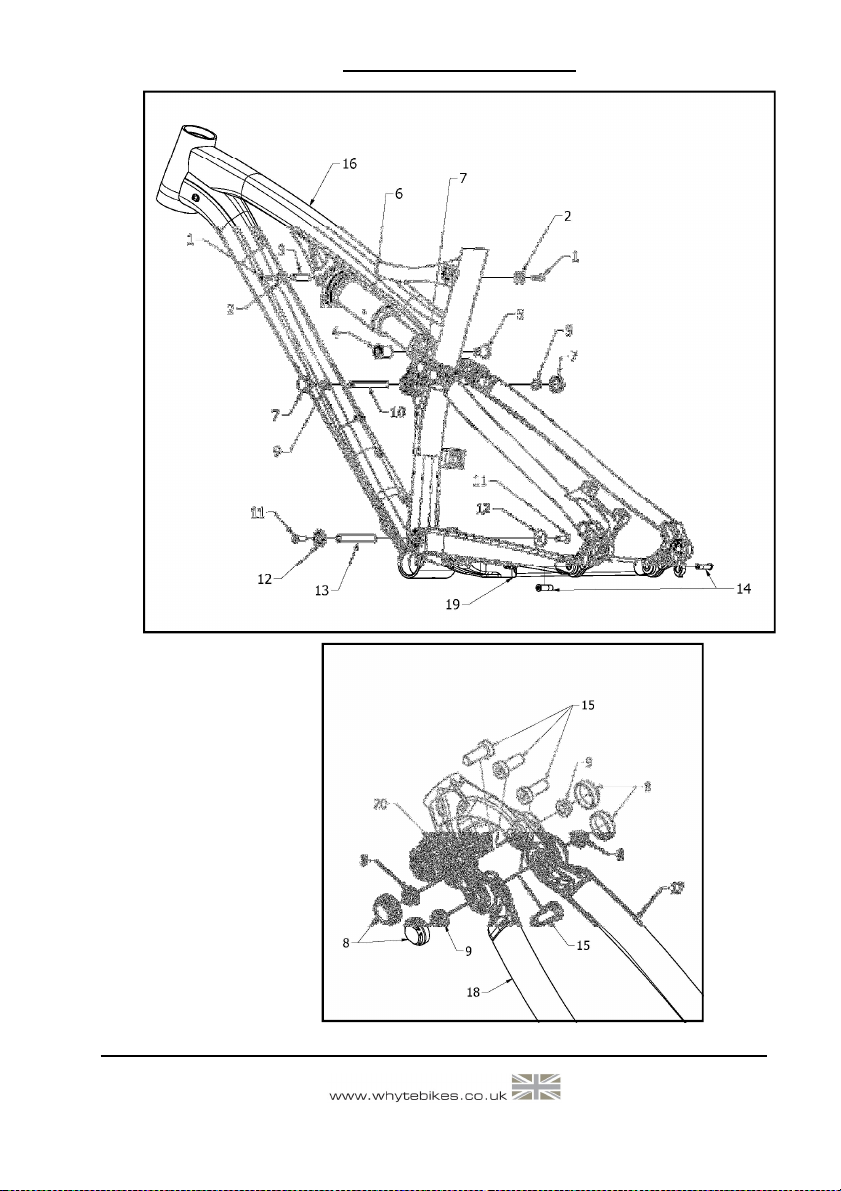

Figure 9: Disassembly of the Whyte G-160

Rear Suspension (First Stage)

Figure 10: Disassembly of the Whyte G-160

Rear Suspension (Second Stage)

Page 16 2016 Edition 1

WHYTE Service Manual

Item Description

1 M5 x 16mm long ocket-head Capscrew (T-25 Torx®)

2 Collar for M5 Capscrew

3 Hollow Pivot Pin Ø8mm x 31mm long

4 Flanged Nut M12 x 19mm long

5 Flanged crew M12 x 15mm long

6 Rear hock Absorber

8 M22 Bearing Cap (15mm A/F)

9 M8 Aerospace Nut (10mm A/F)

10 External M8 x 71mm long tud

11 M6 x 20mm long Countersunk-head Capscrew (4mm A/F Internal Hex)

12 Collar for M6 Countersunk-head Capscrew

13 Internal M6 x 70mm long Hollow Pivot Pin

14 M8 x 23 long Flanged crew (T-25 Torx®)

15 M8 x 20mm long ocket-head Capscrew (5mm A/F)

16 G-160 Main Frame

17 G-160 Right eat-stay

18 G-160 Left eat-stay

19 G-160 Chain-stays

20 75mm centres H-Link Assembly

7 hock Extender

Page 17 2016 Edition 1

6.1.2: Remove the Rear Shock, Links & Swinging Arm from the Whyte T-129, T-130-C

or T-130

Tools Required: 4mm AF Allen Keys (2 o )

5mm AF Allen Key - ball ended (1 o )

15mm Open-ended, or adjustable spanner

T-25 Torx® Keys (2 o )

10mm AF Socket (2 o )

6.1.2.1 To remove only the rear shock absorber (5) from the frameset.

Whilst referencing figure 11, using the T-25 Torx®) Keys, undo the two M5 x 16mm long ock-

et-head Capscrews (1) from the Ø8mm x 31mm long Hollow Pivot Pin (3) that passes through

the Main Frame (14) and front of the Rear hock Absorber (5). Whichever Capscrew (1) be-

comes undone first, remove it and the adjacent Collar (2), and pull the Pivot Pin (3) all the way

out from the other side.

Then undo the two M5 x 16mm long ocket-head Capscrews (1) from the Ø8mm x 45mm long

Hollow Pivot Pin (4) that passes through the eatstays (15 & 16) and rear of the Rear hock

Absorber (5). Whichever Capscrew (1) becomes undone first, remove it and the adjacent Collar

(2), and pull the Pivot Pin (4) all the way out from the other side. You can now remove the

Rear hock Absorber (5).

6.1.2.2 To remove the H-link (18) & swinging arm parts (15, 16 & 17) from the main

frame (14).

Again, whilst referencing figure 11, using the 15mm open ended spanner, unscrew and remove

the two M22 Bearing Caps (6) at the front of the H-link (18). Next, using the 10mm A/F sock-

ets, undo the M8 Aerospace nuts (7) on the M8 x 71mm long stud (8) that passes through the

H-link (18) and Main Frame (14). Whichever Aerospace Nut (7) becomes undone first, remove

it, and then remove the M8 x 71mm long stud (8) from the other side.

Next, using the T-25 Torx®) Key, unscrew and remove the two M8 x 23 long Flanged crews

(12) from either side of the Chainstays (17). The eat-stays (15 & 16) together with the H-

link (18) may now be removed from the Main Frame (14) & Chainstays (17). Be careful to re-

tain all the shield washers (Items 2, Figure 14 & Items 2 & 3, Figure 15) ready for re-

assembly.

Then, using the two 4mm AF Allen keys, undo the two M6 x 20mm long countersunk-head cap

screws (9) in the M6 x 70mm long hollow pivot pin (11). Whichever countersunk head cap

screw (9) becomes undone first, remove it and the adjacent collar (10), and then remove the

M6 x 70mm long hollow pivot pin (11) from the other side. The Chainstays (17) may now be

removed from the Main Frame (14). Be careful to retain all the shield washers (Items 2, Fig

13) ready for re-assembly.

To separate the eat-stays (15 & 16) from the H-link (18), whilst referencing figure 12, using

the 15mm open ended spanner, unscrew and remove the two M22 Bearing Caps (6) at the rear

of the H-link (18). Next, using a 10mm A/F socket and the 5mm AF Allen Key, undo the M8

Aerospace nuts (7) on the M8 x 20 long ocket-head Capscrews (13) that pass through the H-

link (18) and seat-stays (15 & 16). The eat-stays (15 & 16) may now be removed from the H

-link (18). Be careful to retain all the shield washers (Items 2, Fig 11) ready for re-assembly.

WHYTE Service Manual

Page 18 2016 Edition 1

WHYTE Service Manual

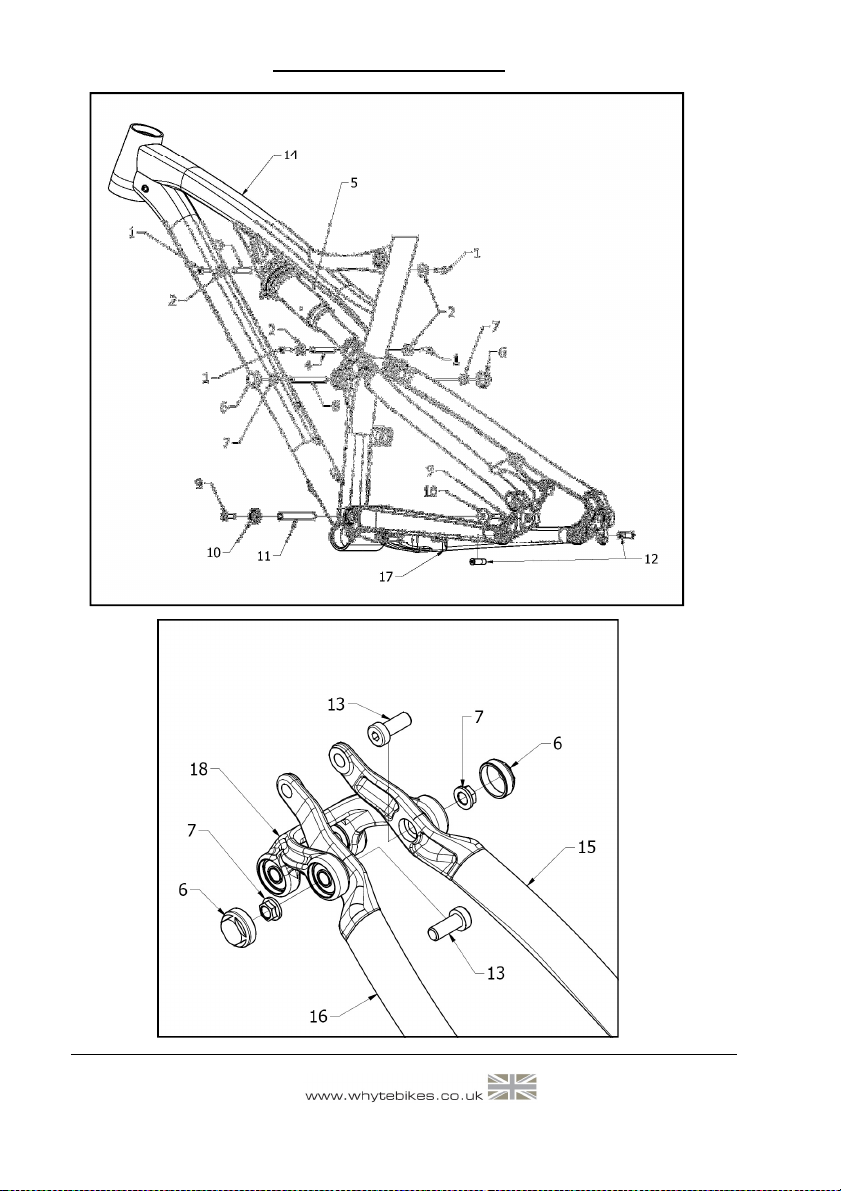

Figure 12: Disassembly of the Whyte T-129

or T-130-C or T-130 Rear Suspension

(Second Stage)

Figure 11: Disassembly of the Whyte T-129

or T-130-C or T-130 Rear Suspension

(First Stage)

Page 19 2016 Edition 1

WHYTE Service Manual

Item Description

1 M5 x 16mm long ocket-head Capscrew (T-25 Torx®)

2 Collar for M5 Capscrew

3 Hollow Pivot Pin Ø8mm x 31mm long

4 Hollow Pivot Pin Ø8mm x 45mm long

5 Rear hock Absorber

6 M22 Bearing Cap (15mm A/F)

7 M8 Aerospace Nut (10mm A/F)

8 External M8 x 71mm long tud

9 M6 x 20mm long Countersunk-head Capscrew (4mm A/F Internal Hex)

10 Collar for M6 Countersunk-head Capscrew

11 Internal M6 x 70mm long Hollow Pivot Pin

12 M8 x 23 long Flanged crew (T-25 Torx®)

13 M8 x 20mm long ocket-head Capscrew (5mm A/F)

14 T-129, T-130 & M-109C Main Frame

15 T-129, T-130 & M-109C Right eat-stay

16 T-129, T-130 & M-109C Left eat-stay

17 T-129, T-130 & M-109C Chain-stays

18 60mm centres H-Link Assembly

Page 20 2016 Edition 1

WHYTE Service Manual

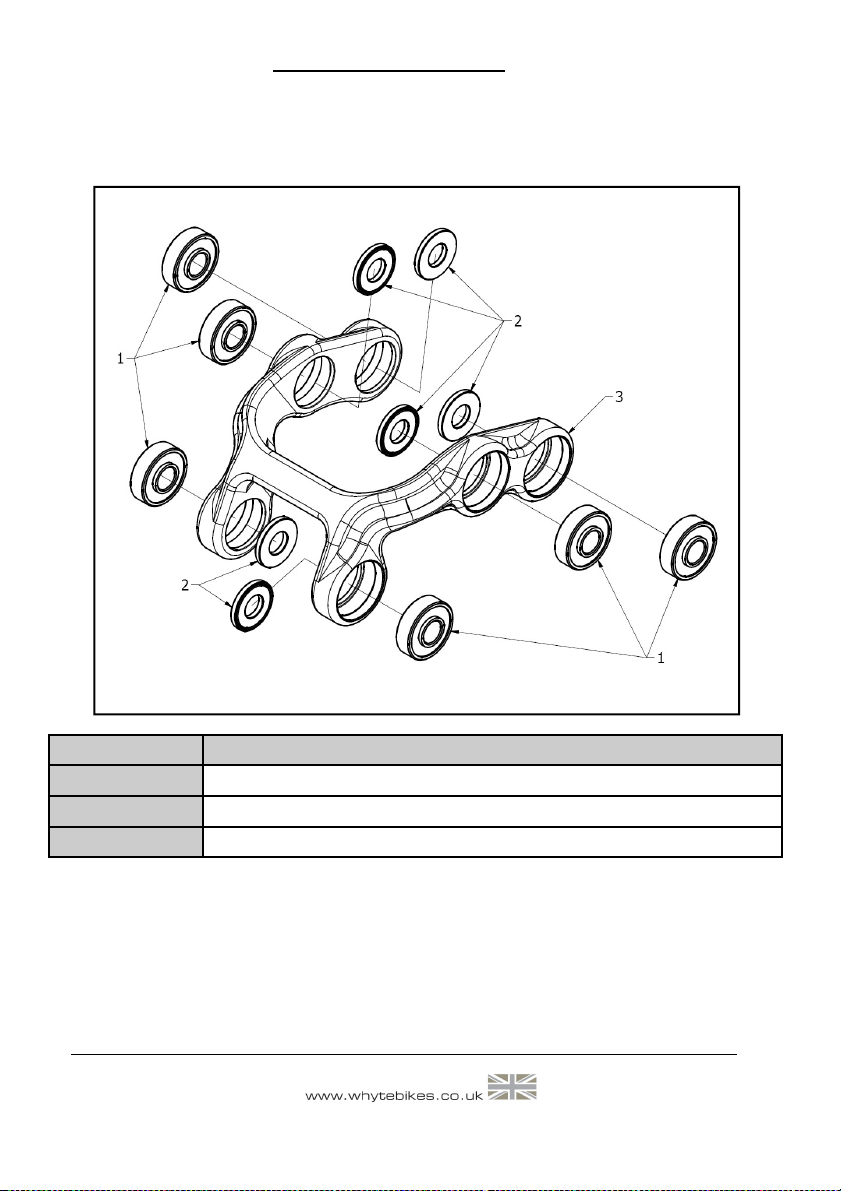

6.2: STRIPPING AND REASSEMBLING BEARINGS.

In the Whyte G-160 (Reference figures 9 & 10)

Figure 13: Assembly of 75mm H-Link

Item Description

1 KP5AX bearing

2 hield washer (O.D. 17.5mm)

3 75mm centre-to-centre Alloy Quad-Link Body

This manual suits for next models

9

Table of contents

Other Whyte Bicycle manuals

Whyte

Whyte C-7 Ridgeway Manual

Whyte

Whyte MTB Hardtail Series Manual

Whyte

Whyte 905 User manual

Whyte

Whyte 20C Team Manual

Whyte

Whyte 27C Works Manual

Whyte

Whyte e-MTB HardTail Series User manual

Whyte

Whyte KYNAMIC User manual

Whyte

Whyte G-150 Works SCR Manual

Whyte

Whyte E-150 Assembly instructions

Whyte

Whyte EC-7 coniston men's Manual