EN

WIKA operating instructions model 116.18.02x6

14557999.01 01/2023 EN/DE/FR/ES

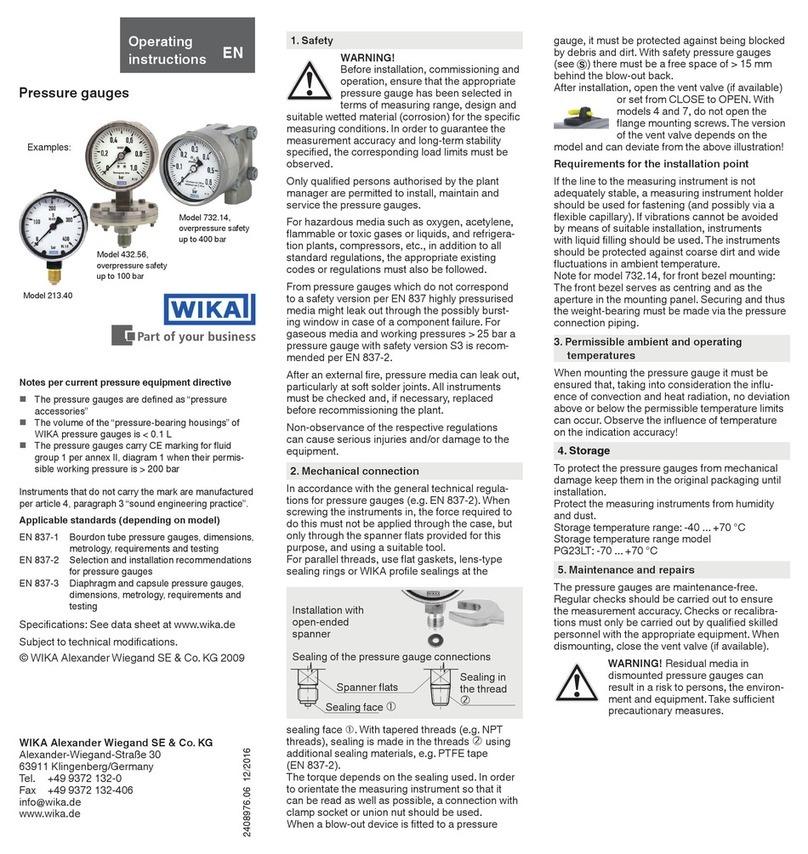

3. Safety

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to property or the environment, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused

by hot surfaces or liquids, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

3.2 Intended use

The mechanical pressure measuring instruments in DirectDrive design should be used

exclusively for measuring static pressures in dry, gaseous, not highly viscous and non-crys-

tallising media that will not attack copper alloy parts.The process connection and the

measuring line must be dry and free from foreign bodies.

The scope of application is defined by the technical performance limits and materials.

The pressure measuring instruments have been designed for industrial applications in

indoor and outdoor areas.

Improper use is defined as any application that exceeds the technical performance limits or

is not compatible with the materials. Checking against improper use is the responsibility of

the operator.

Classification of pressure equipment

■Instrument type: Pressure accessory without safety function

■Media: Liquid or gaseous, group 1 (hazardous)

■Maximum permissible pressure PS, see chapter 3.7 “Dial layout”

■Volume of wetted parts: < 0.1 L

Maximum pressure limitation

■Steady: 3/4 x full scale value of the pressure scale

■Short time: Full scale value of the pressure scale

Permissible temperature ranges

■Ambient: -20 ... +60 °C [-4 ... +140 °F]

■Medium: -20 ... +60 °C [-4 ... +140 °F]

■Storage: --40 ... +70 °C [-40 ... +158 °F]

3. Safety