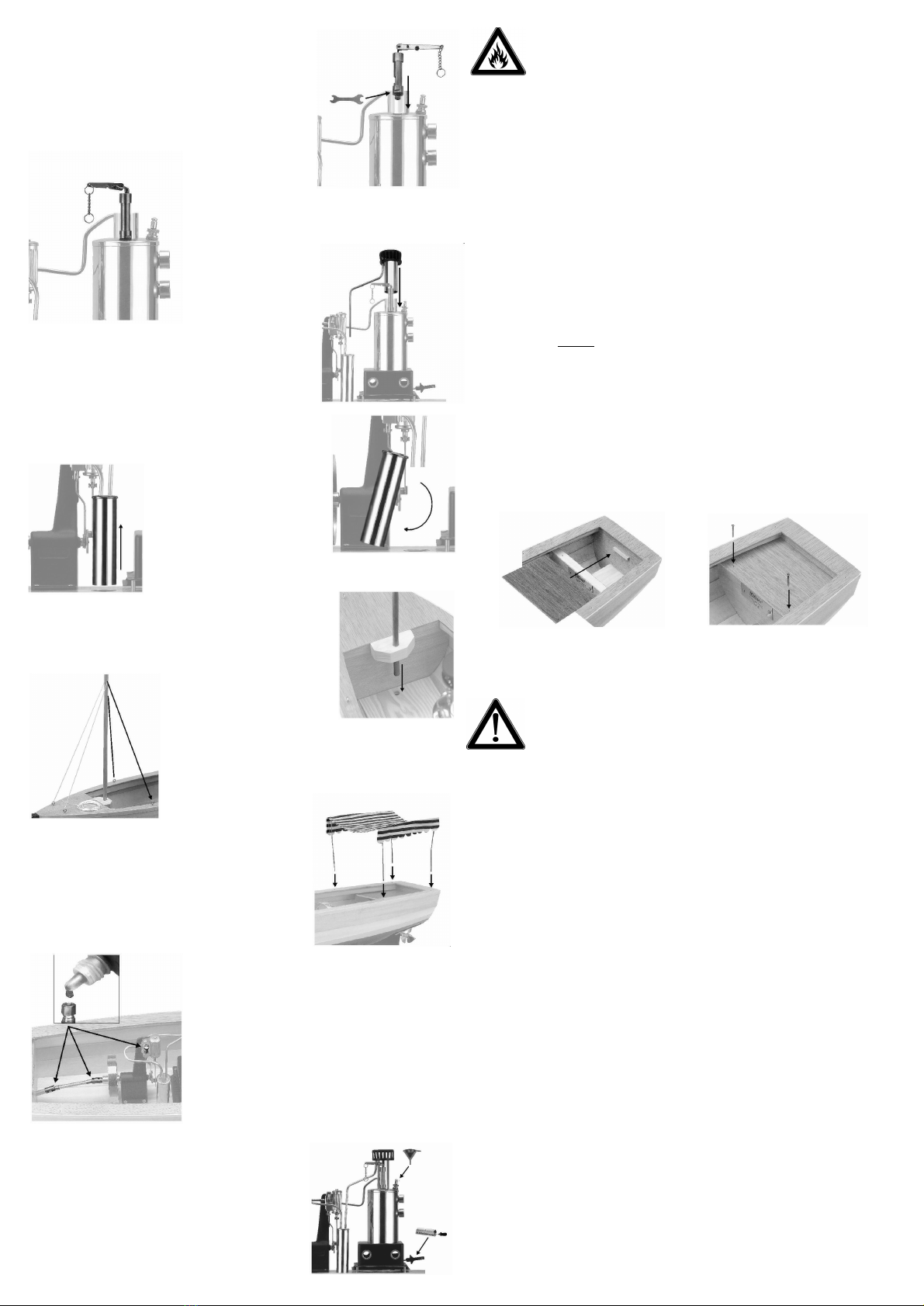

e. Steamwhistleand chimney

First ofallfitthesteam whistleinthe holeoppositethe

steam pipe.Tieuponlywiththespannerprovided with

the boat. Donottighten byturning the leveras thiswill

bedamaged.Whenyou screw inthe steamwhistle,the

leverwiththe chainshouldpointoutwards(useseals if

necessary) sothatthe chainoperatingthe whistledoes

notcome incontact withtheboiler.Pullthechain

gentlytooperatethe

whistle.

Note: Thesteam

whistle canbe usedto

checkanyoverpressu-

reintheboilerorbeforeoiling tocheck whether

the boileris stillunder

pressure.Thenfit the

chimney on the chim-

ney pipe.Please watch

that the exhaust steam

pipe integratedinthe

chimney is indirection

ofthe condenser(see

pointf).Theexhaust

steampipe fromthecylinderisleadingalso inthe con-

denser.

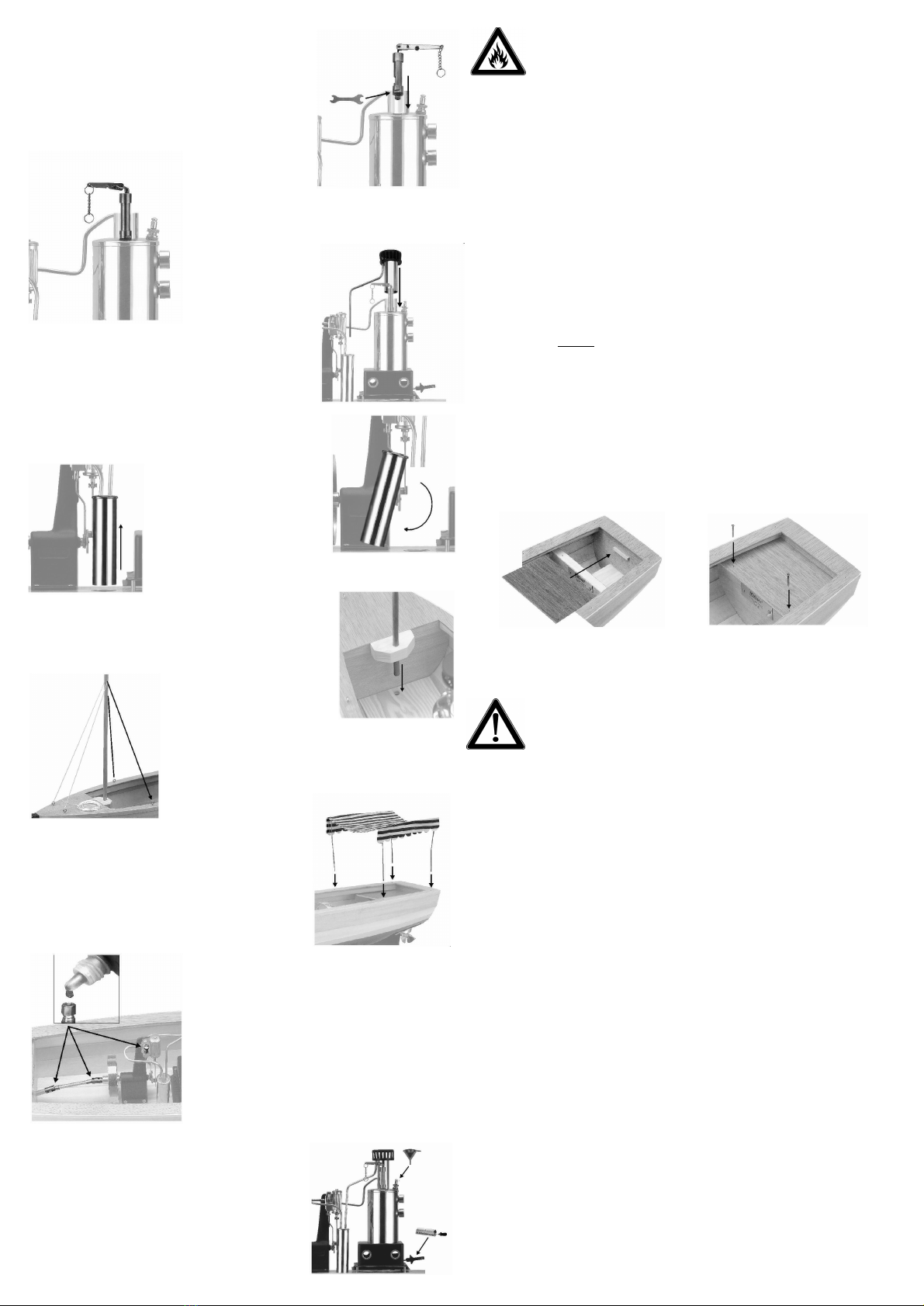

f. Installation ofthecondensatetank

Raise slightlyandcarefullythe exhauststeampipe co-

ming fromthe cylinder,placethe condensatetankinthe

sinkingplannedforit inthe

woodenboardandputtheex-

hauststeampipe inoneofboth

holeswhichare inthecovedof

the condensatetank.Putthe ex-

hauststeampipe leading tothe

chimney intheotherholeof the

condenser.

g. Mastand rigging

Putthe flagpoleinthe guide plannedforit andturnit so

that the flag showsbackwards.

h.Mountingofthemast

Fixthemastcordsaccording to

the picturetooneoftheeye-

lets,pullit through the holeunderneaththe flag andfix

it on the corresponding eyeleton the otherside ofthe

mast. Repeat this procedure withthe secondmastcord.

i. Roofand flags

Placethe roofinthe holesplannedforit ininthe rear.

Please watch thatthe bentroofgirdershave tobepla-

ced intherear holes.Two holes,one inthe bowand

oneinthe rearoftheship, are forbothflags.

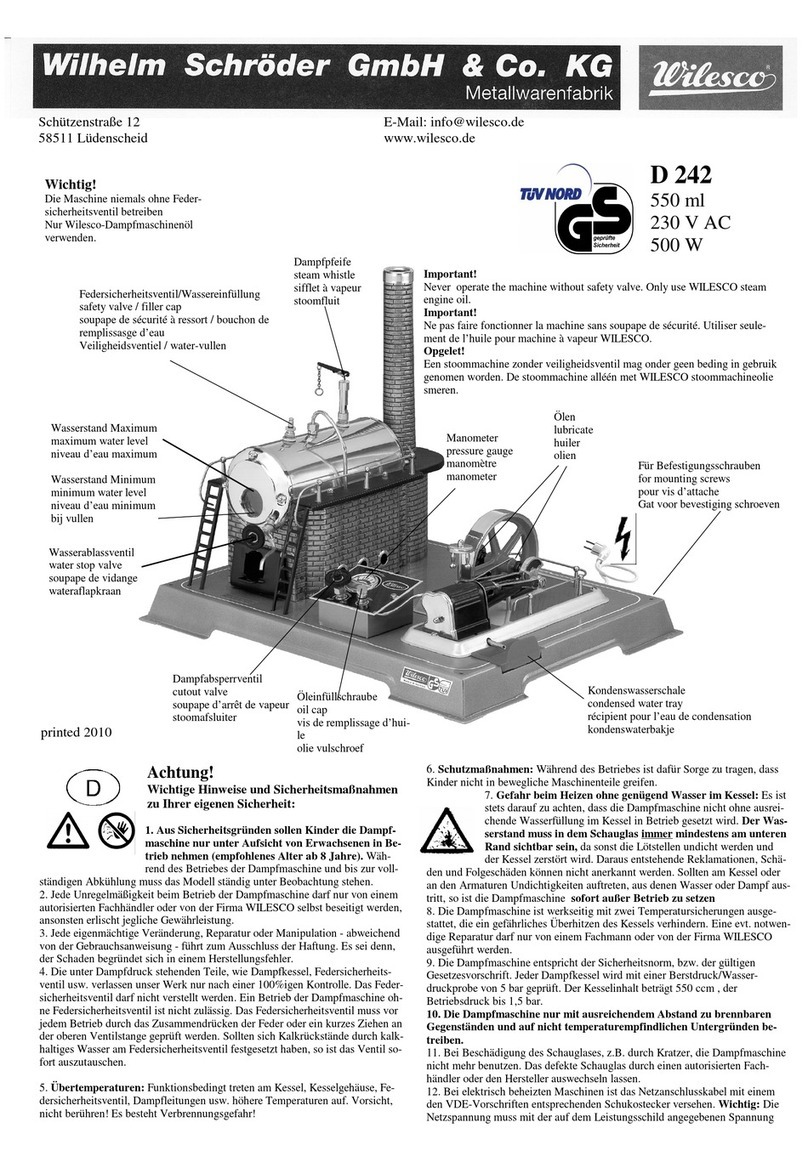

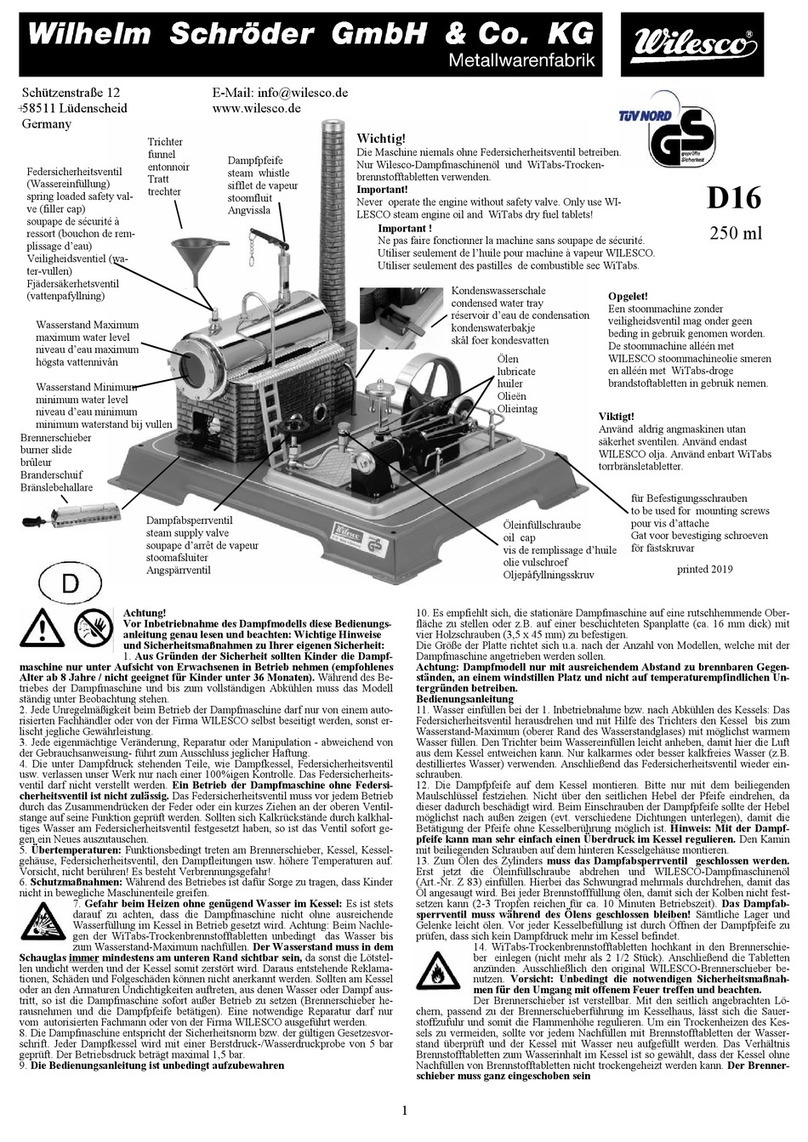

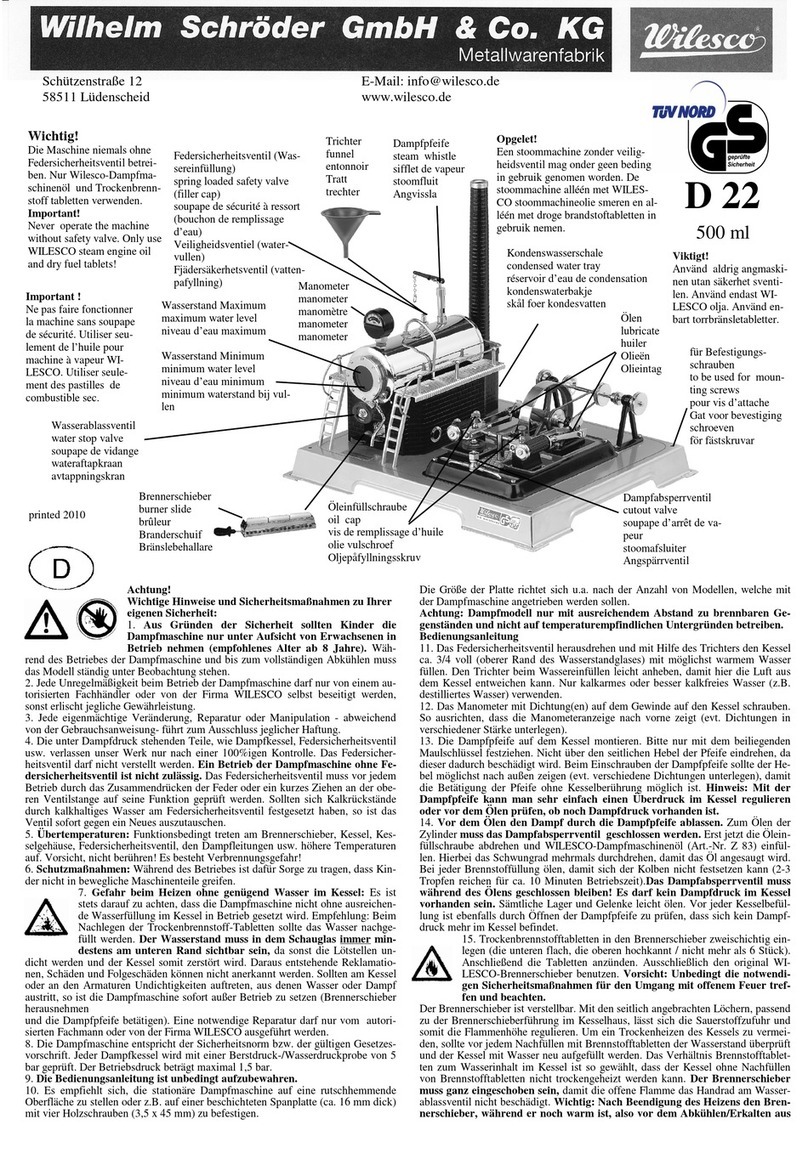

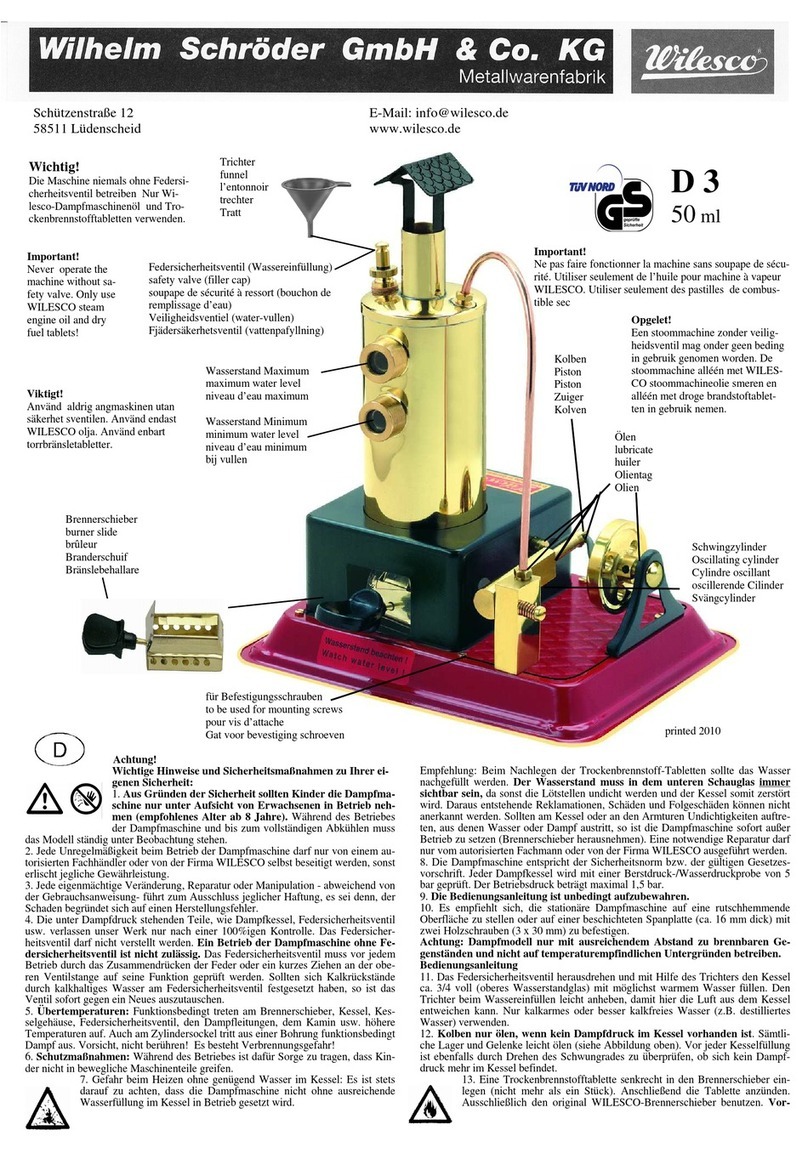

11. Initialoperation

Tooilthecylinder:

There must notbeanysteam pressure intheboiler.

Checkitby operatingthesteamwhistle.Onlythen

turnofftheoilfillerscrewandfill WILESCO

Steam EngineOil(item nr.Z 83)while turning the

flywheelseveraltimes sothatthe oil isdrawnin.

Oilagainwhenyourefillfueltabletssothat the

piston doesnotseize (2-3dropsoil areenoughfor

approx. 10mnrunning time).Oil lightlyallofthe

bearings,linkagesandtheshaft.Beforerefilling

the boilerwithwater,checkbyoperating the

steam whistle if nosteam pressureisinthe boiler.

Unscrewthespring loadedvalve andfill theboiler

withthe funnelapprox.tothe3/4(upperwater gau-

ge),ifpossiblewithwarmwater.Thefunnelshould

raise slightlysothat the air canescapefromthe boi-

ler.Useonlydeficientinlimewater or,better,water

withoutanylimee.g.distilledwater.

Placetwolayersofdry fueltablets intheburner slide

(the lowertabletsflat andthe uppertablets on the

3pcs.).Then lightthe tablets.Use onlytheoriginalWILESCOburner

slide. Caution:Becauseof the risk ofdangerfromanopenflame,

alwaystakethenecessarysafetyprecautions.

Theburnerslideisadjustable.Theoxygensupplyandthe flameheight

canbeadjustedbymovingthe burnerslide inrelationtothe air holes.Beforead-

ding new dry fueltablets, alwayscheck the waterlevelandrefillthe boilerwithwa-

tertoensurethattheboilerdoesnotrundry. Theratiooffueltabletstothe quantity

ofwaterintheboilerisdesignedsothatthe boilercannotrundrywithoutany ad-

ded fuel tablets. Important: Aftertheheating process,removetheburnerslide

fromtheguidewhilstitisstillwarm, otherwise unburntfuelmay cause theslide

tostick. Ifthe slide becomesstuck,it canberemovedbytilting it slightlytothe left

andright.

To preventunpleasantsmells,the fueltabletsshouldbecompletelyburntout-they

shouldnotbe blownout.If thereisnotenough waterintheboiler,place the burner

slide onametalplateuntilthe tabletshave burnedoutcompletely.

Dangerif theboileris heated withoutenough water!

Always ensure that the Steam Enginehasenoughwater intheboiler while running.

Itisrecommendedtorefillwater when adding newdry fueltablets. Thewater

mustbevisible always at leastatthelower watergauge,otherwise thejointsbe-

comeleaking andtheboilerwill bedestructed.Anyfollowing claim, damage or

consequential damage cannotbeaccepted. Ifaleakoccursintheboilerorany other

part wherewaterorsteamescape, stopthe SteamEngineimmediately (remove

the burner trayandoperatethe steamwhistle). Any necessaryrepair hastobe car-

ried outonlybyauthorizedtrainedstafforat WILESCO.

12. RC steering

There is asmallroominthe rearareaofthe shipforthe RC steering.After having

removedbothpins, youcanpullthe woodenboardforwards. Youcanmountinthis

areaastandardRCsteeringwhichcansteer therudder.

13.After theuseofthe SteamEngine andits cooling,theEngineshouldbeservi-

ced.Pouroutany waterleft inthe boiler.Forthis,unscrewthe spring loaded valve

andtake off allof the looseparts before tipping over themodel. Be

verycarefulif thewaterisstill hot! Anywater left inthe boilercan-

notdo anydamage, butmightleave sedimentonthe water gauge.Any

limeformation on the watergaugeorintheboilerhave nottobe remo-

vedinanycaseusing vinegaror corrosive agent (advise:use alime

dissolvingagentwhichdoesnotattackthe brassandthe solder).The

building ofsoodonthelowerside ofthe boilerdoesnotinfluence thefunctionand

canbe removedwithabrush.Finally, dry themodelusing aclean cloth.

14. Storageof theboat

Woodis anaturalproduct.Inordertomaintainthe valueofthe steamship,this

shouldbestoredat room temperature andat arelative humidityof40-70 %. Inca-

seofdirect solarradiation thewoodcanchange colour.

Guarantee:

15.AllWILESCO SteamEnginesarecarefullycheckedbeforeleaving thefactory.

Howeverif aproblemarises,wewillbehelpyouorcarry outrepairs.Youcanre-

turnthe steamshiptoaspecializeddistributorordirectlytoWILESCO. Wearesu-

reyouwill understand thatalready firedorusedmodels cannot be exchanged

fornewones. Themost frequentsclaimsareleakingboilers.Thesolderwill be

destroyedifit isnotenoughwaterinthe boiler.Insuchcases,the solderliquefy

drop-shapedandthe boilerbecomesleaking.This isanobviousproofthat the boi-

ler wasfiredwithoutenoughwater. Pleasewatchalwayscarefullythe waterle-

vel becausetheheating withoutadequatewaterlevel excludesanydemand for

guarantee.

This model isonlymeantforthe abovedescribed function.

Technicaldata canbeamendedwithoutprior notice.

TheWILESCO-Teamwishes youalotof pleasurewithyour SteamEngine and

"weigh theanchor!"