8DR LED SERIES

INSTALLATION INSTRUCTIONS

H.E. Williams, Inc. Carthage, Missouri www.hew.com 417-358-4065

Information contained herein is subject to change without notice.

PN #49091089

Page 1 of 4

REV.09/14/18JJ

WARNING:

■This product must be installed in accordance with the applicable

installation code by a person familiar with the construction and

operation of the product and the hazards involved.

■Make sure all electrical power is turned off while installing the fixture.

■This luminaire must be adequately grounded for protection against

shock hazards and to assure proper operation.

■Disconnect power before servicing.

■LEDs are ESD (Electro Static Discharge) sensitive devices that can be

easily damaged if the proper ESD mitigating steps are not taken.

■LEDs are very sensitive to mechanical damage. Caution must be taken

to avoid damage to the LEDs.

■ESD or mechanical damage voids all warranties.

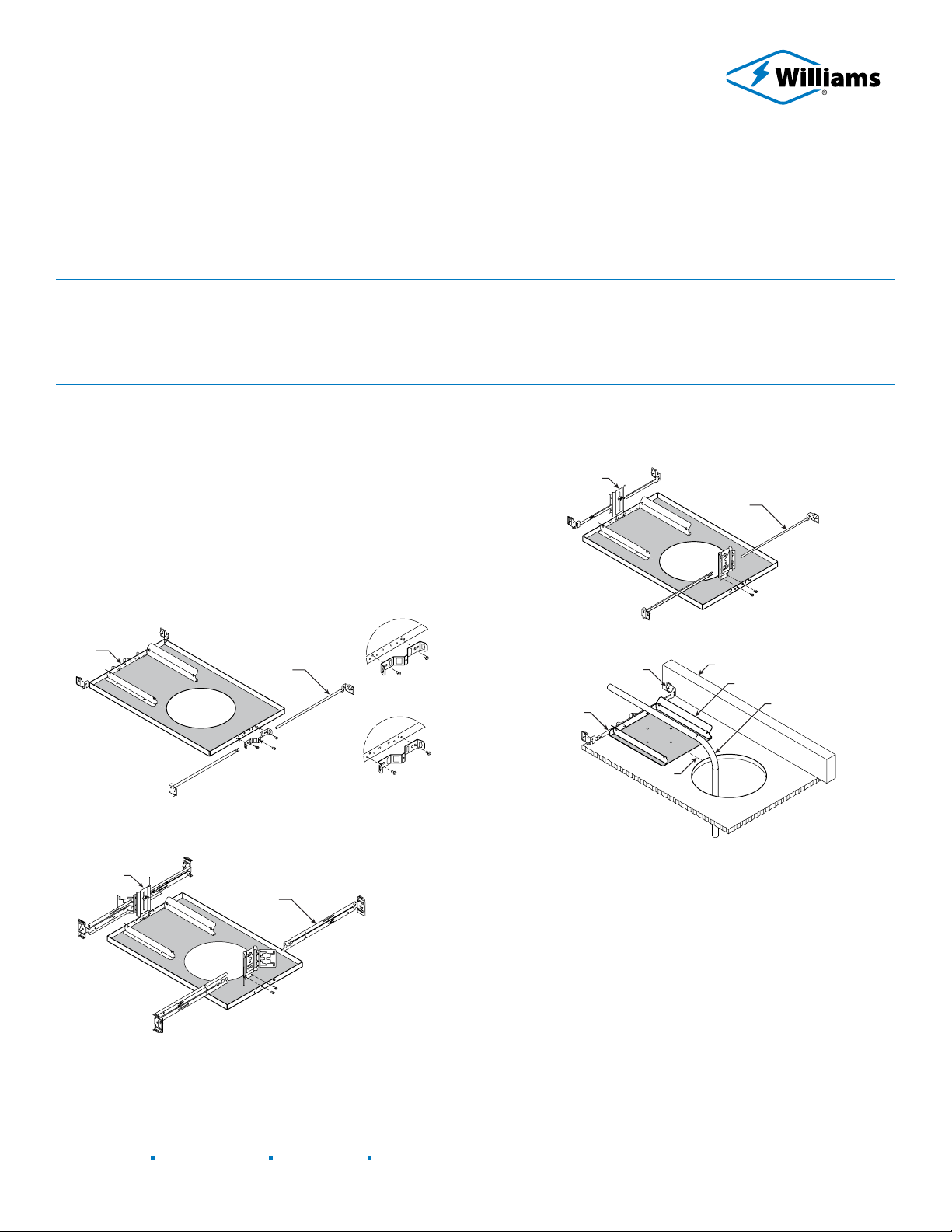

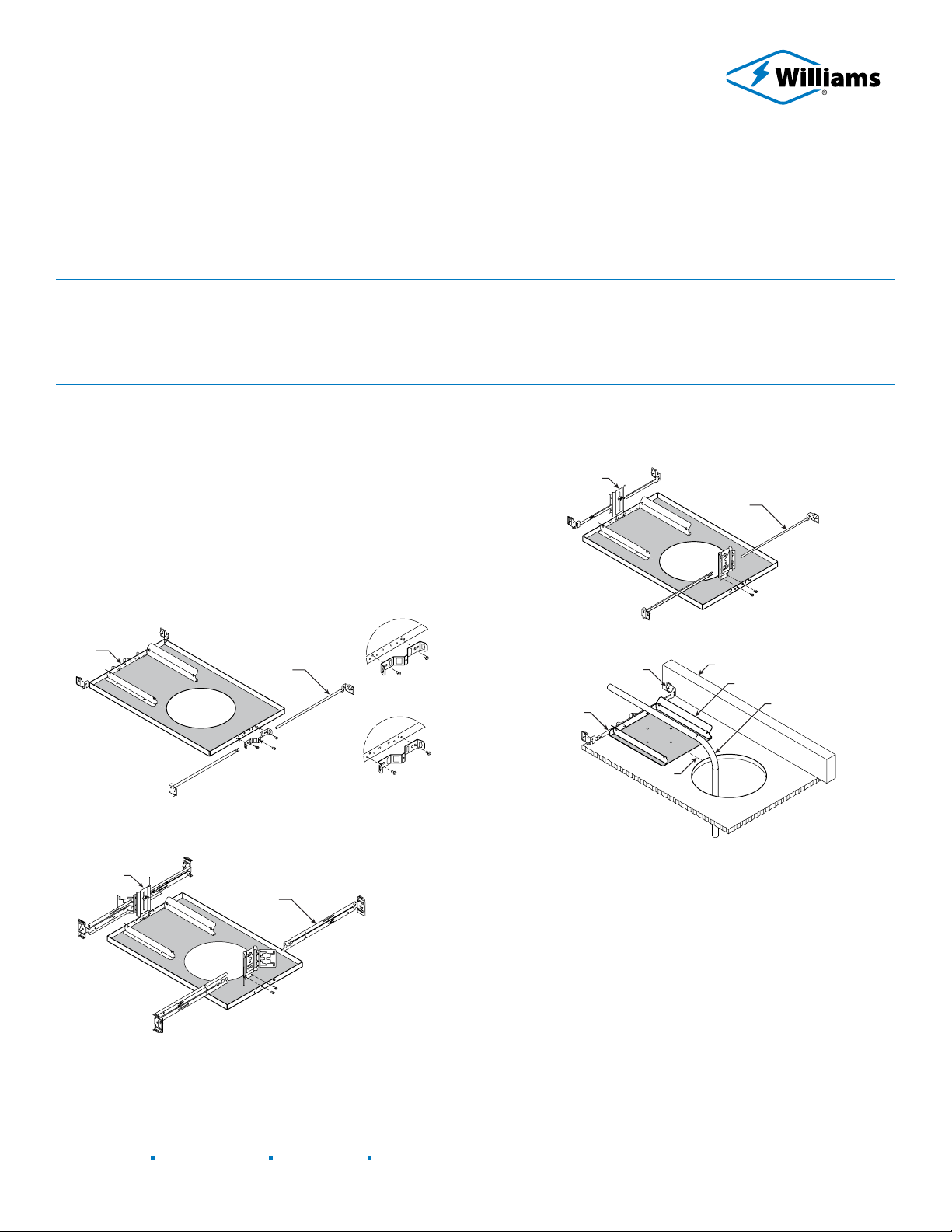

MOUNTING PAN INSTALLATION

Step 1: NEW CONSTRUCTION: Pre-attach the specified mounting

hardware to the fixture pan. See FIGURES 1.1 - 1.3.

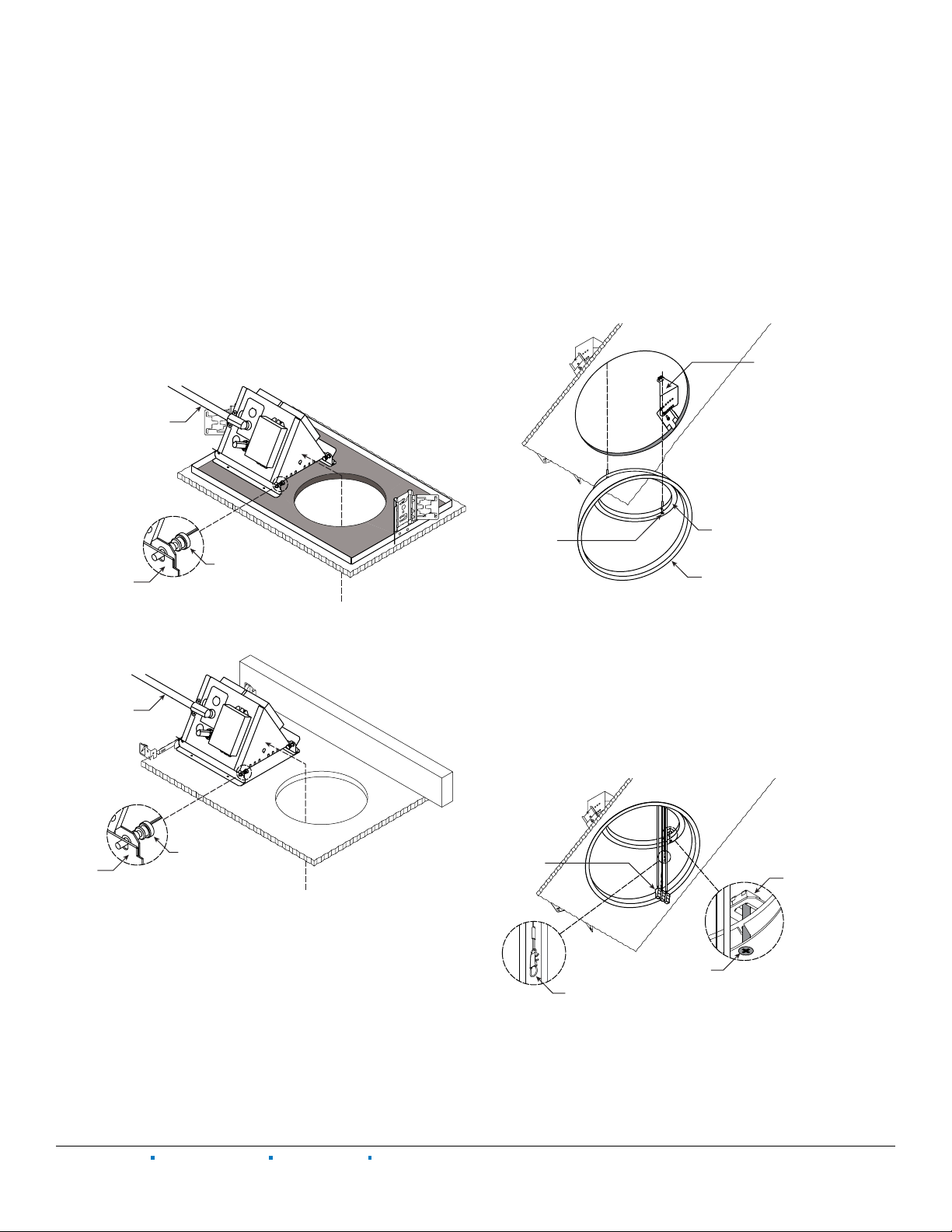

REMODEL: With the expandable bar hangers removed, maneuver

the receiver bracket assembly up through the ceiling cutout.

Once in the ceiling, reinstall the bar hangers, then position the

receiver bracket assembly 2” from the ceiling opening. Expand

the universal bar hangers until they stop against the ceiling joists

(both sides), then use a hammer to tap the nailer tabs into the

joists. See FIGURE 1.4.

FIG. 1.1 2-Position fixed pan bracket

F1: Universal bar hanger, shown | F2: T-bar clip hanger

Low position for

wood joist ceiling

High position for

1-11/16” T-bar grid

Universal

bar hanger

ed pan

et

FIG. 1.2 Adjustable butterfly pan bracket

BA1: Butterfly bracket only | BA2: Heavy-duty universal bar hanger, shown

Heavy-duty

universal

bar hanger

et

FIG. 1.3 Adjustable caterpillar pan bracket

CA1: Universal bar hanger, shown | CA2: T-bar clip hanger

bracket

Universal

bar hanger

FIG. 1.4

Nailer tab

Expandable

Receiver bracket assembl

Flex conduit

2”

MOUNTING PAN INSTALLATION CONTINUED ON NEXT PAGE

TABLE OF CONTENTS

MOUNTING PAN INSTALLATION.................................................................. 1

ELECTRICAL CONNECTIONS .......................................................................2

DRIVER BOX INSTALLATION ........................................................................ 3

SCA TRIM INSTALLATION ............................................................................. 3

DOWNLIGHT INSERT INSTALLATION........................................................ 4