6-18 GAV MANUAL VALVE TEST ....................................................................... 337

6-19 GVU & VALVE TEST ................................................................................... 339

6-20 KNOCK CONTROL ..................................................................................... 341

6-21 LOG MESSAGES ........................................................................................ 343

6-22 MAIN FUEL INJECTION ............................................................................. 345

6-23 PAGE INDEX ............................................................................................... 347

6-24 PERFORMANCE DATA DIESEL ................................................................. 349

6-25 PERFORMANCE DATA GAS ...................................................................... 351

6-26 PILOT FUEL INJECTION ............................................................................ 353

6-27 PILOT FUEL PRESSURE ........................................................................... 355

6-28 SCAVENGE AIR - EWG (optional) .............................................................. 357

6-29 SOFTWARE INFO ....................................................................................... 361

6-30 IMO CRC INFO ........................................................................................... 363

6-31 SOFTWARE TOOLS ................................................................................... 365

6-32 SYSTEM STATUS ....................................................................................... 367

6-33 SYSTEM SETTINGS ................................................................................... 369

6-34 TEMPERATURES ....................................................................................... 371

6-35 USER PARAMETERS ................................................................................. 373

6-36 GAS LEAK TEST ........................................................................................ 375

6-37 LOG ENTRY DATA ...................................................................................... 377

6-38 DATE ........................................................................................................... 379

6-39 ETHERNET ................................................................................................. 381

6-40 iELBA Control .............................................................................................. 383

6-41 SYSTEM INFO ............................................................................................ 388

6-42 TREND ........................................................................................................ 390

6-43 FUEL MODE CONTROL ............................................................................. 393

6-44 GAS SYSTEM ............................................................................................. 394

6-45 MAIN ........................................................................................................... 397

6-46 INSTRUMENTS .......................................................................................... 398

6-47 FUEL / LUBRICATION SYSTEM ................................................................. 405

6-48 Navigation menu of the manual control panel (MCP) .................................. 407

6-49 Function buttons of the manual control panel (MCP) .................................. 407

6-50 WECS-9520 manual control panel .............................................................. 413

6-51 User parameters .......................................................................................... 416

6-52 Maintenance settings .................................................................................. 418

6-53 WECS-9520 failure groups .......................................................................... 421

6-54 Failures of pulse lubrication ......................................................................... 421

6-55 LED color codes .......................................................................................... 422

6-56 Red fail LED and two-digit LED display ....................................................... 422

6-57 Examples of Failure IDs .............................................................................. 423

10 Troubleshooting

10-1 Supply pressure of the cylinder cooling water is too low ............................. 515

10-2 Supply temperature of the cylinder cooling water is too low ....................... 515

10-3 Cylinder cooling water temperature downstream of a cylinder is too high .. 515

10-4 Supply pressure of the cooling water to the SAC is too low ........................ 515

10-5 Supply temperature of the cooling water to the SAC is too low .................. 516

10-6 Temperature of the cooling water downstream of the SAC is too high ........ 516

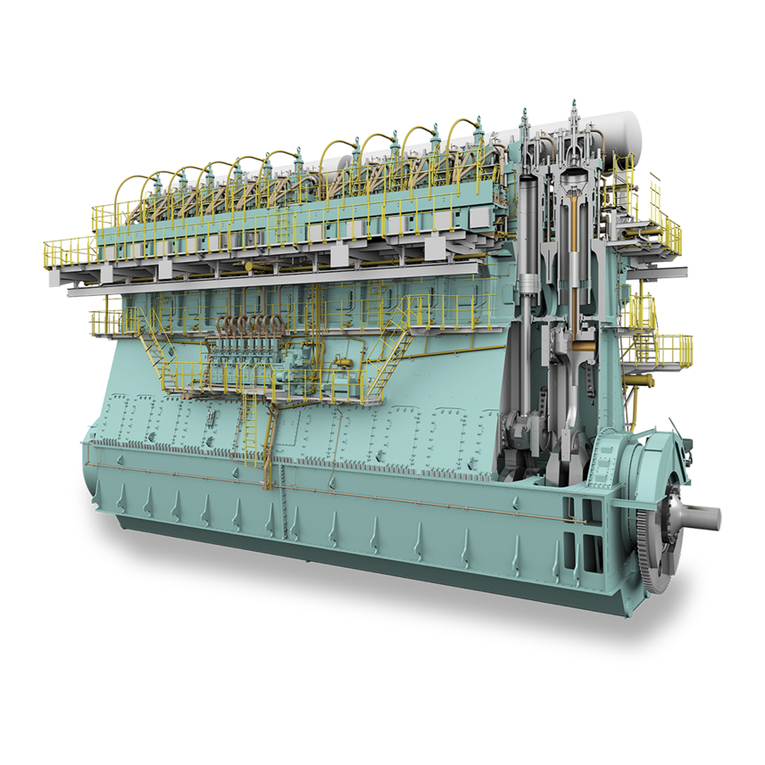

X92DF

Operation Manual

Winterthur Gas & Diesel Ltd. - 10 - Issue 002 2020-08