10-16 Piston cooling oil temperature downstream of a piston is too high ............. 325

10-17 Piston cooling oil flow to a piston is not in the permitted range ................... 325

10-18 TC bearing oil temperature at a turbocharger outlet is too high .................. 325

10-19 TC bearing oil supply pressure upstream of a turbocharger is too low ....... 325

10-20 TC bearing oil temperature at a turbocharger inlet is too high (external oil

supply) ........................................................................................................ 325

10-21 Damper oil supply pressure upstream of the torsional vibration damper is

too low ......................................................................................................... 326

10-22 Damper oil supply pressure upstream of the axial vibration damper is too

low ............................................................................................................... 326

10-23 Cylinder oil supply pressure is too low ........................................................ 326

10-24 Cylinder oil flow is too low ........................................................................... 326

10-25 Fuel supply temperature is not in the permitted range ................................ 327

10-26 Fuel supply pressure at the engine inlet is too low ...................................... 327

10-27 Fuel leakage flow from the fuel supply unit is too high ................................ 327

10-28 Temperature difference of the fuel outlet of the two fuel pumps is too high

(for X35/-B or X40/-B engine) ...................................................................... 327

10-29 Leakage flow from the rail unit is too high ................................................... 327

10-30 Fuel leakage flow from fuel rail items is too high (engine with FLV) ........... 327

10-31 Fuel leakage flow from fuel rail items is too high (engine with ICU) ............ 328

10-32 Fuel pressure in the fuel rail is too high (for X35/-B or X40/-B engine) ....... 328

10-33 Fuel pressure in the fuel rail is too low (for X35/-B or X40/-B engine) ........ 328

10-34 Gas concentration in piston underside is too high ....................................... 329

10-35 Difference pressure of pilot fuel filter is too high ......................................... 329

10-36 Gas supply pressure is too low ................................................................... 329

10-37 Exhaust gas temperature downstream of a cylinder is too high .................. 330

10-38 Exhaust gas temperature difference downstream of all cylinders is too

high .............................................................................................................. 330

10-39 Exhaust gas temperature upstream of a turbocharger is too high .............. 330

10-40 Exhaust gas temperature downstream of a turbocharger is too high .......... 331

10-41 Exhaust valve does not operate, unwanted noise ....................................... 331

10-42 Smoke is too dark ........................................................................................ 331

10-43 Scavenge air temperature in the receiver is too high .................................. 332

10-44 Scavenge air temperature in the receiver is too low ................................... 332

10-45 Scavenge air pressure is too high ............................................................... 332

10-46 Scavenge air pressure is too low ................................................................ 332

10-47 Condensation flow at a water separator is too high .................................... 333

10-48 Condensation flow upstream of a water separator is too high .................... 333

10-49 Scavenge air temperature in the piston underside is too high .................... 333

10-50 Starting air supply pressure is too low ......................................................... 333

10-51 Pressure of the air spring air supply is too high .......................................... 333

10-52 Pressure of the air spring air supply is too low ............................................ 334

10-53 Oil leakage flow in the collector for leakage oil from the air spring is too

high .............................................................................................................. 334

10-54 Control air supply pressure is too low (usual supply) .................................. 334

10-55 Control air supply pressure is too low (stand-by supply) ............................. 334

10-56 Control air supply pressure is too low (safety supply) ................................. 334

10-57 Temperature of a thrust bearing pad is too high ......................................... 335

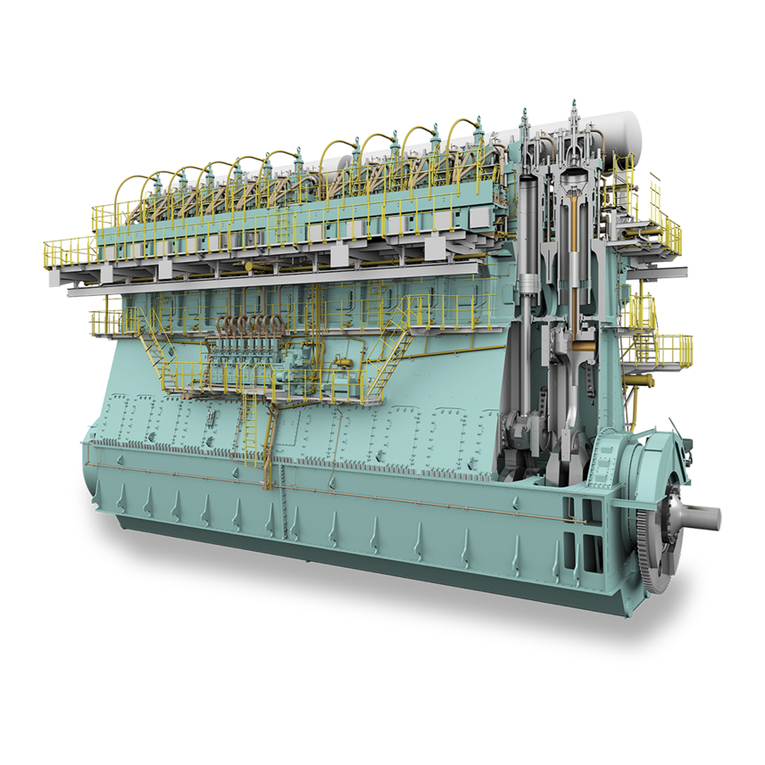

X92-B

Operation Manual

Winterthur Gas & Diesel Ltd. - 10 - Issue 002 2021-11