7.5.3 Cylinder cover - grind the sealing face for pilot injection valve............. 244

7.5.4 Cylinder cover - grind the sealing face for prechamber....................248

7.5.5 Cylinder cover - install................................................252

7.6 Direct controlled injection valve

7.6.1 Direct controlled injection valve - remove............................... 258

7.6.2 Direct controlled injection valve - do a functional test.....................260

7.6.3 Direct controlled injection valve - disassemble...........................264

7.6.4 Direct controlled injection valve - assemble............................. 268

7.6.5 Direct controlled injection valve - install.................................270

7.7 Starting air valve

7.7.1 Starting air valve - remove the solenoid valve........................... 272

7.7.2 Starting air valve - remove............................................274

7.7.3 Starting air valve - disassemble....................................... 278

7.7.4 Starting air valve - grind..............................................280

7.7.5 Starting air valve - assemble..........................................282

7.7.6 Starting air valve - install............................................. 284

7.7.7 Starting air valve - install the solenoid valve.............................286

7.8 Relief valve combustion chamber

7.8.1 Relief valve combustion chamber - remove............................. 288

7.8.2 Relief valve combustion chamber - install...............................290

7.9 Exhaust valve

7.9.1 Exhaust valve - remove.............................................. 292

7.9.2 Exhaust valve - disassemble..........................................296

7.9.3 Exhaust valve - remove the seat (with new tool)......................... 300

7.9.4 Exhaust valve - do a check of the seat................................. 304

7.9.5 Exhaust valve - grind the seat.........................................308

7.9.6 Exhaust valve - install the seat (with new tool)...........................310

7.9.7 Exhaust valve - assemble............................................ 314

7.9.8 Exhaust valve - install................................................322

7.10 Pilot injection valve

7.10.1 Pilot injection valve - remove..........................................326

7.10.2 Pilot injection valve - remove the injection module....................... 330

7.10.3 Pilot injection valve - install the injection module.........................332

7.10.4 Pilot injection valve - do a functional test................................336

7.10.5 Pilot injection valve - remove the pre-chamber...........................340

7.10.6 Pilot injection valve - install the pre-chamber............................342

7.10.7 Pilot injection valve - install........................................... 344

8 Group 3 - Crankshaft, connecting rod and piston

8.1 Crankshaft

8.1.1 Crankshaft - do a check of the crank deflection..........................350

8.1.2 Crankshaft - install the work platform...................................356

8.1.3 Crankshaft - remove the work platform................................. 358

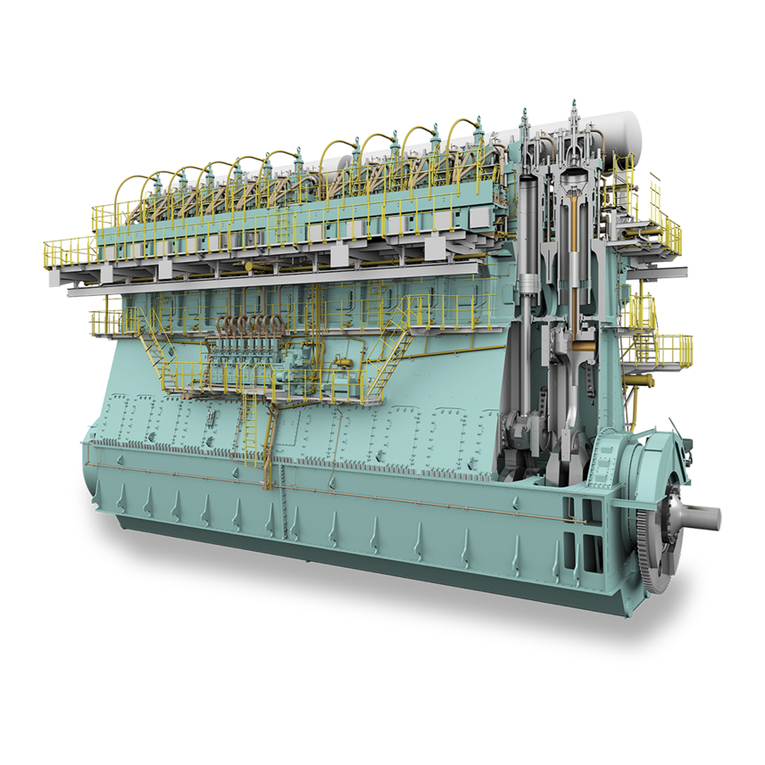

X72DF

Maintenance Manual

Winterthur Gas & Diesel Ltd. - 5 - Issue 002 2020-10