10.1.3 Servo oil pump - install...............................................536

10.2 Fuel pump

10.2.1 Fuel pump - remove................................................. 540

10.2.2 Fuel pump - disassemble.............................................544

10.2.3 Fuel pump - assemble............................................... 550

10.2.4 Fuel pump - install...................................................558

10.2.5 Fuel pump - do a test of the operation..................................562

10.3 Fuel pump actuator

10.3.1 Fuel pump actuator - calibrate.........................................566

10.3.2 Fuel pump actuator - adjust...........................................570

10.4 Fuel pressure control valve

10.4.1 Fuel rail - remove the pressure control valve............................ 574

10.4.2 Fuel rail - do a check of the pressure control valve.......................576

10.4.3 Fuel rail - install the pressure control valve..............................580

10.5 Fuel overpressure safety valve

10.5.1 Fuel rail - remove the overpressure safety valve.........................582

10.5.2 Fuel rail - do a check of the overpressure safety valve....................584

10.5.3 Fuel rail - install the overpressure safety valve...........................588

10.6 Injection control unit

10.6.1 Injection control unit - remove.........................................590

10.6.2 Injection control unit - install...........................................594

10.6.3 Injection control unit - do the preservation...............................598

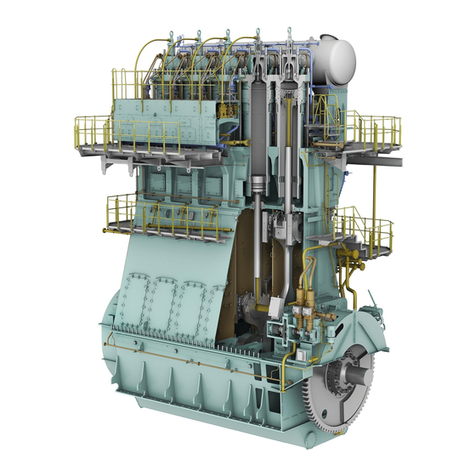

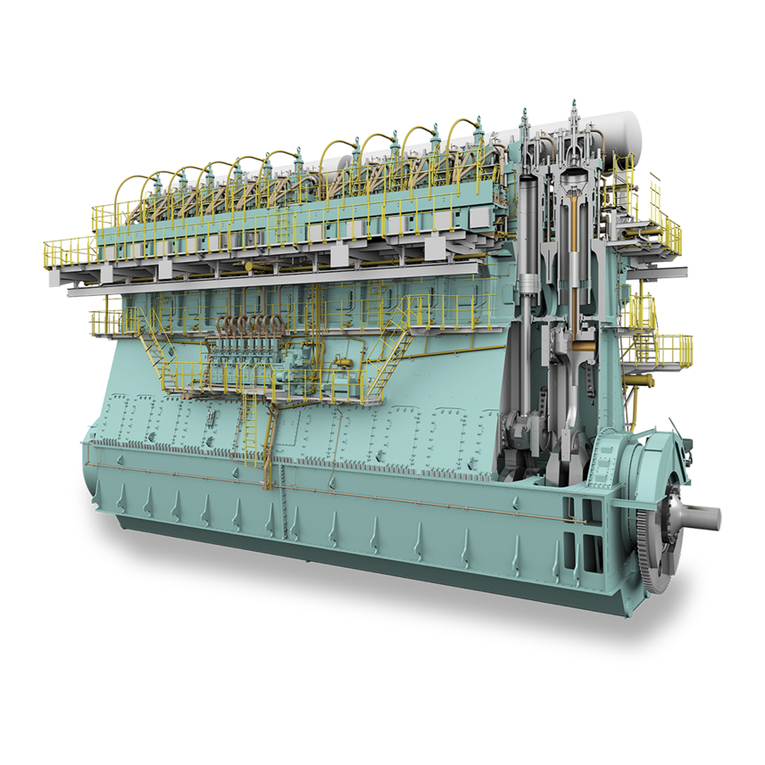

10.7 Supply unit

10.7.1 Supply unit camshaft and bearing shell - prepare before removal.......... 600

10.7.2 Supply unit camshaft and bearing shell - remove........................ 604

10.7.3 Supply unit camshaft and bearing shell - install..........................608

10.7.4 Supply unit bearing bush - remove.....................................612

10.7.5 Supply unit bearing bush - install...................................... 614

10.7.6 Supply unit camshaft and bearing shell - do the follow-on work............ 616

10.8 Exhaust valve control unit

10.8.1 Exhaust valve control unit (VCU) - remove..............................620

10.8.2 Exhaust valve control unit (VCU) - disassemble......................... 622

10.8.3 Exhaust valve control unit (VCU) - assemble............................624

10.8.4 Exhaust valve control unit (VCU) - install............................... 626

11 Group 6 - Scavenge air components

11.1 Scavenge air receiver

11.1.1 Scavenge air receiver - examine.......................................632

11.1.2 Scavenge air receiver - do a check of the relief valve.....................636

11.1.3 Scavenge air receiver - remove the flaps............................... 638

11.1.4 Scavenge air receiver - install the flaps.................................640

11.2 Auxiliary blower

11.2.1 Auxiliary blower - remove.............................................642

X82-B

Maintenance Manual

Winterthur Gas & Diesel Ltd. - 7 - Issue 001 2020-10