8

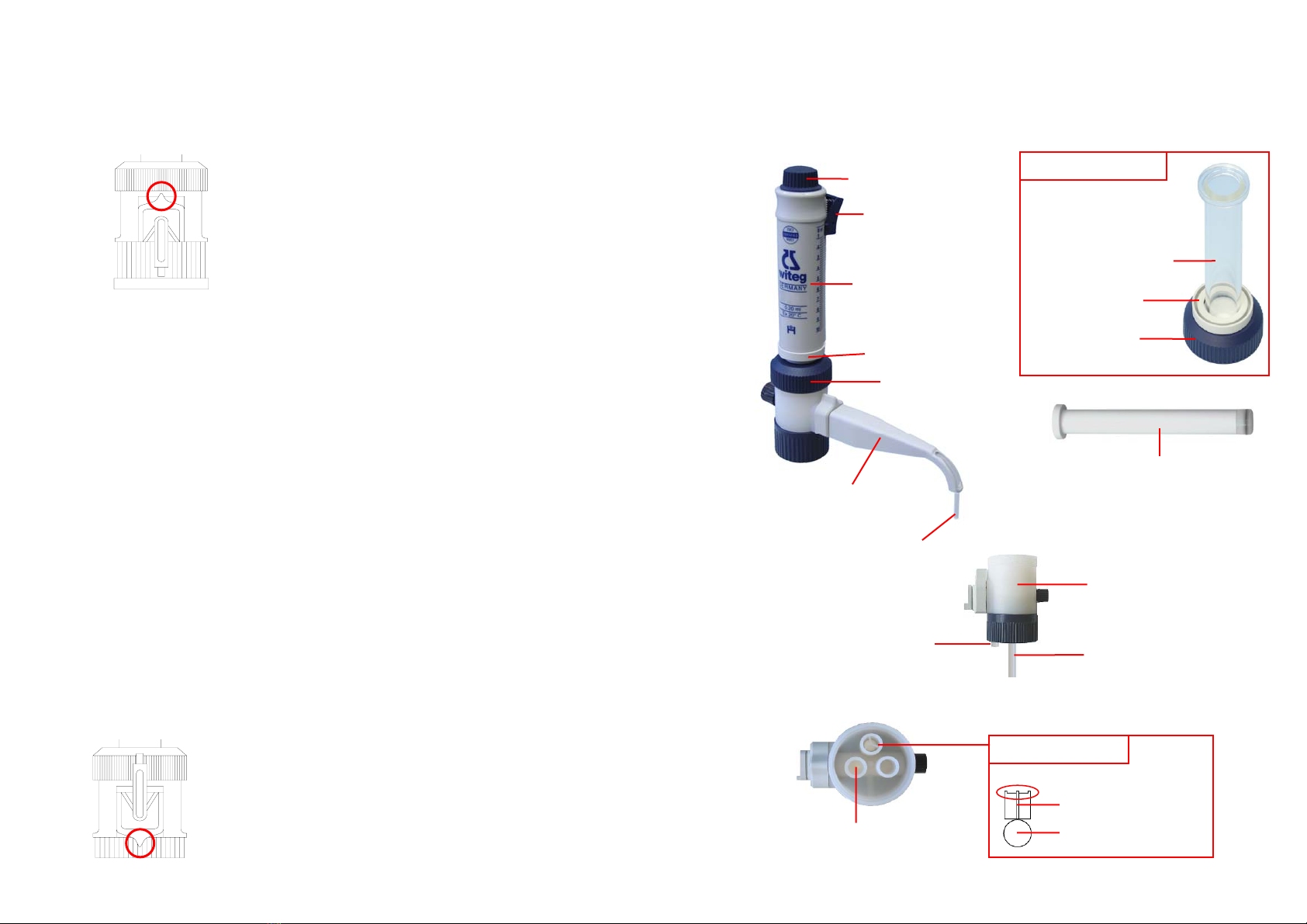

5.4 Disassembly

1. Follow the safety instructions!

2. Push the outer housing (2) down until it stops and then turn the valve

axle (12) to the left stop (Safety-Lock).

3. Let the remaining reagent in the ejection cannula (6) flow back into the

reagent bottle.

4. Place the device with the bottle into a suitable sink.

5. Unscrew the device from the bottle and carefully tap with the suction tube

(20) from the inside against the bottle, so that it is drained as well.

6. Rinse the Labmax “OE” with distilled water or alcohol.

7. Remove the suction tube (20) and the return tube (21).

8. Remove the cannula holder (7) and then the cannula (6).

9. Loosen the fix screw (1).

10. Pull the plunger (17) out of the cylinder (18). Make one pump movement

before. Then the plunger (17) can be handled easier.

(For Labmax 250 ml: before you can screw out the plunger, you have to

loosen the fixing bolt with standard 5 mm Allen key.)

11. Press down the Volume rocker switch (3) and pull it out of the slot.

(For Labmax 100 ml and 250 ml: Loosen the fix screw and the arrow).

12. Remove the outer housing (2).

13. Loosen the cap nut (5).

14. Pull the cylinder set (16) out of the valve head (19), keep in mind that the

valve star (9) and the valve ball (10) might fall out.

15. Take the valve star (9) and the valve ball (10) out of the valve head.

16. Loosen the closing cap (13) and remove the O-ring a (14 a).

(This point is not applicable for Labmax 250 ml)

17. Pull the valve axle (12) out of the valve head (19).

5.5 Assembly

1. Push the valve axle (12) into the valve head (19).

2. Assemble the O-ring a (14 a) and the closing cap (13).

(This point is not applicable for Labmax 250 ml.)

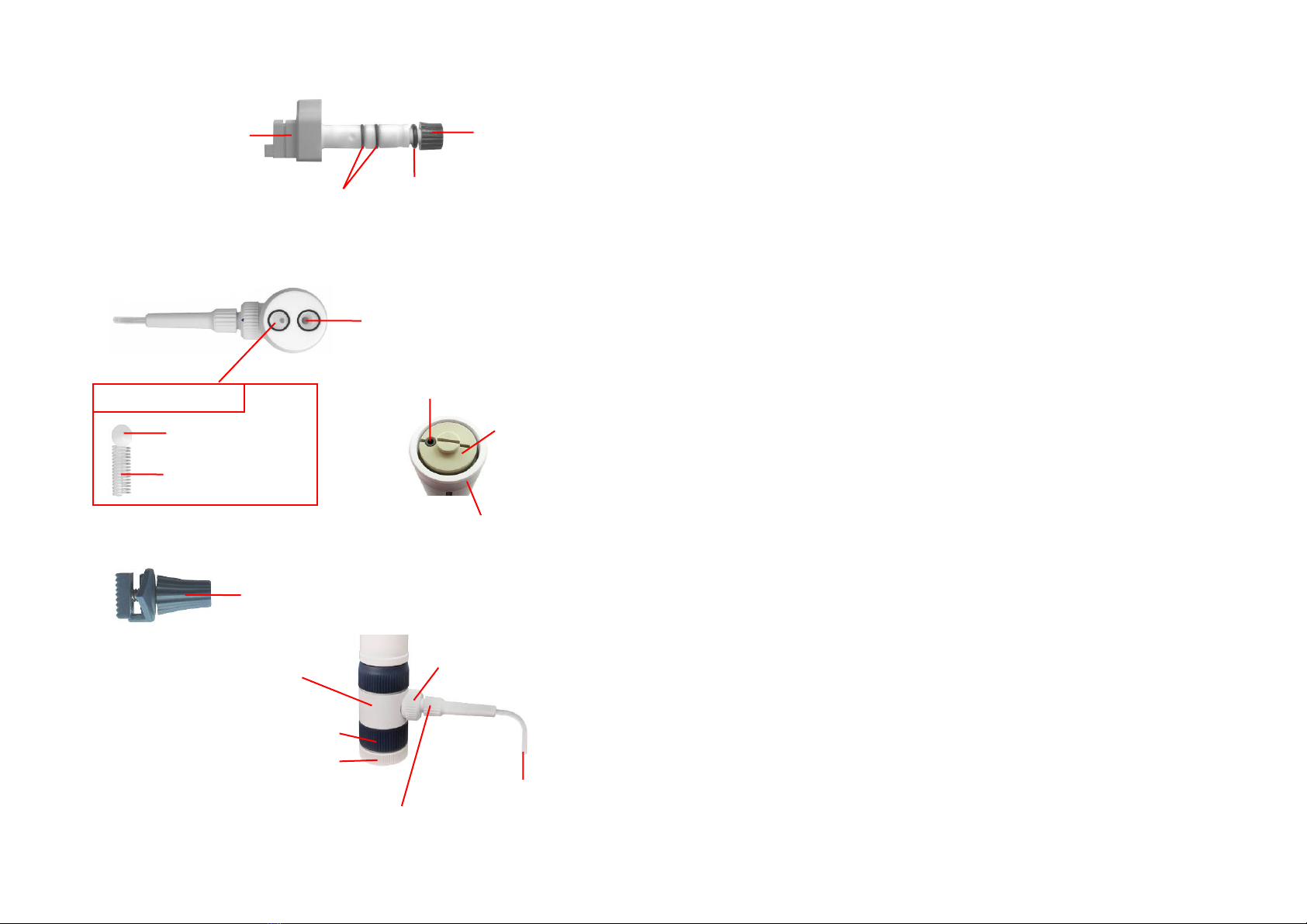

3. Place the valve ball (10) and the valve star (9) into the suction valve.

Check that the spikes of the valve star (9) point upwards.

(For Labmax 250 ml: Place one valve ball (10) in the suction valve.

Place the glass spring (22) and the other ball into the ejection valve).

4. Assemble the cylinder set (16) ontthe valve head (19). Check that the

notches of the cylinder set (16) are placed exactly over the domes of

the valve head (19).

5. Tighten the glass cylinder (18) with the cap nut (5). Check that all parts

fit tightly.

6. Slide the outer housing (2) on the cylinder (18).

9

7. Place the device horizontally and mount the volume rocker switch into

the slot. Than clip the adaptor ring (4) onto the outer housing (2).

For Labmax 100 ml and 250 ml:

8. Erect the device and push the plunger (17) into the cylinder (18) until it

stops. If there is an adaptor ring, make sure it is between plunger and

outer housing before.

9. Screw the fix screw (1) into the outer housing (2).

10. Push the ejection cannula (6) into the valve axle (12) and fix it with the

cannula holder (7).

11. Push the return tube (21) and the suction tube (20) into the valve head

(19).

12. Screw the device on the reagent bottle.

5.6 Avoid clogging

When the Labmax is screwed open, make sure that the valves are always

surrounded by liquid.

You can keep the dispenser smooth-running by rinsing it with distilled water or

alcohol.

Unfix clogged valves with a thin object (wire, paperclip etc.). Therefore stick it

from upper side into the suction valve and from below side into the suction

valve.

Make sure that you clean the valves completely after unfixing otherwise they

may leaking in fact of incrustations.

Step 1 Step 2 Step 3 Step 4 Step 5