LUC+125 impulse-controlled

Revision: 01 1000088472 en-1

Table of contents

1About this manual .............................................................................................................................3

1.1 Information symbols and cross references...................................................................................3

1.2 Scope of delivery..........................................................................................................................3

2Safety..................................................................................................................................................3

2.1 EC/EU Directive............................................................................................................................3

2.2 Personnel .....................................................................................................................................3

2.3 Intended use.................................................................................................................................4

2.4 Reasonably foreseeable misuse ..................................................................................................4

2.5 Guarantee and liability..................................................................................................................4

2.6 General safety instructions...........................................................................................................5

2.7 Structure of warning instructions..................................................................................................5

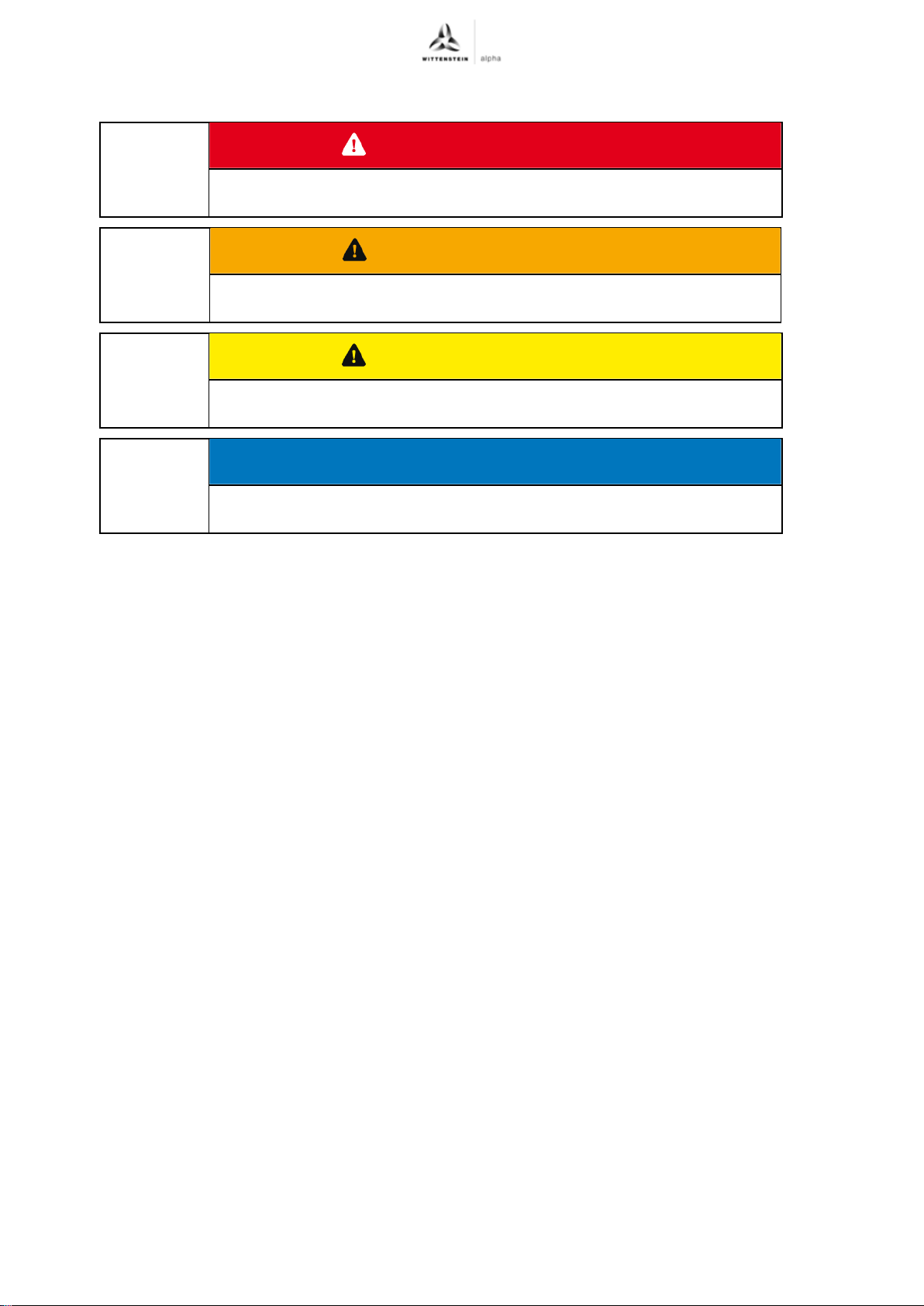

2.7.1 Safety symbols......................................................................................................................5

2.7.2 Signal words..........................................................................................................................6

3Description of the lubricator.............................................................................................................7

3.1 Overview of lubricator components ..............................................................................................7

3.2 Name plate and labeling...............................................................................................................7

3.3 Marking.........................................................................................................................................8

3.4 Ordering codes.............................................................................................................................8

3.5 Dimensions...................................................................................................................................8

3.6 Scope of delivery..........................................................................................................................8

3.7 Technical data..............................................................................................................................9

3.8 Lubricants...................................................................................................................................10

3.9 Cord lengths...............................................................................................................................10

4Transport and storage.....................................................................................................................10

4.1 Transport....................................................................................................................................10

4.2 Storage.......................................................................................................................................10

5Assembly..........................................................................................................................................11

5.1 Preparations...............................................................................................................................11

5.2 Mounting the lubricator...............................................................................................................11

5.3 Connecting the prefilled hose.....................................................................................................12

5.4 Electrical interface connection....................................................................................................12

6Startup and operation .....................................................................................................................13

6.1 Switching on the lubricator .........................................................................................................13

6.2 Operation and settings ...............................................................................................................13

6.2.1 General................................................................................................................................13

6.2.2 Factory settings...................................................................................................................14

6.2.3 Default settings in impulse mode ........................................................................................14

6.3 Menu and display messages......................................................................................................14

6.4 Error messages..........................................................................................................................15