2

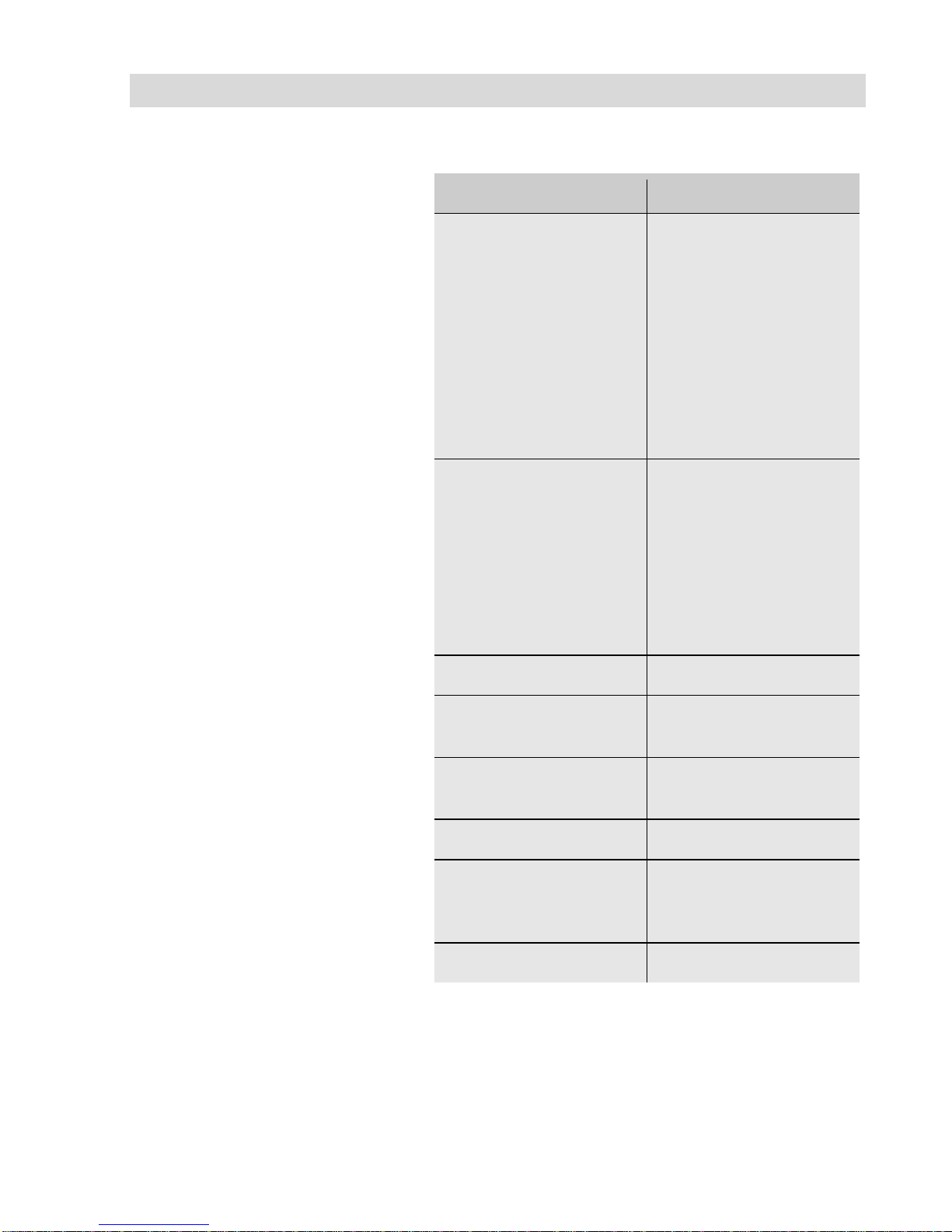

Contents

1General Information..............................4

1.1 Operation Manual Information....................... 4

1.2 Notes............................................................. 4

1.3 Intended Use................................................. 4

1.4 Components.................................................. 5

1.5 Transport....................................................... 5

1.6 Information on disposal................................. 5

1.7 Manufacturer................................................. 5

2Specifications........................................6

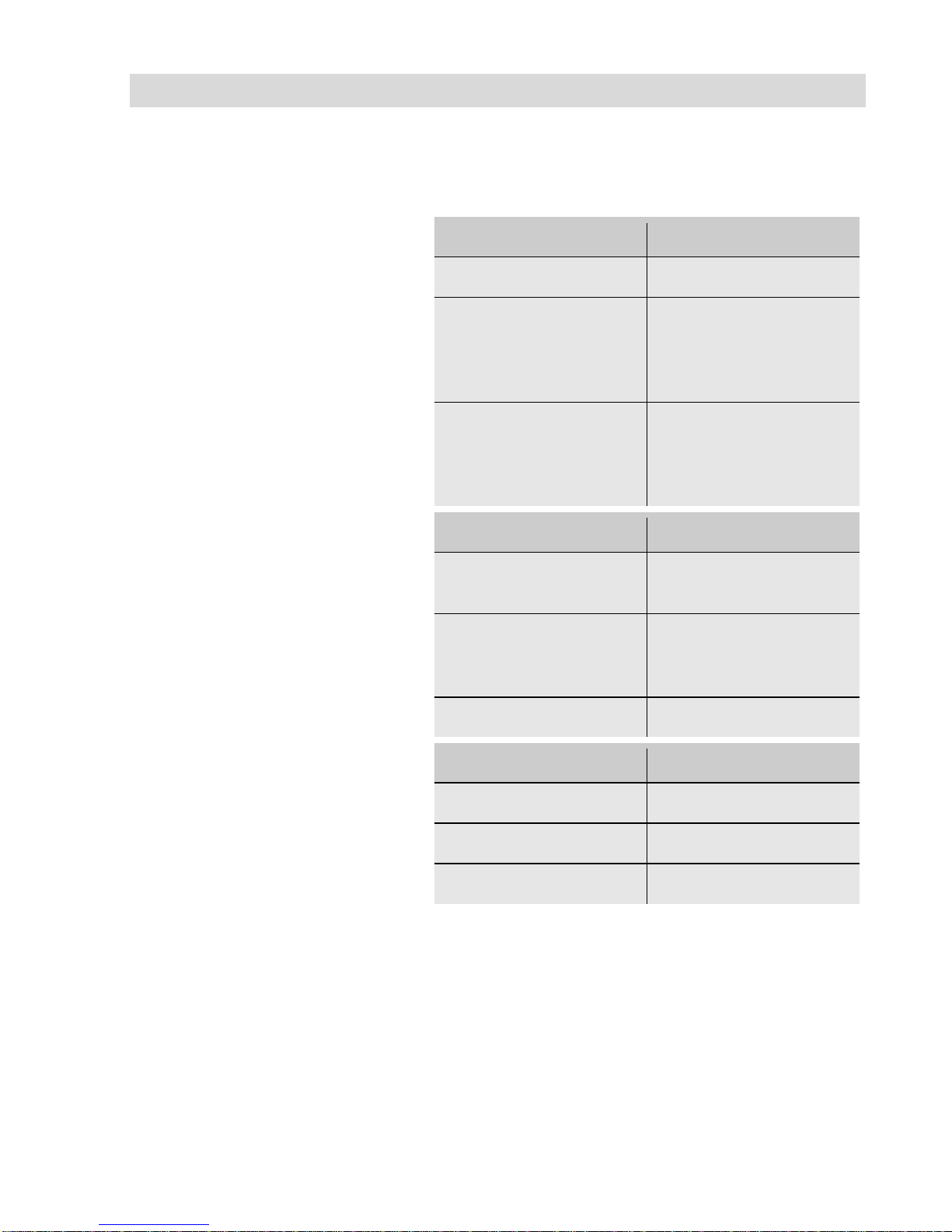

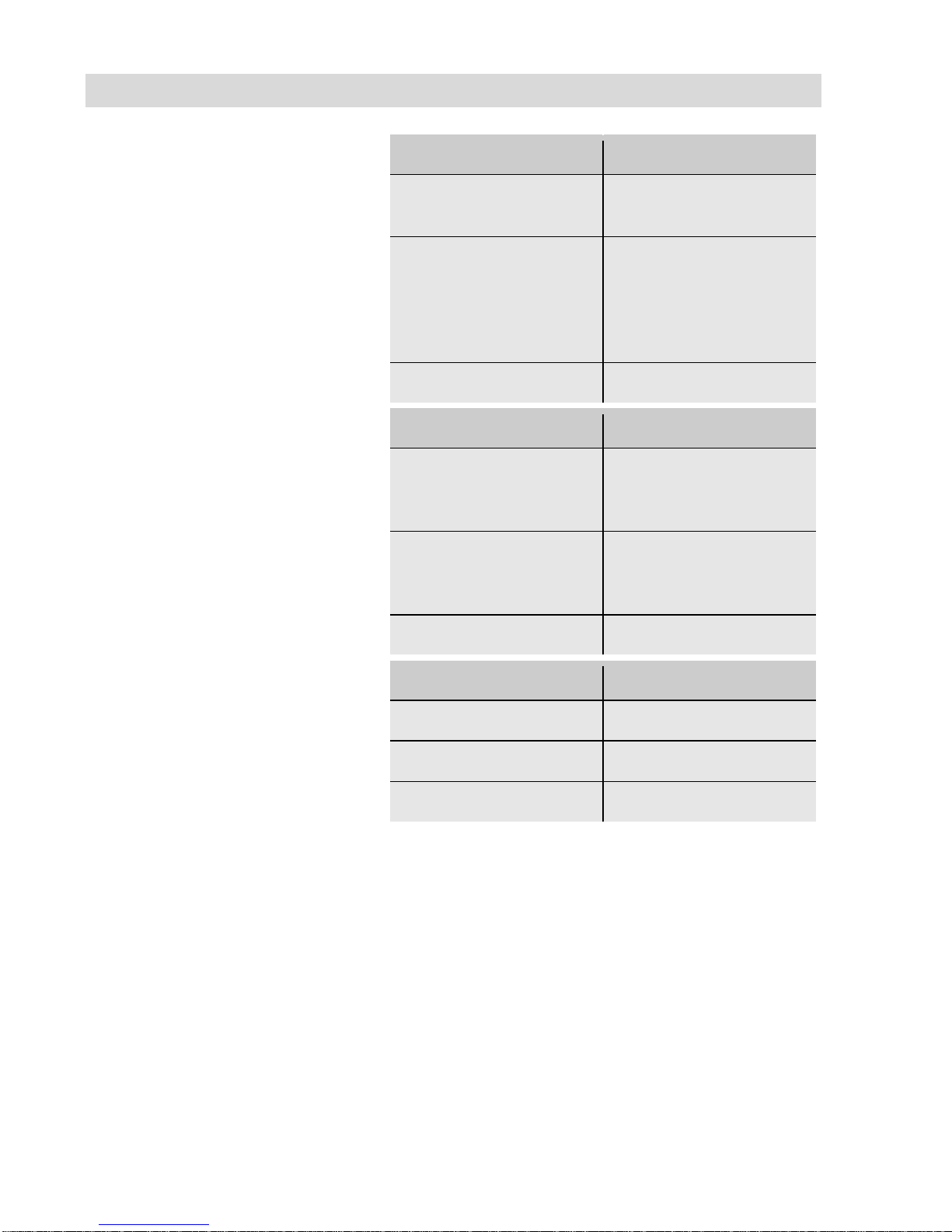

2.1 Measured values........................................... 6

2.2 Calculated Values ......................................... 8

2.3 Logger........................................................... 9

2.4 Technical Data ............................................ 10

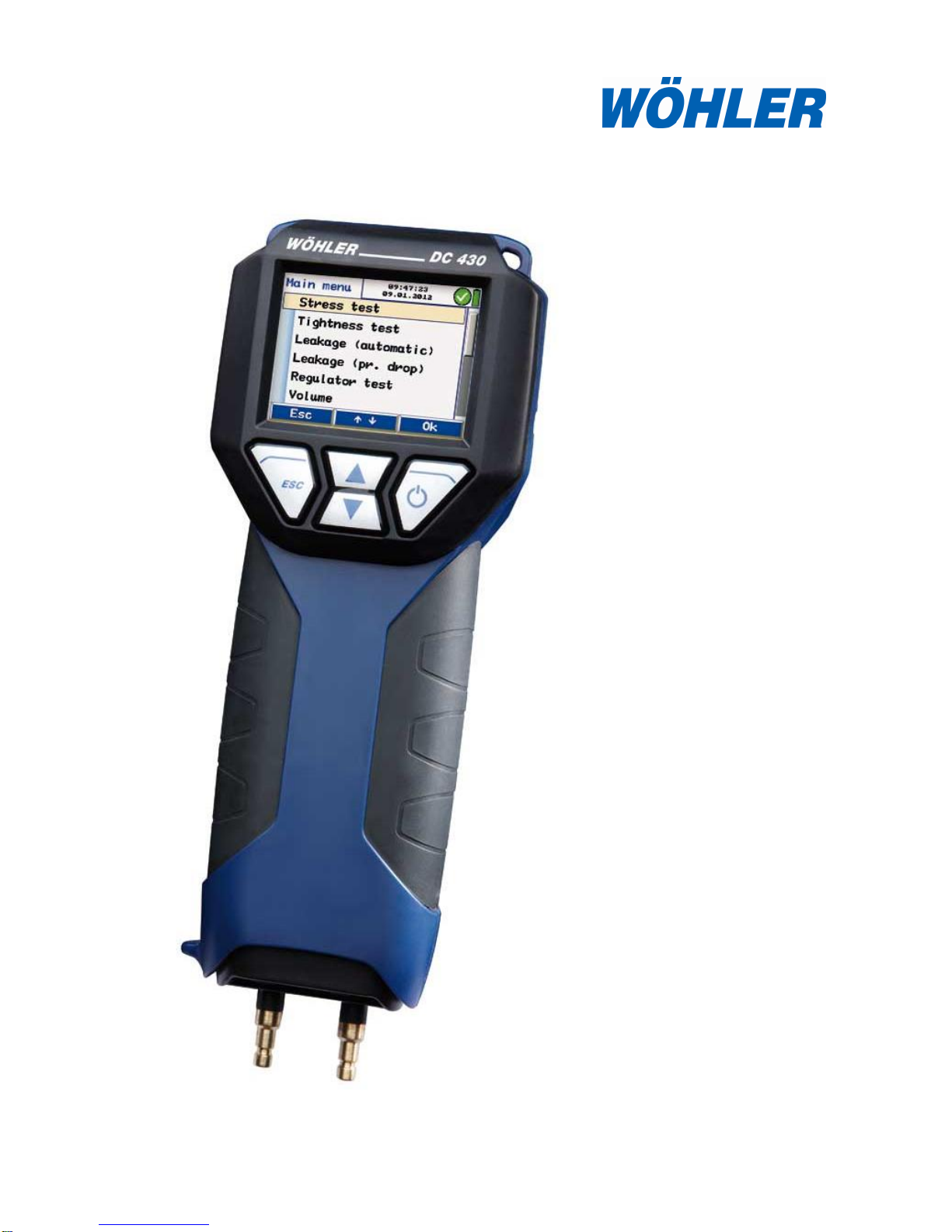

3Component explanation.....................11

3.1 Basic unit..................................................... 11

3.2 Probes and components ............................. 13

3.3 Function ...................................................... 18

3.4 Display and key setup................................. 19

4Getting started ....................................21

4.1 Check battery status.................................... 21

4.2 Tightness test.............................................. 23

5Operation.............................................24

5.1 Turning the meter on................................... 24

5.2 Measuring ................................................... 24

5.3 Using the Pressure computer...................... 25

6Measurement modes in the main menu

..............................................................27

6.1 Calling up the main menu............................ 27

6.2 Option “Stress test” ..................................... 27

6.3 Option “Tightness test” ................................ 29

6.4 Option “Leakage rate” ................................. 34

6.5 Leakage rate, automatic............................. 34