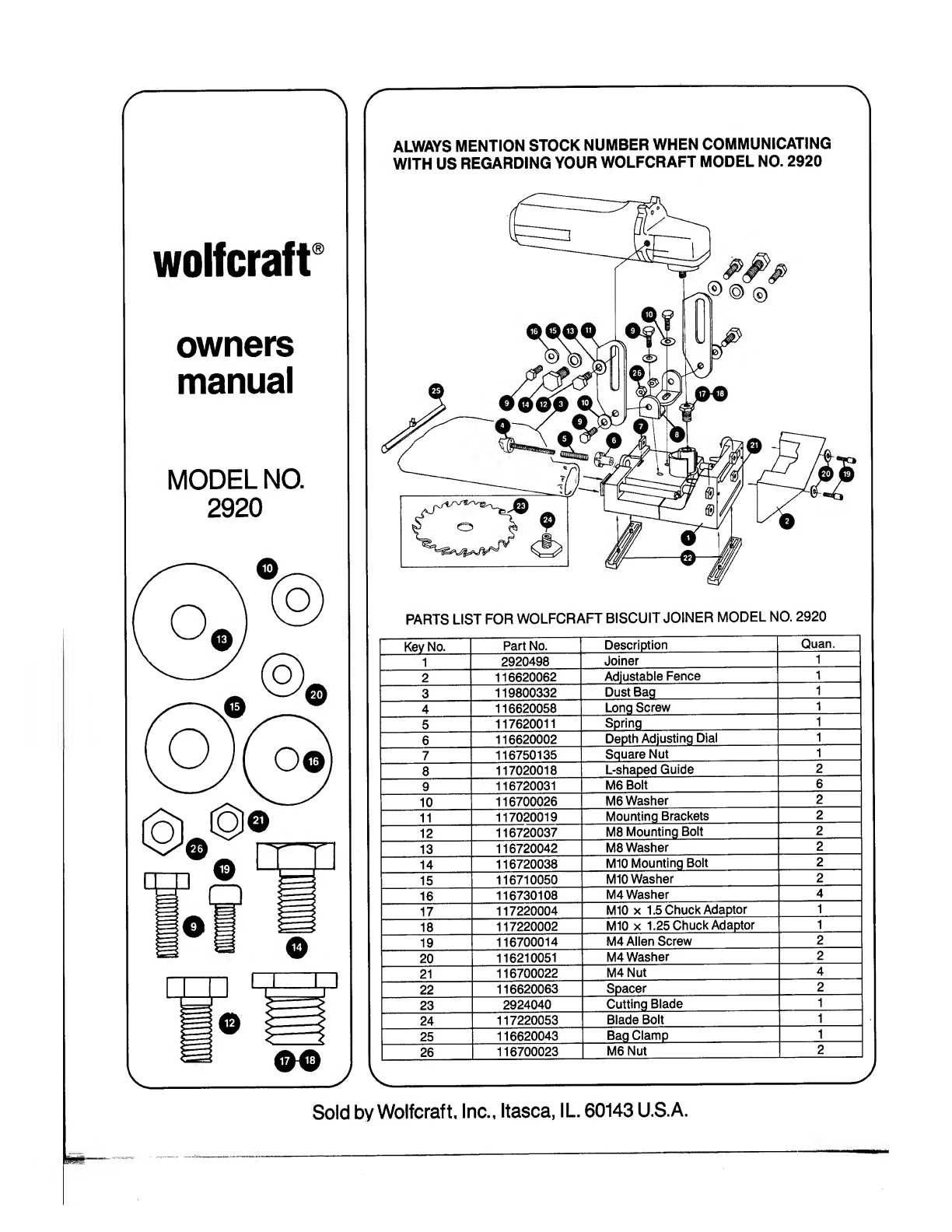

Wolfcraft 2920 User manual

Other Wolfcraft Biscuit Joiner manuals

Popular Biscuit Joiner manuals by other brands

Matrix

Matrix BJ 850-100/1 instructions

Chicago Electric

Chicago Electric 38648 Set up and operating instructions

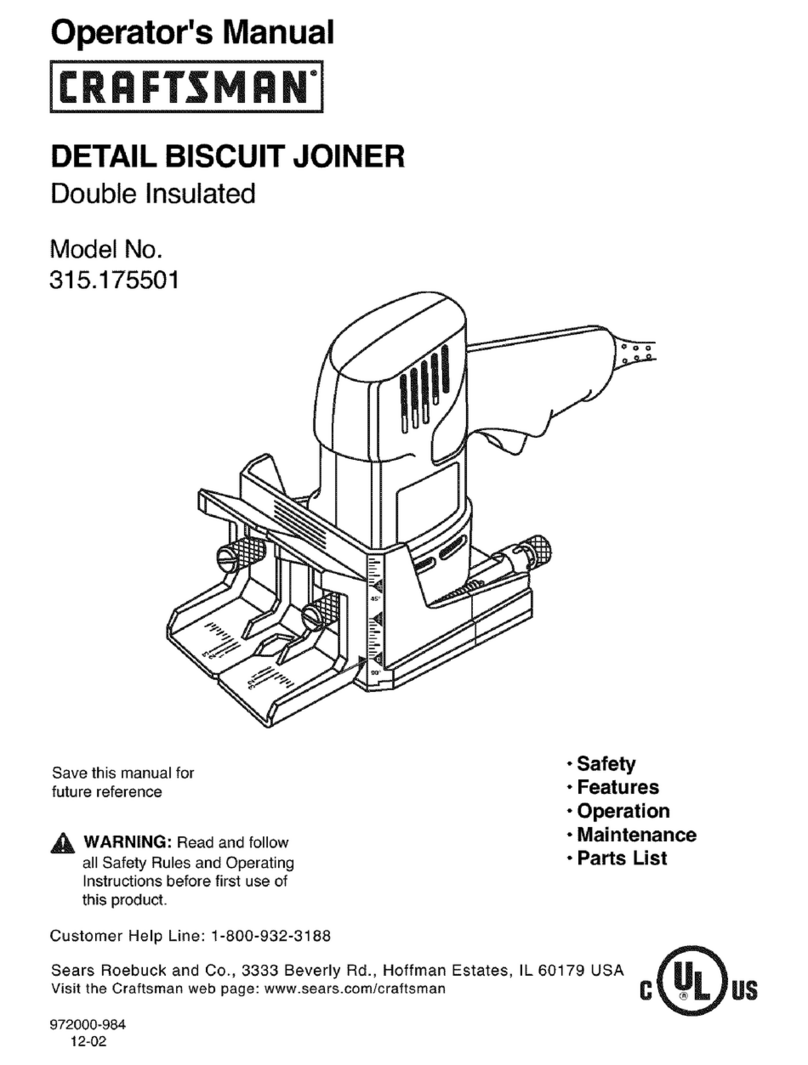

Craftsman

Craftsman 315.175501 Operator's manual

DeWalt

DeWalt DCW682 instruction manual

Triton

Triton BJA 300 Operating and safety instructions

Ferm-Omega Tools

Ferm-Omega Tools FBJ-710 user manual