7.14 Error Code 0215........................................................................................................ 61

7.15

Error Code 0216 ..................................................................................................61

7.16

Error Code 0220 ..................................................................................................61

7.17

Error Code 0221 ..................................................................................................61

7.17.1 Reasons................................................................................................................61

7.17.2 Troubleshooting................................................................................................... 62

7.18 Error Code 0222, 0223, 0224 & 0225.........................................................................63

7.18.1 Reasons................................................................................................................ 64

7.18.2 Troubleshooting...................................................................................................64

7.19

Error Code 0301 ..................................................................................................65

7.19.1 Reasons................................................................................................................65

7.19.2 Troubleshooting................................................................................................... 66

7.20

Error Code 0302 ..................................................................................................66

7.20.1 Reasons................................................................................................................66

7.20.2 Troubleshooting................................................................................................... 66

7.21

Error Code 0303 ..................................................................................................67

7.21.1 Reasons................................................................................................................67

7.21.2 Troubleshooting....................................................................................................67

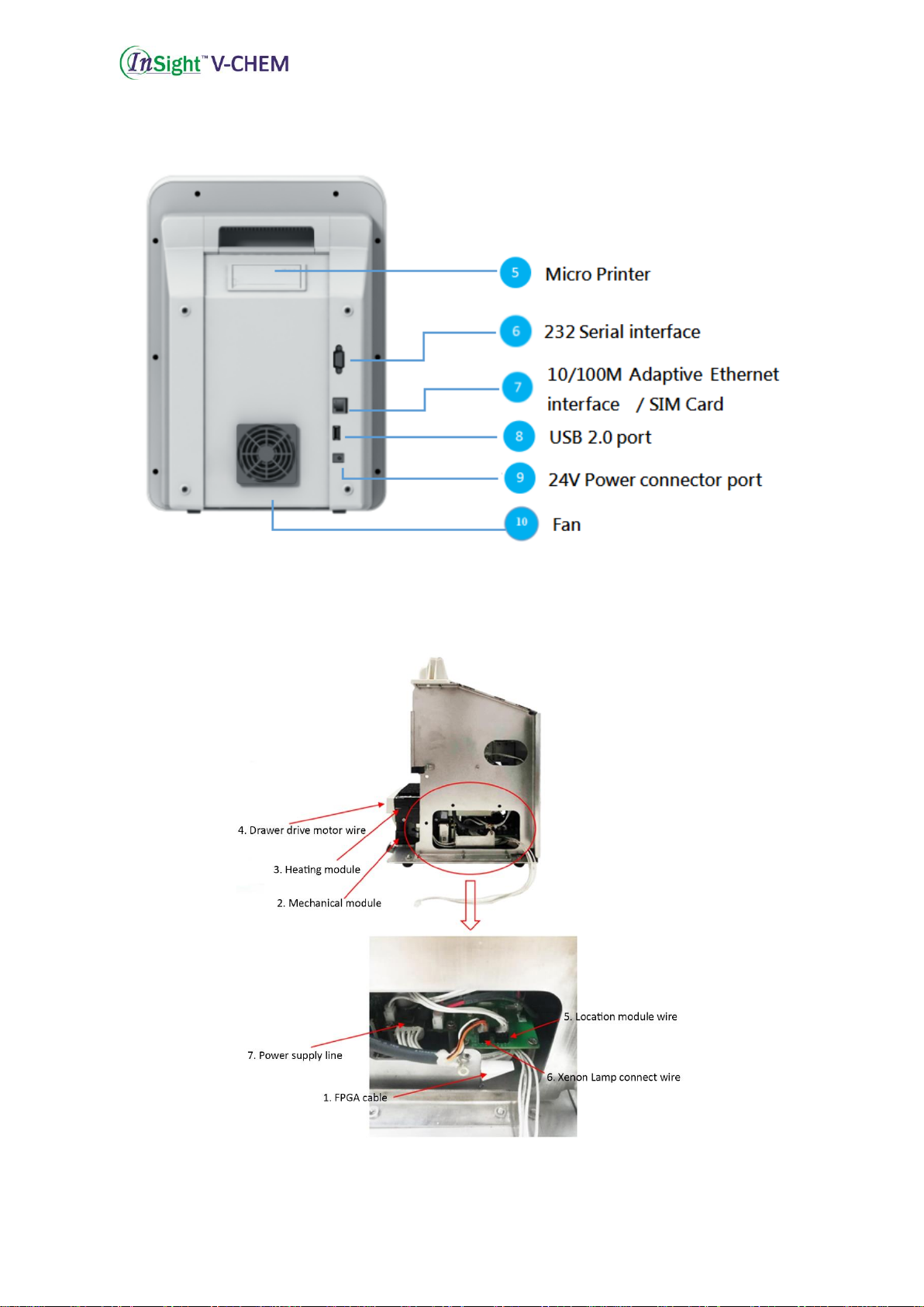

Section 8 Hardware Malfunction and Troubleshooting......................................................68

8.1

Black Screen.................................................................................................................. 68

8.1.1 Reasons................................................................................................................68

8.1.2 Troubleshooting................................................................................................... 68

8.2

White Screen (BIOS Cannot Start)................................................................................69

The screen displays white after startup. .............................................................................. 69

8.2.1 Reasons................................................................................................................69

Program error...................................................................................................................69

8.3

White Screen (BIOS Can Start)..................................................................................... 70

8.3.1 Reasons................................................................................................................70

8.3.2 Troubleshooting................................................................................................... 70

8.4

Blurred Screen...............................................................................................................70