Manual 26758 CPC-DX Current to Pressure Converter

Woodward 2

Illustrations and Tables

Figure 1-1. Basic CPC-DX Application and Configuration............................................................................ 8

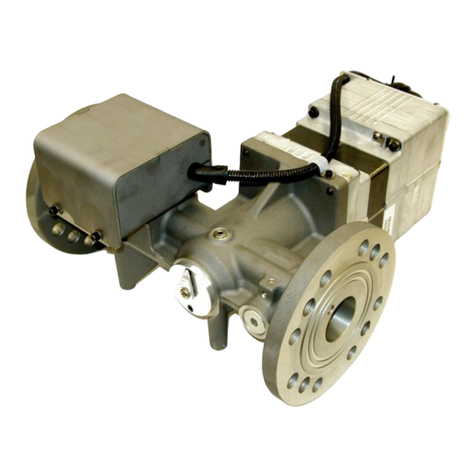

Figure 1-2. CPC-DX Main Components........................................................................................................ 9

Figure 1-3. CPC-DX Installation Drawing Front view.................................................................................. 10

Figure 1-4. CPC-DX Installation Drawing, Top view................................................................................... 11

Figure 1-5. CPC-DX customer interface ..................................................................................................... 12

Figure 1-6. CPC-DX Main Terminal Box, Wiring Diagram.......................................................................... 13

Figure 1-7. CPC-DX Main Terminal Block Connections List ...................................................................... 14

Figure 1-8. Internal CPC wiring diagram..................................................................................................... 15

Figure 2-1. Internal Leakage, CPC-DX Skid, 10 bar supply pressure, oil viscosity 20 cSt; ....................... 18

Figure 2-2. Internal Leakage, CPC-DX Skid, 25 bar supply pressure, oil viscosity 20 cSt; ....................... 18

Figure 3-1. CPC-DX Lifting eyebolt location. .............................................................................................. 20

Figure 3-2. Power Supply Input Connections ............................................................................................. 22

Figure 3-3. Wiring Connections for Master Designation ............................................................................. 23

Figure 3-4. PE ground connection localization and details......................................................................... 24

Figure 4-1. Isolation Valve OPEN / CLOSED Lever Position ..................................................................... 27

Figure 4-2. CPC-DX Unit with All Isolation Valves in CLOSED Position.................................................... 28

Figure 4-3. CPC-DX Unit CPC-II Unit #1 with Supply and Control Isolation Valves in Open Position....... 29

Figure 4-4. CPC-DX Unit With All Isolation Valves in OPEN Position........................................................ 30

Figure 4-5. CPC-DX Skid with CPC-II Unit #1 Control Isolation Valve in CLOSED Position ..................... 30

Figure 4-6. CPC-DX Status Link Disconnection Inside Main Terminal Box ............................................... 31

Figure 4-7. CPC-DX Unit to Unit Control Switchover – Switchover Action Typical Performance............... 32

Figure 4-8. CPC-DX Unit Control Takeover (Second Unit Shutdown Simulation)...................................... 33

Figure 4-9. CPC-DX Skid Pressure between CPC-II Units (Pressure Offset) at 20 cSt Oil Viscosity ........ 34

Figure 4-10. Tuning Runs Showing the Effect of Adjusted Primary Gain Example Parameter Values...... 35

Figure 4-11. Tuning Runs Showing the Effect of Adjusted Proportional Trim Example Parameter Values36

Figure 4-13. 38

Figure 4-14. Low LLC Parameter – Sluggish Response, Visible Controlled Unit Position Variation, and

Unit-To-Unit Performance Difference..................................................................................... 39

Figure 4-15. Low LLC Parameter – Slightly Sluggish Response, Still Visible Controlled Unit Position

Variation, and Unit To Unit Performance Difference.............................................................. 39

Figure 4-16. High LLC Parameter – Visible Controlled Unit Position Overshoot, Acceptable Unit-To-Unit

Performance Difference ......................................................................................................... 40

Figure 4-17. Pressure Gauge Untightening from Manifold ......................................................................... 40

Figure 4-18. Pressure Gauge Untightening From Adapter ......................................................................... 41

Table 1-1. Terms and Definitions.................................................................................................................. 7

Table 1-2. Woodward Reference Literature.................................................................................................. 7

Table 2-1. Environmental ............................................................................................................................ 16

Table 2-2. Physical...................................................................................................................................... 16

Table 2-3. Electrical .................................................................................................................................... 16

Table 2-4. Hydraulic .................................................................................................................................... 16

Table 2-5. CPC-DX Maximum Input/Supply Pressure................................................................................ 17

Table 2-6. Hydraulic parameters................................................................................................................. 17

Table 3-1. Fuse/Breaker Requirements...................................................................................................... 22

Table 5-1. List of available Replacement Kits............................................................................................. 42

Table 5-2. Troubleshooting ......................................................................................................................... 43