Manual 35132 VariStroke-DX Duplex Hydraulic Servo Skid

Woodward 2

Illustrations and Tables

Figure 1-1. Basic VS-DX Application and Configuration...............................................................................9

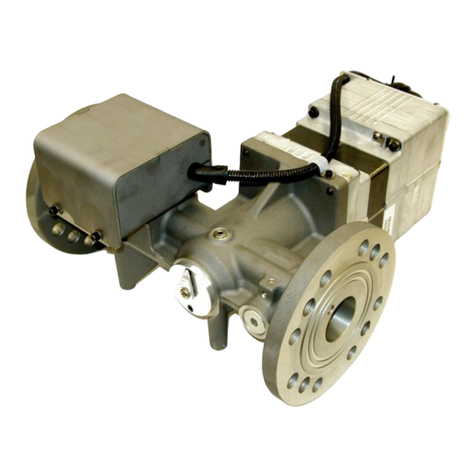

Figure 1-2. VS-DX Main Components (Junction Box Version)...................................................................10

Figure 1-3. VariStroke-DX, Junction Box Version, front view.....................................................................11

Figure 1-4. VariStroke-DX, Junction Box Version, Top View......................................................................11

Figure 1-5. VariStroke-DX, Junction Box Version, Bottom View ................................................................12

Figure 1-6. VariStroke-DX, Junction Box Version, Back View....................................................................12

Figure 1-7. VariStroke-DX, Junction Box Version, Side View.....................................................................13

Figure 1-8. VariStroke-DX, Without Junction Box Version, Front View......................................................14

Figure 1-9. VariStroke-DX, Without Junction Box Version, Rear View.......................................................14

Figure 1-10. VariStroke-DX, Without Junction Box Version, Bottom View.................................................15

Figure 2-1. VariStroke-DX, Hydraulic Schematic........................................................................................18

Figure 3-1. VS-DX Lifting Bracket Locations ..............................................................................................20

Figure 3-2. VariStroke-DX, Junction Box Version, Main Terminal Box, Wiring Points Access ..................22

Figure 3-3. VariStroke-DX, Junction Box Version, Main Terminal Block Connections Chart.....................23

Figure 3-4. VariStroke-DX, Junction Box Version, Wiring Diagram............................................................24

Figure 3-5. VariStroke-DX, VariStroke-DX, Without Junction Box Version, Wiring Diagram .....................25

Figure 3-6. Cylinder Position Sensor Connection Scheme.........................................................................26

Figure 3-7. PE Ground Connection Localization and Details, Junction Box Version .................................28

Figure 3-8. PE / Chassis Ground Connection Localization and Details, Without Junction Box Version (On

Both VS).................................................................................................................................28

Figure 4-1. Isolation Valve Lever Positions.................................................................................................33

Figure 4-2. VS-DX Unit Components Topology..........................................................................................34

Figure 4-3. VS-DX Unit with Both Servos Control Port Paths Isolated.......................................................34

Figure 4-4. VS-DX unit VS-GI Unit “A” with Control Isolation Valves in Open Position..............................35

Figure 4-5. VS-DX Unit with All Isolation Valves in OPEN (Not Isolating) Position....................................36

Figure 4-6. VS-DX Unit to Unit Control User Demanded Switchover Action Typical Performance............38

Figure 4-7. VS-DX Unit to Unit Control Switchover Action Typical Performance (One Unit Shutdown) ....39

Table 1-1. Definitions and Abbreviations ......................................................................................................7

Table 1-2. Woodward Reference Literature..................................................................................................7

Table 2-1. Environmental............................................................................................................................16

Table 2-2. Physical......................................................................................................................................16

Table 2-3. Electrical Specifications.............................................................................................................16

Table 2-3. VS-DX without Junction Box Version (to Each VS Unit)............................................................17

Table 2-4. Cylinder Position Sensor Requirements....................................................................................17

Table 2-5. Hydraulic Specifications.............................................................................................................18

Table 3-1. Recommended Fuse Ratings or Circuit Breakers.....................................................................27

Table 5-1.List of available Replacement Kits..............................................................................................40

Table 5-2. Trouble Shooting Data...............................................................................................................42