CONTENTS

1 Safety Precautions..................................................................................5

2 General Information...............................................................................6

2.1 Machine Description........................................................................6

2.2 Characteristics .................................................................................6

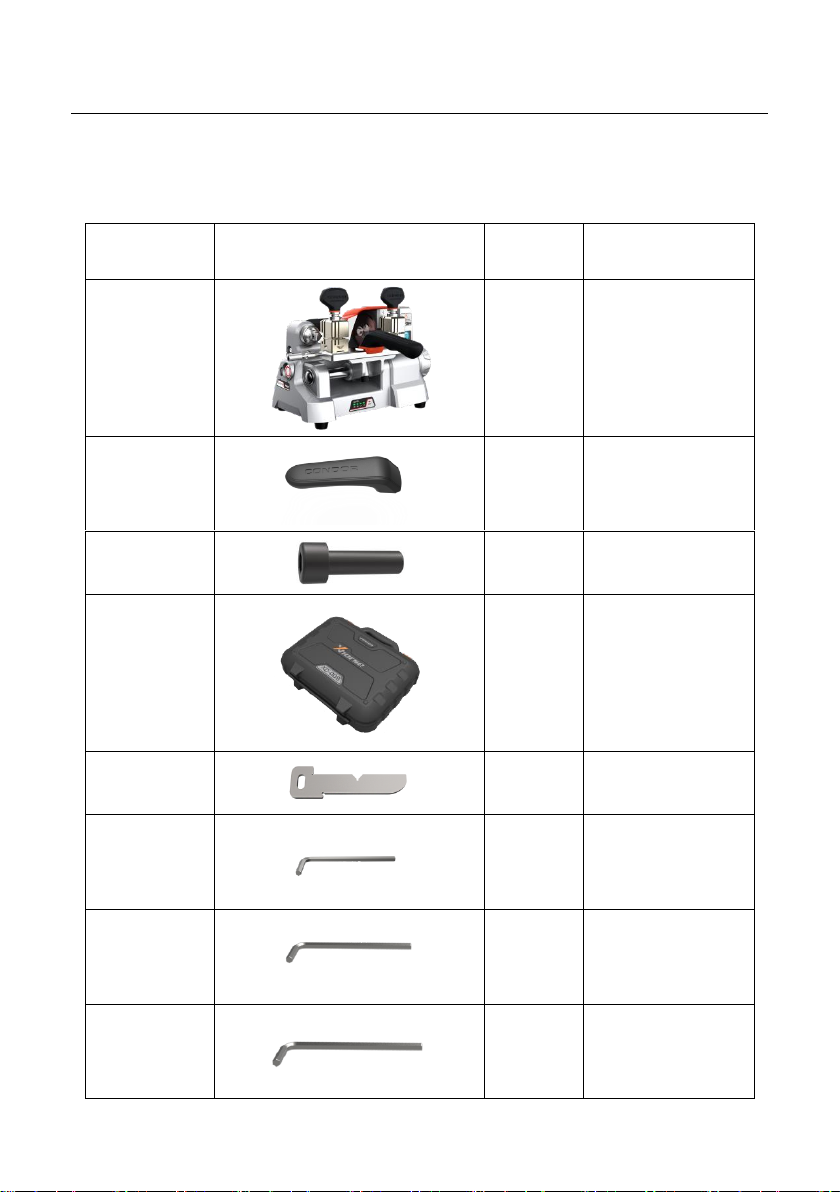

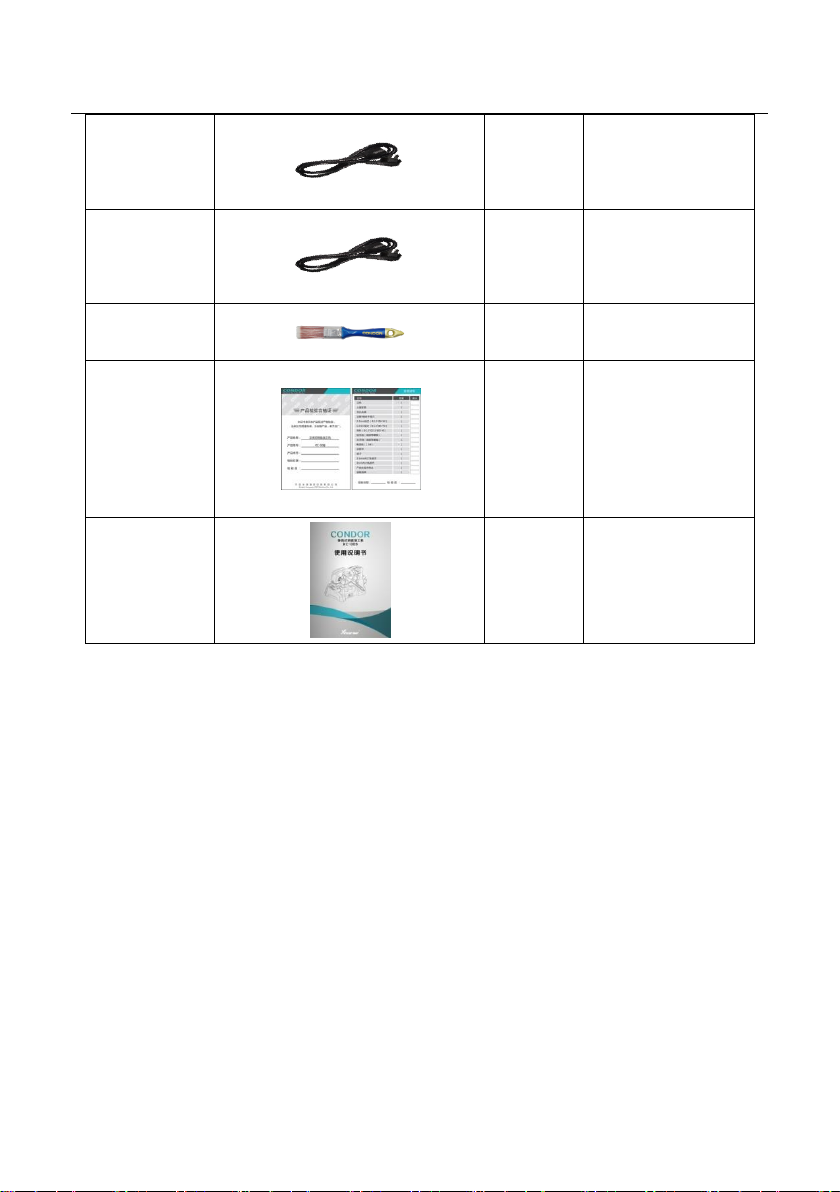

3 Product Packaging Checklist...................................................................7

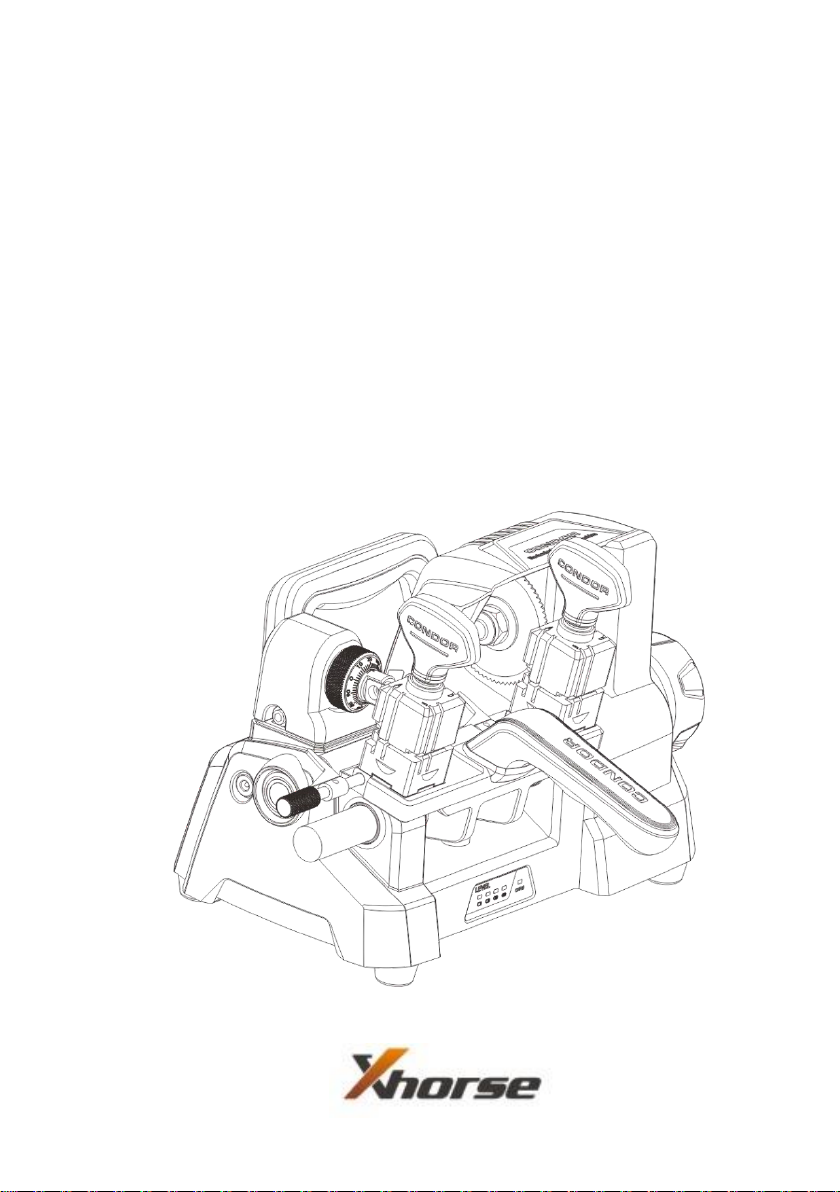

4 Overview...............................................................................................10

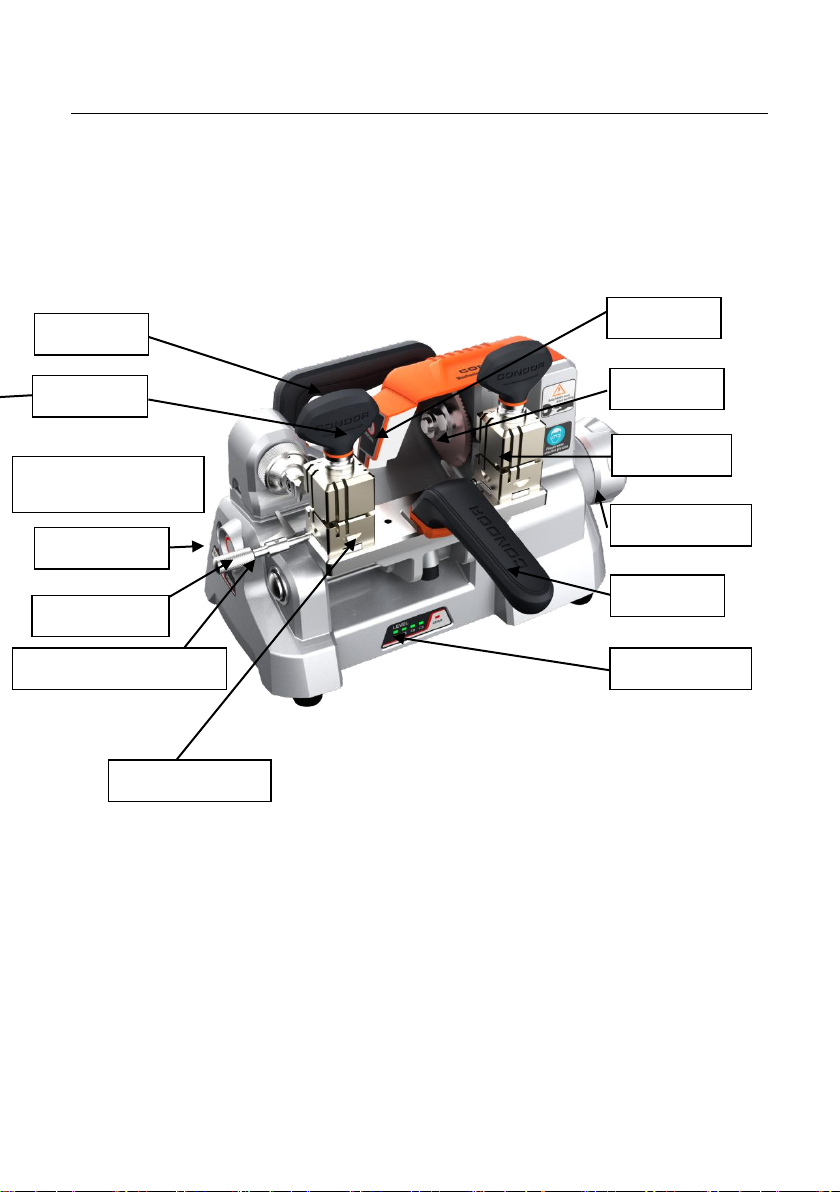

4.1 Schematic ......................................................................................10

4.2 Specifications.................................................................................11

4.3 Main Parts and Function Declaration............................................13

4.3.1 Hand Wheel............................................................................13

4.3.2 Skid Platform ..........................................................................14

4.3.3 Micro-adjust slide...................................................................15

4.3.4 Clamp......................................................................................16

4.3.5 Power Parts.............................................................................17

5 Equipment Installing and Debugging....................................................18

5.1 Handle Installing............................................................................18

5.2 Cutter Installing .............................................................................19

5.3 Micro-adjust Slide Calibration.......................................................20

5.3.1 Lateral Micro-adjust Slide Calibration....................................21

5.3.2 Longitudinal Micro-adjust Slide Calibration ...........................22