Extension ED module

XD-4GBOX-ED

Fast manual

Thanks for purchasing XINJE XD series PLC and extension module. This manual will

introduce the electric features and using method of XD series extension ED module. Please

read this manual carefully before using the products, make sure the wiring operation is safe.

Features of analog extension module

XD-4GBOX-ED

Remote diagnosis of equipment fault

Equipment after-sales maintenance, such as air compressor

Ensure the test equipment data is real and reliable, such as Li battery test

Intellegent city construction, such as sewage treatment, waste recycling, cold

storage

Intellegent agriculture and car industries, smart home

Safety precautions

Control system design attentions

Dangerous!

Make sure design the safety circuit, to ensure that the control system can still work

safety when the external power supply cut off or PLC broken.

Make sure set emergency braking circuit, protection circuit, interlock circuit of forward-

reverse running in PLC external circuit and upper-lower limit switch to prevent from

machine damage.

In order to make the equipment safe operation, please design external protection circuit

for important output signal.

PLC CPU will close all the output when detecting the system error; the output will lose

control when the PLC circuit has problem. Please design suitable external control circuit

to ensure the device working normally.

If the PLC relay or transistor unit is broken, the output cannot be ON or OFF.

The PLC is designed for indoor environment, the lightning protection must be installed

in the power supply system to avoid PLC and other device damage.

Installation and wiring attentions

Dangerous!

Do not use the PLC in the following environment: dust, soot, corrosive gases,

flammable gas, high temperature, condensation, vibration, impact, lightning, fire.

Do not let the metal scrap and wire head drop into the ventilation hole of PLC, otherwise

it will cause fire or error operation.

Do not cover the ventilation hole of PLC, otherwise it will cause fire, error operation.

The I/O wiring must be fixed enough, otherwise the bad contactor will cause fault.

Attention!

It can use external power supply for extension module DC24V power.

Please use shield cable for high frequency I/O wiring to avoid interference.

Run and maintenance

Dangerous!

Please connect all the cable include PLC, extension module and BD board after shutting

down the power supply.

Please operate as the manual for online operation, forced output, RUN, STOP.

Attention!

Please discard the product as industrial waste.

Make sure cut off the power supply when installing or uninstalling the extension card.

Product information

Naming rule

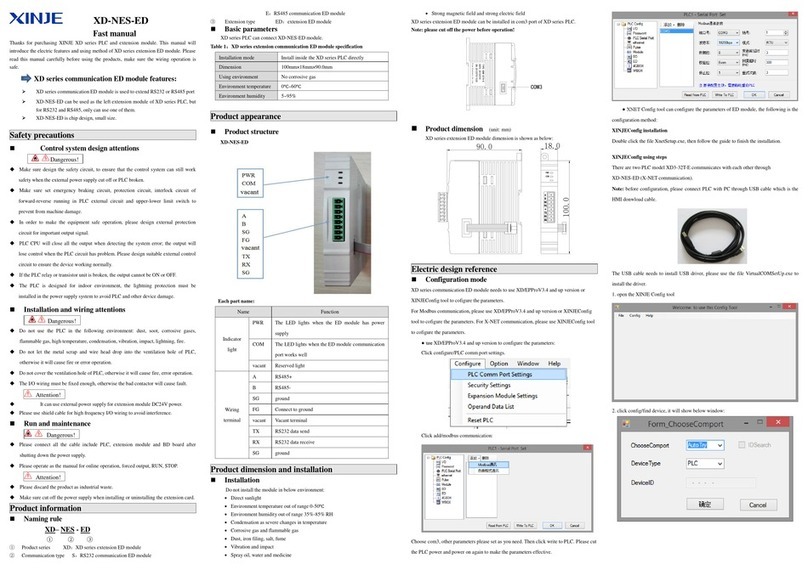

XD–4GBOX - ED

①②③

①Product series XD: XD series extension module

②Module name 4G: 4G communication module

③ED left extension

Basic parameters

XD series PLC can connect 1 extension ED module, the type is not limited.

Table 1: analog extension module XD-4GBOX-ED general specifications

Fix with M3 screw or install on the rail DIN46277(width

35mm)

的导轨上

Table 2: analog extension module XD-4GBOX-ED product features

GSM/GPRS: 900, 1800MHz EDGE: 900, 1800MHz

UMTS: CDMA2000(BC0), WCDMA(B1, B8),

TD-SCDMA(1.9G, 2G)

LTE: FDD(B1, B3, B8) TDD(B38, B39, B40, B41)

GNSS: GPS, GLONASS

GSM/GPRS: 2W EDGE: 0.5W

UMTS: 0.25W LTE: 0.25W

Product appearance

Product structure

Product dimension and installation

Product dimension (Unit: mm)

XD series extension ED module XD-4GBOX-ED dimension is shown as below:

Installation

Please connect the extention cable of XD-4GBOX-ED to XD series PLC left ED port, and

install with screw or fix on DIN46277 rail.

Note:

(1) Please do not let the chip and wire cuttings fall into the module when installing.

(2) Please confirm the module and equipment specification before wiring.

(3) Please pay attention to whether the connection is fixed and the loss of connection will

cause incorrect data and short circuit. The installation, wiring and other operation must

be done after the power supply is cut off.

Electric design reference

Structure

Terminals

Note: the view direction is facing the module at front side, the terminal sequence from up to

down is +24V, 0V, FG. The module power supply voltage is 24V DC, the range is DC21.6V

to 26.4V.

Status indicator

Module and PLC serial port connection succeeded

Log on target server succeeded

Visit telecom operator and build the network

Signal strength

The module running state, 4GBOX visiting server succeeded. L0~L3 show the signal

strength of network. In error state, L0~L3 will show the error type, please see below table:

No SIM card or SIM card insert error

4GBOX cannot open the network (SIM

card arrears or not open the data traffic

service)

4GBOX not configure server information

DIP switch

If the serial port configuration of 4GBOX is error and cannot connect the PLC, please turn

on switch 1, then repower on the module to restore the out of factory parameters. The

configured serial port connection flag, signal strength flag, SIM binding flag, white list still

exist, no need to configure again. But remote parameters and serial port parameters are back

to default value.

Back to default parameters when re-power on

Factory mode (XD-4GBOX-ED)

Configuration mode (4GBOX-M)

Initialization time

The module initialization time is depend on the telecom operator. The table shows the time

of Chinese telecom operators:

Using steps

Preparation

Open the function of data traffic for the Nano SIM card

Open the message function (optional)

XD series PLC hardware V3.4.5 and up

XD/EPPro programming software V3.5 and up

XD series PLC programming cable

PC (enable to visit internet, installed XD/EPPro software)

Module configuration

4GBOX is the left extension ED module of XD series PLC, the configuration needs

XD/EPPro software and Config tool. Please make sure the PLC hardware version is V3.4.5

and up, XD/EPPro version is V3.5 and up, XinjeConfig tool version is v1.6.343 and up.

Serial port

XD series PLC serial port communication protocol includes Modbus RTU, XNET

(OMMS/TBN/PPFD), free format protocol. For 4GBOX, PLC serial port protocol must set

to XNET-PPFD, physical layer is TTL. The baud rate must be same. Network number,

station number is recommended to use default parameters.

PWR

COM

LINK

+24V

0V

FG

NETSTATUS

SIM

4G

PWR

COM

LINK

+24V

0V

FG

NETSTATUS

SIM

4G