3

Index

.................................................................................................................................................................1

Introduction .............................................................................................................................................5

Safety information ...................................................................................................................................6

•Definitions of warning words and symbols .........................................................................................6

•Reporting terms: .................................................................................................................................6

•Additional documents for safety.........................................................................................................7

•Use according to destination...............................................................................................................7

•Basic requirements for a safe use .......................................................................................................7

•Unauthorized use ................................................................................................................................7

•Device maintenance............................................................................................................................7

•Responsibility of the owner of the instrument ...................................................................................8

Instrumental features ..............................................................................................................................8

•Parameters ..........................................................................................................................................8

•Datasheet ............................................................................................................................................8

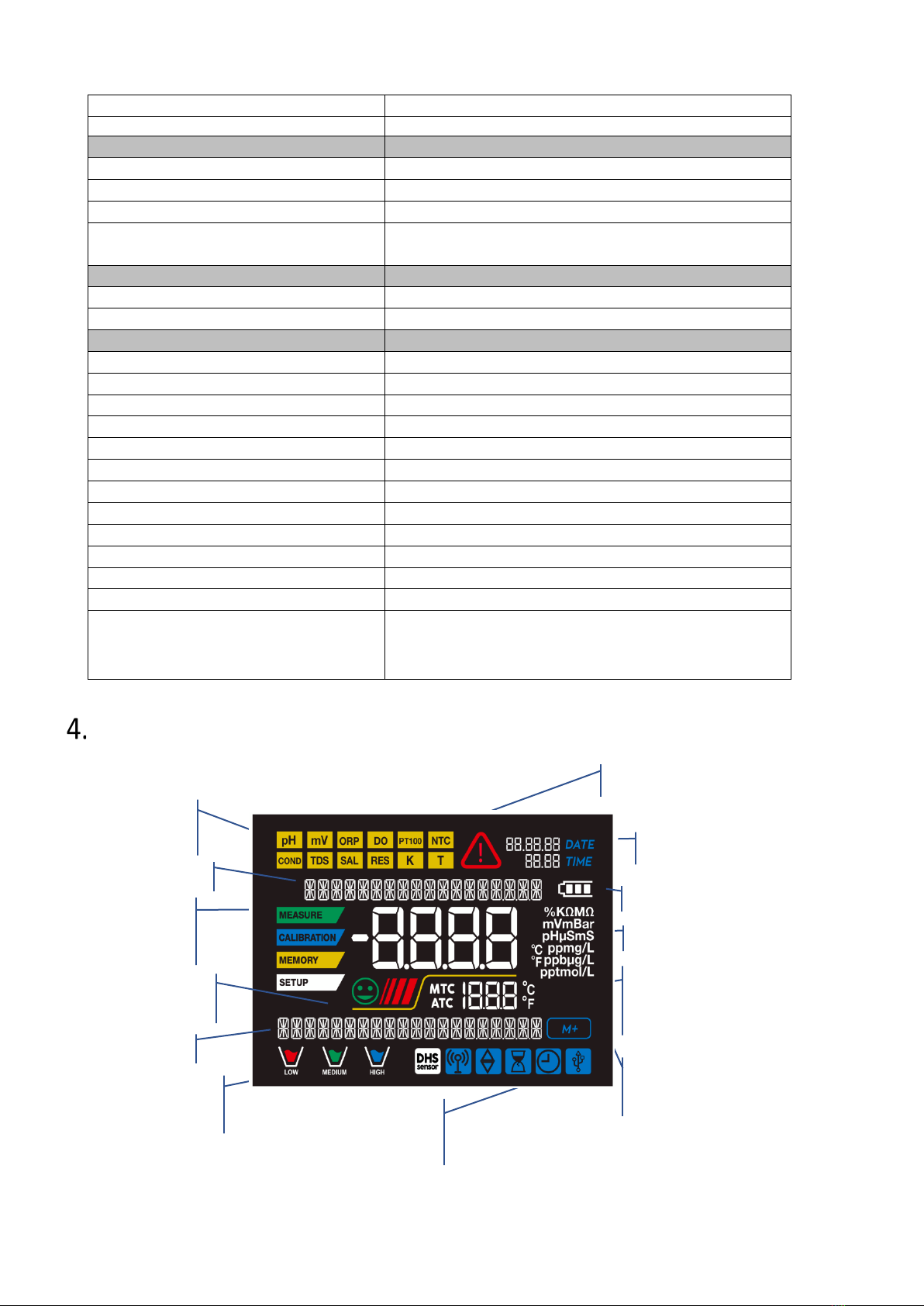

Instrument description ............................................................................................................................9

•Display .................................................................................................................................................9

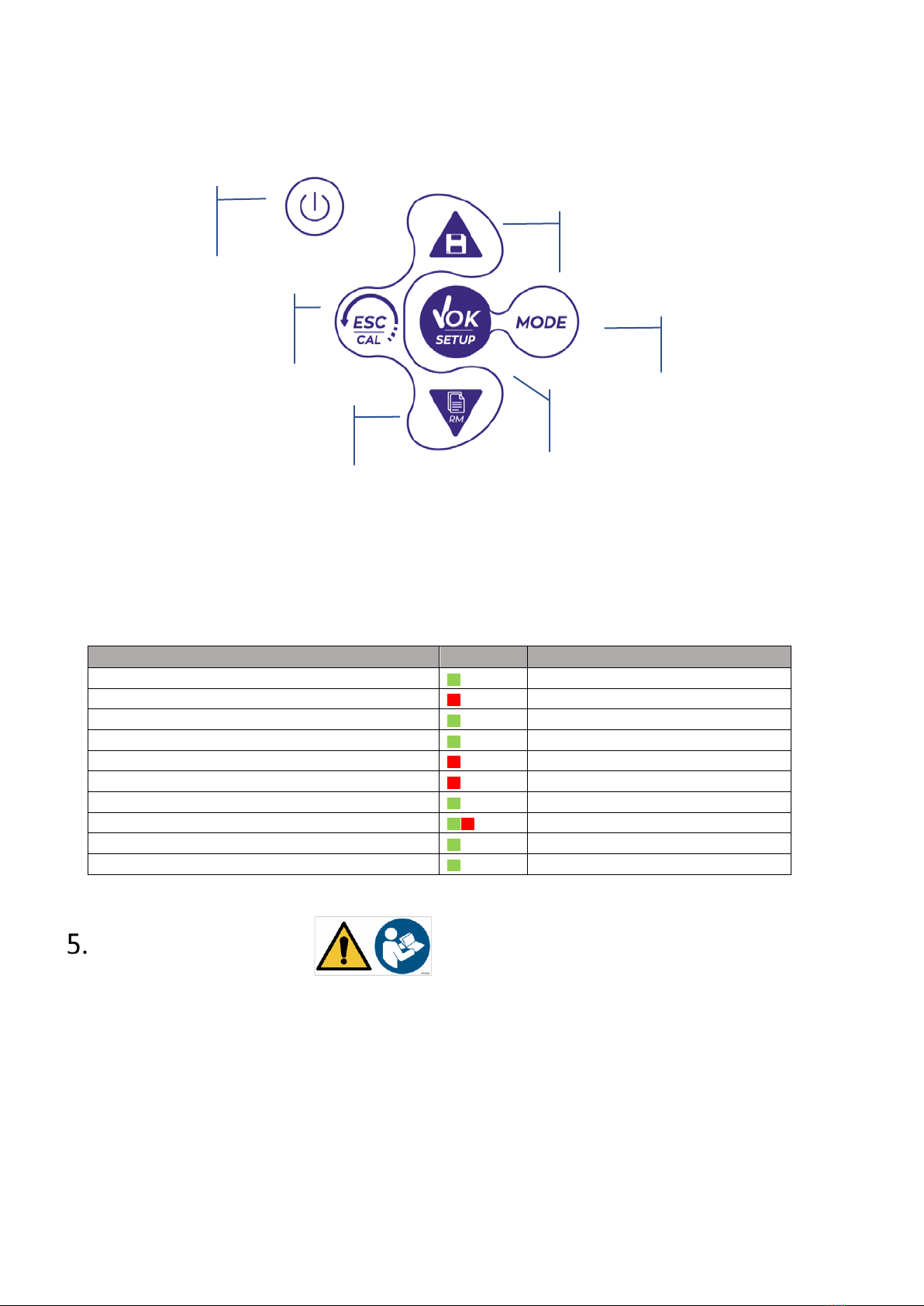

•Keyboard ...........................................................................................................................................10

•LED.....................................................................................................................................................10

Installation .............................................................................................................................................10

•Supplied components........................................................................................................................10

•Start-up..............................................................................................................................................11

•Connection of the power supply.......................................................................................................11

•Power on, date and time update, power off.....................................................................................11

•Replacement of batteries..................................................................................................................12

•Instrument transportation ................................................................................................................12

•Key functions.....................................................................................................................................12

•Inputs / Outputs connections ...........................................................................................................13

READ THE MANUAL BEFORE PROCEEDING TO CONNECT THE PROBES OR PERIPHERALS ........................13

•Symbols and icons on the display .....................................................................................................13

Operation of the device.........................................................................................................................14

Setup menu ...................................................................................................................................15

•Setup Menu Structure .....................................................................................................................16

Temperature measurement ATC – MTC ....................................................................................16

%O2 Parameter .............................................................................................................................17

•O2parameter Setup ..........................................................................................................................17

•Composition of the Setup menu for O2 Parameter...........................................................................17

•Information about LDO70 probe.......................................................................................................19