9

Need help or have any questions? Email us at service@globalhobby.net

Engine Break-In

☛XTM .15 series engines are ABC engines. The cylinder

sleeve is tapered at the top, causing severe resistance when the

piston moves through the top of the stroke. This is normal. When

the engine heats up to operating temperature, this resistance will

decrease and the proper clearance will be achieved. The break-

in procedure will guide you through the steps necessary to prop-

erly break in your new XTM .15 series engine. Please follow

the steps closely.

☛The break-in process allows the engine parts to perfectly

fit to each other and properly protect each part from premature

wear. The engine should be broken in using a good quality R/C

car fuel that contains no more than 20% nitromethane.

❑Follow steps # 17 through # 22 in the Quick-Start Guide to

fill the fuel tank and to become familiar with the engine's start-

ing and shut down procedures.

❑Once the engine starts, keep the glow starter attached to

the glow plug and let the engine to run for about 1 minute with-

out giving it throttle. This will allow the engine to warm up. At

this point the engine should be running very “rich” and there

should be excessive white smoke coming from the exhaust pipe.

❑After the engine has been running for about 1 minute, re-

move the glow starter from the glow plug. Advance the throttle

in short, quick bursts and drive the truck around for about 2-3

minutes. If the engine is running rich enough, you should notice

excessive white smoke coming from the exhaust and the engine

should sound like it’s running very rough. Also, the truck will

barely be moving. If there is not excessive white smoke coming

from the exhaust, richen the high speed needle valve. After 2-3

minutes stop the engine by pinching the fuel line to the carbu-

retor (see Quick-Start Guide, step # 22).

❑Let the engine cool for approximately 10 minutes, then re-

startit. Setthehighspeedneedlevalve mixture to a slightly leaner

setting, about 1/8 turn more in. Repeat the step above then stop

the engine and let it cool for approximately 10 minutes.

❑Repeat the procedure in the step above, while leaning the

needle valve slightly more each time. In all, you should run the

engine a total of about 30 minutes. After 30 minutes of run-time

the engine will be broken in. Run the engine with the needle

valve set slightly rich, but lean enough to power the truck. At

this point the engine should hold a good setting on the high

speed needle valve and you can begin to fine tune the needle

valve settings to increase performance.

WARNING - Please Read Before Starting your Engine

If at any time the pull-start becomes very tight or difficult to pull - STOP! The engine has become flooded and the excess fuel must be

removed or damage to the pull-start and/or engine could occur. To remove the excess fuel from the engine follow the steps listed below:

❑Completely close the high speed needle valve (turn clockwise) until it bottoms out.

❑Remove the glow plug from the cylinder head.

❑With the top of the engine pointing away from you, pull the pull-start cord several times to clear the excess fuel from the engine.

❑Check to make sure the glow plug has not been fouled, then reinstall it.

❑Reset the high speed needle valve 2-1/2 turns out from bottom.

☛Itisoftheutmostimportancethat the engine never be leaned

out too much. When running the engine, you should always be

able to see a trail of white smoke coming from the exhaust pipe.

If you can’t, stop the engine immediately and richen the mix-

ture. You should also make sure there is plenty of air flowing

over the cylinder head to keep the engine from overheating.

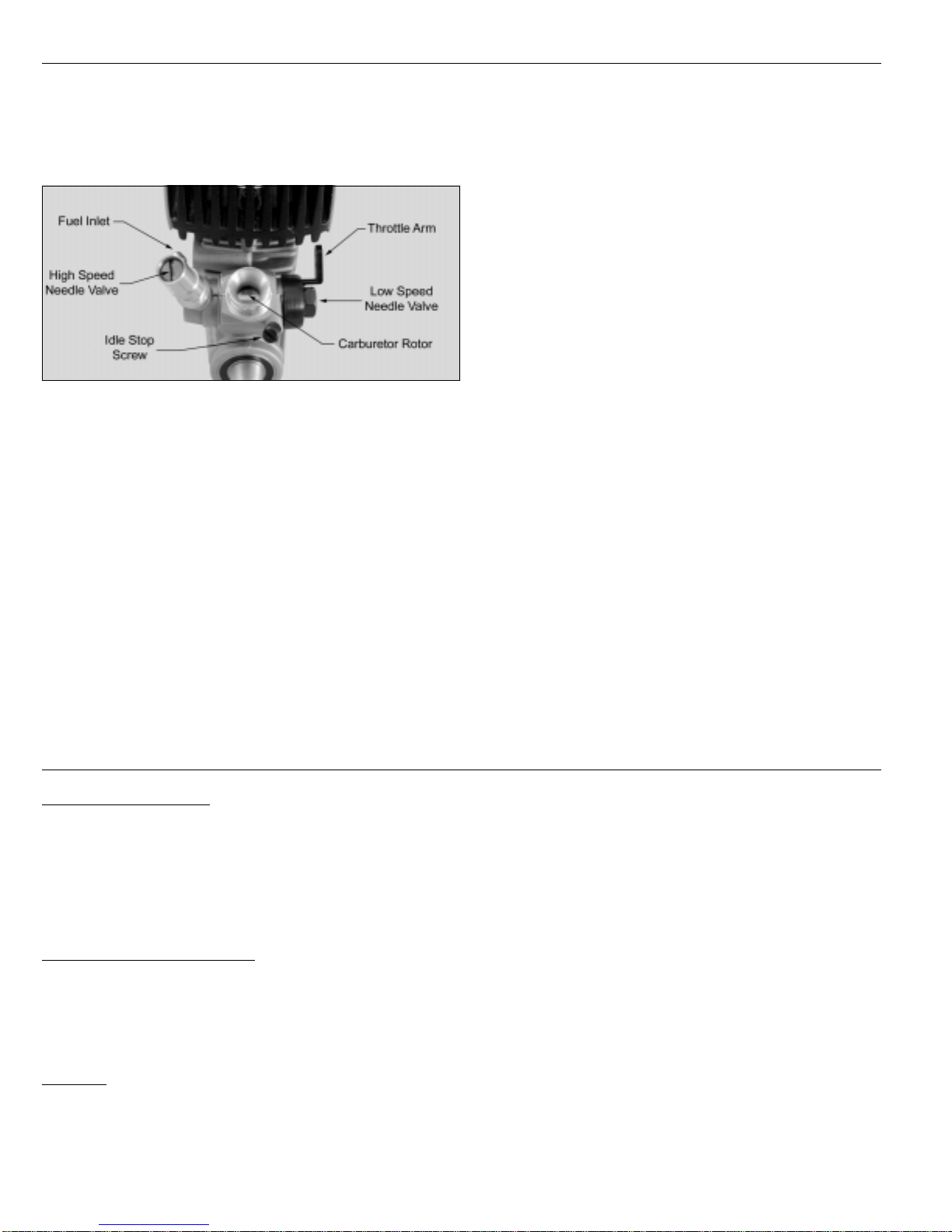

Fine Tuning Your XTM Engine

After your engine has been broken-in, you can set the high and

low speed needle valves for optimum engine performance.

☛Be careful to never lean the engine out too much. Re-

member that the lubricants for your engine are suspended in

the fuel. If you lean out the fuel mixture too much you will

also be lowering the amount of lubricant entering your engine.

Less lubricant means more chance of your engine overheating

and possible engine failure.

Setting the High Speed Needle Valve

❑Start the engine and remove the glow starter from the glow

plug. Allow the engine to warm up for about 1 minute.

❑After the engine has warmed up, drive the car as you nor-

mally would. If the engine seems to be running rich, lean the

mixture screw about 1/16 of a turn at a time until the desired

setting is achieved. Always make sure you run the engine slightly

rich - you want to be able to see a white exhaust trail at all times.

❑To get more power from your engine you can use fuels

containing up to 30% nitromethane. We must caution you,

though, that once you run the engine with increased nitro you

may not get satisfactory results if you decide to go back to a

lower nitro content. Also, if you use fuels containing 30% nitro,

we highly suggest replacing the stock .01mm head gasket with a

thicker .02mm head gasket (available separately: P/N 148186)

to lower the compression ratio. If you don’t lower the compres-

sion ratio, overheating and erratic running will likely occur.

Setting the Low Speed Needle Valve

❑Start the engine and lean out the high speed needle valve

as per the previous steps. Close the throttle until the engine slows

down enough so that the clutch is disengaged and the wheels

don’t turn when the car is lifted from the ground. Allow the

engine to idle for about 10-15 seconds.

Continued on Next Page