Page 2

TABLE OF CONTENTS

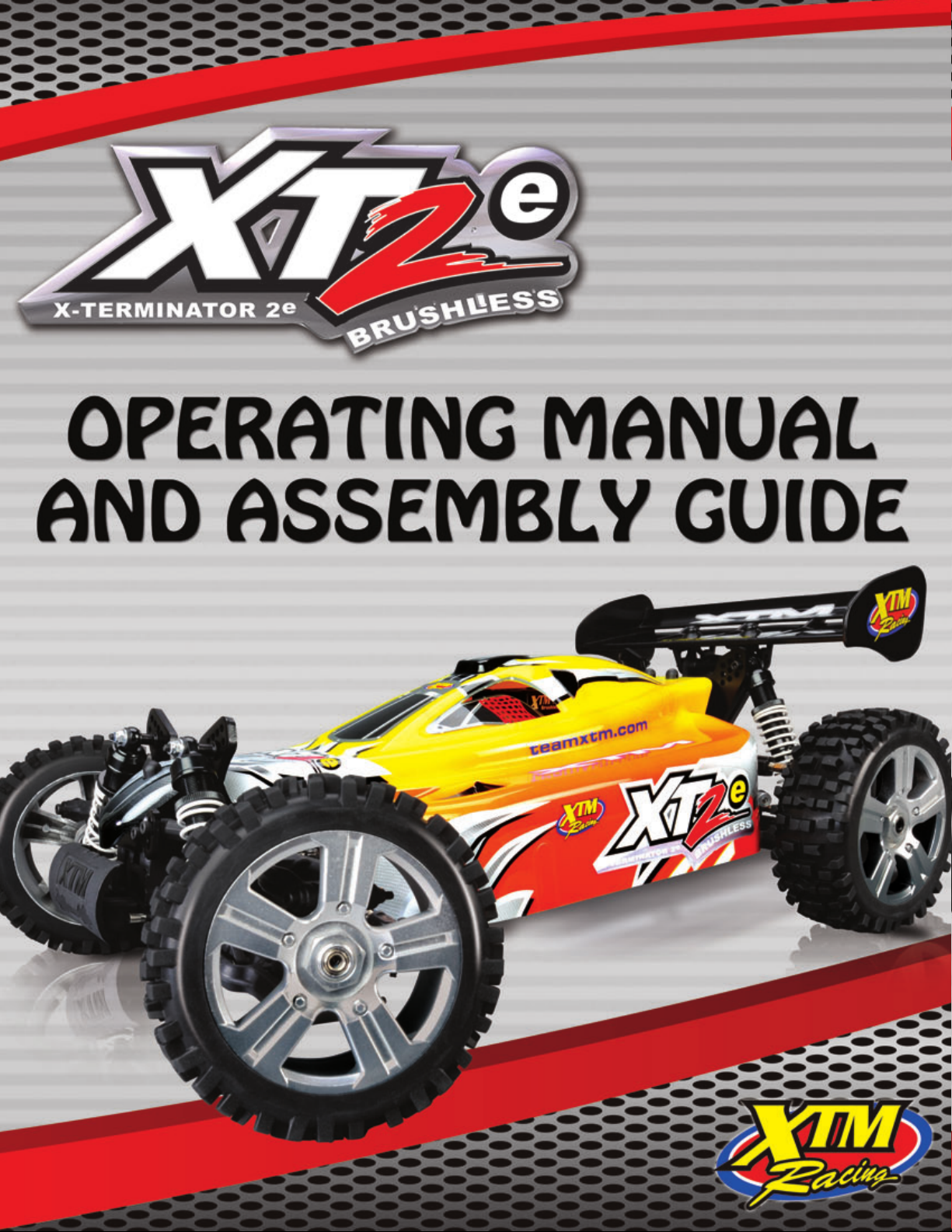

Before operating your new X-Terminator 2e, please read and understand the warnings listed on the next page. Failure to do

so could lead to injury and/or property damage. The X-Terminator 2e is not intended for persons under 14 years of age, unless

closely supervised by an adult.

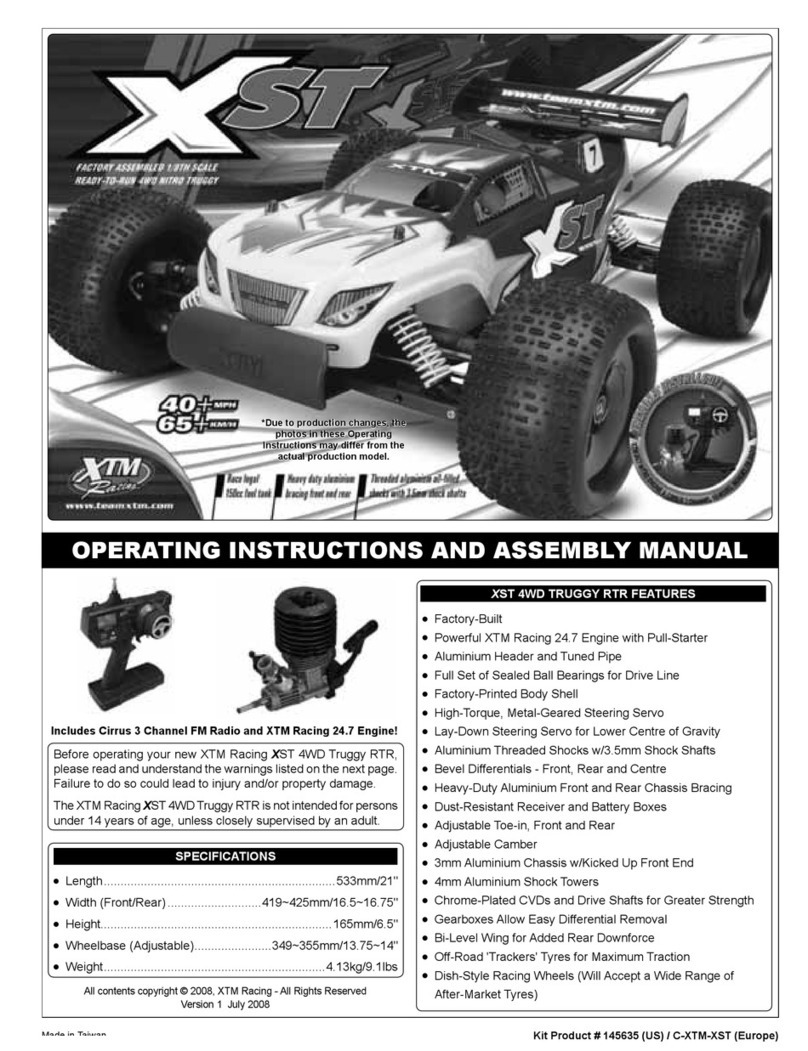

l Heavy-Duty Aluminium Front and Rear Chassis Bracing

l Balanced Weight Distribution for Stable Handling

l Adjustable Toe-in, Front and Rear

l Adjustable Camber, Front and Rear

l 4mm Aluminium Shock Towers

l Heavy-Duty Drive-Line with Chrome-Plated Front CVDs

l Complete Hex Head Steel/Alloy Screw Set

l Gearboxes Allow Easy Differential Removal

l Adjustable Differentials with the Use of After-Market Silicone Oils

l High-Grip, All-Terrain Tyres Mounted on Satin Chrome Wheels

l Optional Parts Available for Increased Performance and Handling

l Weight (Without Batteries) .............................................................................................................................................. 3.63kg (8.0lbs)

l Length ............................................................................................................................................................................. 483mm (19.0")

l Width ............................................................................................................................................................................... 305mm (12.0")

l Height (Measured to the Top of the Body Shell with Settled Suspension) ........................................................................ 154mm (6.1")

l Wheelbase (Adjustable) ....................................................................................................................324mm ~ 330mm (12.75" ~ 13.0")

l Factory-Assembled with Factory-Printed Body Shell

l Uses 6 ~ 12 Cell Ni-MH Batteries or 2 ~ 4 Cell Li-Po Batteries

l High-Current Sensored/Sensorless Electronic Speed Controller

l High-Powered 1/8th Scale Brushless Motor

l Program Card for Customised Electronic Speed Controller Settings

l Electronic Speed Controller Cooling Fan and Motor Heat-Sink

l Full Set of Sealed Ball Bearings for Drive-Line

l High-Torque Metal-Geared Steering Servo

l Lay-Down Steering Servo for Lower Centre of Gravity

l Fully-Threaded Aluminium Shocks with 3.5mm Shock Shafts

l Bevel Differentials - Front, Rear and Centre

INTRODUCTION

Thank you for your purchase of the XTM Racing X-Terminator 2e Brushless 4WD Buggy. The X-Terminator 2e is a high-quality, powerful,

1/8th scale brushless-powered buggy that offers both the casual user and the racer tremendous value. Whether it's racing on the track

or just bashing in a eld, the X-Terminator 2e is ready to tear up the terrain and carve through the curves with ease.

This Operating Manual is designed to help you get your X-Terminator 2e up and running as quickly as possible. In addition to basic

information about your new model, this Operating Manual includes pro tips, a chassis tuning guide, detailed exploded view assembly

drawings and a complete replacement parts list with option parts. Be sure to keep this Operating Manual handy for future reference!

n

X-Terminator 2e Features

n

X-Terminator 2e Specications

Introduction ...................................................................................... Page 2

X-Terminator 2e Features ............................................................ Page 2

X-Terminator 2e Specications .................................................... Page 2

Customer Service Information ......................................................... Page 3

Safety Warnings and Important Information .................................... Page 3

General Warnings ........................................................................ Page 3

Brushless Power System Warnings and Information .................. Page 3

Lithium Polymer (Li-Po) Battery General Warnings ..................... Page 4

Battery Instructions for Disposal .................................................. Page 4

Kit Contents ..................................................................................... Page 4

Items Required to Operate and Maintain......................................... Page 5

Battery Requirements .................................................................. Page 5

Miscellaneous Requirements ...................................................... Page 5

ESC Programming Card Requirements ...................................... Page 5

Becoming Familiar with Your X-Terminator 2e ................................ Page 6

Chassis Component Overview .................................................... Page 6

Brushless Power System Overview ............................................ Page 7

Tips From the Pros .......................................................................... Page 8

Preparing to Run Your X-Terminator 2e .......................................... Page 8

Transmitter and Receiver ............................................................ Page 8

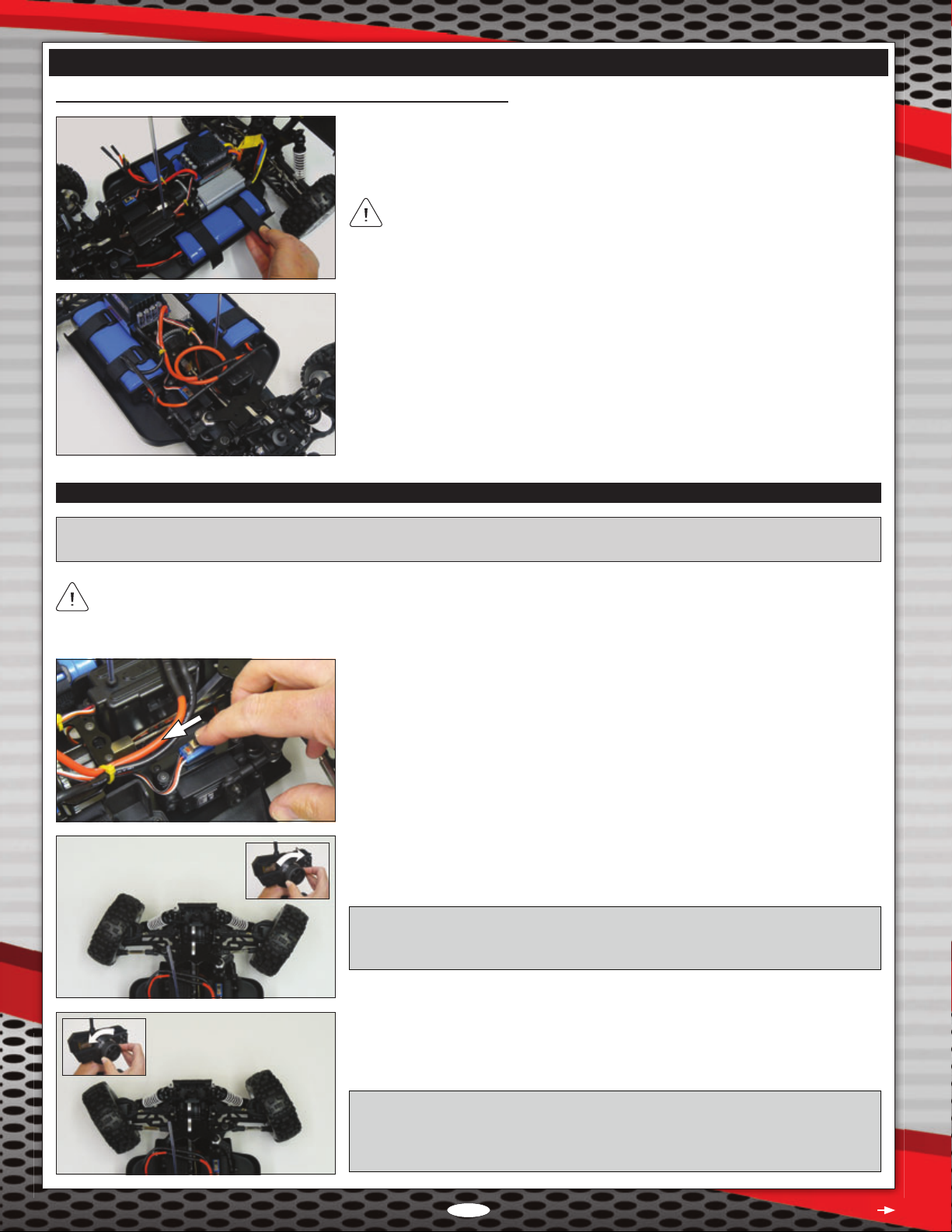

Battery Pack Installation and Power Connections ....................... Page 9

Checking the Steering and Throttle Controls............................. Page 10

Throttle Control Range Calibration ............................................ Page 11

Using the ESC Programming Card ........................................... Page 11

Installing the Body ..................................................................... Page 13

Chassis Tuning Guide ................................................................... Page 14

Adjusting Toe Angle - Front and Rear........................................ Page 14

Adjusting Gearing ...................................................................... Page 14

Adjusting Camber Angle - Front and Rear ................................ Page 15

Adjusting Shock Spring Tension - Front and Rear..................... Page 15

Changing Shock Springs - Front and Rear ............................... Page 16

Adjusting Shock Damping - Front and Rear .............................. Page 16

Adjusting Shock Mounting Positions - Front and Rear .............. Page 16

Adjusting Bump Steer - Front .................................................... Page 17

Adjusting Droop - Front and Rear ............................................. Page 17

Adjusting Steering Sensitivity - Front ........................................ Page 17

Adjusting the Differentials - Front, Centre, and Rear................. Page 18

Maintenance Guide ....................................................................... Page 19

Adjusting Gear Mesh ................................................................. Page 19

Troubleshooting Guide .................................................................. Page 20

Exploded View Assembly Drawings .............................................. Page 21

Replacement Parts List ................................................................. Page 49

Option Parts List ............................................................................ Page 54

Returning Your Product for Warranty Repair ................................. Page 59

Warranty Information ..................................................................... Page 59