2

ENGINE WARNINGS

●Never use any fuel in your engine other than glow fuels

specifically designed for use in model car engines. Use of any

other types of fuel can cause severe damage to your engine and/or

personal injury. NEVER USE GASOLINE OR DIESEL FUEL!

●Never operate your model on any public streets. This could

cause traffic accidents, personal injury or property damage.

●Glow fuel engines emit exhaust vapors that are poisonous and

can be dangerous to your health. It is important that you operate

your engine in a very well-ventilated area, preferably outdoors.

●Before starting your engine, make sure that the throttle trim is

set to the idle position. Starting your engine at any setting above

idle can cause the model to lurch out of your hands.

●When your engine is running, there are certain parts that

rotate at high speeds. Be careful not to touch the drive shafts,

gears, clutch assembly or any other moving parts. Otherwise,

serious injury could result.

●It is normal for your engine and tuned pipe to get very hot

during operation. Never touch these parts while they are hot or

you could be burned.

●Model car engines produce vibration when they are running. It

is important to periodically check the engine mounting screws

and other assemblies to ensure they are tight. Running your

engine with the engine mounting screws loose can lead to

severe engine and/or chassis damage.

FUEL WARNINGS

●Glow fuels like those used in your model are poisonous.

Follow all the precautions that are printed on the fuel

manufacturer's container.

●Keep glow fuel out of the reach of children.

●Glow fuel is extremely flammable. Keep away from high heat,

sparks and flame.

GENERAL WARNINGS

●Under no circumstances should you operate your model in

crowds of people. Serious injury could result.

●Never operate your model on busy streets or if there are cars

around.

●Do not use your model to chase pets or other animals.

●The receiver and battery boxes are not waterproof; therefore,

do not drive through water, wet grass, mud or snow.

●Because your model is operated by radio control, it is important

to make sure you always are using fresh and/or fully charged

batteries. Never allow the batteries to run low or you could lose

control of the model.

●If your model becomes stuck, allow the engine to idle, then

retrieve your model by hand.

●To prevent excessive r.p.m.'s from damaging your engine and/or

drivetrain components, we suggest reducing throttle while in the

air during jumps.

FOR YOUR SAFETY - PLEASE READ THESE WARNINGS FIRST!

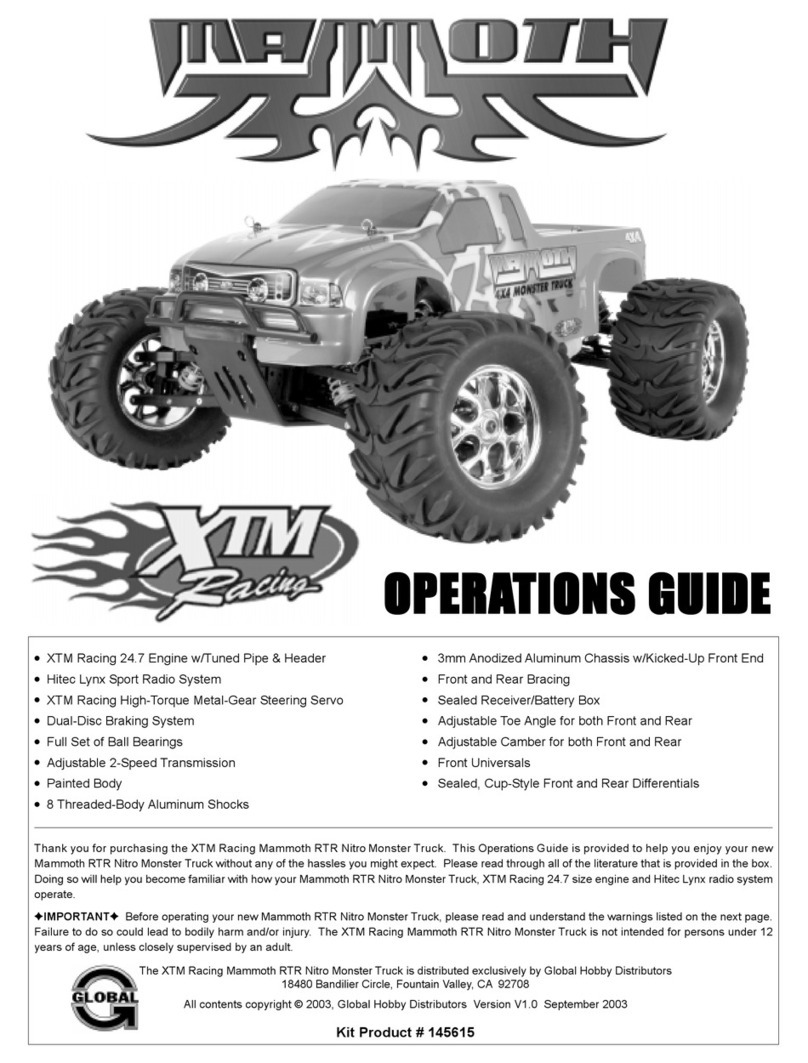

CUSTOMER SERVICE INFORMATION

If you should have trouble with any of the steps listed in these pages, or if you find a missing or damaged part in your kit, please contact

us at the address below:

Global Services

18480 Bandilier Circle

Fountain Valley, CA 92708

Phone: (714) 963-0329 Fax: (714) 964-6236 Email: service@globalhobby.net

To allow us to serve your needs better, please include your email address with any correspondence you send to us. Your email address will be added to our Customer

Service Database so you will automatically receive free updates and tech notices for your particular product. You will also receive repair status updates (if applicable) and

other important information about your product as it becomes available.

IMPORTANT INFORMATION ABOUT YOUR EMAIL ADDRESS

Global Hobby Distributors will not disclose the information it collects to outside parties. Global Hobby Distributors does not sell, trade, or rent

your personal information to others . Your privacy is important to us.

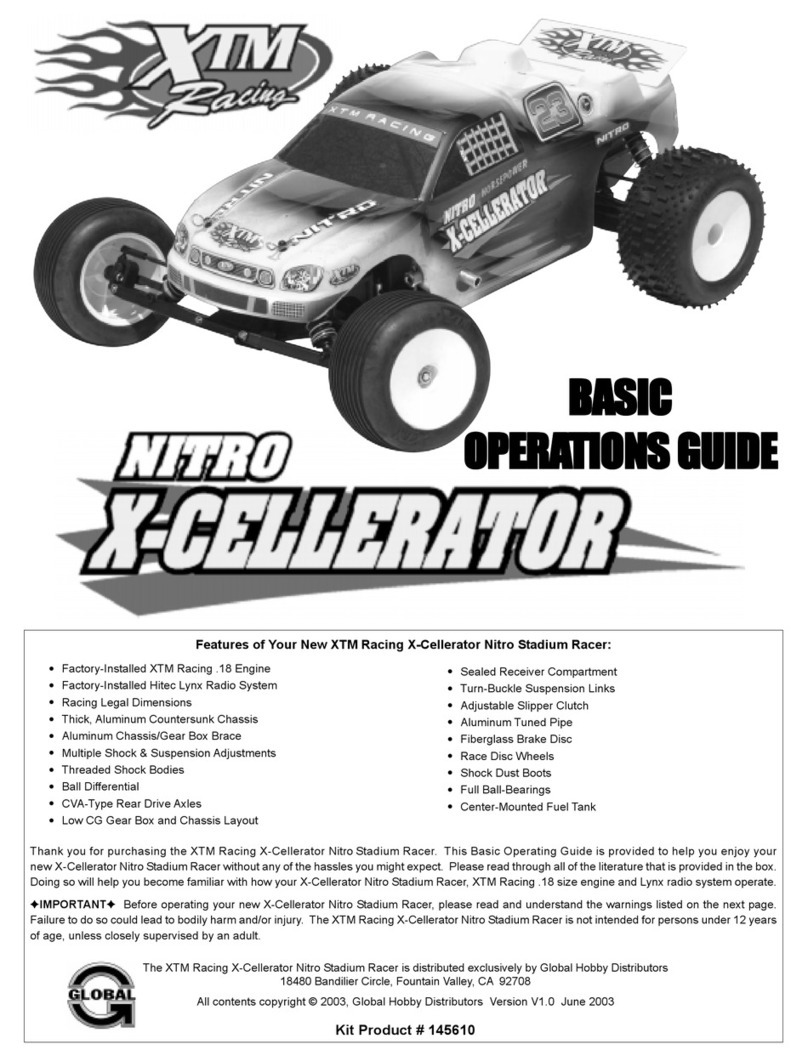

CHECK IT OUT! We urge you to come check out our website at http://globalservices.globalhobby.com. There you will find public message boards

frequented by other XTM Racing product owners and the XTM Racing support staff. This is a great place to learn about new XTM Racing products,

get help and suggestions for your current XTM Racing products or just simply hang out and chat with people that share your same interests.

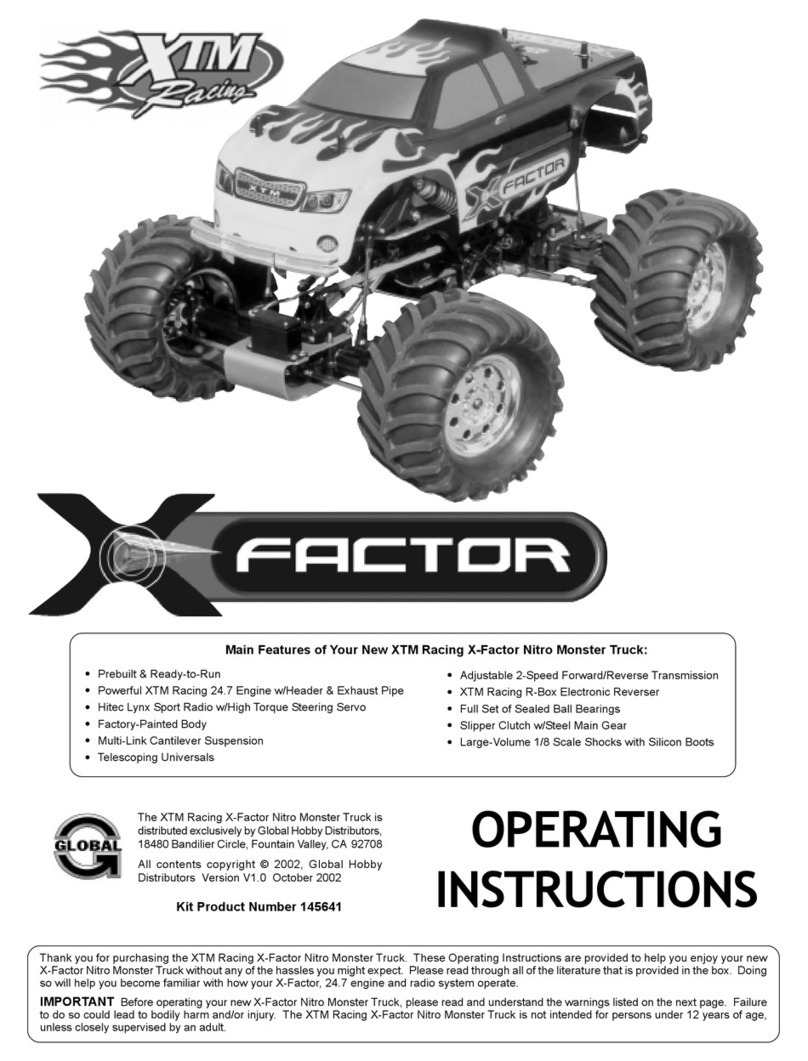

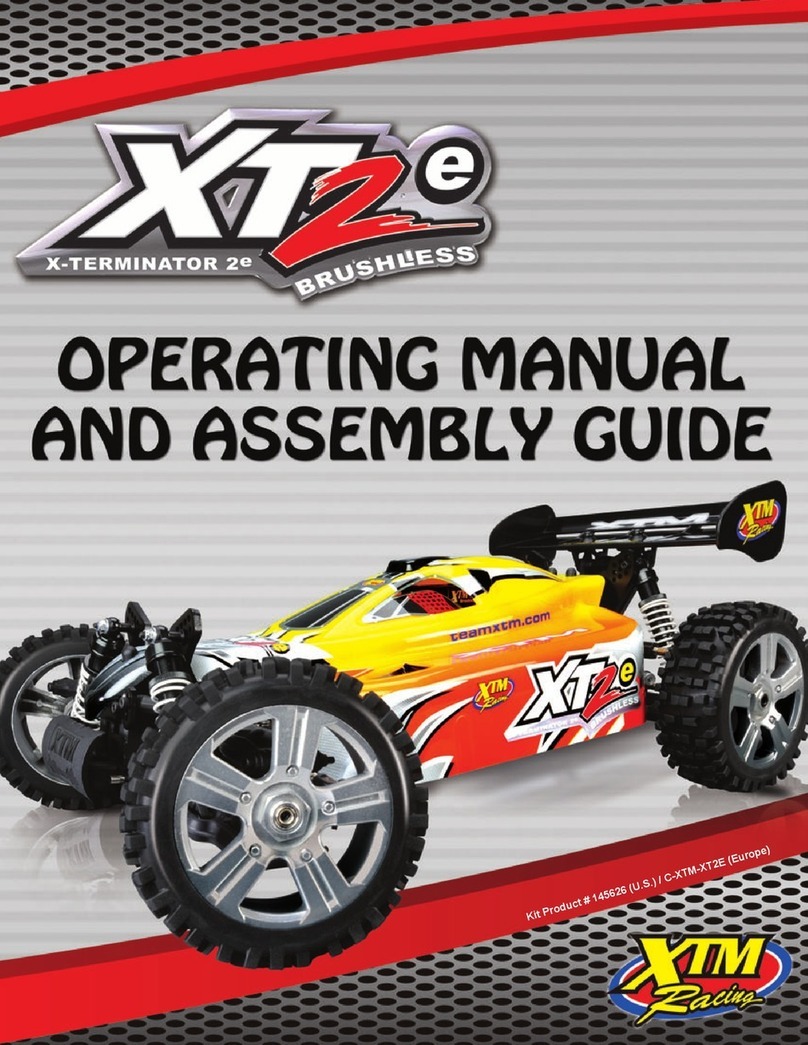

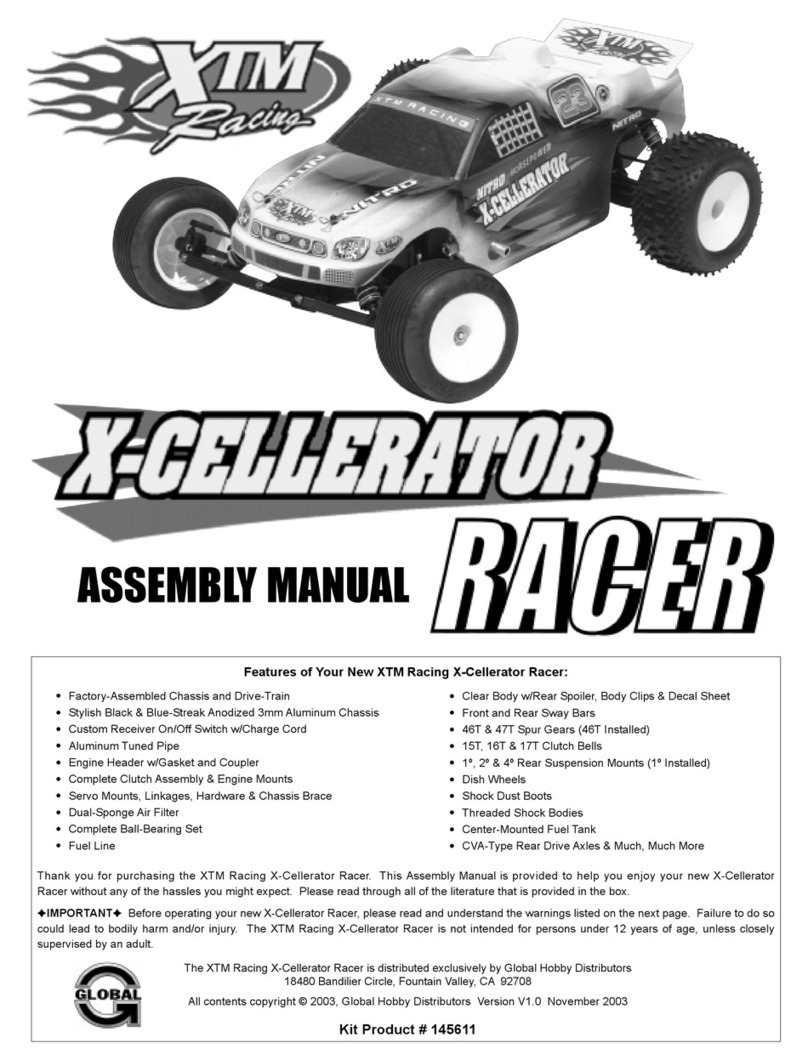

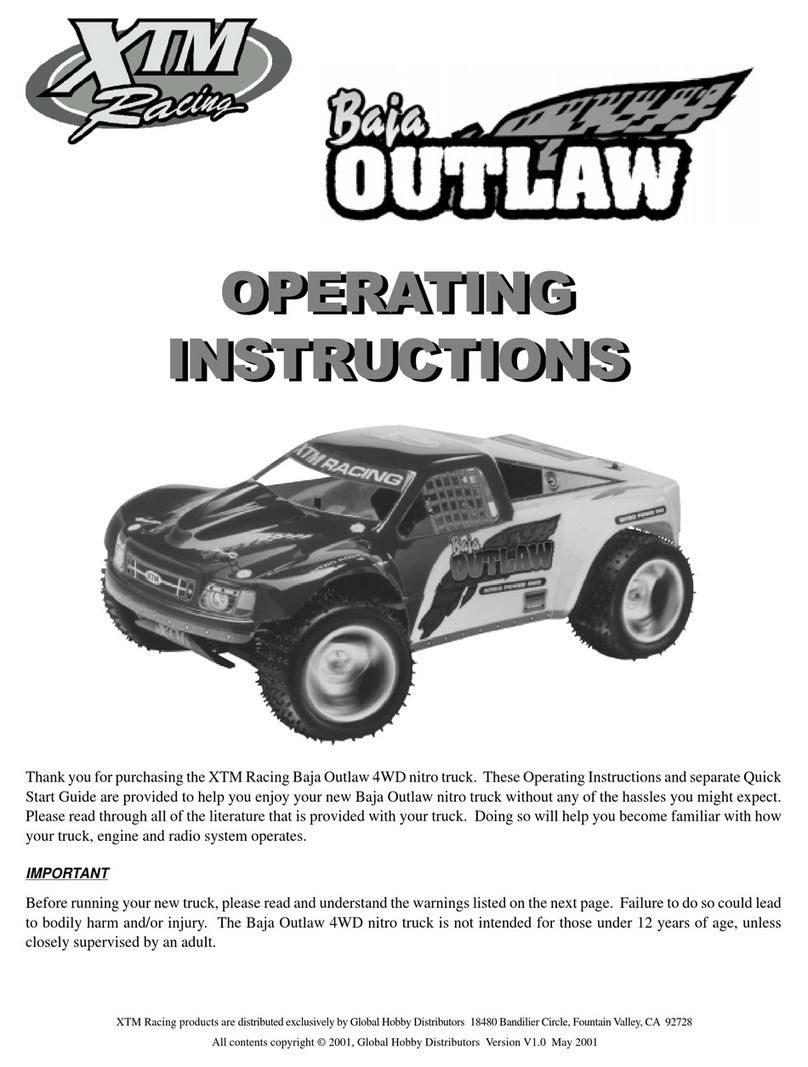

Check out our website for more information on

this and other exciting XTM Racing products!

http://xtm.globalhobby.com