9

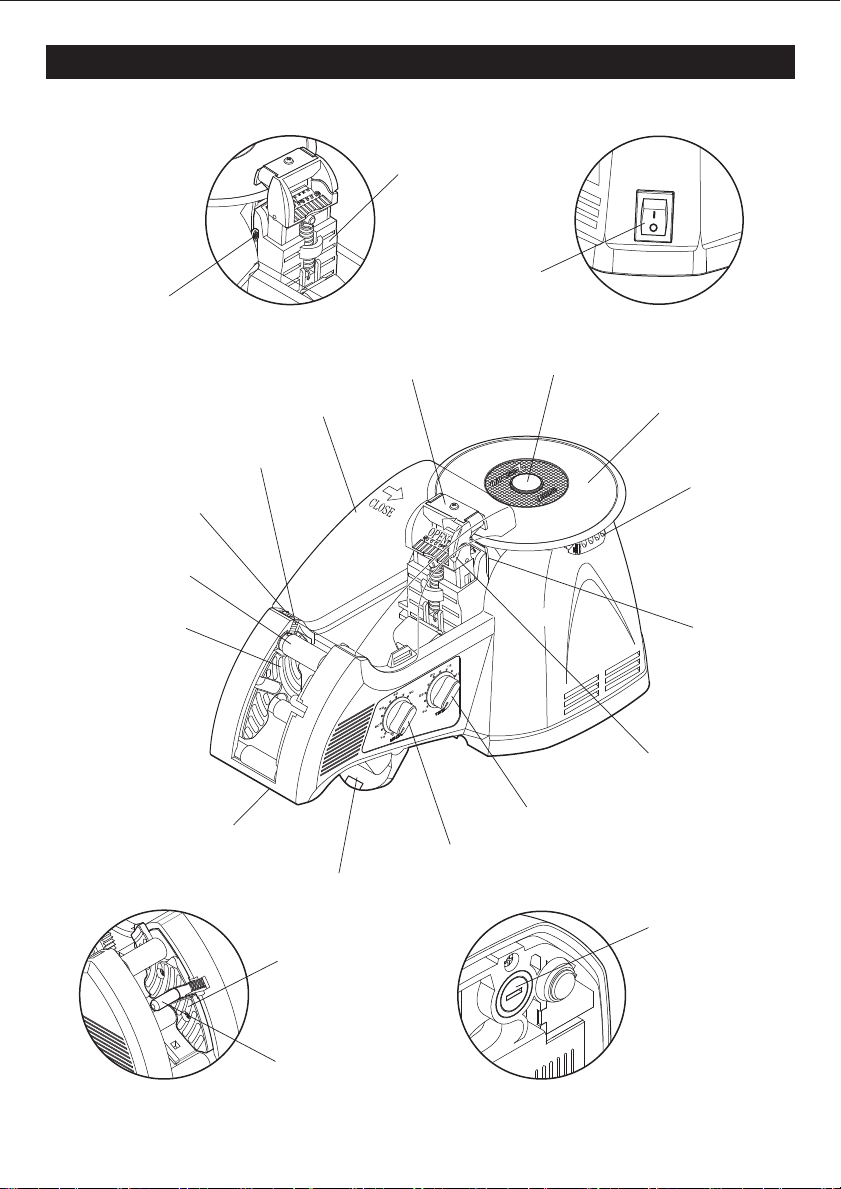

ZCUT-870 is able to be programmed.

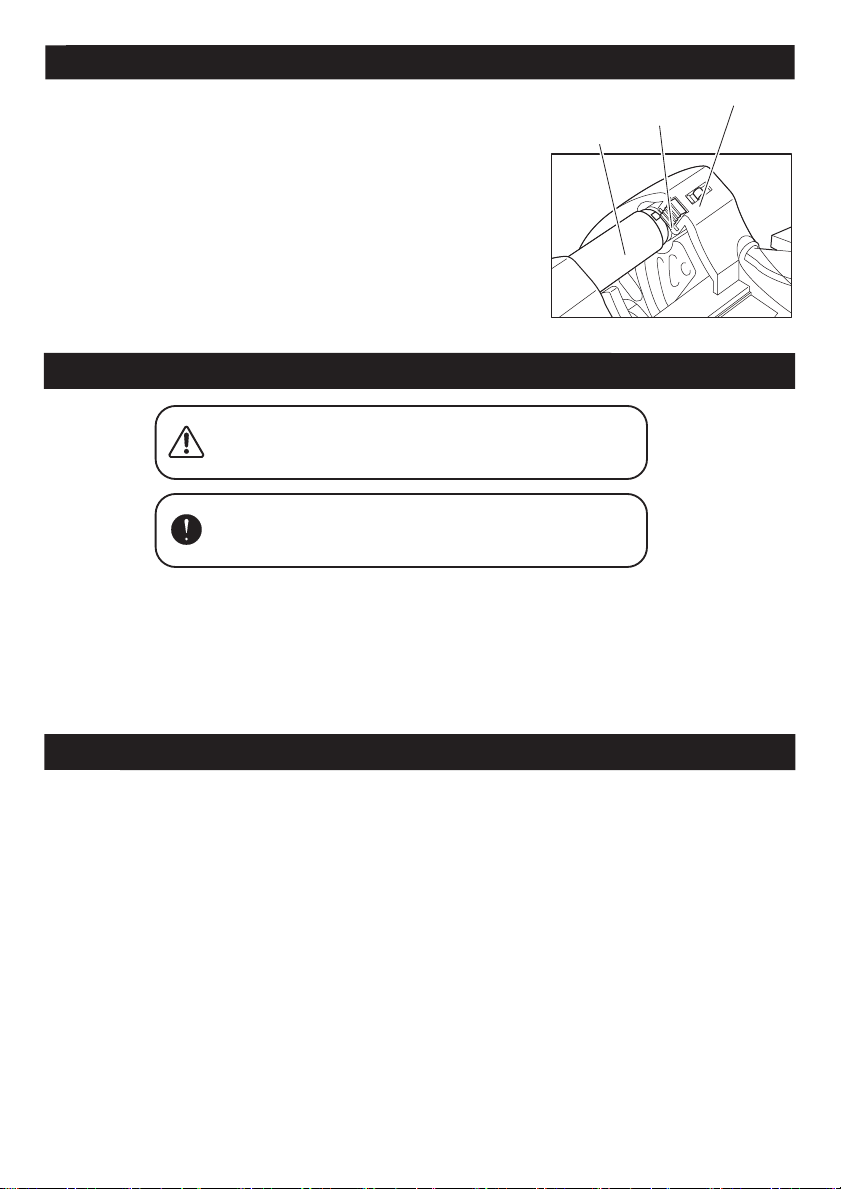

■Turn the POWER SWITCH off.

■During pressing the START BUTTON, turn the POWER SWITCH on in a same time.

■When the beep sound come, leave your finger from the START BUTTON.

(Confirm the beep sound comes again, and START BUTTON is flashing in Red and Bluealternately.)

■Press the START BUTTON and set the desired the number of cut minus two.

(For example, if you want to set 10 pieces, you should press the START BUTTON eight times.

Maximum set number of cut is 15 pieces.)

■When you set the number of cut, press the START BUTTON longer until beep sound comes.

■Make sure the START BUTTON light turned Red.

■Press the START BUTTON and start to operate.

(The machine will stop cutting when reach the number of cut which you set.)

(After turn the POWER SWITCH off, the number of cut is still memorized.)

(When you stop the machine during operation, press the START BUTTON.

At this moment, the machine has already reset the number of cut.)

(Press START BUTTON again for re-start.)

SENSOR MODE A SENSOR MODE B PRESET MODE

PRESET MODE

Stop after cut

Press Start Button for Re-Start

Press Start Button for Re-Start

Remove the tape

Remove the tape

Re-Start automatically

Start

Start

Start

RedPurpleBlue

Stop

Stop

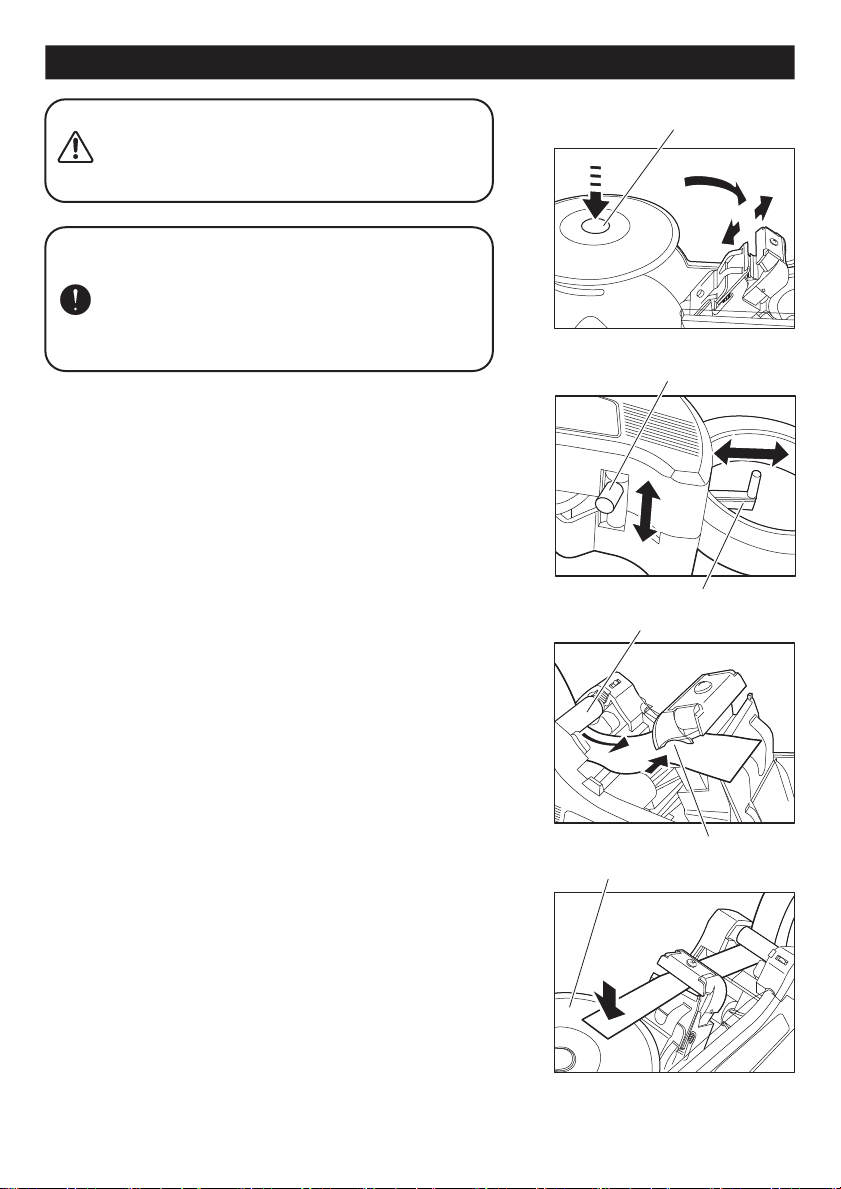

■Press the START BUTTON longer. (Purple light is on)

■Move the MOVABLE SENSOR to the desired position.

■Press the START BUTTON then start.

■When the tape reach over the MOVABLE SENSOR, machine will stop cutting.

(If the machine can not stop cutting to pass through the MOVABLE SENSOR, check and adjust the

position of MOVABLE SENSOR again.)

■When you remove the tape from the TURN TABLE, press the START BUTTON again.

■When the tape reach over the MOVABLE SENSOR, the machine will stop cutting.

■Press the START BUTTON longer. (Blue light is on)

■Move the MOVABLE SENSOR to the desired position.

■Press the START BUTTON then start.

■When the tape reach over the MOVABLE SENSOR, machine will stop cutting.

(If the machine can not stop cutting to pass through the MOVABLE SENSOR, check and adjust the

position of MOVABLE SENSOR again.)

■When you remove the tape over the MOVABLE SENSOR, machine will start to cut again automatically.

SENSOR MODE A

SENSOR MODE B