設定例:100枚

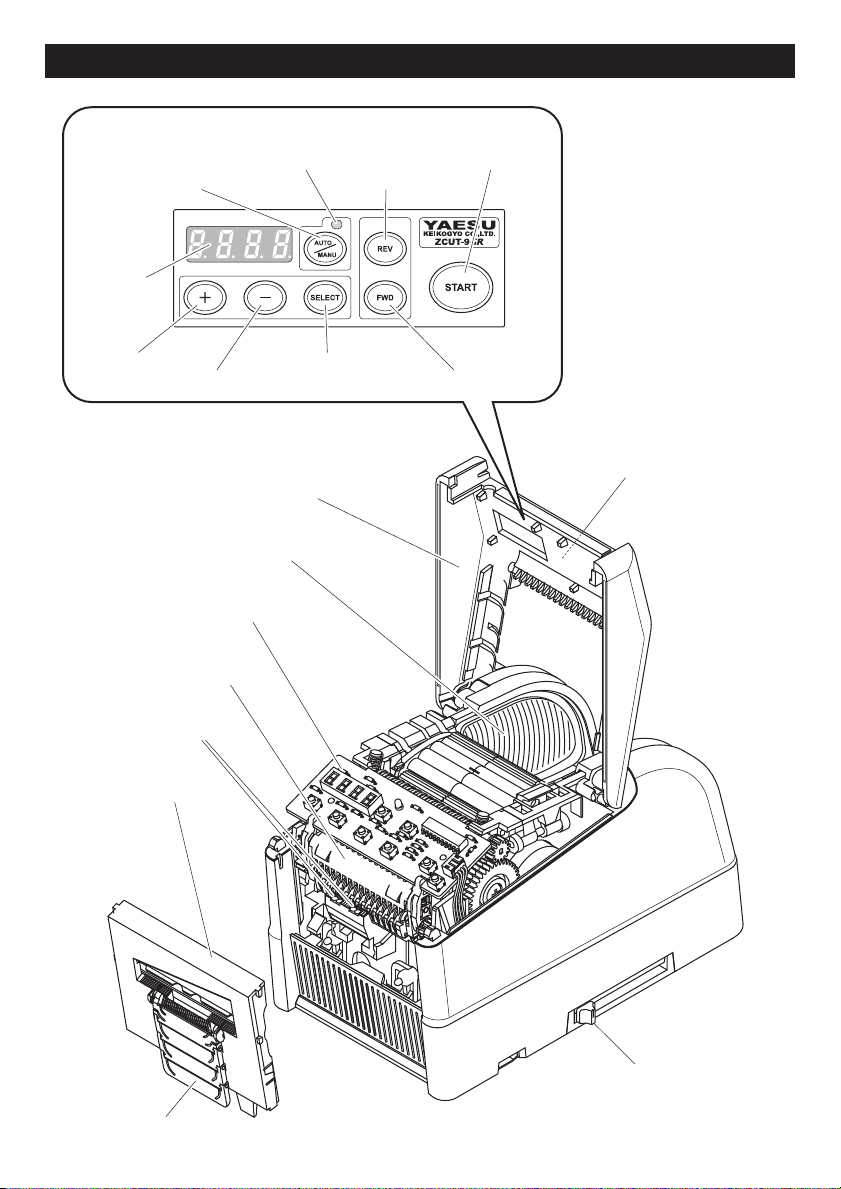

The machine is able to be programmed.

A signal will be shown based on your selected quantity of pieces and it will all

cut out. (Maximum 999 pieces.)

A buzzer will has sound when the program is finished.

You can use the mode either MANUAL or AUTO.

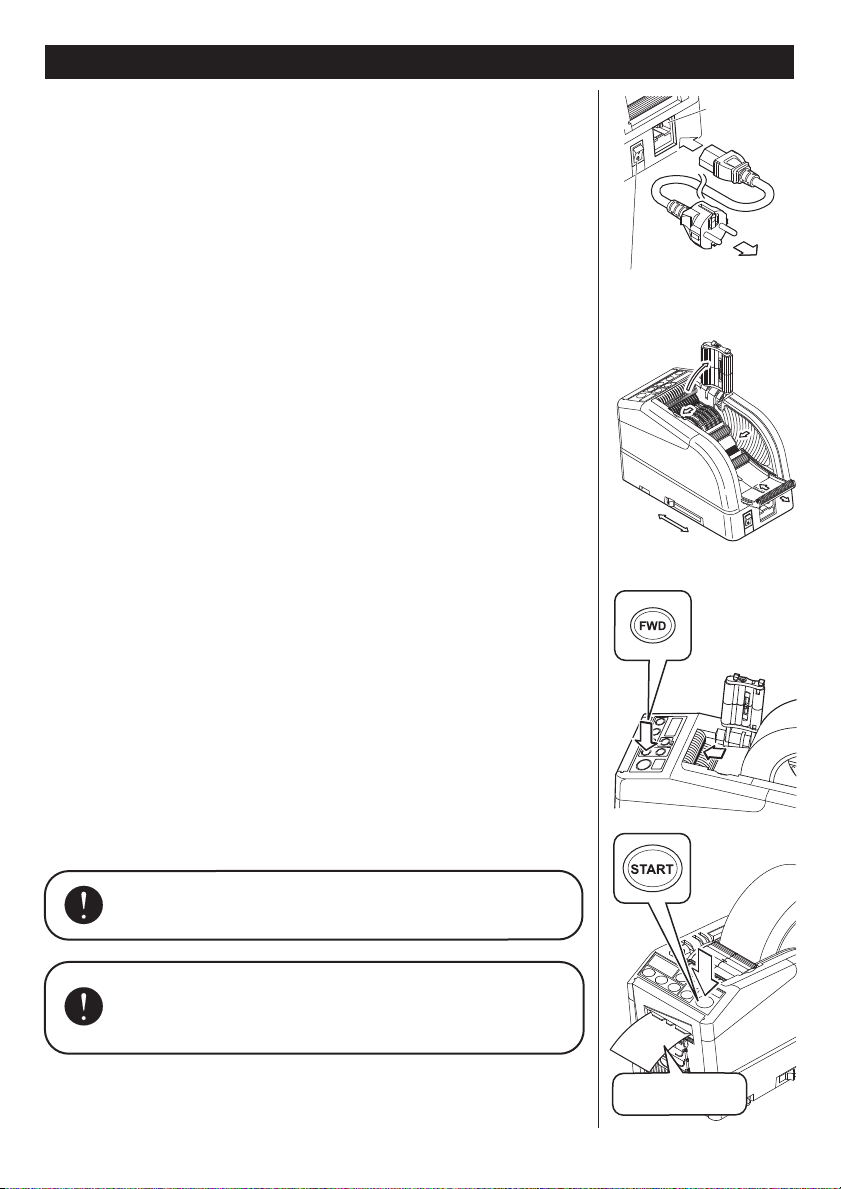

◆Press SELECT BUTTON to choose your needed length.

◆Press SELECT BUTTON for three seconds then it will indicates "Lcon".

◆Press SELECT BUTTON again then it will indicates "P".

◆Use +/- BUTTON and set your needed number of quantity.

◆Choose AUTO or MANUAL by USING AUTO/MANUAL BUTTON.

◆When you press the START BUTTON, the machine will feed-in and cut out

a piece of tape for testing purpose.

To operate the machine by using MANUAL MODE, press the START

BUTTON and feed-in a piece of tape after take it out.

To operate the machine by using AUTO MODE, the machine will feed-in a

piece of tape automatically.

◆The signal shows numbers backwards when feeding-in another piece of tape.

◆When the DISPLAY indicates "0", the buzzer will has a sound.

The DISPLAY indicates the number of pieces that is preset.

Please wait until the buzzer stops.

If you take the tape out before the buzzer stops, the LED LAMP will flash

so you need to press the START SWITCH again.

◆If you try to change the mode (AUTO/MANUAL) when machine is operating,

just press AUTO/MANUAL BUTTON.

◆If remaining P MODE and switching off, the number of cutting set will be

registered.

You can preset the quantity of piece which will be cut out. (Maximum 999 pieces)

The machine will cut out the pieces based on your selected quantities then it

will stop.

◆Press the SELECT BUTTON and decide the length of tape.

◆Press and hold SELECT BUTTON so that DISPLAY will indicates "Lcon".

◆Set the number of pieces to be cut out by using +/- BUTTON.

If you want to set the number of cutting in every 100pcs, please press

AUTO/MANUAL BUTTON while L con description and increase by 100pcs

every time you press. If you want to set the number of cutting in 1-figure or

2 figure, please press +BUTTON or -BUTTON.

◆When you press the START BUTTON, DISPLAY indicates a signal shows

numbers backwards and cutting continuously.

When the DISPLAY indicates "0", the buzzer will has sound then the

machine is stopped.

To stop the mahicne while running under L-MODE, press the START

BUTTON.

Caution

The number of cutting set will remain registered even if switching off while

L MODE. However, it will be eliminated if pressing SELECT BUTTON longer

for setting.

P-MODE (Preset Mode)

L-Mode (Loop Mode)

A~F

L-MODE

P-MODE

PRESS FOR 3SEC.

(exp.100pcs.)

INDICATE CUTTING LENGTH

MANUAL MODE

AUTO MODE

(exp. A-100mm)

A~F

PRESS FOR 3SEC.

(exp.100pcs.)

(exp. A-100mm)

INDICATE CUTTING LENGTH

9