Maintenance and Repair 1300 YRM 1330

CAUTION

Make sure the lift truck is blocked at the same

height as with the drive tire installed to ensure the

proper fluid level reading.

11. Bleed the service brakes. Refer Brake System

1800 YRM 1332 for procedures.

12. Check fluid level in transaxle. Fill as necessary.

See Fluid Level Check.

13. Install drive tire and wheel assembly on wheel hub.

Install lug nuts and tighten to 170 N•m (125 lbf ft).

14. Connect battery connector, turn key switch to ON

position, and test lift truck for proper operation.

15. Lower lift truck from the blocks.

See Periodic Maintenance 8000 YRM 1339 for lift

truck models

•ERP15-20VT (ERP030-040VT) (G807)

See Periodic Maintenance 8000 YRM 1373 for lift

truck models

•ERP16-20VF (ERP30-40VF) (A955)

16. Install mast on lift truck.

See Mast Repair,2- and 3-Stage High Visibility

Masts 4000 YRM 1386 for European lift truck mod-

els

•ERP15-20VT (G807)

•ERP16-20VF (A955)

See Mast Repair,2-, 3-, And 4-Stage Heavy Duty

Masts 4000 YRM 1405 for European and American

lift truck models

•ERP15-20VT (ERP030-040VT) (G807)

•ERP16-20VF (ERP30-40VF) (A955)

Maintenance and Repair

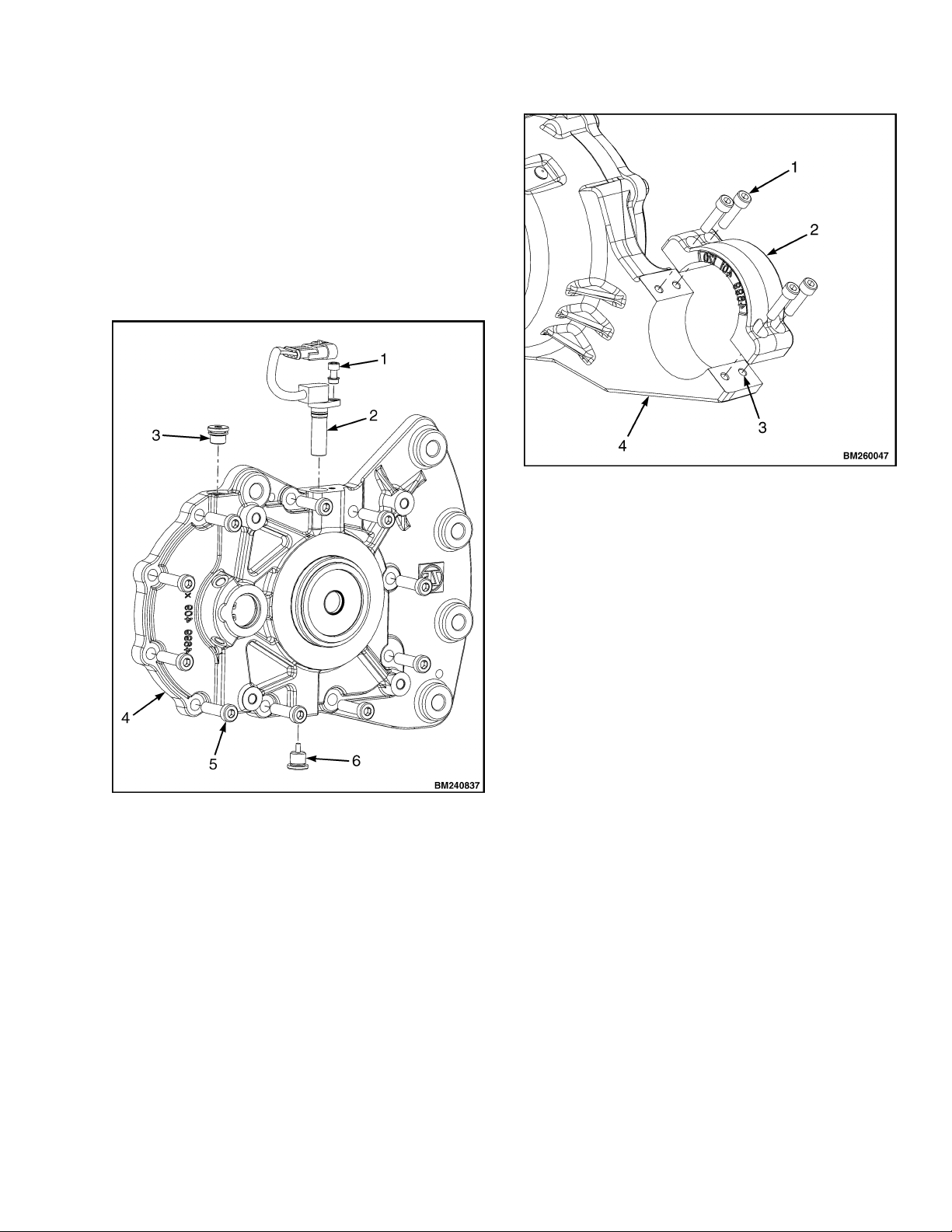

SPEED SENSOR REPAIR

The speed sensor monitors the speed of the transaxle

and relays the information to the controller. The speed

sensor can be replaced with the transaxle installed to

the lift truck.

1. Park lift truck on a level surface. Turn key switch to

OFF position and unplug battery connector.

2. Discharge capacitors. See section Discharging the

Capacitors.

3. Remove floor mat and floor plates from operator

compartment to access top of transaxle(s).

4. Disconnect sensor wiring harness from main wiring

harness.

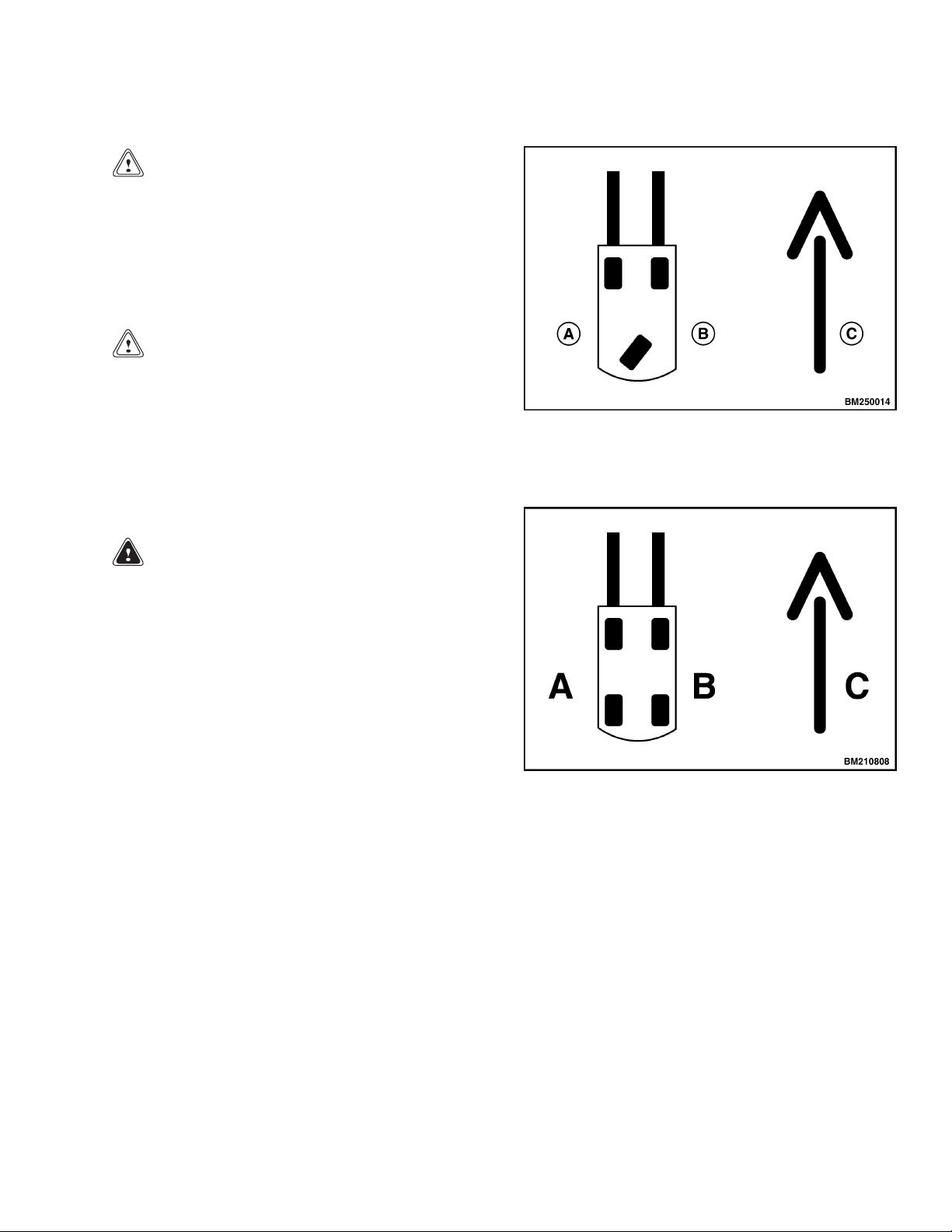

CAUTION

Use a brush to clean around the sensor before re-

moving to avoid contaminating the transaxle.

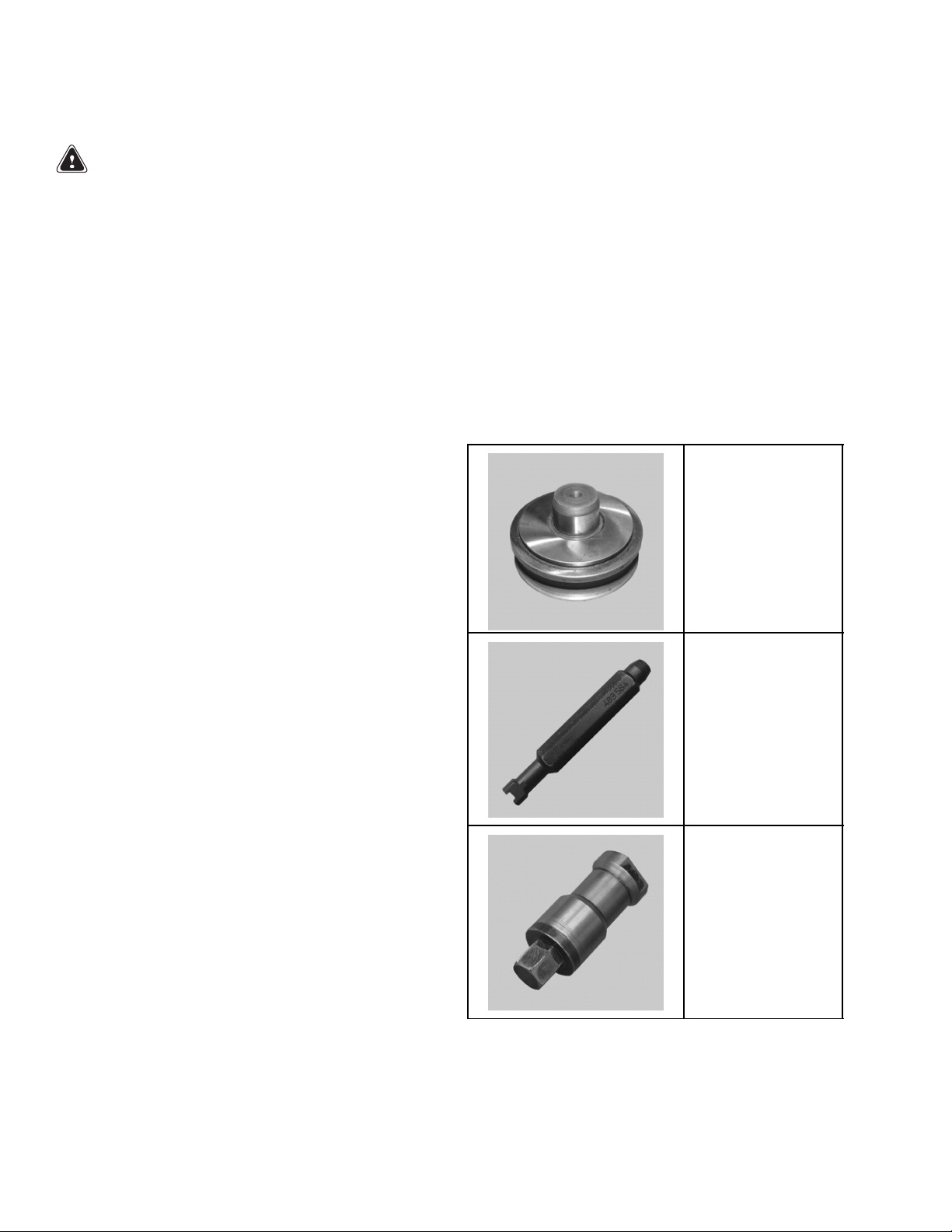

5. Remove capscrew holding sensor to transaxle us-

ing a 5mm Allen wrench. See Figure 5.

6. Pull sensor out of transaxle.

7. Insert new sensor into transaxle.

8. Align screw holes and install capscrew. Tighten

capscrew to 9.5 N•m (84.0 lbf in).

9. Connect sensor wiring harness to main wiring har-

ness.

10. Replace floor plates and floor mat in operator com-

partment.

11. Connect battery, turn key to ON position and test lift

truck for proper operation.

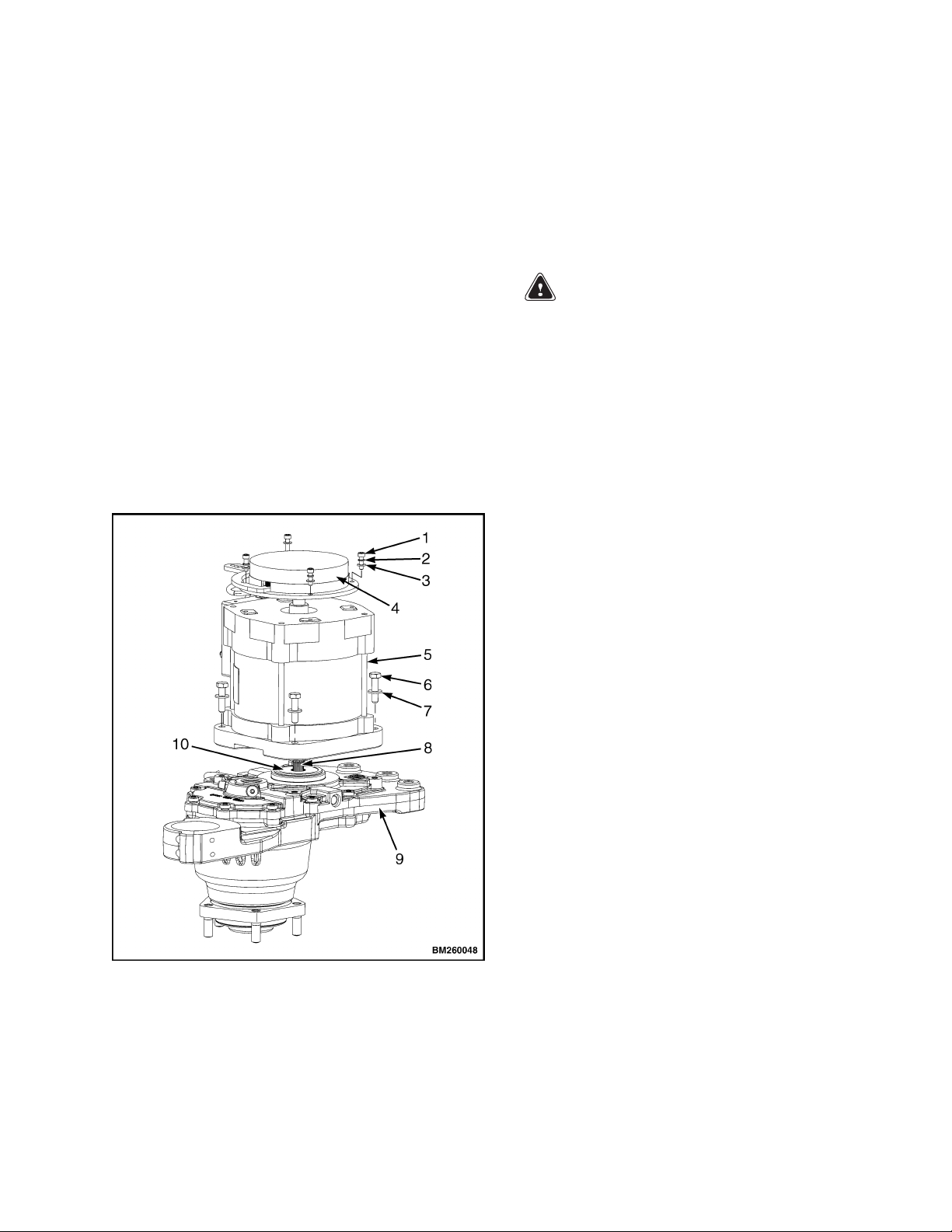

TRUNNION CAP REPAIR

To repair the trunnion cap:

1. Remove load from forks and park lift truck on a level

surface. Adjust mast to a vertical position, then turn

key switch to OFF position and separate battery

connectors.

2. Remove four capscrews holding trunnion cap on

transaxle housing. Remove trunnion cap. See Fig-

ure 6.

3. Wipe away any dirt or grease near mounting holes.

Clean holes with a proper sized tap and tap wrench

as necessary.

6