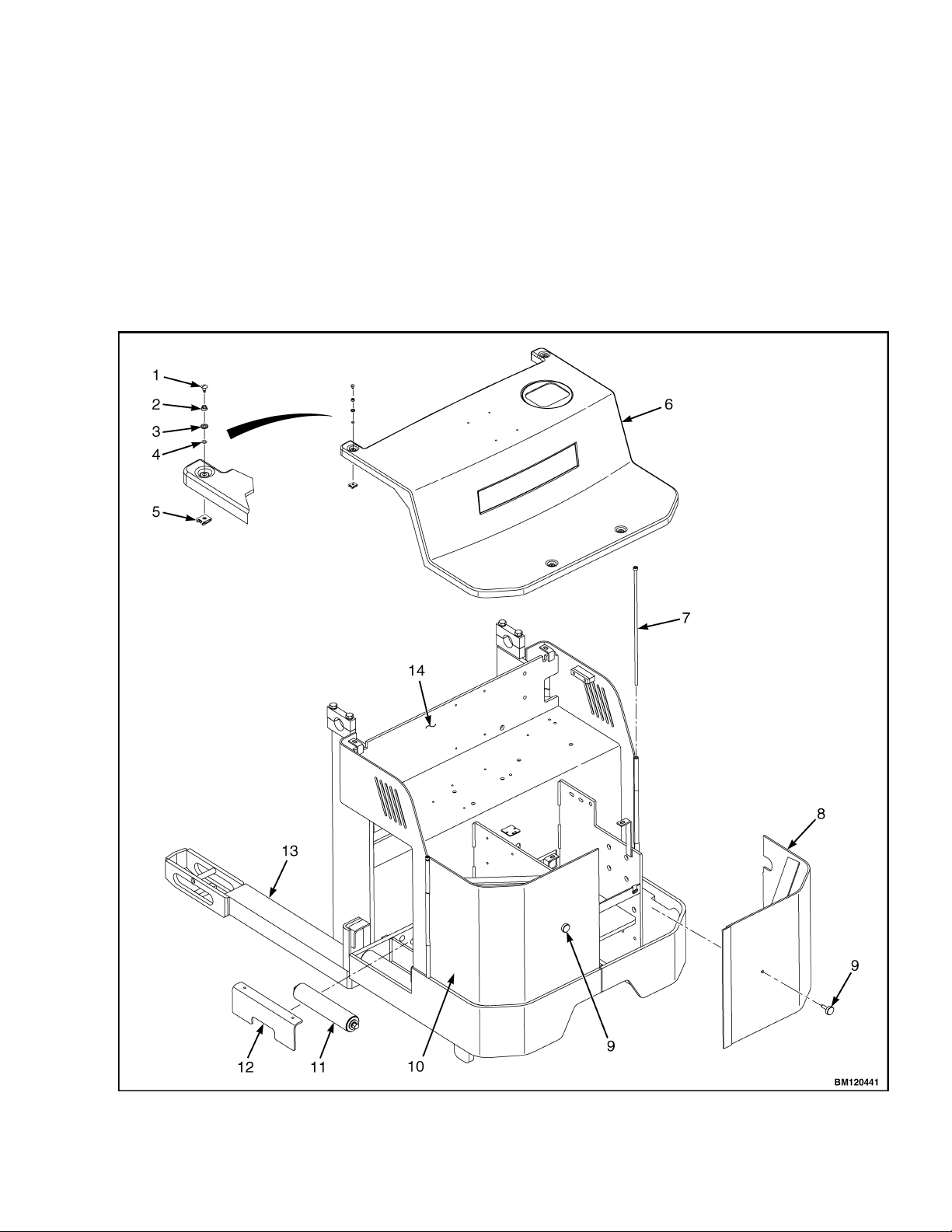

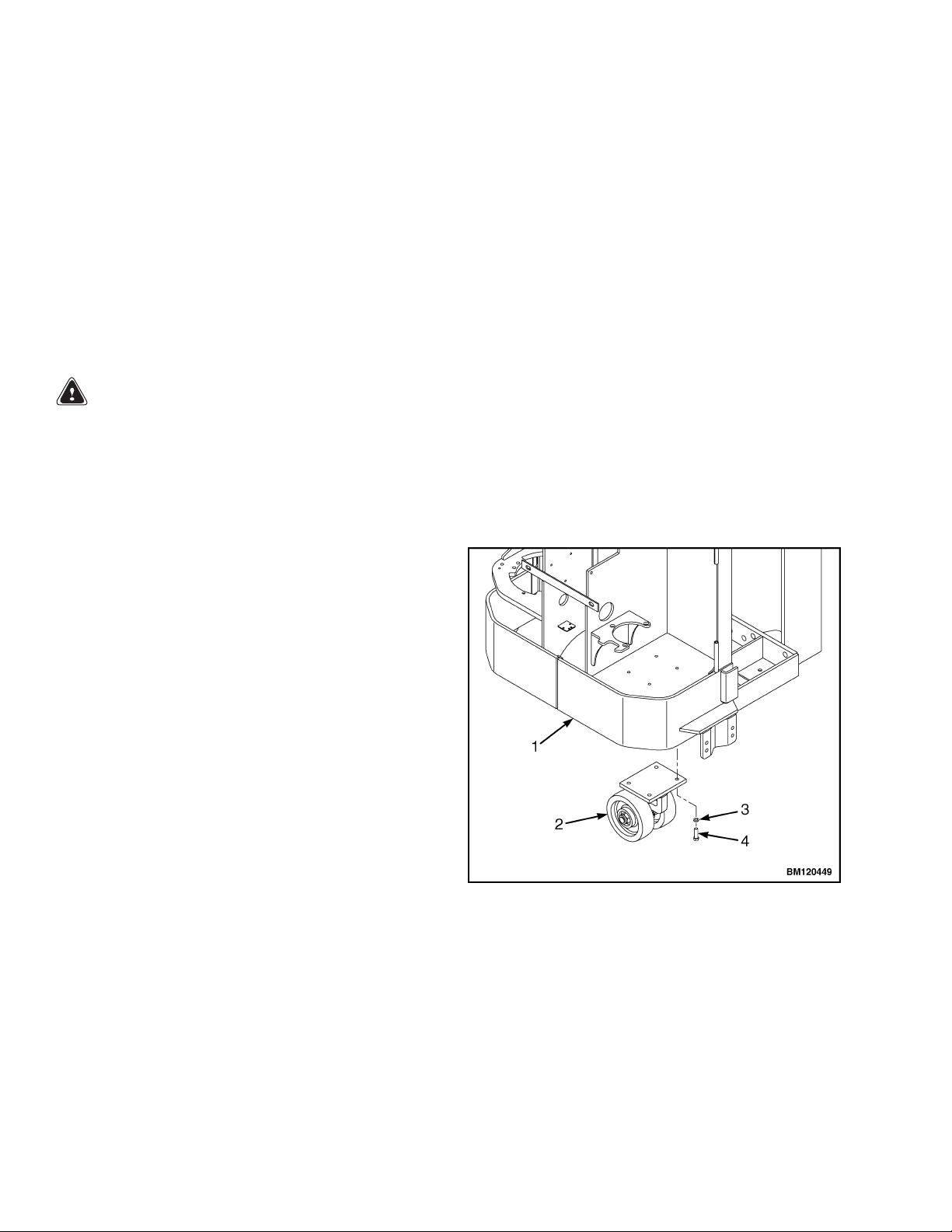

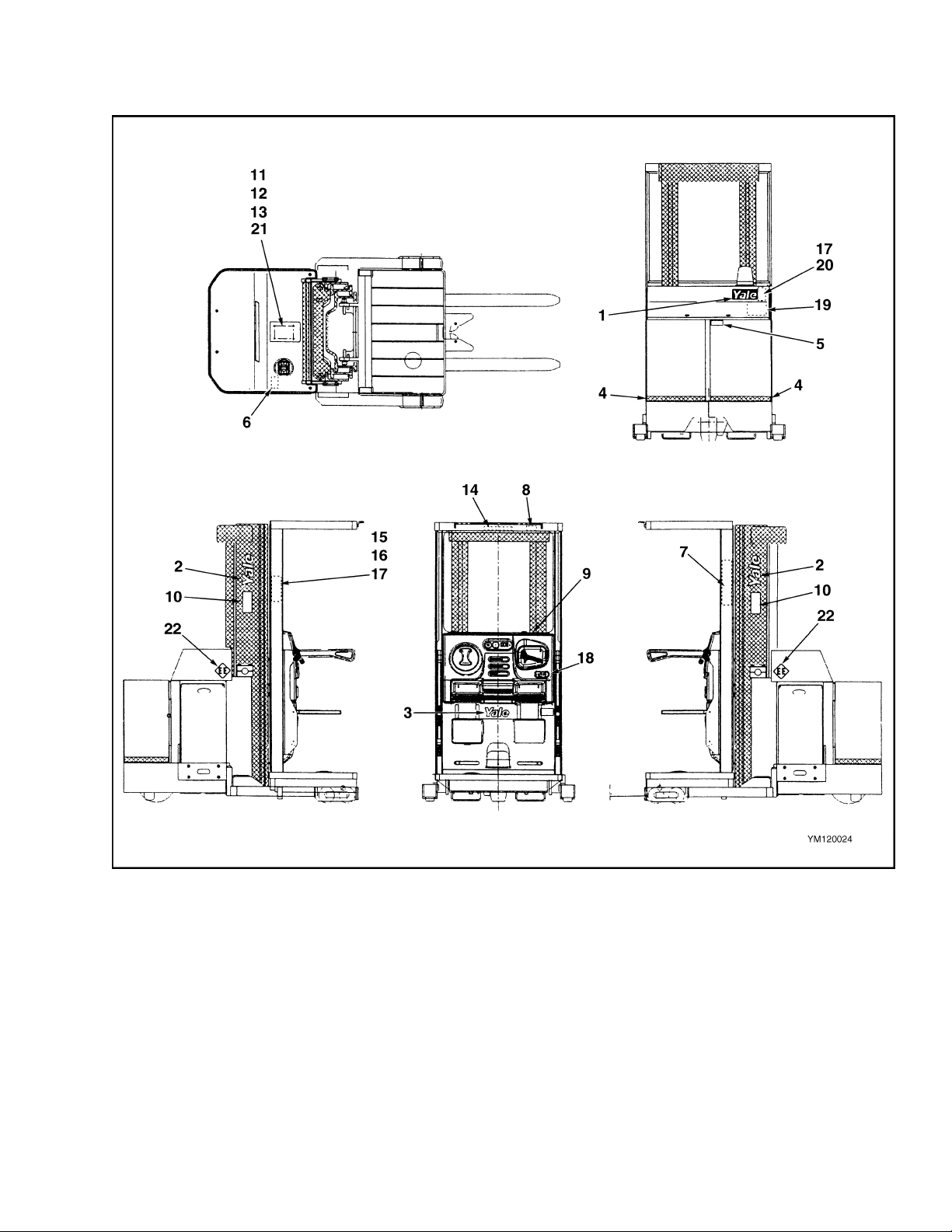

SS030BF (A474), FS030BF (A497), OS030EF (D801), OS030BF (E826)

SERVICE MANUAL CONTENTS

SECTION

PART

NUMBER

YRM

NUMBER

REV

DATE

FRAME............................................................................................................................ 524163979 0100 YRM 0760 01/12

DC MOTOR MAINTENANCE.......................................................................................... 524158039 0620 YRM 0294 03/08

AC MOTOR REPAIR...................................................................................................... 550032942 0620 YRM 1461 01/12

A/C MOTOR REPAIR S/N A474N03000L=> S/N A497N030000L=> S/N

D801N02161L=> S/N E826N01917L=>..................................................................... 550073166 0620 YRM 1621 02/14

MASTER DRIVE UNIT.................................................................................................... 550032941 0630 YRM 1460 01/12

MASTER DRIVE UNIT S/N D801N03000L=> S/N A474N03000L=> S/N

A497N030000L=> S/N E826N03000L=>................................................................... 550073167 0630 YRM 1609 06/14

STEERING SYSTEM...................................................................................................... 550032943 1600 YRM 1462 01/12

BRAKE SYSTEM............................................................................................................ 550032944 1800 YRM 1463 01/12

HYDRAULIC GEAR PUMP............................................................................................. 524153907 1900 YRM 0097 05/12

HYDRAULIC SYSTEM [D801 (OS030EF)]..................................................................... 550032945 1900 YRM 1464 08/14

HYDRAULIC SYSTEM (LARGE).................................................................................... 550032946 1900 YRM 1465 05/12

WIRE DRIVER MANUAL................................................................................................ 520371765 2200 YRM 1229 01/12

GUIDE WIRE INSTALLATION........................................................................................ 520371764 2200 YRM 1230 01/12

AC MOTOR CONTROLLER........................................................................................... 550032947 2200 YRM 1466 02/14

ELECTRICAL SYSTEM [D801 (OS030EF)]................................................................... 550032948 2200 YRM 1467 08/14

ELECTRICAL SYSTEM (LARGE).................................................................................. 550032949 2200 YRM 1468 01/12

USER INTERFACE SUPERVISOR FUNCTIONS =>S/N A474N02999L =>S/N

A479N02999L =>S/N D801N02999L =>S/N E826N02999L...................................... 550032950 2200 YRM 1469 12/13

USER INTERFACE SERVICE-LEVEL FUNCTIONS =>S/N A474N02999L =>S/N

A479N02999L =>S/N D801N02999L =>S/N E826N02999L...................................... 550032951 2200 YRM 1470 12/13

WIRE GUIDANCE........................................................................................................... 550032952 2200 YRM 1471 05/13

USER INTERFACE SUPERVISOR FUNCTIONS S/N D801N03000L=> S/N

A474N03000L=> S/N A497N030000L=> S/N E826N03000L=>............................... 550089217 2200 YRM 1650 12/13

USER INTERFACE SERVICE TECHNICIAN S/N A474N03000L=> S/N

A497N030000L=> S/N D801N03000L=> S/N E826N03000L=>............................... 550089220 2200 YRM 1651 12/13

INDUSTRIAL BATTERY................................................................................................. 524158040 2240 YRM 0001 09/14

LIFT CYLINDERS........................................................................................................... 524150794 4000 YRM 0135 03/11

MAST-DESCRIPTION..................................................................................................... 524164052 4000 YRM 0763 01/12

MAST-REPAIR................................................................................................................ 524164053 4000 YRM 0764 01/12

METRIC AND INCH (SAE) FASTENERS....................................................................... 524150797 8000 YRM 0231 10/13

PERIODIC MAINTENANCE............................................................................................ 550032953 8000 YRM 1472 02/14

DIAGRAMS..................................................................................................................... 550032954 8000 YRM 1473 11/12

CAPACITIES AND SPECIFICATIONS........................................................................... 550032955 8000 YRM 1474 10/13

CONTROLLER DIAGNOSTICS...................................................................................... 550089223 9000 YRM 1648 10/14

PART NO. 550032940 (10/14)