YASKAWA yasnac MX2 User manual

Other YASKAWA Controllers manuals

YASKAWA

YASKAWA MOTOMAN-NX100 Parts list manual

YASKAWA

YASKAWA Motoman DX200 User manual

YASKAWA

YASKAWA CIPR-GA50C series User manual

YASKAWA

YASKAWA Z1000 CIMR-ZU*A Series User manual

YASKAWA

YASKAWA Motoman DX200 User manual

YASKAWA

YASKAWA AO-A3 Guide

YASKAWA

YASKAWA 1000-Series User manual

YASKAWA

YASKAWA MOTOMAN FS100 User manual

YASKAWA

YASKAWA MP2200 User manual

YASKAWA

YASKAWA Lift Inverter L1000V User manual

YASKAWA

YASKAWA MP2200 User manual

YASKAWA

YASKAWA 1000 Series User manual

YASKAWA

YASKAWA L1000E User manual

YASKAWA

YASKAWA Motoman DX200 User manual

YASKAWA

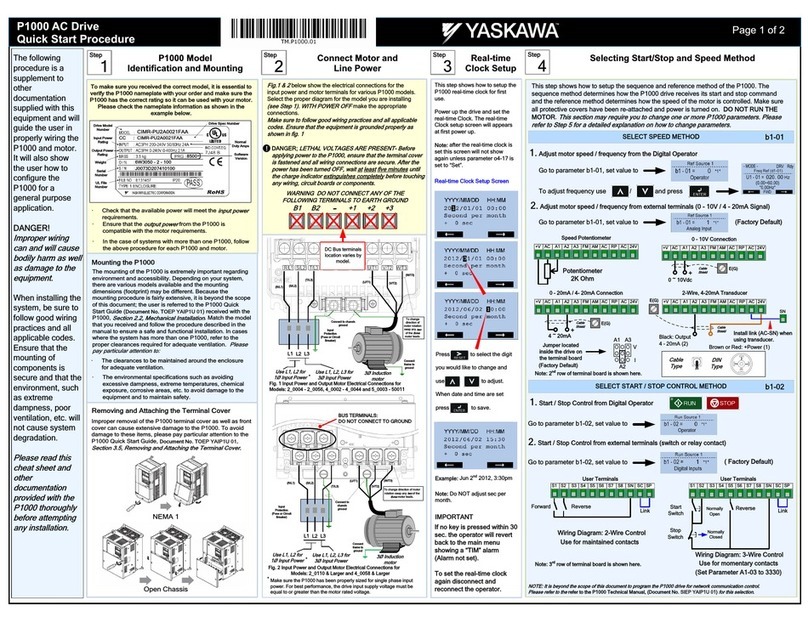

YASKAWA P1000 User manual

YASKAWA

YASKAWA motoman NX100 User manual

YASKAWA

YASKAWA YASNAC J50 Quick start guide

YASKAWA

YASKAWA motoman NX100 User manual

YASKAWA

YASKAWA MOTOMAN FS100 User manual

YASKAWA

YASKAWA Z1000 CIMR-ZU*A Series Owner's manual

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions

ABB

ABB ACS580-01 drives Hardware manual