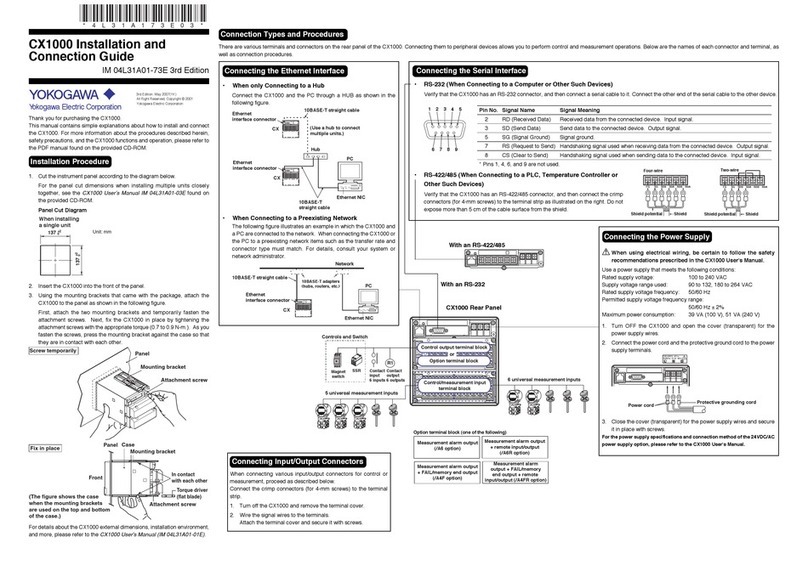

Arrangement of the Terminal Blocks

VIDEOOUT(VGA)

LN

Analog Input Terminal Block

(Terminal number: 001 to 036)

Measurment Input Terminal Block

(Terminal number: 101 to 136)

Measurment Input Terminal Block

(Terminal number: 201 to 236)

Control Output Treminal Block

(Terminal number: 301 to 336)

Control Output Treminal Block

(Terminal number: 401 to 436)

Control Output Treminal Block

(Terminal number: 501 to 536)

)

Option Terminal Block

(Terminal number: 601 to 636)

1

2

0

0 6

5

6

4

3

to

Terminal block number

Chracters indicating the type

of input/output signal

Te r minal number

005

A

+

One screw terminal is shown in the figure below. The upper and lower symbols

represent a unique terminal number and the terminal type, respectively.

No screw terminal is attached.

C: Common

NO: Normally Opened

NC: Normally Closed

mA: Current output

PULSE: Voltage pulse output

Input Assignments of the Analog Control Input

Terminal Block (Terminal Block: 0)

6 loops

LOOP1

PV(RSP)

LOOP2

PV(RSP)

LOOP3

PV(RSP)

LOOP4

PV(RSP)

LOOP5

PV

LOOP6

PV

PV(RSP)PVPV(RSP)PV PVPV

PV1PV2PV1PV2PV1PV2PV1PV2 PV

PV

028

029

030

b

A

+

B

−

031

032

033

b

A

+

B

−

025

026

027

b

A

+

B

−

022

023

024

b

A

+

B

−

019

020

021

b

A

+

B

−

016

017

018

b

A

+

B

−

013

014

015

b

A

+

B

−

010

011

012

b

A

+

B

−

007

008

009

b

A

+

B

−

004

005

006

b

A

+

B

−

During single loop control

During cascade control

During loop control with

PV switching

[Control mode setting]

4 loops

LOOP1

PV(RSP)

LOOP2

PV(RSP)

LOOP3

PV(RSP)

LOOP4

PV(RSP)

PV(RSP)PVPV(RSP)PV

PV1(RSP) PV2PV1PV2PV1PV2(RSP)PV1

PV2

028

029

030

b

A

+

B

−

031

032

033

b

A

+

B

−

025

026

027

b

A

+

B

−

022

023

024

b

A

+

B

−

019

020

021

b

A

+

B

−

016

017

018

b

A

+

B

−

013

014

015

b

A

+

B

−

010

011

012

b

A

+

B

−

007

008

009

b

A

+

B

−

004

005

006

b

A

+

B

−

During single loop control

During cascade control

During loop control with

PV switching

[Control mode setting]

2 loops

LOOP1

PV(RSP)

LOOP2

PV(RSP)

PV(RSP)PV

PV1PV2(RSP)PV1PV2

During single loop control

During cascade control

During loop control with

PV switching

[Control mode setting]

016

017

018

b

A

+

B

−

013

014

015

b

A

+

B

−

010

011

012

b

A

+

B

−

007

008

009

b

A

+

B

−

004

005

006

b

A

+

B

−

Terminal Assignments of the Control Output

Terminal Block (Terminal Blocks: 3, 4, and 5)

Loop 1 and 2 (Terminal block: 3)

Contact

input

Transistor

output

Control current/

voltage pulse output

relay contact

output

LOOP1LOOP21

Control relay

contact output

LOOP1LOOP2 2

525

526

527

528

529

530

522

523

519

520

516

517

518

513

514

515

510

511

512

507

508

509

504

505

506

4

5

6

3

4

C

5

6

C

mA

PULSE

C

mA

PULSE

C

NO

C

NO

C

NO

NC

C

NO

NC

C

1

2

3

501

502

503

Loop 3 and 4 (Terminal block: 4)

Contact

input

Transistor

output

Control current/

voltage pulse output

relay contact

output

LOOP3LOOP41

Control relay

contact output

LOOP3LOOP4 2

525

526

527

528

529

530

522

523

519

520

516

517

518

513

514

515

510

511

512

507

508

509

504

505

506

4

5

6

3

4

C

5

6

C

mA

PULSE

C

mA

PULSE

C

NO

C

NO

C

NO

NC

C

NO

NC

C

1

2

3

501

502

503

Loop 5 and 6 (Terminal block: 5)

Contact

input

Transistor

output

Control current/

voltage pulse output

relay contact

output

LOOP5LOOP61

Control relay

contact output

LOOP5LOOP6 2

525

526

527

528

529

530

522

523

519

520

516

517

518

513

514

515

510

511

512

507

508

509

504

505

506

4

5

6

3

4

C

5

6

C

mA

PULSE

C

mA

PULSE

C

NO

C

NO

C

NO

NC

C

NO

NC

C

1

2

3

501

502

503

Terminal Assignments of the Measurement Input

Terminal Block (Terminal Blocks: 1 and 2)

Channel 1 to 10 (Terminal block: 1)

Channel number

1245679

10 38

128

129

130

b

A

+

B

−

131

132

133

b

A

+

B

−

125

126

127

b

A

+

B

−

122

123

124

b

A

+

B

−

119

120

121

b

A

+

B

−

116

117

118

b

A

+

B

−

113

114

115

b

A

+

B

−

110

111

112

b

A

+

B

−

107

108

109

b

A

+

B

−

104

105

106

b

A

+

B

−

Channel 11 to 20 (Terminal block: 2)

Channel number

1112141516171920 1318

228

229

230

b

A

+

B

−

231

232

233

b

A

+

B

−

225

226

227

b

A

+

B

−

222

223

224

b

A

+

B

−

219

220

221

b

A

+

B

−

216

217

218

b

A

+

B

−

213

214

215

b

A

+

B

−

210

211

212

b

A

+

B

−

207

208

209

b

A

+

B

−

204

205

206

b

A

+

B

−

Terminal Assignments of the Option Terminal

Block (Terminal Block: 6)

/CTS1

Contact input

Transistor output

625

626

627

628

629

630

622

623

619

620

613

614

615

610

611

612

607

608

609

604

605

606

4

5

6

7

8

9

10

11

12

C

C

C

1

2

2

4

5

6

C

7

8

C

628

629

630

9

10

C

628

629

630

11

12

C

1

2

3

601

602

603

/A6

Alarm output

625

626

627

628

629

630

619

620

610

611

612

NC

C

NO

NC

C

NC

C

NO 621

NO

NC

C

NO

616

617

618

NC

C

NO

06 05 04 03 02 01

634

635

636

NC

C

NO

/A6R

Measurement remote input

Alarm output

625

626

627

628

629

630

619

620

610

611

612

607

608

609

604

605

606

3

4

5

6

7

8

NC

C

NO

NC

C

NC

C

NO 621

NO

NC

C

NO

616

617

618

NC

C

NO

06 05 04 03 02 01

634

635

636

NC

C

NO

C

1

2

601

602

603

/A4F

FAIL

output

Memory end

output Alarm output

625

626

627

628

629

630

619

620

610

611

612

NC

C

NO

NC

C

NC

C

NO 621

NO

NC

C

NO

616

617

618

NC

C

NO

04 03 02 01

634

635

636

NC

C

NO

/A4RF

Measurement remote input

FAIL

output

Memory end

output Alarm output

625

626

627

628

629

630

619

620

610

611

612

607

608

609

604

605

606

3

4

5

6

7

8

NC

C

NO

NC

C

NC

C

NO 621

NO

NC

C

NO

616

617

618

NC

C

NO

04 03 02 01

634

635

636

NC

C

NO

C

1

2

601

602

603

/TPS4

24VDC Transmitter power supply

625

626

628

629

+

−

+

631

+

−

632

−

06

634

635

+

−

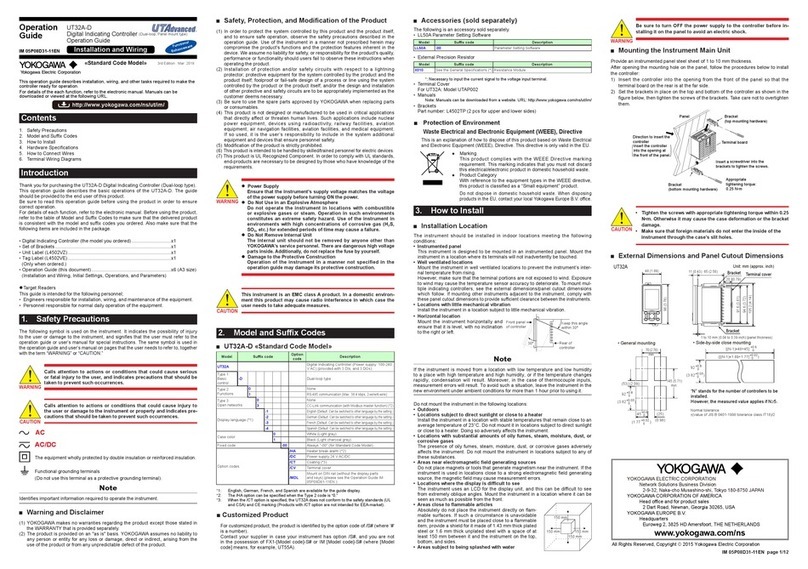

Measurement Input Wiring

DC voltage input

• Thermocouple Input

• DC Voltage Input

• RTD Input

• DC Current Input

DC current input

Shunt resistor

Example: For 4 to 20 mA input,

shut resistance values should be

250 Ω±0.1%.

–

+

Lead wire resistance

per wire of 10 Ωor less.

Make the resistance of

the three wires equal.

A

b

B

Compensation lead

b

A

B

b

A

B

b

A

B

b

A

B

–

+

Contact Input (DIGITAL IN) Wiring

•Control Output Terminal Block (DIGITAL IN)

1

2

3

4

5

6

C

• Transistor Input• Relay Contact Input

2

1

4

63

5

C

•Control DIO Expansion Terminal Block

• Relay Contact Input

• Transistor Input

7

8

9

10

11

12

1

2

3

4

5

6

C

C

C

8

7

10

12 9

11

C

5

4

6

2

1

3

C

C

Relay Contact Input/Transistor Input

Input signal: no-voltage contact, open collector

Input condition: ON voltage, under 0.5 V (30 mADC); OFF voltage, leakage

current under 0.25 mA

Input format: photocoupler isolation (common)

Withstand voltage: 500 VDC, 1 min (between input terminal and earth)

Option Terminal Block Remote Input (REMOTE)

C

1

2

3

4

5

6

7

8

• Transistor Input• Relay Contact Input

C

1

2

3

4

5

6

7

8

Relay Contact Input/Transistor Input

See the “Contact Input (DIGITAL IN) Wiring.”

Control Output (LOOP1 to 6) Wiring

C

mA

+

–

4 to 20 mADC or

0 to 20 mADC

• Voltage Pulse Output

• Current Output

C

PULS

Voltage pulse (12 V)

+

–

• Relay Contact Output

NC

C

NO

250 VAC, 3 A or

30 VDC, 3 A

(resistive load)

(when set to energized)

Current Output

Output signal: 4 to 20 mADC or 0 to 20 mADC

Resistive load: 600 Ωor less

Voltage Pulse Output

Output signal: ON voltage=12 VDC

Resistive load: 600 Ωor more

Relay Contact Output

Output signal: NC, NO, COM

Contact rating: 250 VAC (50/60 Hz)/3 A or 30 VDC/3 A (resistive load)

Contact Output (DIGITAL OUT) Wiring

• Relay Contact Output of the Control Output Terminal Block

C

NO

250 VAC, 1 A or

30 VDC, 1 A

(resistive load)

• Transistor Output of the Control Output Terminal Block

C

6

5

4

3

24 VDC/50 mA

• Transistor Output of the Control Expansion DIO Terminal Block

4

3

2

1

24 VDC/50 mA

6

5

C

C

12

11

C

3 to 6

1 to 12

+

−

Pull-up resistor

Connection example

for a transistor output

Relay Output

Output form: relay contact

Contact rating: 250 VAC (50/60 Hz)/1 A or 30 VDC/1 A (resistive load)

Transistor Output

Output method: open collector output

Contact rating: 24 VDC/50 mA

Option Terminal Block Contact Output (ALARM, FAIL,

MEMORY) Wiring

C

NO

NC

Relay Output

Output form: relay contact

Contact rating: 250 VAC/3A,

250 VDC/0.1 A(resistive load)

Transmitter Power Supply Wiring (/TPS4 Option)

–

+

+

–

Transmitter

Current

CX2000

Transmitter

power supply

output terminal

Measurement

input terminal

Shunt resistor: 250 Ω

Output

Number of loops: 4

Output voltage: 22.8 to 25.2 V

(at rated current load)

Rated output current: 4 to 20 mADC

Maximum output current: 25 mADC

(overcurrent protection operating

current: approx. 68 mADC)

Maximum length of wiring: 2 km

(when using CEV cables)

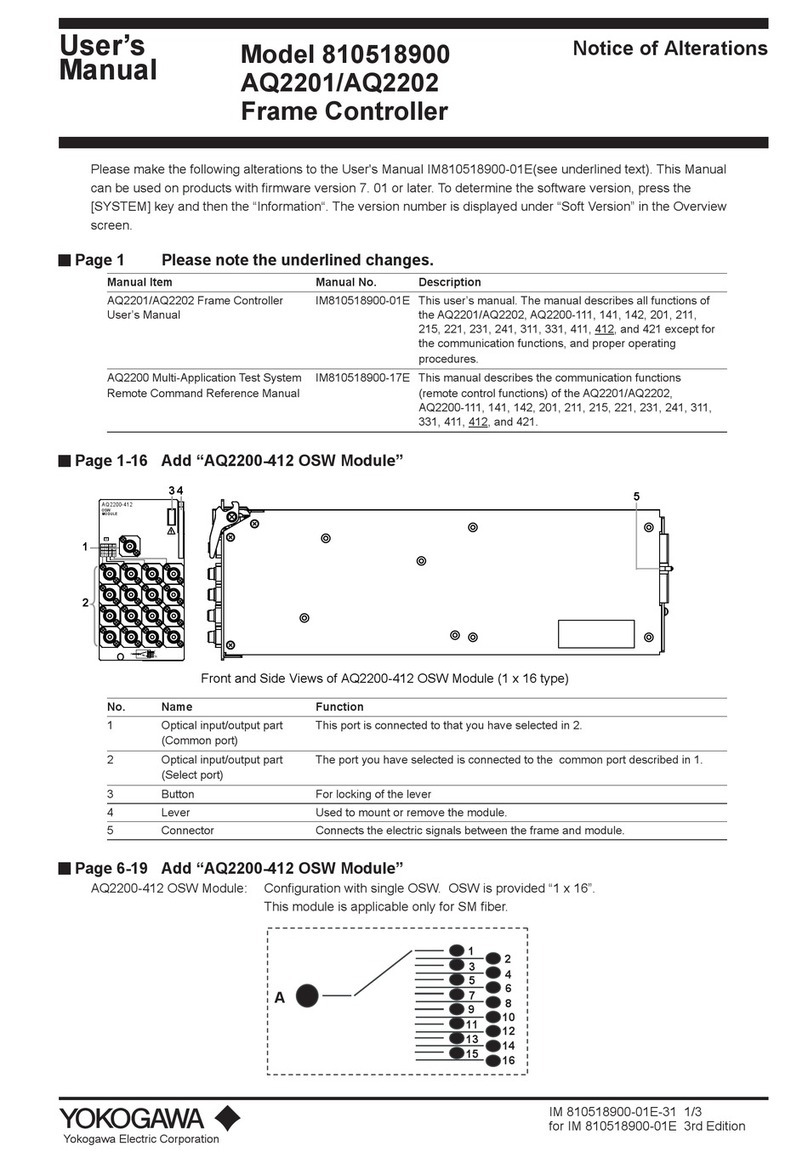

Label on the Back of the Terminal Cover

Indicates the type of input/output signals for each terminal.

Yo u can select the control modes from "single loop control", "cascade control", and "loop control with

PV switching" on the CX.The arrangement of the analog control input (PV) terminals are changed

depending on the control mode selected. The terminal arrangement for these three control modes are

written on the label on Analog Control Input Terminal.

LOOP5

004

005

006

007

008

009

010

011

012

013

014

015

016

017

018

019

020

021

022

023

024

025

026

027

028

029

030

031

032

033

LOOP1LOOP4 LOOP2LOOP3LOOP6

CAT

Label on the Front

(

For the 6 Loop Analog Control Input Terminal Block

)

b

A

B

SNGL

CAS

PVSW

211

LOOP4 LOOP6

(RSP) PV PV

PV

PV1PV2

1

PV

PV

PV1

2

LOOP3

(RSP)

(RSP)

PV2

1

PV

PV

PV1

LOOP1

2

(RSP)

(RSP)

PV2

1

PV

PV

PV1

LOOP2

1

PV

LOOP5

2

(RSP)

PV2

CAT

Te r minal symbol

Label on the Back

(

For the 6 Loop Analog Control Input Terminal Block

)

PV, PV1, PV2: measurement input, (RSP): remote input (not used during program control), : unused terminal

During single-loop control

During cascade control

During loop control with

PV switching

[Control mode setting]

Label on the Front of the Terminal Cover

The terminal numbers are written on the label on the front of the terminal cover. Terminal numbers are

unique three-digit numbers.They are used to locate terminals on the wiring diagram, etc. The highest

digit indicates the arrangement position of the terminal block; the lower two digits indicate the terminal

position within the terminal block (top right terminal is assigned "01" bottom left terminal is assigned

"36"). The terminals that cannot be used are indicated as " ".