YOKOGAWA YewSeries 80 User manual

User’s

Manual

Yokogawa Electric Corporation

IM 01B04K02-02E

9th Edition

Model SALD (Style S)

mV and Temperature Alarm Unit

Toc-1

IM 01B04K02-02E

1

2

3

App

1

2

3

5

6

7

8

4

Contents

Chapter 1 Introduction

1.1 Inspection............................................................................................................................1-2

1.2 Documentation Conventions ...............................................................................................1-3

1.3 Notice ..................................................................................................................................1-4

1.4 Compatibility with Previous Models.....................................................................................1-5

Chapter 2 General

2.1 Standard Specifications ......................................................................................................2-2

2.2 Model and Suffix Codes ......................................................................................................2-3

2.3 Measurement Range and Accuracy Warranty.....................................................................2-4

2.4 Accessories.........................................................................................................................2-5

Chapter 3 Installation

3.1 External Wiring....................................................................................................................3-2

3.2 Example of Alarm Wiring.....................................................................................................3-3

3.2.1 High-limit and High-high-limit Alarms .....................................................................................3-3

3.2.2 Three-position Alarm ..............................................................................................................3-3

Chapter 4 Principles of Operation

4.1 Principle of Operation..........................................................................................................4-1

4.2 Description of Functions......................................................................................................4-2

4.2.1 Input Processing Functions....................................................................................................4-3

4.2.2 Alarm Processing Function ....................................................................................................4-5

4.3 Example of Alarm Function Setting .....................................................................................4-6

4.3.1 Condition of Alarm Function...................................................................................................4-6

4.3.2 Parameters of Alarm Function................................................................................................4-6

4.3.3 Operating Condition of Alarm Function ..................................................................................4-6

Chapter 5 Setting

5.1 Names of Components .......................................................................................................5-2

5.2 Setting Jumper ....................................................................................................................5-3

5.2.1 Check of Setting Jumper and its Location..............................................................................5-4

5.2.2 Change of Setting Jumper .....................................................................................................5-4

5.3 Setting of Parameters .........................................................................................................5-5

5.3.1 Parameter Change Disable Function .....................................................................................5-5

5.3.2 Setting of Parameters Using Display Setter (SALD-xx4) .......................................................5-5

5.3.3 Setting of Parameters Using Handy Terminal ........................................................................5-9

5.4 Parameter List...................................................................................................................5-10

Chapter 6 Maintenance

6.1 Test Equipment ...................................................................................................................6-2

6.2 Reference Table of Thermocouple and RTD.......................................................................6-3

6.3 Adjustment and Check ........................................................................................................6-4

6.3.1 Adjustment of Input ................................................................................................................6-4

6.3.2 Check of Alarm Set Point .......................................................................................................6-6

6.3.3 Correction of Input Wiring Resistance....................................................................................6-7

6.3.4 Check of Reference Junction Temperature Compensation Action.........................................6-7

6.4 List of Replaceble Parts ......................................................................................................6-8

Toc-2 IM 01B04K02-02E

Chapter 7 Troubleshooting

7.1 Action in Fault Condition. ....................................................................................................7-2

Chapter 8 Power Supply Terminal Connections (Option /TB, /A2TB, and /REK)

8.1 External View and Names of Components .........................................................................8-2

8.2 Power Supply and Ground Wiring.......................................................................................8-3

General Specifications

Contents

1-1

IM 01B04K02-02E

Introduction

1

2

3

App

1

2

3

5

6

7

8

4

Introduction

This manual describes the functions and operations of the SALD mV and Temperature Alarm

Unit.

● IntendedReaders

This manual is intended for personnel in charge:

• Installation and wiring

• Instrumentation and setup of the function

• Operation and monitoring of the controller

• Maintenance of equipment

● RelatedDocuments

The following documents all relate to the SALD mV and Temperature Alarm Unit. Read them

as necessary. The codes enclosed in parentheses are the document numbers.

Manual Title Manual No. Description

Rack-Mounted Instruments IM 1B4F2-01E Describes mounting and wiring for the YS80 rack-mounted instruments.

Model JHT200 Handy Terminal IM 77J50H01-01EN Describes operation of JHT200.

Chapter 1 Introduction

1-2 IM 01B04K02-02E

1.1 Inspection

The SALD mV and temperature alarm unit is shipped only after stringent inspection at the

factory. Visually inspect the product upon delivery to make sure it is not damaged in any

way.

Store the box and inner packing material of the package in a safe place / they may be

needed if there is a problem with the product and it needs to be sent back for repair.

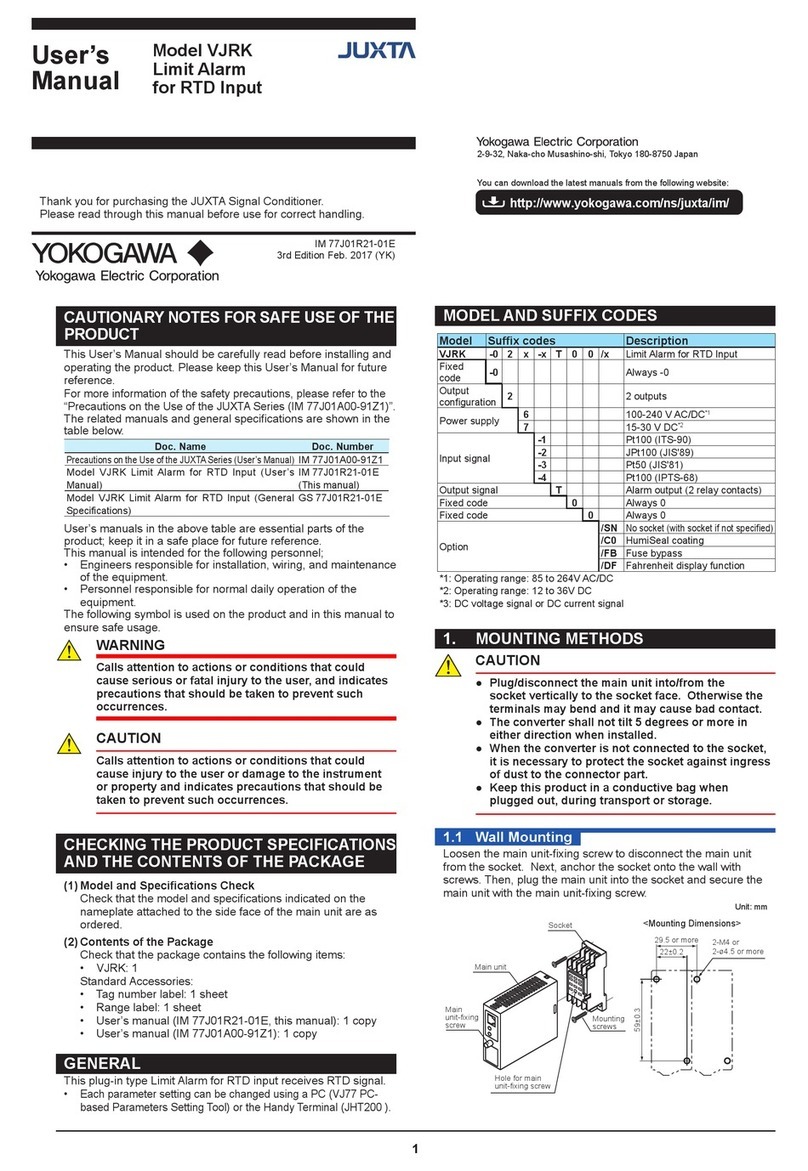

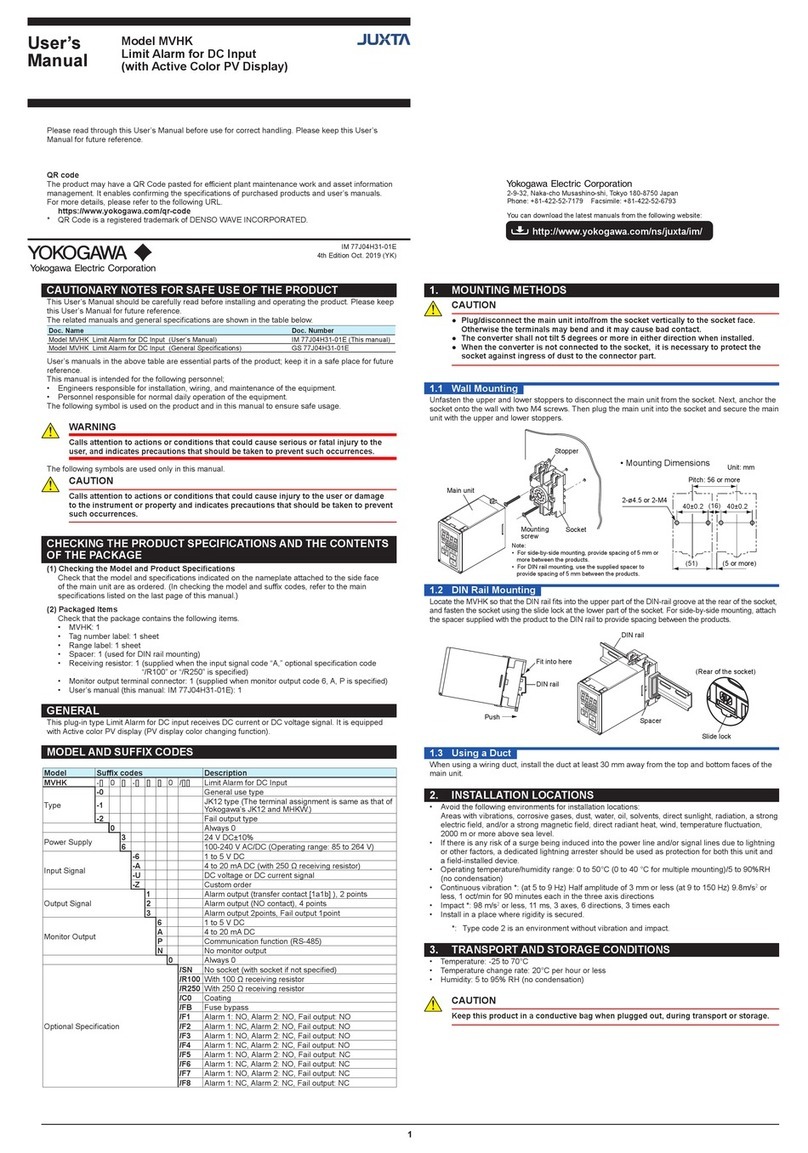

Check of Model and Suffix Codes

The model and suffix codes are indicated on the Name plate attached to the front cover of

the instrument. Crosscheck this information with the model and suffix codes of Section 2.2

to ensure that the product is as specified in the order.

F0101.ai

100-120VAC 50/60Hz

ALARM

SALD

-314-PD*S

XXXXXXXXX

Pt100(ITS-90)

0-100℃

60mA

6.0VA

24-110VDC

100-120VAC 50/60Hz

ALARM

SALD

-314-PD*S

XXXXXXXXX

Pt100(ITS-90)

0-100℃

60mA

6.0VA

24-110VDC

Figure 1-1 Name plate for Thermocouple Input (Description example)

Confirmation of the Package Contents

Check the package contents against the list below. If anything is missing or damaged,

immediately contact the sales office from which you purchased the product or your nearest

Yokogawa representative.

• SALD mV and Temperature Alarm Unit ............................................................1

• Alarm Label (Parts No.: L4040JA).....................................................................1

• Precautions on the Use of the YS80 Series ......................................................1

Downloadable Electronic Manuals

You can download the latest manuals from the following website:

http://www.yokogawa.com/ns/ys/

1-3

IM 01B04K02-02E

Introduction

1

2

3

App

1

2

3

5

6

7

8

4

1.2 Documentation Conventions

This manual uses the following notational conventions

Symbols

The following symbols are used in this manual.

Markings

Indicates that operating the hardware or software in a particular

manner may damage it or result in a system failure.

Draws attention to information that is essential for understanding the

operation and/or features of the product.

Note Gives additional information to complement the present topic and/or

describe terms specific to this document.

Gives reference locations for further information on the topic.

Description of Displays

Some of the representations of product displays shown in this manual may be exaggerated,

simplified, or partially omitted for reasons of convenience when explaining them.

QR Code

The product has a QR Code pasted for efficient plant maintenance work and asset

information management. It enables confirming the specifications of purchased products and

user’s manuals.

For more details, please refer to the following URL.

https://www.yokogawa.com/qr-code

QR Code is a registered trademark of DENSO WAVE INCORPORATED.

1-4 IM 01B04K02-02E

1.3 Notice

This Instruction Manual

• This manual should be passed on to the end user. Keep at least one extra copy of the

manual in a safe place.

• Read this manual carefully to gain a thorough understanding of how to operate this

product before you start using it.

• This manual is intended to describe the functions of this product. Yokogawa Electric

Corporation (hereinafter simply referred to as Yokogawa) does not guarantee that these

functions are suited to the particular purpose of the user.

• Under absolutely no circumstances may the contents of this manual, in part or in whole,

be transcribed or copied without permission.

• The contents of this manual are subject to change without prior notice.

• Every effort has been made to ensure accuracy in the preparation of this manual. Should

any errors or omissions come to your attention however, please contact your nearest

Yokogawa representative or sales office.

Protection, Safety, and Prohibition against Unauthorized Modification

• The following safety symbols are used on the product and in this manual.

Markings

CAUTION

If this symbol is indicated on the product, the operator should refer

to the explanation given in the instruction manual in order to avoid

personal injury or death to either themselves or other personnel, and/

or damage to the instrument. The manual describes that the operator

should exercise special care to avoid shock or other dangers that may

result in injury or loss of life.

Protective ground terminal:

This symbol indicates that the terminal must be connected to ground

prior to operating the equipment.

Function ground terminal:

This symbol indicates that the terminal must be connected to ground

prior to operating the equipment.

AC voltage:

This symbol indicates that AC voltage is present.

DC voltage:

This symbol indicates that DC voltage is present.

• In order to protect the product and the system controlled by it against damage and ensure

its safe use, make certain that all of the instructions and precautions relating to safety

contained in this document are strictly adhered to. Yokogawa does not guarantee safety

if products are not handled according to these instructions.

• If protection/safety circuits are to be used for the product or the system controlled by it,

they should be externally installed on the product.

• Do not turn off the power of the product during adjustment and parameter setting.

• Be sure to confirm the parameters referring to ‘‘5.4 Parameter List’’ before installing the

product in a system or plant. After confirming them, install the product in a system or plant

and turn on the power.

• When you replace the parts or consumables of the product, only use those specified by

Yokogawa.

• If the product is to be used in systems with special requirements for human safety, such

in as nuclear power and radiation related equipment, railway facilities, aircraft facilities,

and medical devices, please consult with your sales representative.

• Do not modify the product.

Force Majeure

• Yokogawa does not make any warranties regarding the product except those mentioned

in the WARRANTY that is provided separately.

• Yokogawa assumes no liability to any party for any loss or damage, direct or indirect,

caused by the use or any unpredictable defect of the product.

1-5

IM 01B04K02-02E

Introduction

1

2

3

App

1

2

3

5

6

7

8

4

1.4 Compatibility with Previous Models

Compatibility with style A

●Operation and settings differ from previous model (styles A). Please read this document

carefully before operating the product.

●Before installing this product in a system or plant, you must check the jumper settings and

parameters described in chapter 5, “Settings.” After checking settings and parameters,

install the product in the system or plant, and then turn ON the power.

Compatibility with style R

●Operation and settings are the same as for the previous model (style R). Please read this

document carefully before operating the product.

●Before installing this product in a system or plant, you must check the jumper settings and

parameters described in chapter 5, “Settings.” After checking settings and parameters,

install the product in the system or plant, and then turn ON the power.

Blank

2-1

IM 01B04K02-02E

General

1

2

3

App

1

2

3

5

6

7

8

4

General

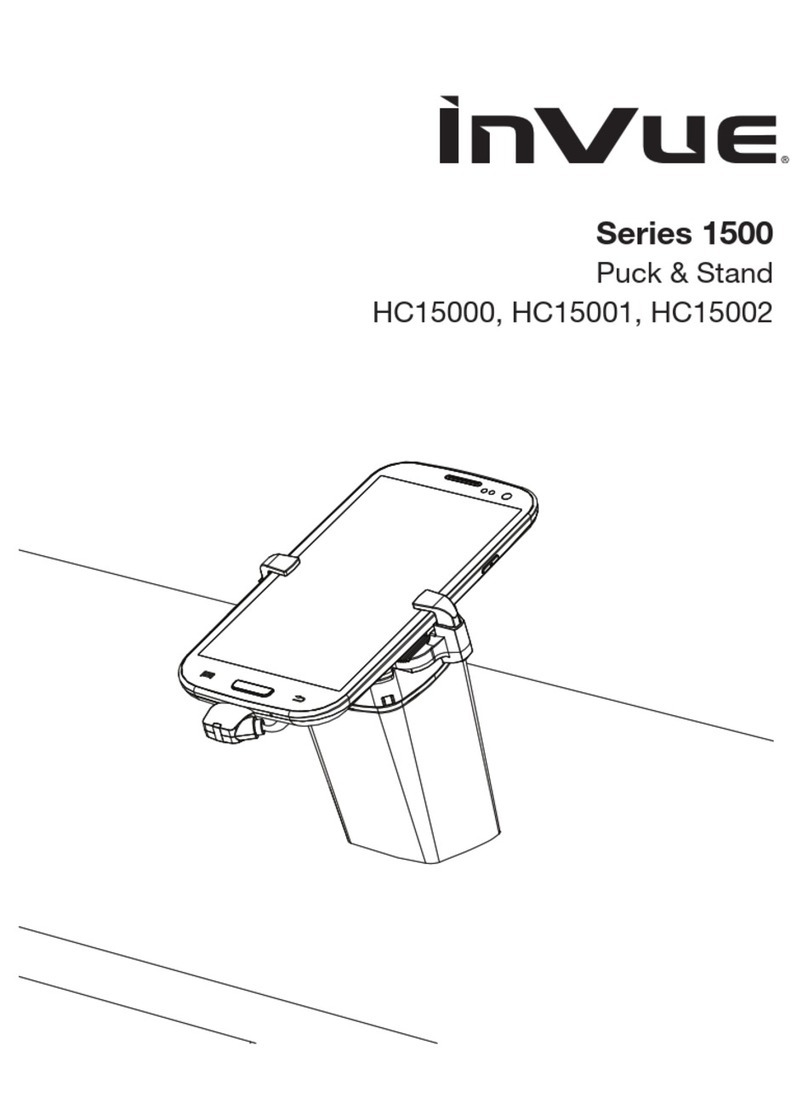

The SALD mV and temperature alarm unit receives a mV DC, thermocouple or RTD

(resistance temperature detector) input directly, compares this input with an alarm set point,

and outputs an alarm contact signal. The input has one or two absolute-alarm outputs.

Direct or reverse alarm action can be selected for each of the alarm output set points. The

front panel is provided with an alarm LED indicator lamp for confirming alarm relay action

(when relay is energized).

The JHT200 Handy Terminal*1 is used for setting the SALD parameters.

On the SALD model with display setter (SALD-x04), input indication (engineering unit) can

be displayed and alarm set points can be displayed / set on the front panel.

*1: The modular jack conversion adapter (E9786WH) is required for connecting the JHT200 Handy

Terminal to the mV and Temperature Alarm Setter.

The 5 pin-connector type communication cable (F9182EE) and modular jack conversion adapter

(E9786WH) is required for connecting the BT200 BRAIN Terminal of YOKOGAWA ELECTRIC

Corporation.

F0201.ai

Figure 2-1 External View

Chapter 2 General

2-2 IM 01B04K02-02E

2.1 Standard Specifications

Please see the General Specifications (GS 01B04K02-02E) at the end of this manual.

2-3

IM 01B04K02-02E

General

1

2

3

App

1

2

3

5

6

7

8

4

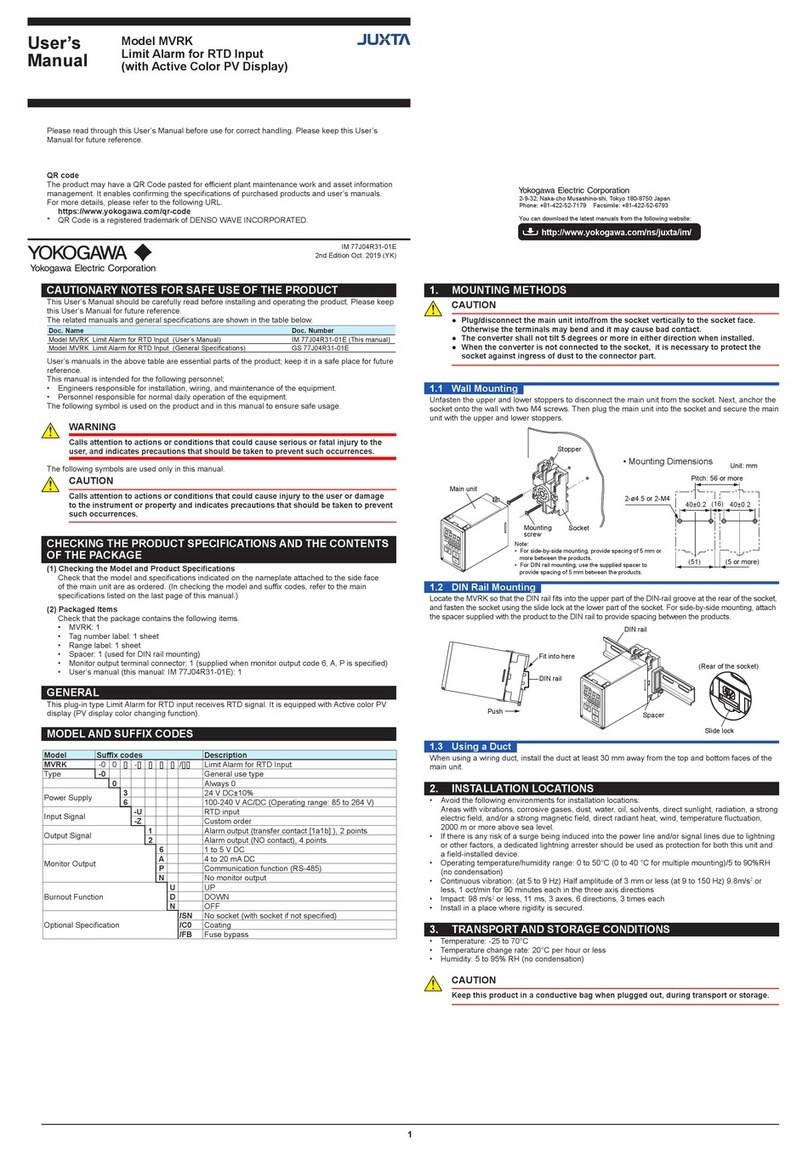

2.2 Model and Suffix Codes

Model Suffix Codes Optional

Suffix Codes

Description

SALD mV and Temperature Alarm Unit

Input

Signal

-1

-2

-3

-7

mV input

Thermocouple input

RTD input

Universal input (mV, TC, RTD input)

Alarm 1

2

1 input, 1 setpoint absolute alarm

1 input, 2 setpoints absolute alarm

Display Setter 0

4

Not provided

Provided

Selectable Combination

Suffix Codes

SALD-110/-114

SALD-210/-214

SALD-310/-314

SALD-710/-714/-724

Auxiliary Codes

SALD-1xx: “-MV”

SALD-2xx: “-TK” to “-TS”

SALD-3xx: “-PA” to “-PD”

SALD-7xx: “-UN”

-MV

-TK

-TT

-TJ

-TE

-TB

-TR

-TS

-PA

-PB

-PD

-UN

mV DC

Type K (ITS90, JIS C1602)

Type T (ITS90, JIS C1602)

Type J (ITS90, JIS C1602)

Type E (ITS90, JIS C1602)

Type B (ITS90, JIS C1602)

Type R (ITS90, JIS C1602)

Type S (ITS90, JIS C1602)

JPt100 (JIS’89)

Pt50 (JIS’81)

Pt100 (ITS-90, JIS C1604)

Universal input (mV, TC, RTD input)

Style Code *S Style S

Option Codes (*1) (*2) /NHR

/FBP

/LOCK

/WSW

/REK

/TB

/A2TB

/A2ER

/FCAL

Without rack case

Power supply fuse bypass

Power supply plug with lock

With spring washer

Mount to same line with EK series rack

With power supply terminal

220V version with power supply terminal

220V version with power supply plug

Fahrenheit range

*1: /LOCK, /REK, /TB, /A2TB, and /A2ER cannot be specified together.

*2: /FBP, /A2TB, and /A2ER cannot be specified together.

2-4 IM 01B04K02-02E

2.3 Measurement Range and Accuracy Warranty

Input Type Measuring Range Measuring Range (K) Measuring Range (°F)

(*6)

Input Accuracy

mV DC Input 0 to100 mVDC ±0.5% of measuring

range (*1)

Thermocouple

Input (*3)

Type K -270.0 to 1372.0 °C 0.0 to 1640.0 K -450.0 to 2500.0 °F ±0.5% (*1) of measuring

range + reference junction

compensation error (*2)

Type T -270.0 to 400.0 °C 0.0 to 670.0 K -450.0 to 750.0 °F

Type J -210.0 to 1200.0 °C 80.0 to 1470.0 K -340.0 to 2300.0 °F

Type E -270.0 to 1000.0 °C 0.0 to 1270.0 K -450.0 to 1830.0 °F

Type B 50.0 to 1820.0 °C 330.0 to 2090.0 K 130.0 to 3300.0 °F

Type R -50.0 to 1768.0 °C 230.0 to 2040.0 K -50.0 to 3210.0 °F

Type S -50.0 to 1768.0 °C 230.0 to 2040.0 K -50.0 to 3210.0 °F

Type N (*5) -270.0 to 1300.0 °C 0.0 to 1570.0 K -450.0 to 2400.0 °F

Type W3 (*5) 0 to 2315 °C 280 to 2580 K 32 to 4190 °F

Type W5 (*5) 0 to 2315 °C 280 to 2580 K 32 to 4190 °F

RTD (*4) JPt100 -200.0 to 510.0 °C 80.0 to 780.0 K -320.0 to 940.0 °F ±0.5% of measuring

range

Pt50 -200.0 to 649.0 °C 80.0 to 920.0 K -320.0 to 1200.0 °F

Pt100 (ITS-90) -200.0 to 850.0 °C 80.0 to 1120.0 K -320.0 to 1560.0 °F

Pt100 (IPTS-68) -200.0 to 660.0 °C 80.0 to 930.0 K -320.0 to 1210.0 °F

*1: The accuracy is ±2.5% for a temperature range below -200 °C.

The accuracy is ±2.5% for a temperature range below 600 °C.

*2: Reference junction compensation error:

Above 0 °C: ±0.5% (except for TypeR, TypeS)

±1% (for TypeR, TypeS)

Below 0 °C: Multiply accuracy for temperatures over 0°C by K, where

K = (Thermocouple output change/°C near 0°C) / (Thermocouple output change/°C at

measurement temperature)

*3: Thermocouple JIS C 1602, IEC 60584-1 (ITS-90)

TypeK, T, E, J, R, S, B, N, W3(Note 1), W5(Note 2)

Note 1: ASTM E988 Standard: W97Re3-W75Re25

(tungsten97% rhenium3%-tungsten75% rhenium25%)

Note 2:ASTM E988 Standard: W95Re5-W74Re26

(tungsten95% rhenium5%-tungsten74% rhenium26%)

*4: RTD JIS C 1604, IEC 60751 (ITS-90) Pt100

JIS C 1604: 1989, DIN (IPTS-68) Pt100

JIS C 1604: 1989, JPt100

JIS C 1604: 1981, Pt50 JIS C 1604

*5: For SALD-7 type only

*6: Measuring range (°F) is displayed when the option /FCAL is specified.

2-5

IM 01B04K02-02E

General

1

2

3

App

1

2

3

5

6

7

8

4

2.4 Accessories

Alarm Label: 1 sheet

Blank

3-1

IM 01B04K02-02E

Installation

1

2

3

App

1

2

3

5

6

7

8

4

Installation

For details of the installation procedure and wiring precautions, refer to the instruction

manual “Installation of Rack-Mounted Instruments” (IM 1B4F2-01E).

Chapter 3 Installation

3-2 IM 01B04K02-02E

3.1 External Wiring

(1) All cable ends must be furnished with crimp-on type solderless lugs (for 4mm screws).

(2) Draw out the internal unit from the rack case.

(3) Connect the cables to the correct terminals referring to Figure 3-1.

(4) Return the internal unit into the rack case after completing the wiring.

(5) Always return the terminal block cover to its original position after completing the wiring.

The terminal block cover cannot be returned to its original position if the internal unit

is not installed correctly inside in the rack case. Securely return the terminal block

cover because it also functions as lock for the internal unit.

K

J

H

F

D

C

B

A

8

7

6

5

4

3

2

1

OUT

IN

Terminal arrangement

Figure 3-1 Terminal Layout and Terminal Wiring

Terminal

Designation Description

ANC Alarm output 1

BCOM

C

D

FNC Alarm output 2 (*1)

HCOM

JNO

KNO

Do not connect to the output terminal when the terminal is not in use.

*1: For SALD-724 only.

Terminal

Designation

Description

SALD-1, 2 SALD-3

1 + Input 1 A

b

2 -

3

4Input 1

5

6 (RJC block installation

terminal)

7 B

8

For SALD-7 , the connection depends on the selected sensor type

(mV DC, thermocouple or RTD).

3-3

IM 01B04K02-02E

Installation

1

2

3

App

1

2

3

5

6

7

8

4

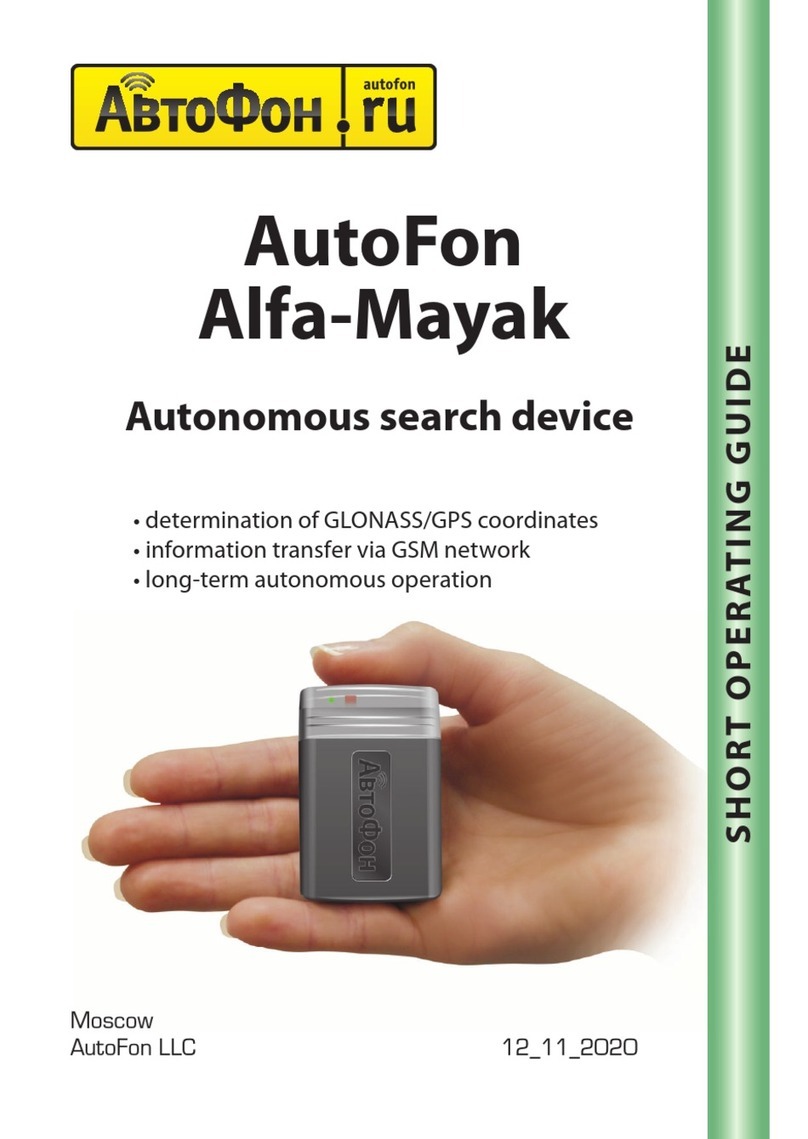

3.2 Example of Alarm Wiring

The SALD mV and temperature alarm unit provides various types or alarms depending on

the setting of the alarm action or the method of connecting the alarm output terminals.

Thus, the necessary wiring should be made with reference to the following two examples:

3.2.1 High-limit and High-high-limit Alarms

Set the direct action (DIRECT) for the alarm actions of both alarms 1 and 2. Then wire the

terminals as illustrated in Figure 3-2.

F0302.ai

SALD

mV and Temperature

Alarm Unit

H

H

Alarm output terminal

Alarm 2 setting

Alarm 1 setting

Input value

Figure 3-2 External Wiring - Example 1

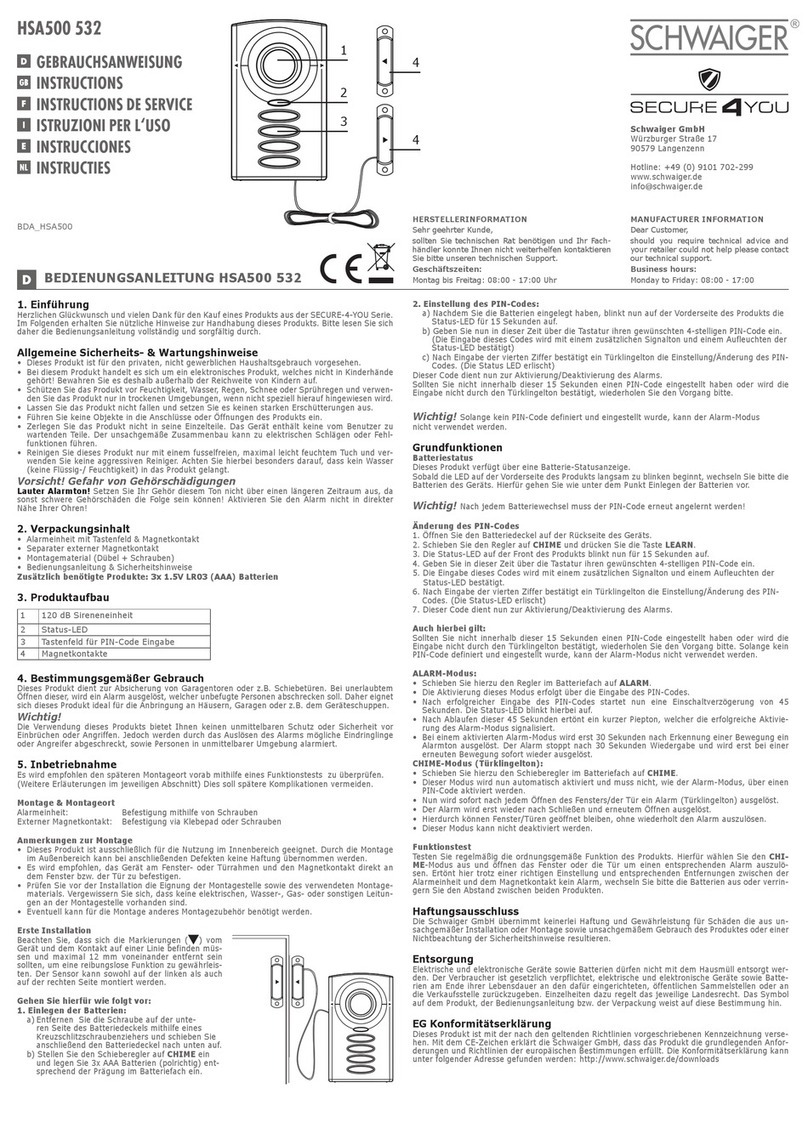

3.2.2 Three-position Alarm

Set the reverse action (REVERSE) for the alarm action of alarm 1, and the direct action

(DIRECT) for the alarm action of alarm 2. Then wire the terminals as illustrated in Figure

3-3..

F0302.ai

L

Alarm outputterminal

Alarm 2 setting

Alarm 1 setting

Input value

N

H

Alarm

SALD

mV and Temperature

Alarm Unit

Figure 3-3 External Wiring - Example 2

3-4 IM 01B04K02-02E

Applicable Cables

(1)Signal circuit wiring

• Cross-sectional area of the cable conductor: 0.5 to 0.75 mm2

• Examples of applicable cables: Single core PVC insulated flexible cable (VSF)

stranded wires (JIS C 3306); heat-resistant vinyl-insulated cable (UL style 1007)

(2)Alarm circuit wiring

• Cross-sectional area of the cable conductor: 0.5 to 1.25 mm2

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires (JIS C

3307); PVC insulated cable for electric appliances (KIV) stranded wires (JIS C 3316);

heat-resistant vinyl-insulated cable (UL style 1007)

(3)Power supply wiring

• Cross-sectional area of the cable conductor: 1.25 to 2.00 mm2

• Examples of applicable cables: 600 V PVC insulated cable (IV) stranded wires (JIS C

3307)

3.2 Example of Alarm Wiring

This manual suits for next models

1

Table of contents

Other YOKOGAWA Security System manuals

YOKOGAWA

YOKOGAWA JUXTA VJAK User manual

YOKOGAWA

YOKOGAWA VJRK User manual

YOKOGAWA

YOKOGAWA Yew 80 Series User manual

YOKOGAWA

YOKOGAWA JUXTA MVRK User manual

YOKOGAWA

YOKOGAWA JUXTA MVHK User manual

YOKOGAWA

YOKOGAWA JUXTA VJHK User manual

YOKOGAWA

YOKOGAWA JUXTA VJ Series User manual

YOKOGAWA

YOKOGAWA JUXTA VJTK User manual

Popular Security System manuals by other brands

SleuthGear

SleuthGear Zone Shield user manual

Bridgesecure Technologies

Bridgesecure Technologies Alarmster ONE user manual

Interlogix

Interlogix ZeroWire installation manual

D-Link

D-Link mydlink DCH-S220 user manual

Honeywell

Honeywell SILENT KNIGHT RA-2000 manual

Electronic.Star

Electronic.Star M703SN4 manual