2IM 77J01A21-01E 3rd Edition

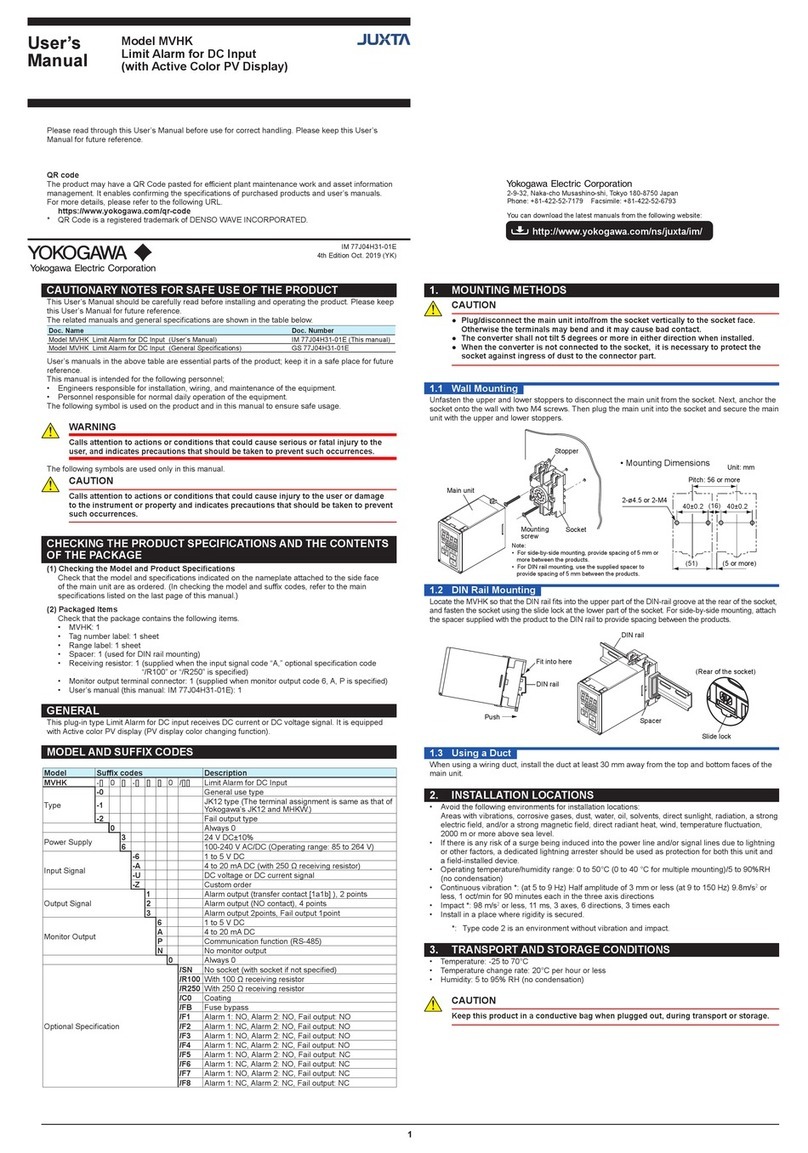

1.1 Wall Mounting

Loosen the main unit-xing screw to disconnect the main unit

from the socket. Next, anchor the socket onto the wall with

screws. Then, plug the main unit into the socket and secure the

main unit with the main unit-xing screw.

Main

unit-fixing

screw

Socket

Main unit

Hole for main

unit-fixing screw

Mounting

screws

<Mounting Dimensions>

Unit: mm

29.5 or more

22±0.2

59±0.3

2-M4 or

2-ø4.5 or more

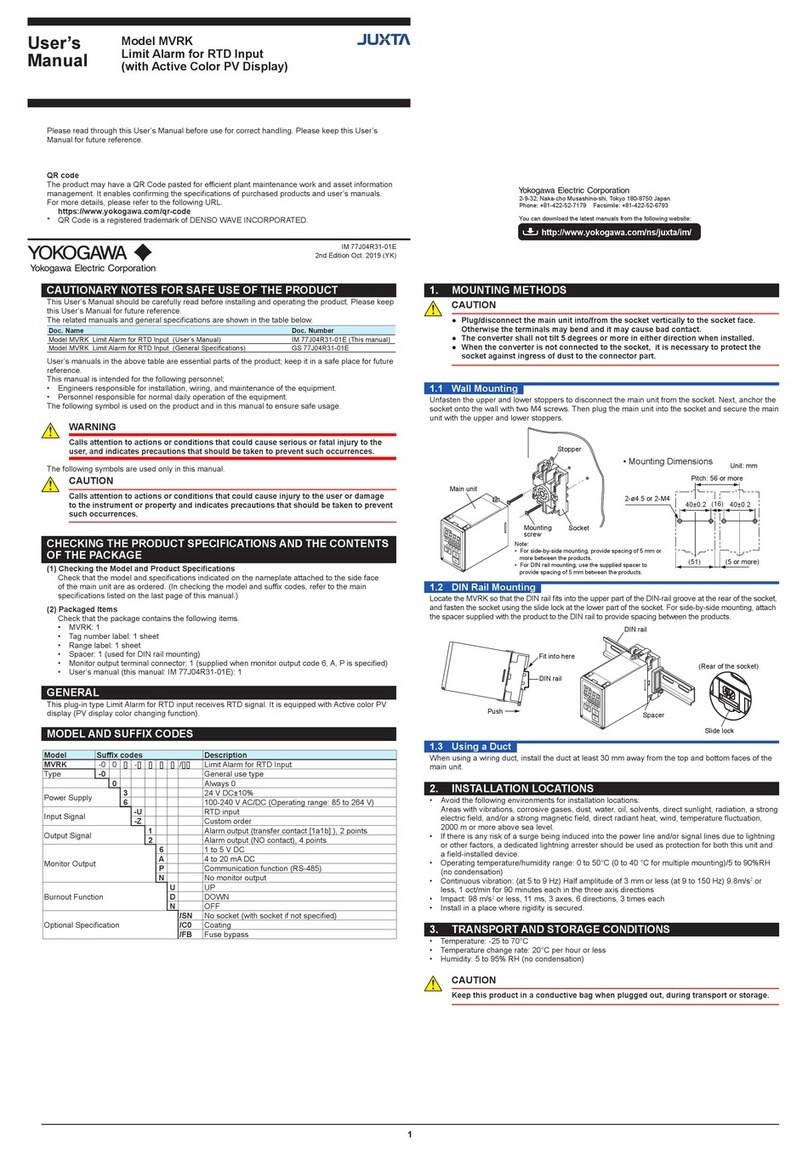

1.2 DIN Rail Mounting

Locate the VJAK so that the DIN rail ts into the upper part of the

DIN-rail groove at the rear of the socket, and fasten the socket

using the slide lock at the lower part of the socket.

rail

here

Push

DIN rail

(Rear of the socket)

DIN rail

1.3 Mounting Using a Multi-mounting Base

For mounting using a multi-mounting base, see the Instruction

Manual for VJCE (VJ Mounting Base).

1.4 Using a Duct

Wiring duct should be installed at least 30 mm away from the top

and bottom faces of the main unit.

2. INSTALLATION LOCATIONS

• Avoid the following environments for installation locations:

Areas with vibrations, corrosive gases, dust, water, oil,

solvents, direct sunlight, radiation, a strong electric eld,

and/or a strong magnetic eld, direct radiant heat, wind,

temperature uctuation, 2,000 m or more above sea level.

• If there is any risk of a surge being induced into the power line

and/or signal lines due to lightning or other factors, a dedicated

lightning arrester should be used as protection for both the

product and a eld-installed device.

• Operating temperature/humidity range: -10 to 55°C (-10

to 45°C for side-by-side mounting*)/5 to 90%RH (no

condensation)

* If the previous model (style S3.xx earlier) is installed

together, the ambient temperature is 0 to 40°C.

• Continuous vibration: (at 5 to 9 Hz) Half amplitude of 3 mm or

less (at 9 to 150 Hz) 9.8m/s2or less, 1 oct/min for 90 minutes

each in the three axis directions

• Impact: 98 m/s2 or less, 11 ms, 3 axes, 6 directions, 3 times

each

3. EXTERNAL WIRING

WARNING

●Toavoidtheriskofanelectricshock,turnothe

power supply and use a tester or similar device to

ensure that no power is supplied to a cable to be

connected, before carrying out wiring work.

●Do not operate the product in the presence of

ammableorexplosivegasesorvapors.Todosois

highly dangerous.

●Useoftheproductignoringthespecicationsmay

cause overheating or damage. Before turning on

the power, ensure the following:

•Power supply voltage and input signal value

applied to the product should meet the required

specications.

•The external wiring to the terminals and wiring to

ground are as specications.

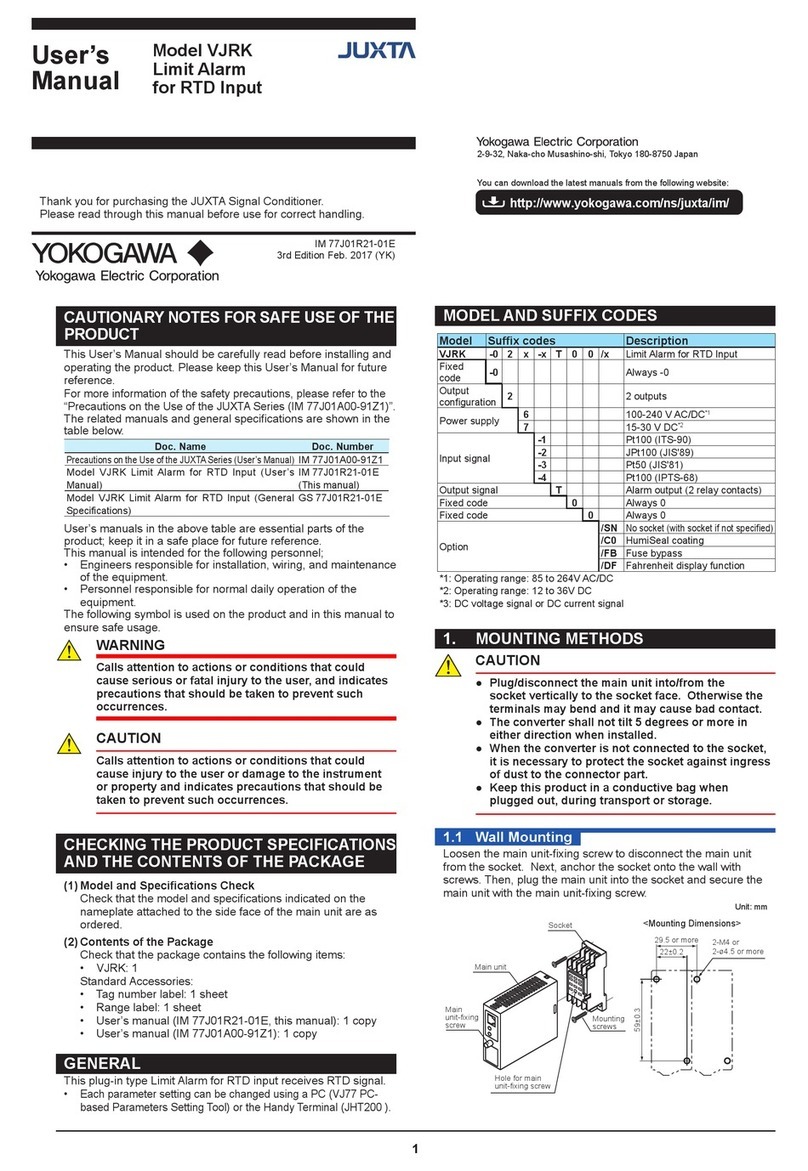

Wiring should be connected to the terminals on the socket of the

VJAK. The terminals for external connections are of M3 screws.

Use crimp-on lugs for connections to the terminals.

• It is recommended that signal wires have a nominal cross-

sectional area of 0.5 mm2or thicker, while the power cable has

a nominal cross-sectional area of 1.25 mm2or thicker.

1011

3 2 1

4

56

789

3

1

3

1

44

11

10

8

5

2

9

7

GND

L

+

N

–

COM

ALM2 (NO)

COM

COM

ALM1 (NO)

COM

PS

+

Input signal

+

–

+

–

––

When using

internal

power supply

When using

external

power supply

Power supply

Alarm-1 output signal

Alarm-2 output signal

When connecting the transmitter to the VJAK directly without using the transmitter

power supply, connect [+] of the transmitter output to the terminal no. 3 and connect [

–

CAUTION

●The product is sensitive to static electricity;

exercisecareinoperatingit.Beforeyouoperate

the product, touch a nearby metal part to discharge

static electricity.

●Ifaninductance(L)loadsuchasauxiliaryrelaysor

solenoid valves is used, always insert a spark killer

fordiminishingsparks,suchasaCRlteroradiode

in parallel with the inductance load. Otherwise a

malfunction or relay failure may occur. Refer to the

following guidelines for a capacitor and resistor:

Capacitor : 0.5 to 1 μF with respect to a contact current

of 1 A

Resistor: 0.5 to 1 Ω with respect to a contact voltage of

1 V

●The power line and input/output signal lines should

be installed away from noise-generating sources.

Otherwise accuracy cannot be guaranteed.

●Make sure to earth ground the ground terminal

through minimum resistance. The length and

thickness of the grounding cable should be as

short and thick as possible. Directly connect the

lead from the ground terminal (terminal no. 8) of

the product to the ground. Do not carry out daisy-

chained inter-ground terminal wiring.

●If the ambient temperature is 50 °C or more, please

use the cable that the rated temperature is 70 °C or

more.

4. DESCRIPTION OF FRONT PANEL AND

CONNECTION OF SETTING TOOLS

4.1 Front Panel

The communications connector on the front panel is used for

setting up parameters using a PC (VJ77 PC-based Parameters

Setting Tool) or the Handy Terminal (JHT200). The alarm indicator

lamps for alarm 1 and alarm 2 light up if an alarm occurs.

Alarm indicator lamp

(for alarm 1)

Communication connector

Alarm indicator lamp

(for alarm 2)