3IM 77J01H21-01E 5th Edition

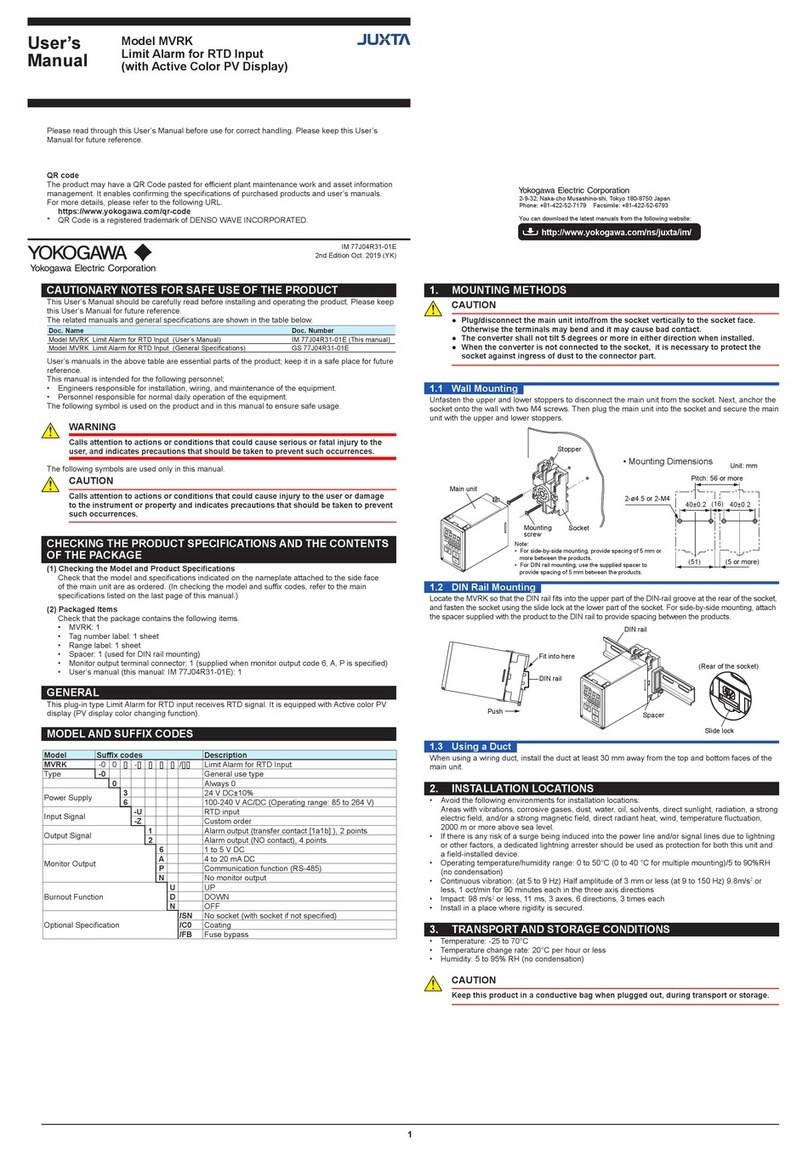

4.2 Connecting the Setting Tools

Used to set JUXTA parameters on a PC (VJ77 Parameter Setting

Tool).

JUXTA

VJ series

conversion

adapter

Dedicated adapter for VJ77

(L4506HA)

Micro USB (USB2.0) cable

• Use the VJ77 of version R2.02.01 or later.

5. SETTING PARAMETERS

Set the parameters using a PC (VJ77 PC-based Parameters

Setting Tool). Refer to the list of parameters in this manual and

the user’s manual for VJ77 PC-based Parameters Setting Tool

(IM 77J01J77-01E).

5.1 Settings Related to Input

5.1.1 Input Type

Select the input type from among VOLTS (DC voltage) and

CURRENT (DC current) in [D12: INP TYPE].

5.1.2 Input Range

Set the 0% value of input range in [D25: INPUT1 L_RNG]

and the 100% value of input range in [D26: INPUT1 H_RNG]

numerically within the specied range.

5.1.3 Software Filter

Set the software lter in [D57: S/W FILTER].

OFF, LOW, MIDDLE, HIGH (default value: OFF)

When LOW, MIDDLE, or HIGH is selected, a rst-order lter

equivalent to 100 ms, 300 ms, or 1 s is inserted in the input.

5.1.4 ExternalInputResistanceCorrection

For current input, set the external resistance to [D13: IN

RESIST]. There is a dierence between this value and the

actual external resistance. If this dierence causes an error,

the input can be corrected.

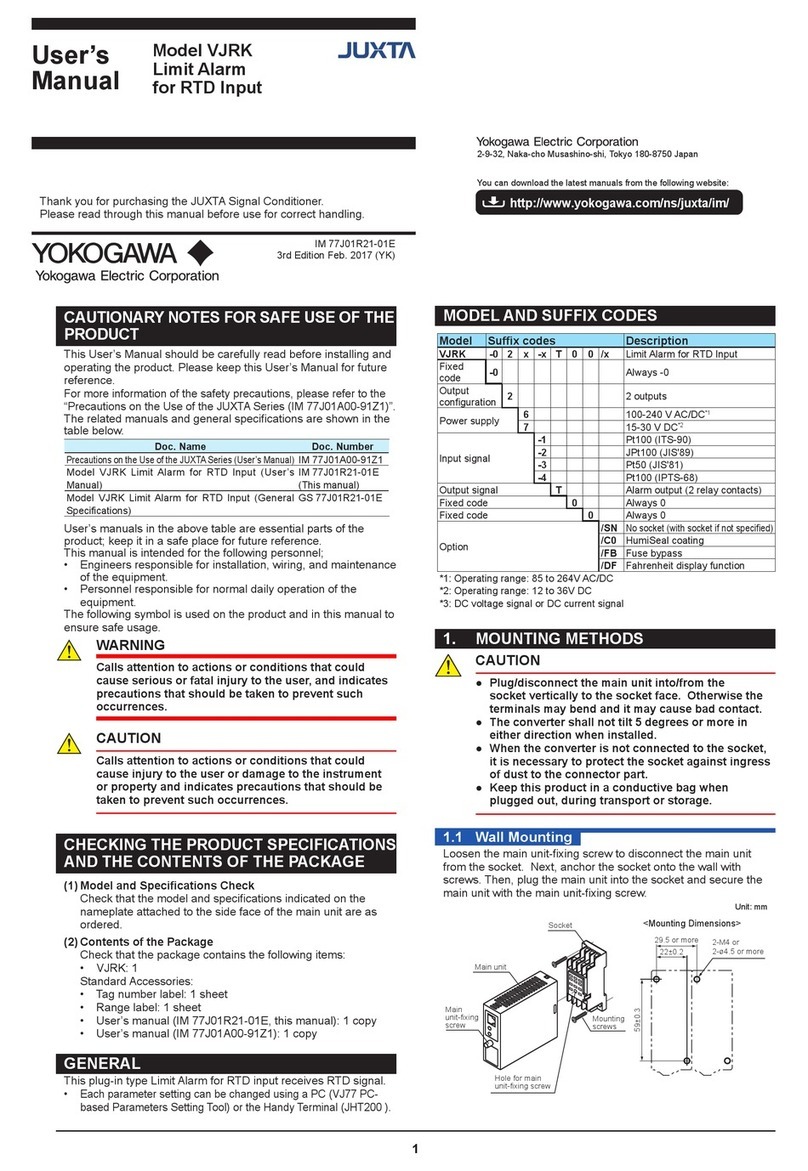

To perform correction, wire as shown in the gure below, apply

a stable input equivalent to 100%, and set [P40:RESISTOR

ADJ] to EXECUTE.

If you need perform correction again such as when the

external resistance is changed, reset the correct value. To do

so, set [P40: RESISTOR ADJ] to RESET.

A current

generator

VJHK

R:External resistor

R

1

3

5.2 Settings Related to Alarm Output

5.2.1 Alarm Setpoint

Set the alarm setpoints of alarm 1 and alarm 2 in [E03: SET

POINT1] and [E04: SET POINT2] numerically.

• Setting range: 0 to 100% of input range

• Setting resolution: 0.1%

5.2.2 Direction of Alarm Action

Select the direction of alarm-1 action and that of alarm-2

action from among HIGH ALM (high-limit alarm) and LOW

ALM (low-limit alarm) in [E05: ALM1 ACTION] and [E06:

ALM2 ACTION].

• To activate alarm status when input signal ≥ alarm setpoint,

select HIGH ALM.

• To activate alarm status when input signal ≤ alarm setpoint,

select LOW ALM.

5.2.3 Hysteresis

Set the alarm-1 and alarm-2 hysteresis in [E09:

HYSTERESIS1] and [E10: HYSTERESIS2]. Hysteresis is a

value added to the alarm setpoint in order for an alarm status

to be released (to normal) after the alarm status has been

activated. The alarm status will be released in the following

conditions, depending on the direction of alarm action.

* When HIGH ALM (high-limit alarm) is set: Alarm is released

when input signal < (alarm setpoint - hysteresis).

* When LOW ALM (low-limit alarm) is set: Alarm is released

when input signal > (alarm setpoint + hysteresis).

• Setting range: 0 to 100% of input range

• Setting resolution: 0.1%

5.2.4 Alarm ON Delay and Alarm OFF Delay

Set the alarm-1 and alarm-2 ON delays in [E11: ON DELAY1]

and [E12: ON DELAY2] and then alarm-1 and alarm-2 OFF

delays in [E13: OFF DELAY1] and [E14: OFF DELAY2].

An alarm ON delay is the condition monitoring time from the

establishment of alarm conditions to its output; an alarm OFF

delay is the condition monitoring time from the establishment

of return-to-normal conditions to its output.

• Setting range: 0 to 999 seconds

• Setting resolution: 1 second (However, about 0.2 second is

to be added to the set time to prevent wrong operation.)

For example, when an alarm ON delay is set to 1 second,

alarm output is generated if alarm status continues for 1

second or more after the input value exceeds the alarm

setpoint. Further, when an alarm OFF delay is set to 2

seconds, alarm output is released if normal condition

continues for 2 seconds or more after the input value has

returned to normal from the alarm status.

5.2.5 Direction of Relay Action

Select the direction of relay energizing in alarm-1 normal

condition and alarm-2 normal condition from among NRM DE-

ENERGIZED (de-energized under normal condition) and NRM

ENERGIZED (energized under normal condition) in [E15: RL1

ACTION] and [E16: RL2 ACTION].

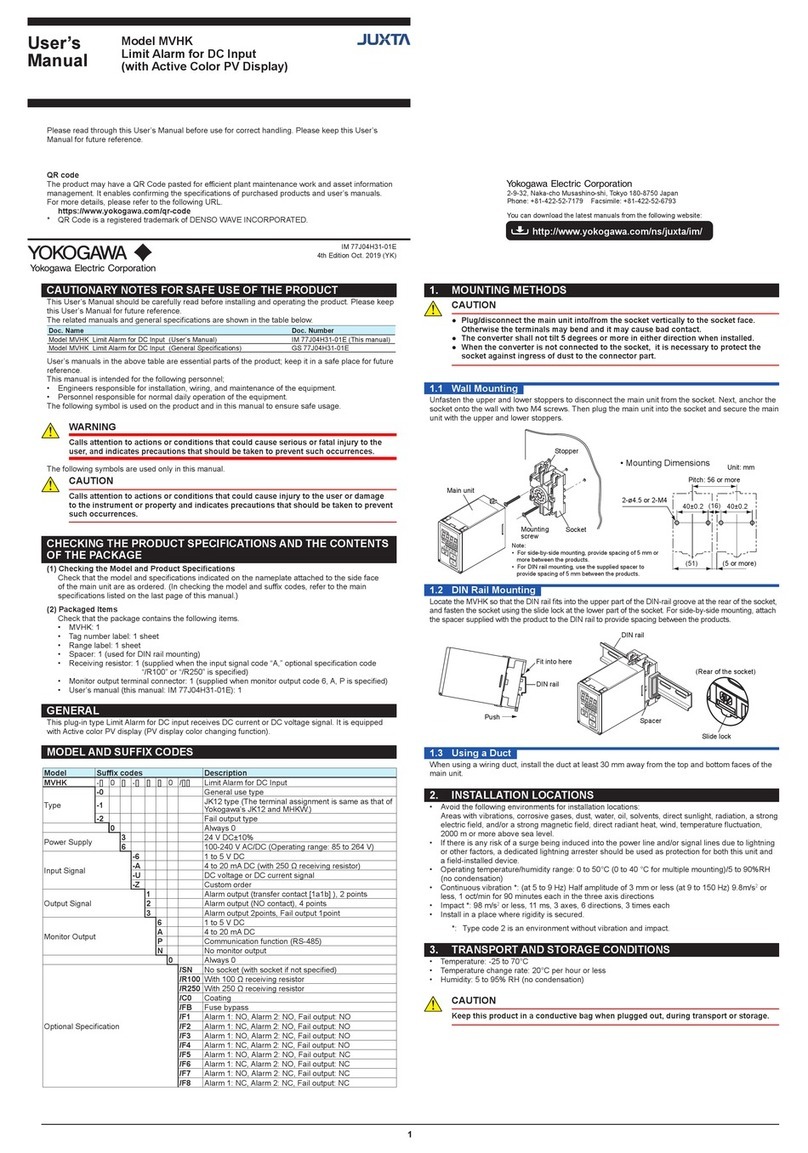

6. DESCRIPTION OF ALARM ACTIONS

This chapter describes examples of alarm actions under the

following conditions.

Item Alarm 1 Alarm 2

Parameter Setpoint Parameter Setpoint

Direction of

alarm action

E05 : ALM1

ACTION

High-

limit

alarm

E06 : ALM2

ACTION

Low-limit

alarm

Alarm setting E03 : SET

POINT1 80% E04 : SET

POINT2 15%

Hysteresis E09 :

HYSTERESIS1 10% E10 :

HYSTERESIS2 5%

Alarm ON

delay

E11 : ON

DELAY1 1 sec E12 : ON

DELAY2 3 sec

Alarm OFF

delay

E13 : OFF

DELAY1 2 sec E14 : OFF

DELAY2 4 sec

Description of

alarm actions

The alarm is output if the

condition where the input

value is 80% or more of

high-limit alarm continues

for 1 second or more.

After the alarm is output,

when the condition where

the input value is less than

70% of high-limit alarm

continues for 2 seconds or

more, the status returns to

normal.

The alarm is output if the

condition where the input

value is 15% or less of low-

limit alarm continues for 3

seconds or more.

After the alarm is output,

when the condition where

the input value is more

than 20% of low-limit alarm

continues for 4 seconds or

more, the status returns to

normal.