3IM77J01T21-01E 5th Edition

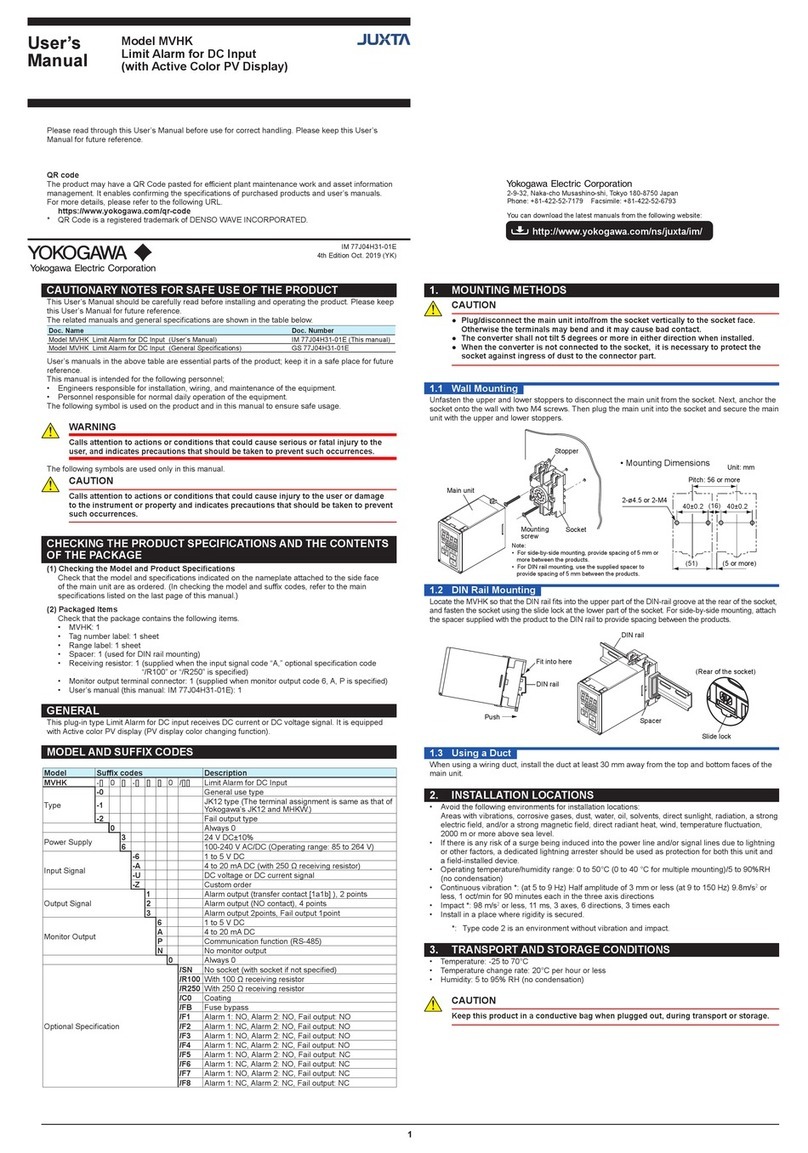

4. DESCRIPTION OF FRONT PANEL AND

CONNECTION OF SETTING TOOLS

4.1 Front Panel

The communications connector on the front panel is used for

setting up parameters using a PC (VJ77 PC-based Parameters

Setting Tool). The alarm indicator lamps for alarm 1 and alarm 2

light up if an alarm occurs.

Alarm indicator lamp

(for alarm 1)

Communication connector

Alarm indicator lamp

(for alarm 2)

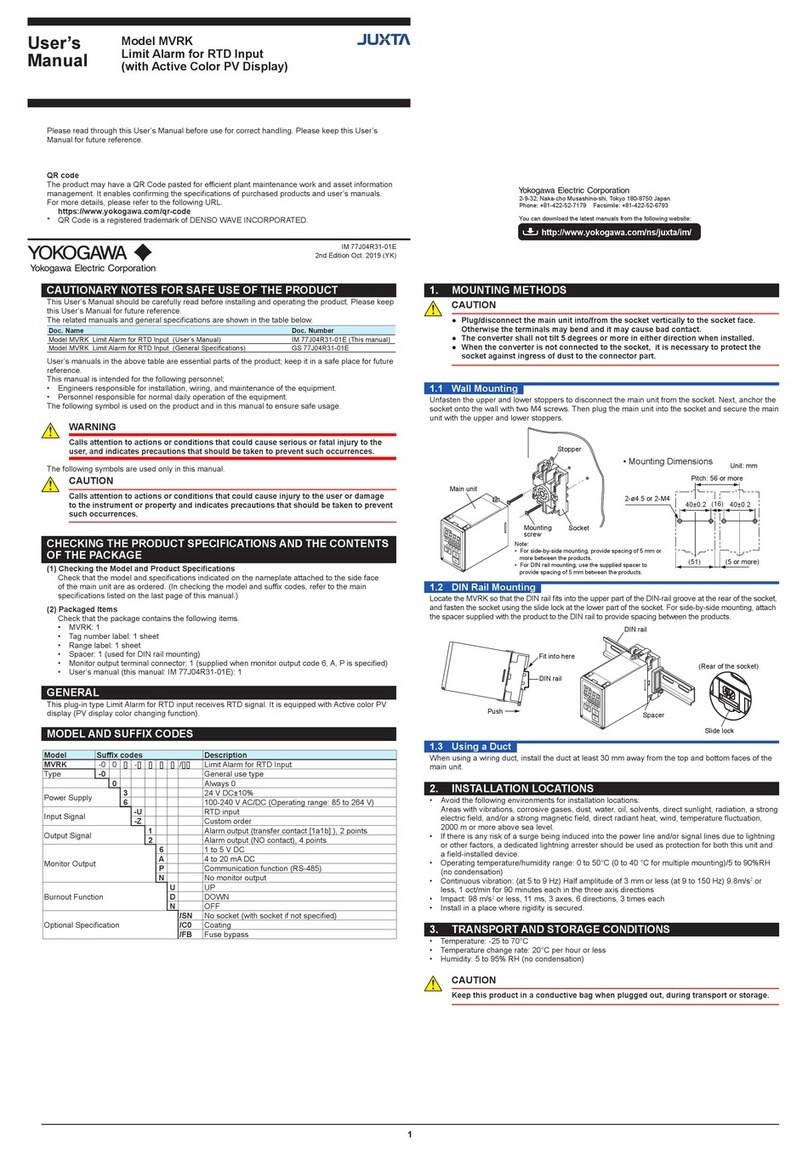

4.2 Connecting the Setting Tools

Connect the modular jack conversion adapter to the JUXTA

communication cable with 5-pin connector and then connect this

adapter to the communication connector of JUXTA.

JUXTA

VJ series

conversion

adapter

Dedicated adapter for VJ77

(L4506HA)

Micro USB (USB2.0) cable

• Use the VJ77 of version R2.02.01 or later.

5. SETTING PARAMETERS

Set the parameters using a PC (VJ77 PC-based Parameters

Setting Tool). Refer to the list of parameters in this manual and

the user’s manual for VJ77 PC-based Parameters Setting Tool

(IM 77J01J77-01E).

CAUTION

For the input sensor type, input type and temperature

unit, the default values of the input range, alarm setpoints

and others are pre-dened according to the values to be

selected. Set the parameters as follows.

1. Settings related to inputs: Set the parameters in order

starting with (1).

(1) Input type

(2) Temperature unit

(3) Input range

2. Before setting the parameters related to alarm output

and making the adjustments such as wiring resistance

correction and output correction, set the parameters

described in 1 above.

If setting the parameters (1) to (2) in 1 above after set-

ting the parameters related to alarm output or making

the adjustment, the setpoint will be changed or the

adjustment will be reset to the default.

5.1 Settings Related to Input

5.1.1 Input Type and Temperature Unit

Select the thermocouple type to use from among K, T, E, J, R,

S, B, N, W3 and W5 in [D08: TC TYPE].

Select the temperature unit to use in [D21: UNIT].

5.1.2 Input Range

Set the 0% value of input range in [D24: INPUT1 L_RNG]

and the 100% value of input range in [D25: INPUT1 H_RNG]

numerically within the following specied range.

Input type (TC) Measurable range (°C)

JIS C 1602, IEC 60584-1 (ITS-90) TYPE K -270 to 1372

JIS C 1602, IEC 60584-1 (ITS-90) TYPE T -270 to 400

JIS C 1602, IEC 60584-1 (ITS-90) TYPE E -270 to 1000

JIS C 1602, IEC 60584-1 (ITS-90) TYPE J -210 to 1200

JIS C 1602, IEC 60584-1 (ITS-90) TYPE R -50 to 1768

JIS C 1602, IEC 60584-1 (ITS-90) TYPE S -50 to 1768

JIS C 1602, IEC 60584-1 (ITS-90) TYPE B 0 to 1820

JIS C 1602, IEC 60584-1 (ITS-90) TYPE N -270 to 1300

Type W3(Note 1) 0 to 2300

Type W5(Note 2) 0 to 2300

Note 1: W3 is the abbreviation of W97Re3-W75Re25 (tungsten97

% rhenium 3 % - tungsten75 % rhenium25 %) ASTM E988

Standard

Note 2: W5 is the abbreviation of W95Re5-W74Re26 (tungsten95

% rhenium 5 % - tungsten74 % rhenium 26 %) ASTM E988

Standard

5.1.3 Software Filter

Set the software lter in [D57: S/W FILTER].

OFF, LOW, MIDDLE, HIGH (default value: OFF)

When LOW, MIDDLE, or HIGH is selected, a rst-order lter

equivalent to 100 ms, 300 ms, or 1 s is inserted in the input.

5.1.4 Setting Burnout Action

Set the burnout action in [D39:BURN OUT]. Set “OFF”, “UP”,

or “DOWN.”

CAUTION

• Changing the burnout action direction resets the input

adjusted value and the wiring resistance corrected

value.

• Changing the input range resets the input adjusted

value.

• Execute the wiring resistance correction when the

burnout action direction or input wiring is changed.

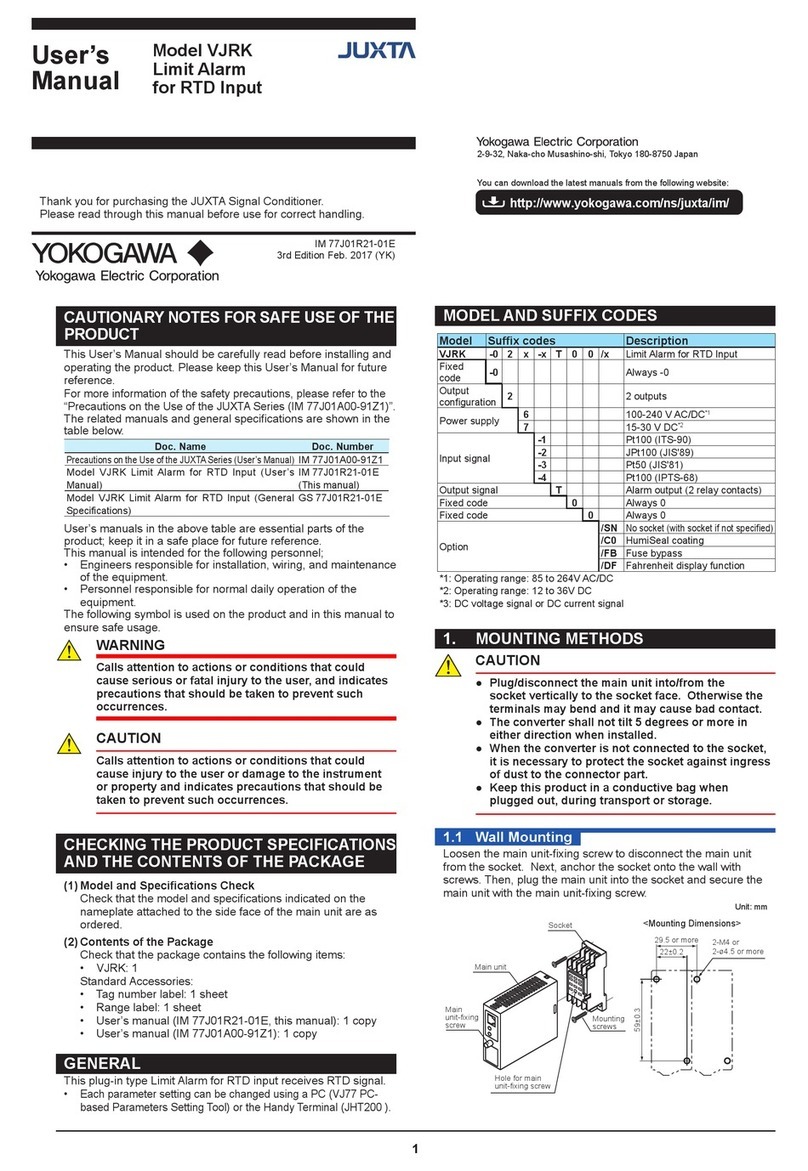

5.1.5 Wiring Resistance Correction

When an error occurs due to the inuence of the input wiring

resistance, the input can be corrected. Apply a stable input as

shown below and select EXECUTE in [P01: WIRING R]. The

correction is also required when the direction of burnout action

is changed from UP (DOWN) to DOWN (UP) or the wiring for

input is changed.

VJTK

VJ77

Short-circuit at the cable end.

5.2 Settings Related to Alarm Output

5.2.1 Alarm Setpoint

Set the alarm setpoints of alarm 1 and alarm 2 in [E01: SET

POINT1] and [E02: SET POINT2] numerically.

• Setting range: 0 to 100% of input range

• Setting resolution: 4 signicant digits

5.2.2 Direction of Alarm Action

Select the direction of alarm-1 action and that of alarm-2

action from among HIGH ALM (high-limit alarm) and LOW

ALM (low-limit alarm) in [E05: ALM1 ACTION] and [E06:

ALM2 ACTION].

• To activate alarm status when input signal ≥ alarm setpoint,

select HIGH ALM.

• To activate alarm status when input signal ≤ alarm setpoint,

select LOW ALM.