JOHNSON CONTROLS 7

FORM 150.62-NM8 (1020)

SECTION 2 - UNIT CONTROLS .....................................................................................................81

INTRODUCTION .........................................................................................................................................81

IPU II AND I/O BOARDS ............................................................................................................................81

UNIT SWITCH .............................................................................................................................................82

DISPLAY ......................................................................................................................................................82

KEYPAD.......................................................................................................................................................82

BATTERY BACK-UP...................................................................................................................................82

TRANSFORMER ........................................................................................................................................82

SINGLE SYSTEM SELECT AND PROGRAMMING # OF COMPRESSORS........................................82

STATUS KEY..............................................................................................................................................83

General Status Messages......................................................................................................................83

Fault Status Messages ..........................................................................................................................85

Unit Warning...........................................................................................................................................87

STATUS KEY MESSAGES.........................................................................................................................88

DISPLAY/PRINT KEYS ..............................................................................................................................89

Oper Data Key ........................................................................................................................................89

Oper Data Quick Reference List ...........................................................................................................92

Print Key .................................................................................................................................................93

Operating Data Printout.........................................................................................................................93

History Printout ......................................................................................................................................94

History Displays .....................................................................................................................................94

Software Version ....................................................................................................................................97

ENTRY KEYS ..............................................................................................................................................98

Up and Down Arrow Keys .....................................................................................................................98

Enter/Adv Key.........................................................................................................................................98

SETPOINTS KEYS......................................................................................................................................99

Cooling Setpoints ..................................................................................................................................99

Leaving Chilled Liquid Control .............................................................................................................99

Return Chilled Liquid Control .............................................................................................................100

Schedule/Advance Day Key ................................................................................................................100

Program Key.........................................................................................................................................102

UNIT KEYS ...............................................................................................................................................107

Options Key ..........................................................................................................................................107

CLOCK....................................................................................................................................................... 111

SECTION 3 - UNIT OPERATION ..................................................................................................113

CAPACITY CONTROL..............................................................................................................................113

SUCTION PRESSURE LIMIT CONTROLS ............................................................................................113

DISCHARGE PRESSURE LIMIT CONTROLS.......................................................................................113

LEAVING CHILLED LIQUID CONTROL.................................................................................................113

Leaving Chilled Liquid Control Override to Reduce Cycling...........................................................114

RETURN CHILLED LIQUID CONTROL..................................................................................................114

SYSTEM LEAD/LAG.................................................................................................................................116

COMPRESSOR LEAD/LAG.....................................................................................................................116

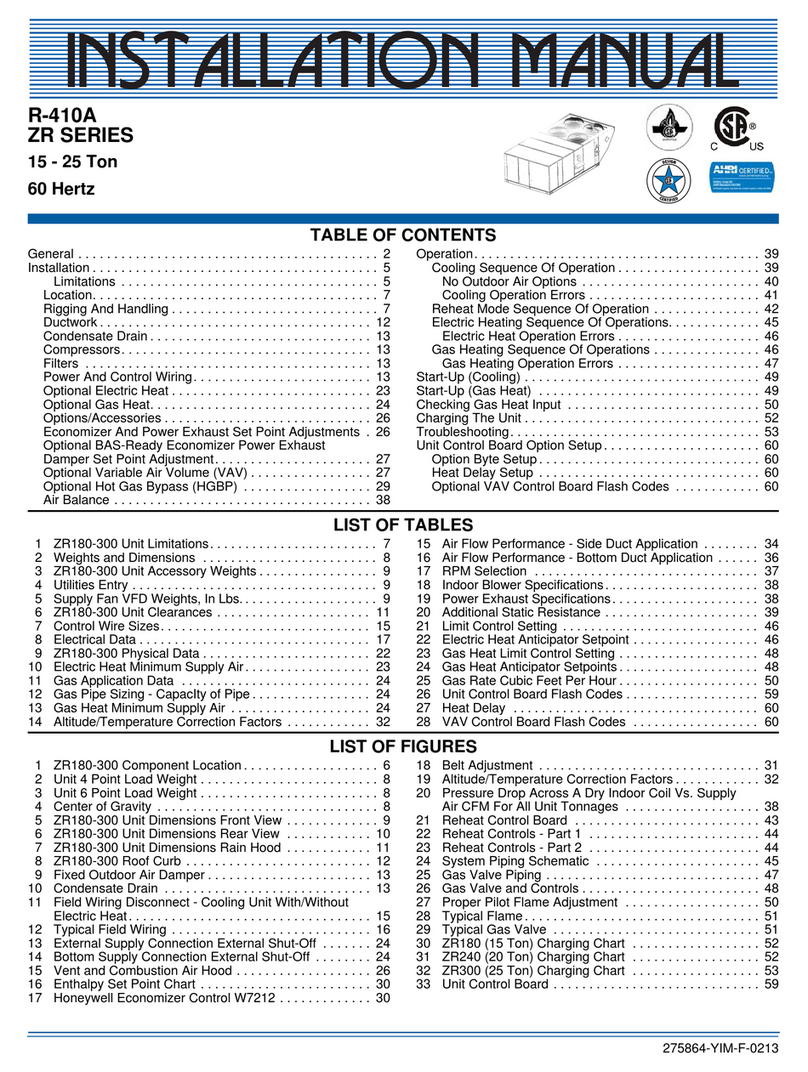

TABLE OF CONTENTS (CONT'D)