recommended for lab use or controlled conditions where a more rugged, field

cable is not necessary. These cables include:

Cable number 605107 1-meter cable; single-junction pH sensor

Cable number 605177 4-meter cable; single-junction pH sensor

Cable number 605108 1-meter cable; single-junction ORP sensor

Cable number 605178 4-meter cable; single-junction ORP sensor

Cable number 605109 1-meter cable; single-junction pH/ORP sensors

Cable number 605179 4-meter cable; single-junction pH/ORP sensors

STANDARD PRO SERIES SENSOR INSTALLATION

Throughout the manual, the term “sensor” refers to the removable portion or

electrode sensing portion of the cable assembly. For example, the DO sensor or

pH sensor is the part that can be removed from a field cable and replaced with a

new sensor. The conductivity sensor is not removable from a non-Quatro cable

but still refers to the “sensing” portion and will be referred to as a sensor. This

section covers most of the sensor installations on a Professional Series cable

bulkhead including the following sensors:

2003 - Polarographic

DO (black)

1001 - pH 1003 - pH/ORP 1005 - Chloride

2002 - Galvanic

DO (gray)

1002 - ORP 1004 - Ammonium 1006 - Nitrate

See the next section of this manual for installation instructions for the Quatro

cable’s Conductivity/Temperature sensor.

Dual sensor bulkhead ports are numbered 1

and 2, see figure to the left. Please refer to the

following tables to determine correct sensor

installation into each port of a two port cable.

Batteries must be installed in the instrument even if powering

the unit via the USB connection. This will retain the correct

date and time if the PC is turned off. If the USB power is

disconnected and there are no batteries in the instrument, the

date and time will need to be reset upon subsequent power on.

NOTE - On subsequent battery changes you will have approximately 2 minutes

to change the batteries before the clock resets. If the clock resets, the instrument

will automatically bring up the Date/Time menu the next time it is powered on

in order to update this information. This is important, especially if you intend

to log data!

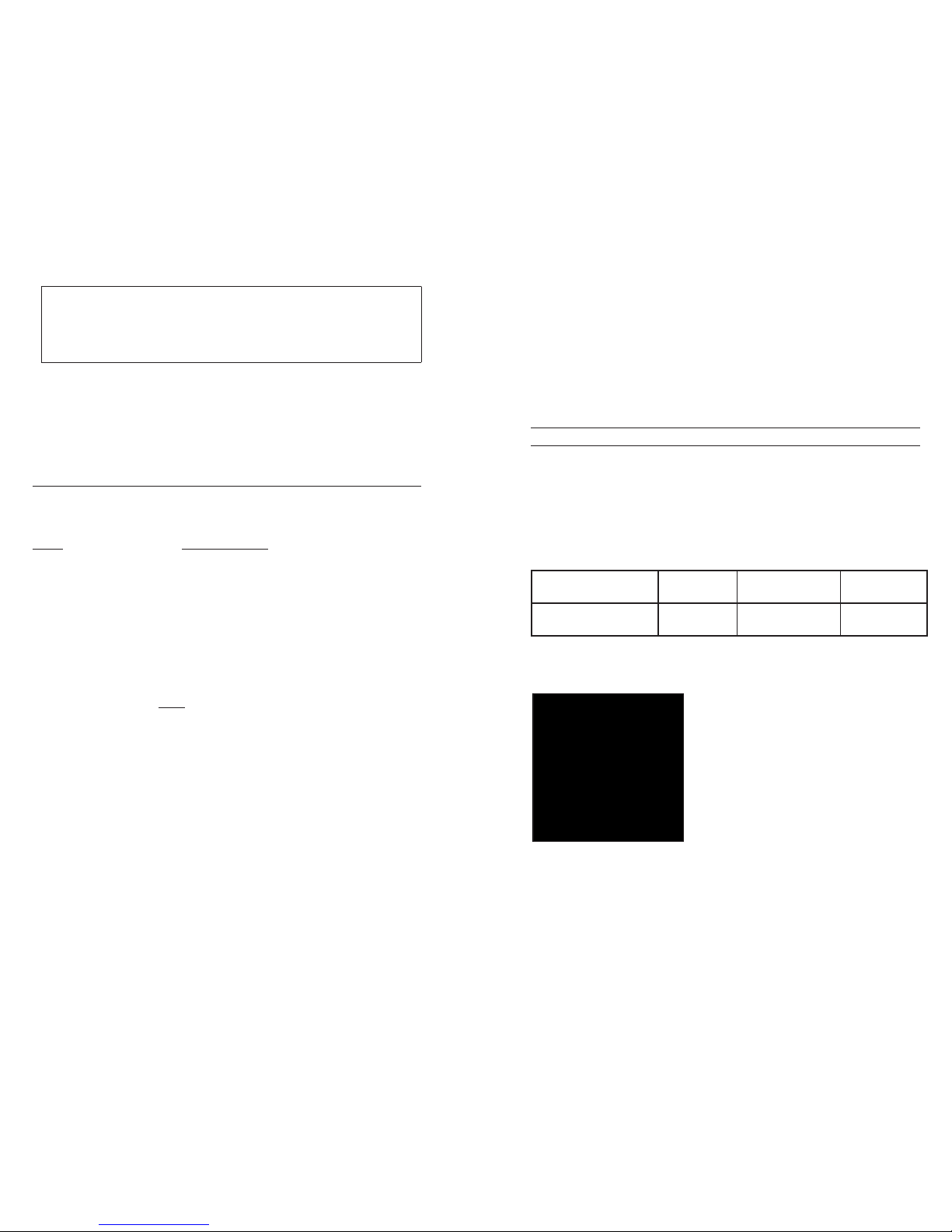

setup

The Pro Plus instrument has several compatible field-rugged cable/sensor

options, each with temperature:

Cable: Available Sensors:

Cable number 60520-x DO/temp (605780 for lab BOD)

Cable number 60530-x Conductivity/temp

Cable number 60510-x ISE*/temp

Cable number 6051010-x ISE*/ISE*/temp

Cable number 6051020-x ISE*/DO/temp

Cable number 6051030-x ISE*/conductivity/temp

Cable number 6052030-x DO/conductivity/temp

Cable number 605790-x DO/conductivity/ISE*/ISE*/temp (Quatro**)

*ISE (Ion Selective Electrode) notates a port that can accept pH, ORP, Ammonium,

Nitrate, Chloride, and, in some cases, a pH/ORP combination sensor.

**Cable 605790 will be referred to as a Quatro cable throughout this manual.

All cables come in standard lengths of 1, 4, 10, 20, and 30-meters (3.28, 13,

32.8, 65.6, and 98.4-feet) with options for special order lengths up to 100-meters

(328-feet) on the 60520-x cables. Contact YSI or your local representative for

additional information.

In addition there are several cable options with built in sensors for the

measurement of pH and ORP that are not considered field-rugged (non-

replaceable sensors, less rugged single-junction sensors). These cables are

i