Electro-Pneumatic Positioner YT-1000R

13. CAUTION AND HANDLING

cDo not apply large vibration or impact to the positioner. It causes trouble.

The positioner must be handled very carefully during transportation and operation.

dIf the positioner is used under temperature outside of the specification, the sealing

materials deteriorate quickly and also the positioner may not operate normally.

eDo not remove the terminal cover at a dangerous position during power conduction.

fBe sure that the terminal cover and body cover are put on during the operation.

gIf you leave the positioner at the operation site for a long time without using it, put the

cover on it so that the rain water does not enter the positioner.

If the atmosphere is of high temperature or high humidity, take measures to avoid

condensation inside. The condensation control measures must be taken thoroughly for

export shipment.

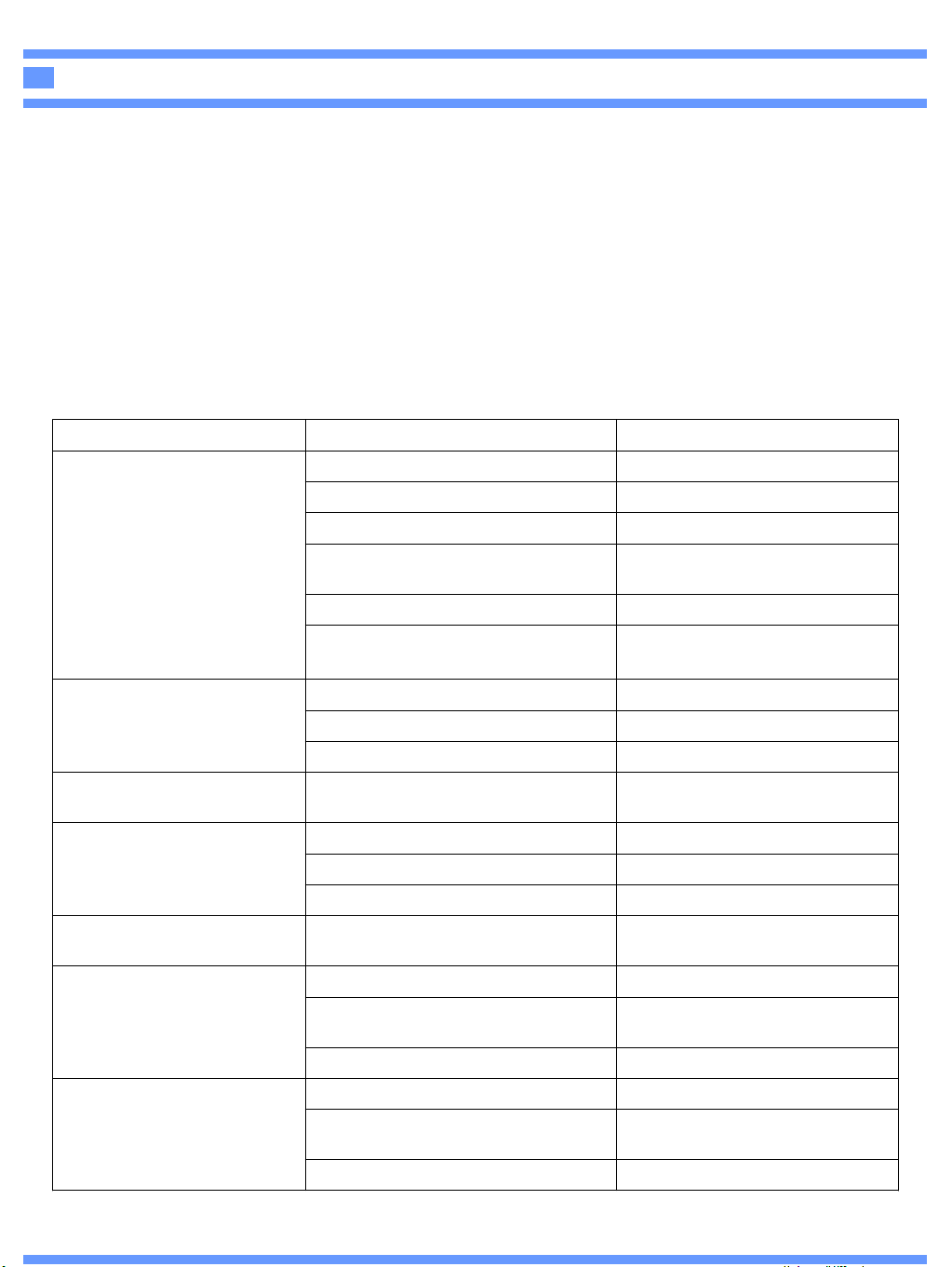

14. TROUBLE SHOOTING

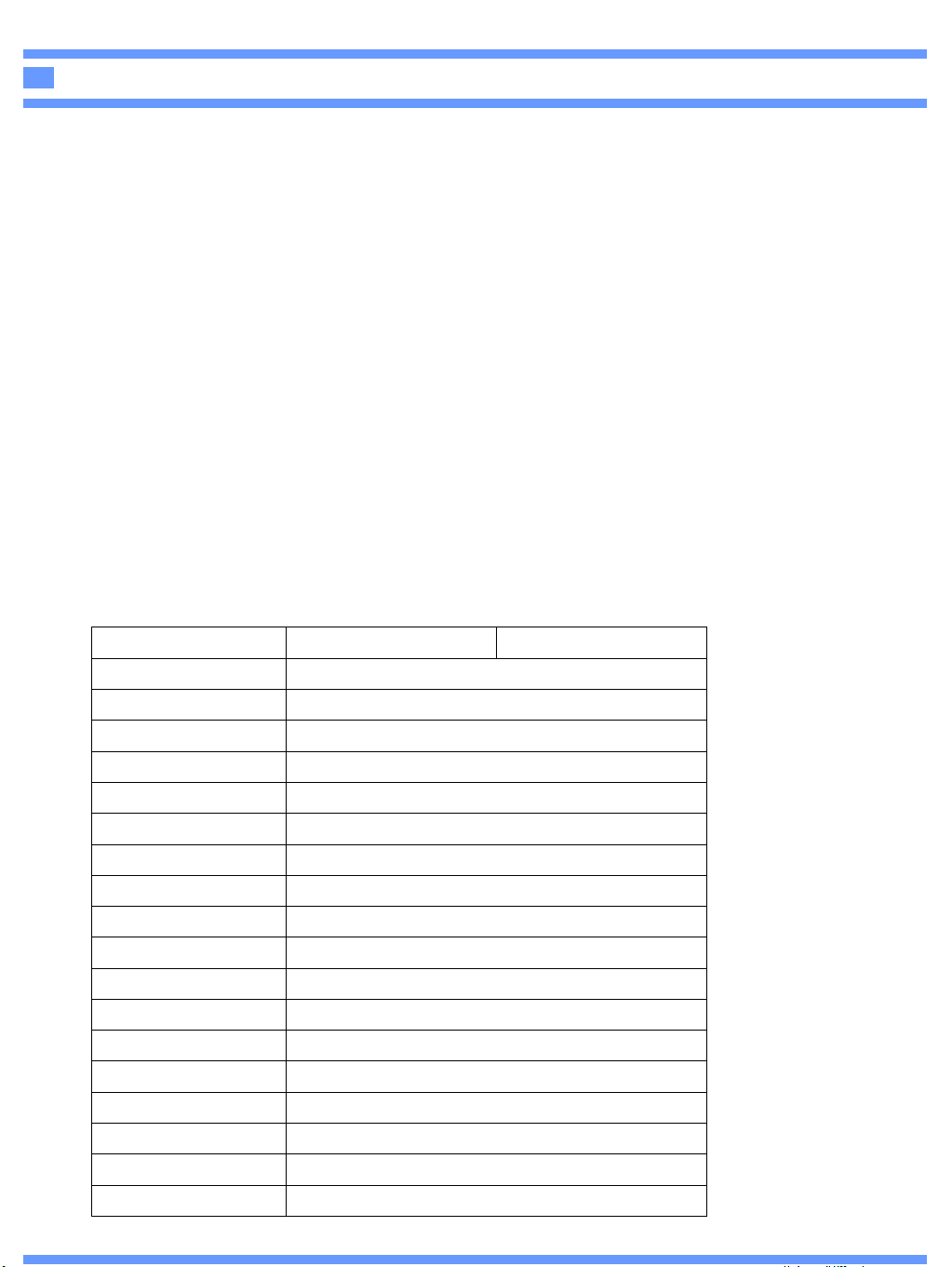

Replace Cam Shaft Cam shaft is worn out

Tighten connection

Loose connection of actuator and

poisitioner

Readjust Seat adjusterWrong setting of Seat Adjuster

Hysteresis is not good

Replace regulatorSupply pressure is unstable

Readjustment of Zero, Span

Adjustment

Wrong Zero, Span adjustment

Readjust setting of feedback leverWrong setting of feedback lever

Linearity is not good

Correct position of tube

Wrong connection of OUT1 and

OUT2 tube

Actuator is operated by

On/Off only

Clean or replace fixed orificeClogged fixed orifice

Insert orificeToo low of actuator volume

Insert stabilizer springOff-positioned stabilizer spring

Hunting is occured

Clean nozzle or repalce Motor

Unit

Clogged nozzle

Output pressure is operated

by A/M Switch only

Clean or replace fixed orifice Clogged fixed orifice

Replace Motor UnitWrong contact or search of Flapper

Tighten or replace A/M switchLeakage of A/M switch

OUT1 pressure raised

And stay, does not

Come down

Correct setting and tighten

Loose or wrong setting of Feedback

Lever

Replace Motor UnitClogged Nozzle

Replace Motor Unit

Short or open circuit of terminal

Motor

Connect wiring (+) and (-)Wrong wiring for (+) and (-)

Tighten set screw of TerminalLoose connection

Input supply airToo low or none supply air

Not operated with Input

Signal applied

What to doCauseCondition