CONTENTS

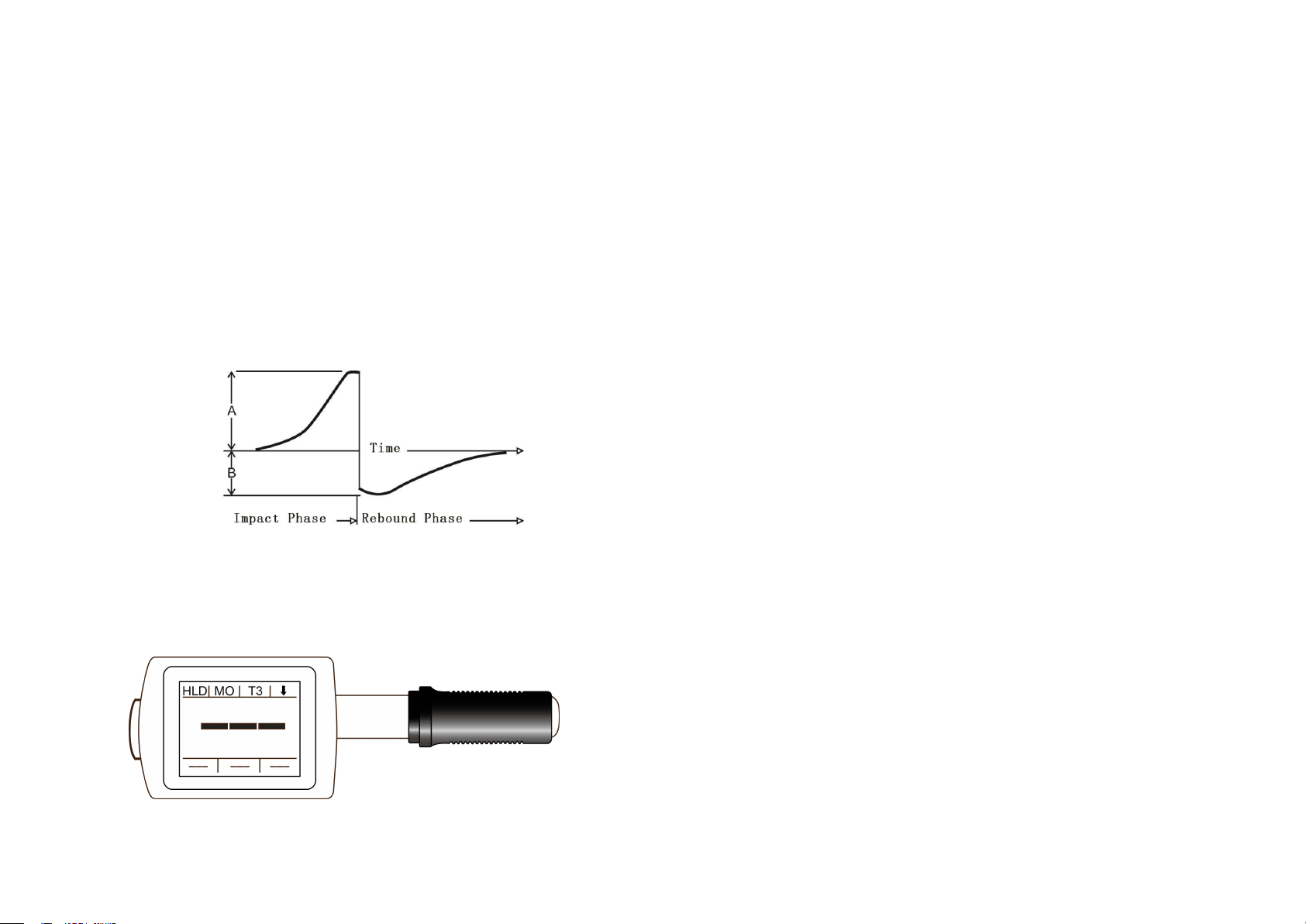

1. Principle of Leeb Hardness Testing Method.............................. 1

2. Instrument and Impact Device Diagram ...............................................1

2.1 Instrument Diagram......................................................................... 1

2.2 Standard Configuration .................................................................. 2

2.3 Optional Accessories........................................................................2

3. Functions And Applications.......................................................................... 2

3.1 Technical Specifications...................................................................2

3.2 Applications......................................................................................3

4.Pre-treatment of Workpiece............................................................................ 4

4.1 Workpiece Requirements.............................................................................4

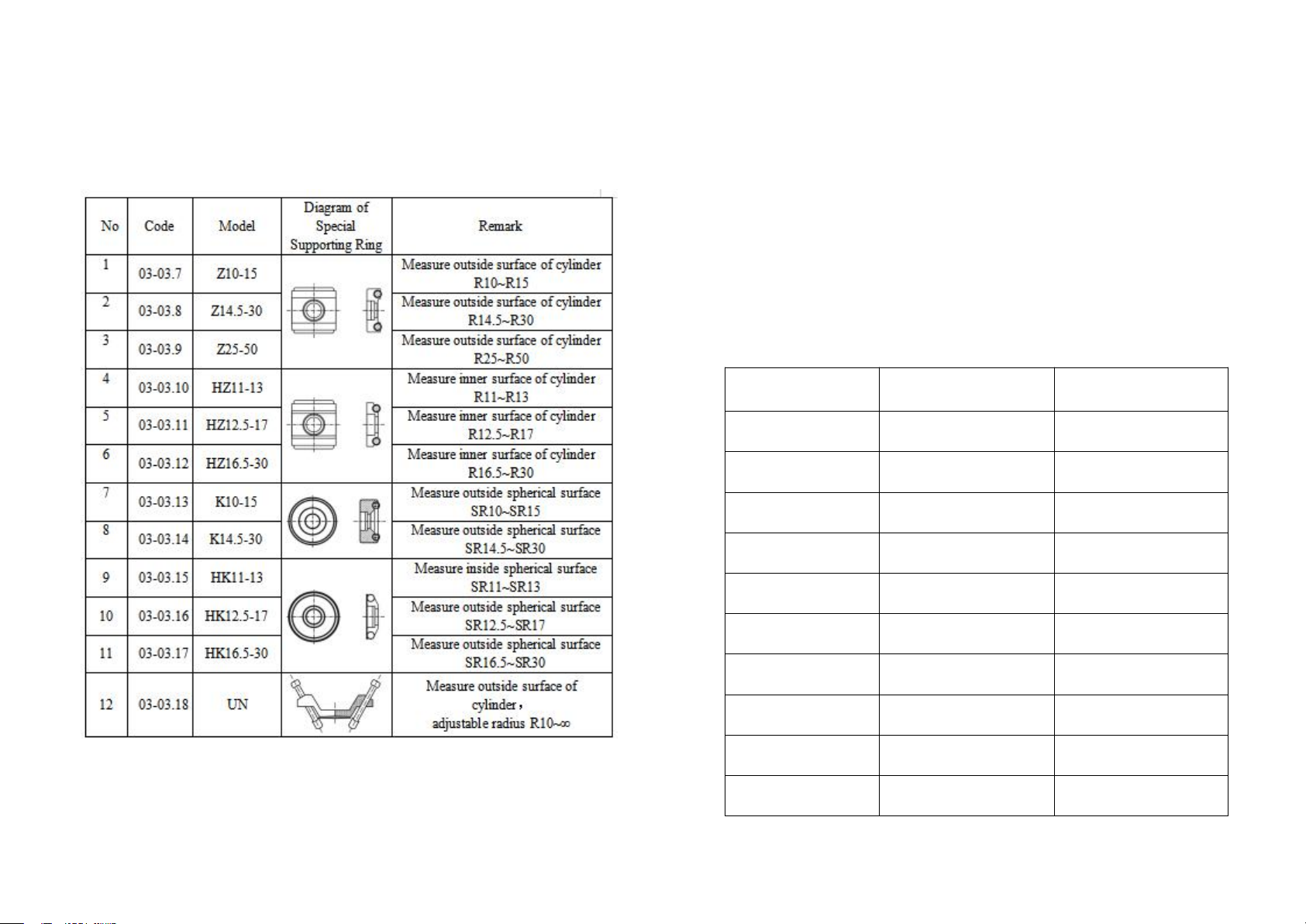

4.2 Selection of Supporting Ring.......................................................................5

5. Operation.................................................................................................................6

5.1 Turn On the Instrument.............................................................................6

5.2 Parameters Setting..........................................................................6

5.2.1 Material.............................................................................. 6

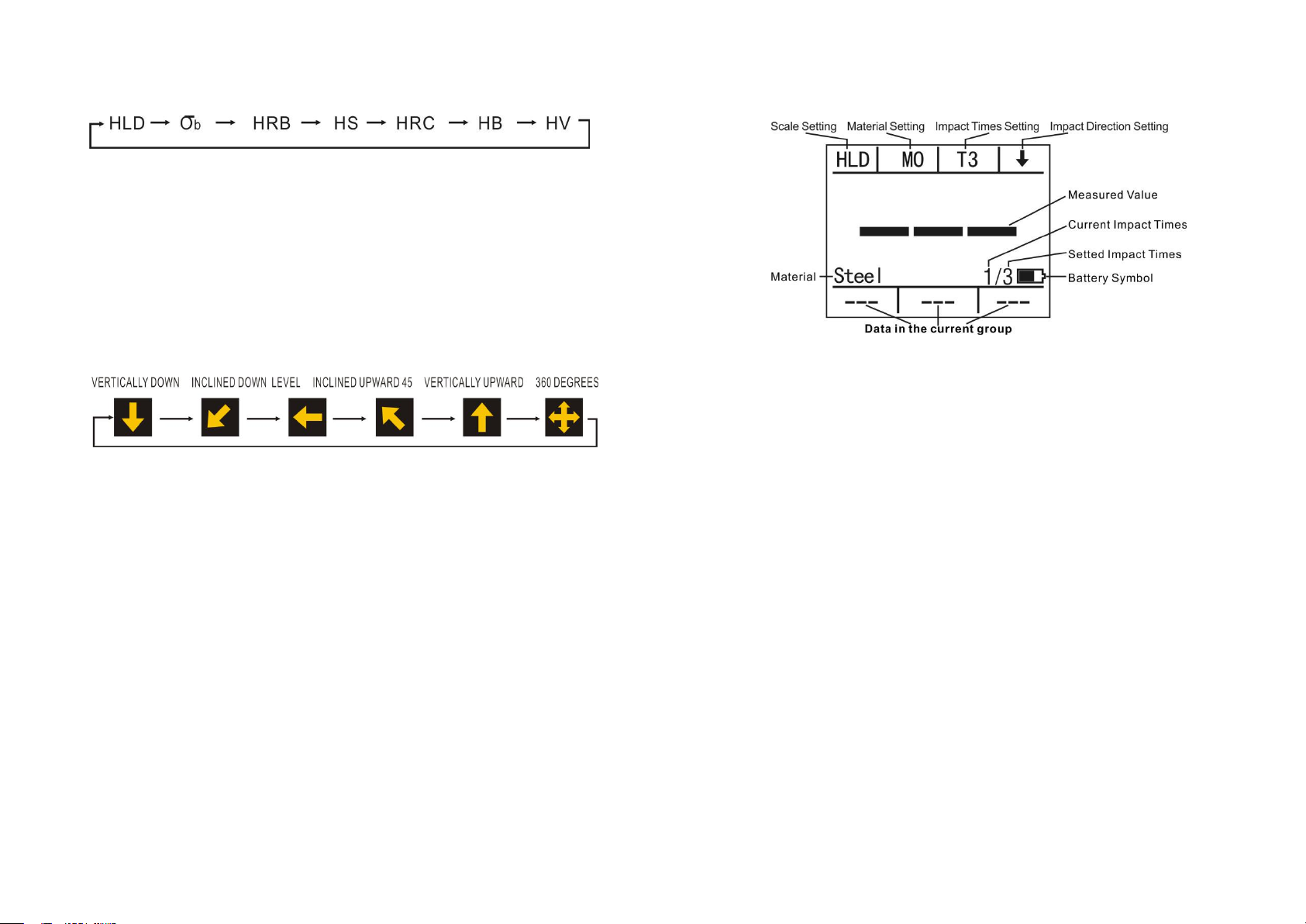

5.2.2 Hardness Scale................................................................... 7

5.2.3 Impact Times......................................................................7

5.2.4 Impact Direction................................................................ 7

5.3 Measuring......................................................................................7

5.3.1 Operating............................................................................7

5.4 Interface Description.....................................................................8

5.4.1 Default Interface ............................................................ 9

5.4.2 Calibration Interface.......................................................... 9

5.4.3 Sub-interface of Read The Storage ................................10

5.4.4 Sub-interface of Read The Storage..................................10

5.4.5 Setting and Shutdown Interface....................................... 11

5.4.6 Storage Data Transmission...............................................11

6.Maintenance&Servicing.................................................................................11