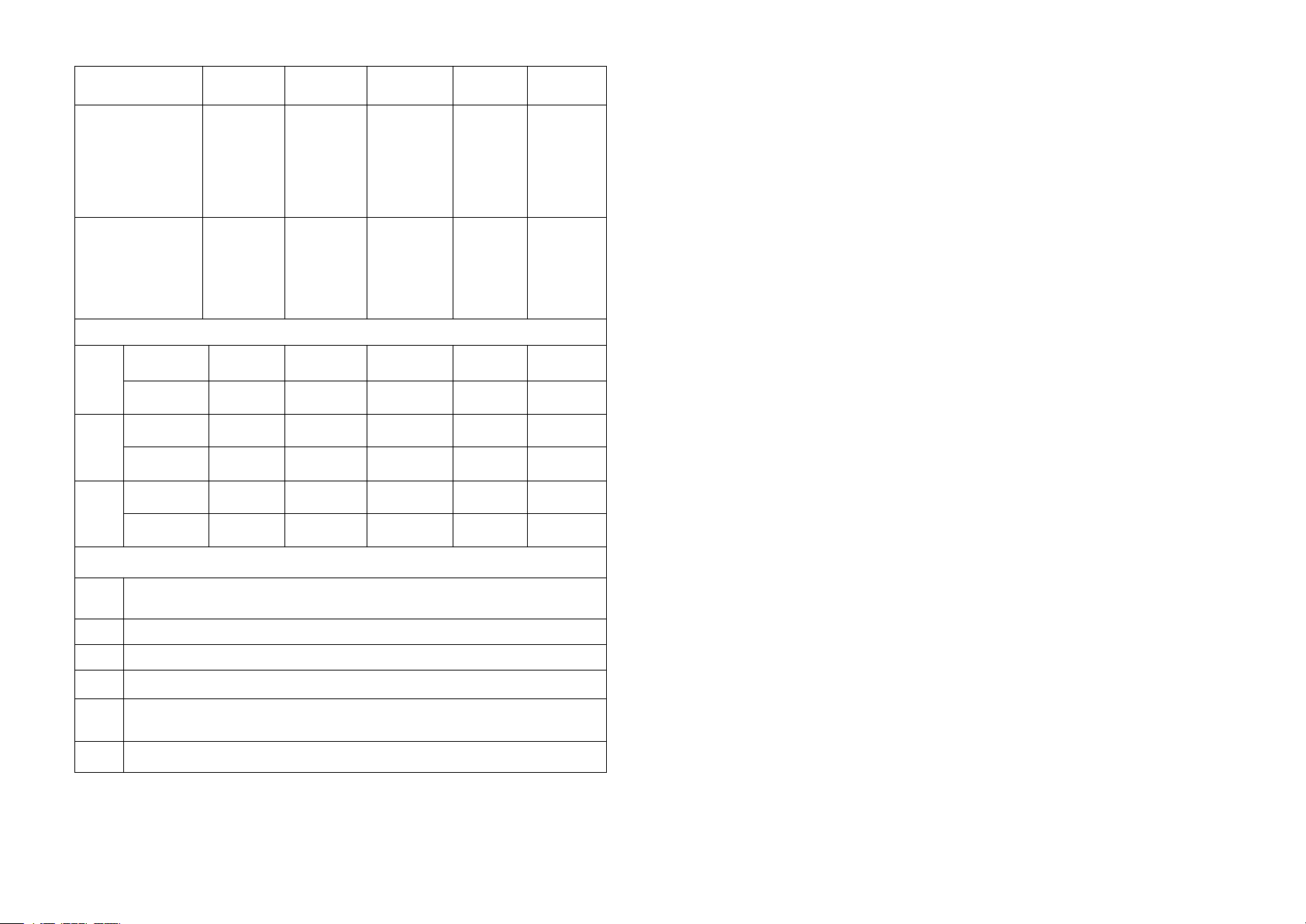

CONTENTS

1.Principle of Leeb Hardness Testing Method................................1

2. Instrument and Impact Device Diagram.............................................2

2.1 Instrument Diagram ...................................................................... 2

2.2 D Type Impact Device Diagram....................................................... 3

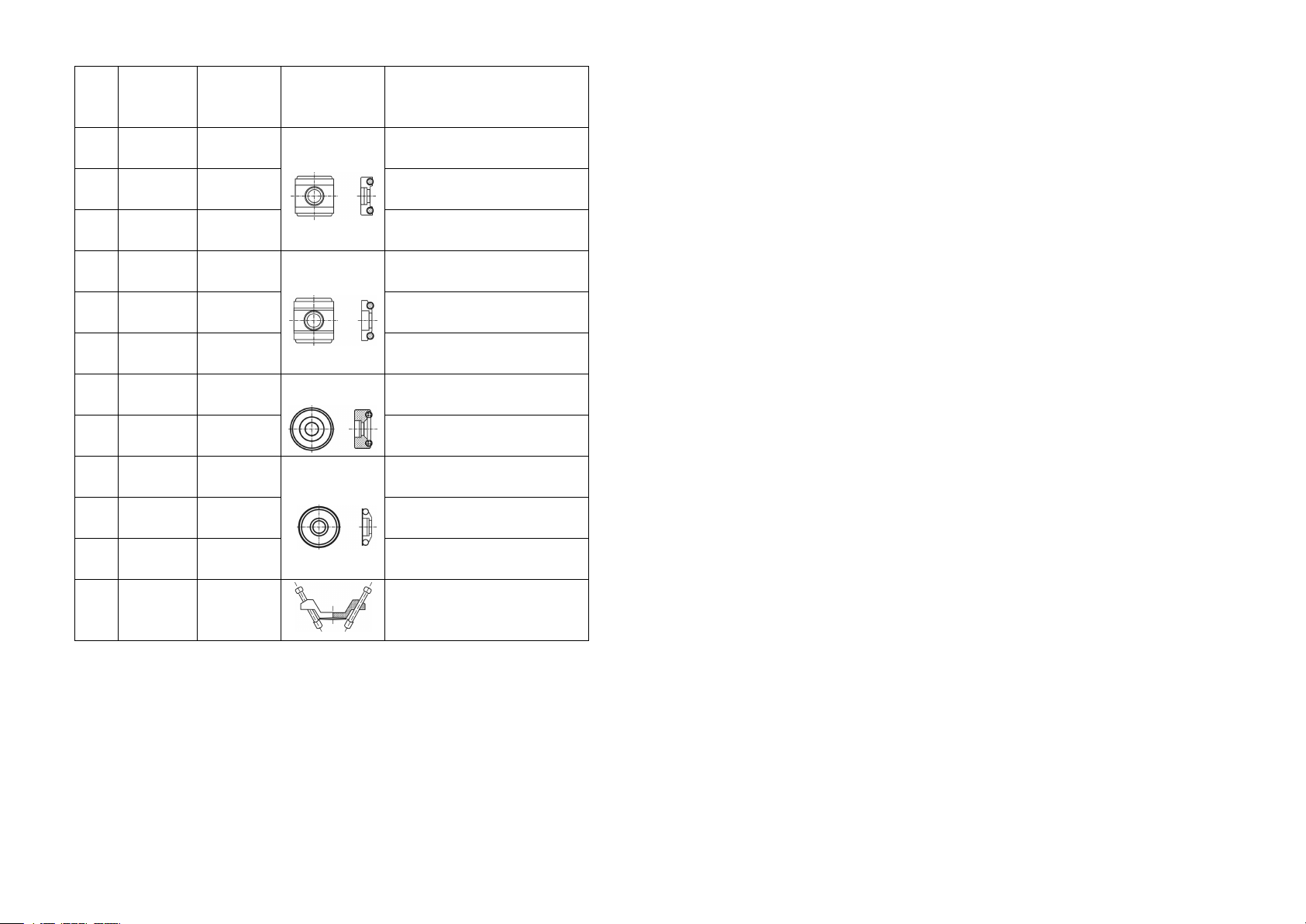

2.3 Types of Impact Device.................................................................... 4

2.4 Impact Devices Specification........................................................... 4

2.5 Standard Configuration.....................................................................6

2.6 Optional Accessories.........................................................................6

3.Functions and Applications..........................................................7

3.1 Technical Specifications................................................................... 7

3.2 Applications.......................................................................................8

4.Pre-Treatment of Workpiece........................................................ 8

4.1 Workpiece Requirements.................................................................. 8

4.1.1 Surface Roughness Requirements......................................... 8

4.1.2 Weight and Thickness Requirements.....................................9

4.1.3 Surface Hardened Layer Thickness....................................... 9

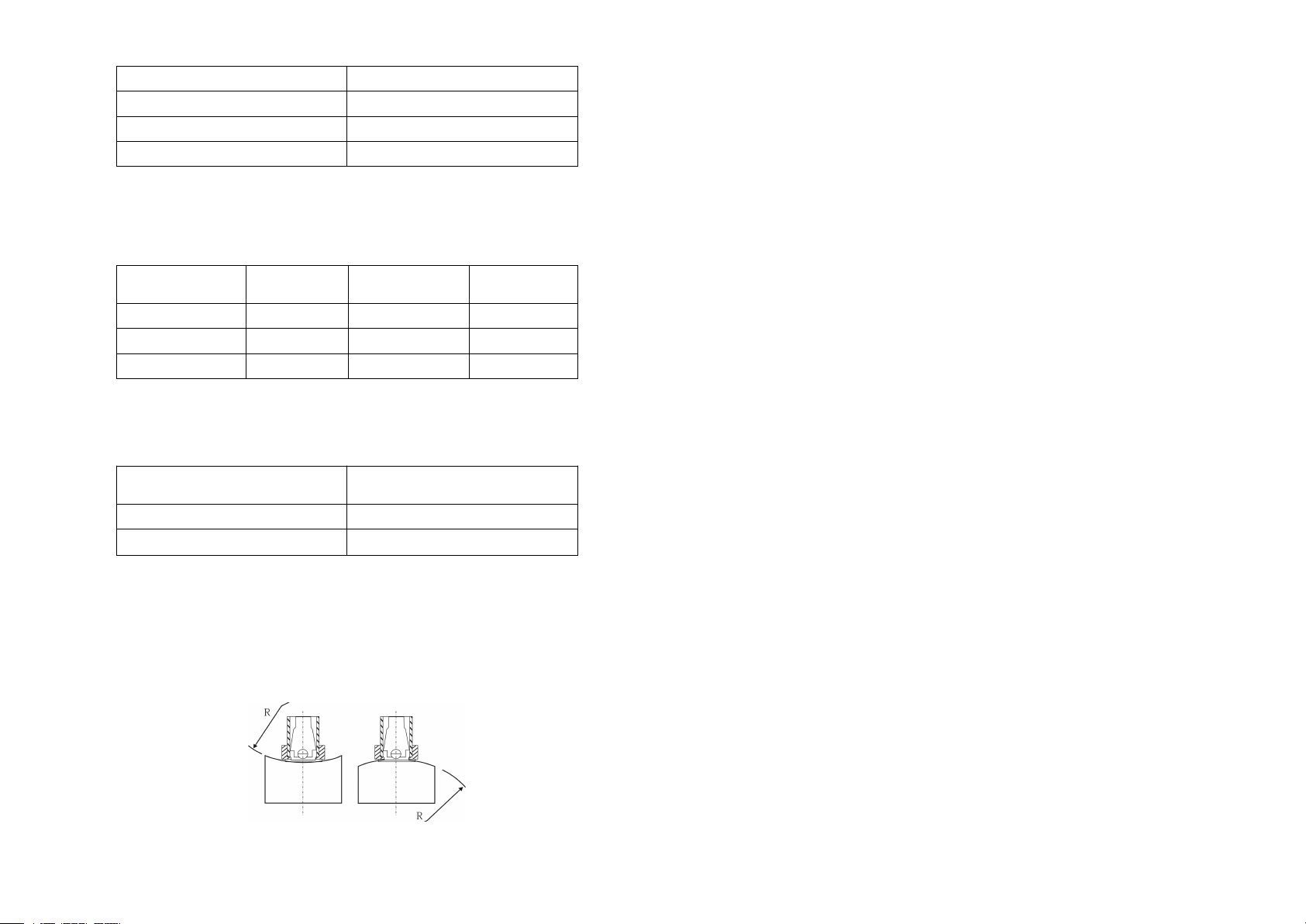

4.1.4 Curved Surface Requirement.................................................9

4.2 Support of Test Piece...................................................................... 10

5.Operation....................................................................................10

5.1 View Switching............................................................................... 10

5.2 Keyboard......................................................................................... 11

5.3 Turn on the Instrument....................................................................12

5.4 Parameters Setting...........................................................................12

5.4.1 File Number......................................................................... 12

5.4.2 Material................................................................................ 12

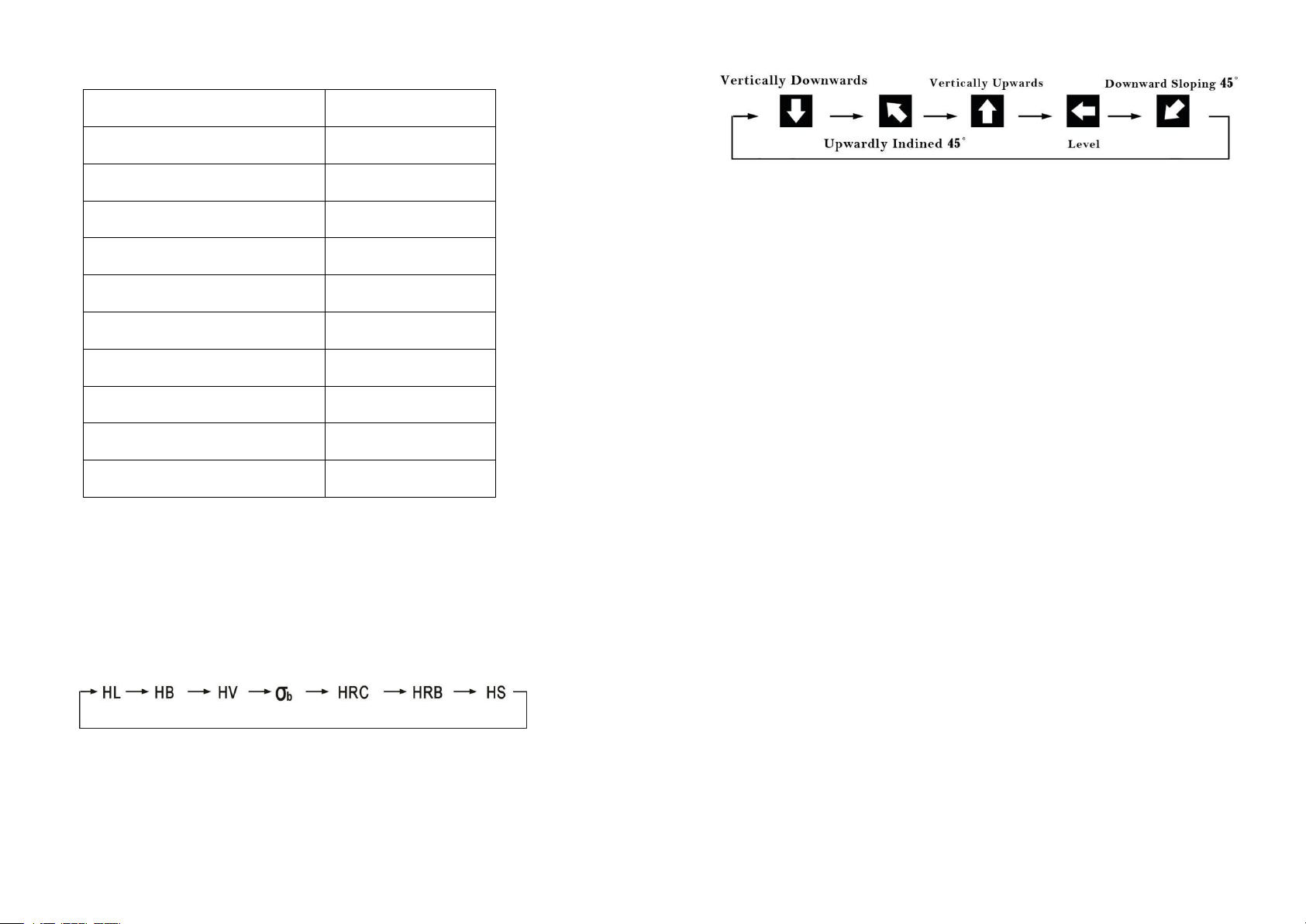

5.4.3 Hardness Scale..................................................................... 13

5.4.4 Impact Direction.................................................................. 13

5.4.5 Impact Times........................................................................14

5.4.6 Set Upper Limit and Lower Limit Alarm............................ 14

5.4.7 Set the types of the Impact Device...................................... 15

5.4.8 Languages............................................................................ 15

5.4.9 Auto Power-Off Setting ..................................................... 15

5.4.10 Delete All Files.................................................................. 15

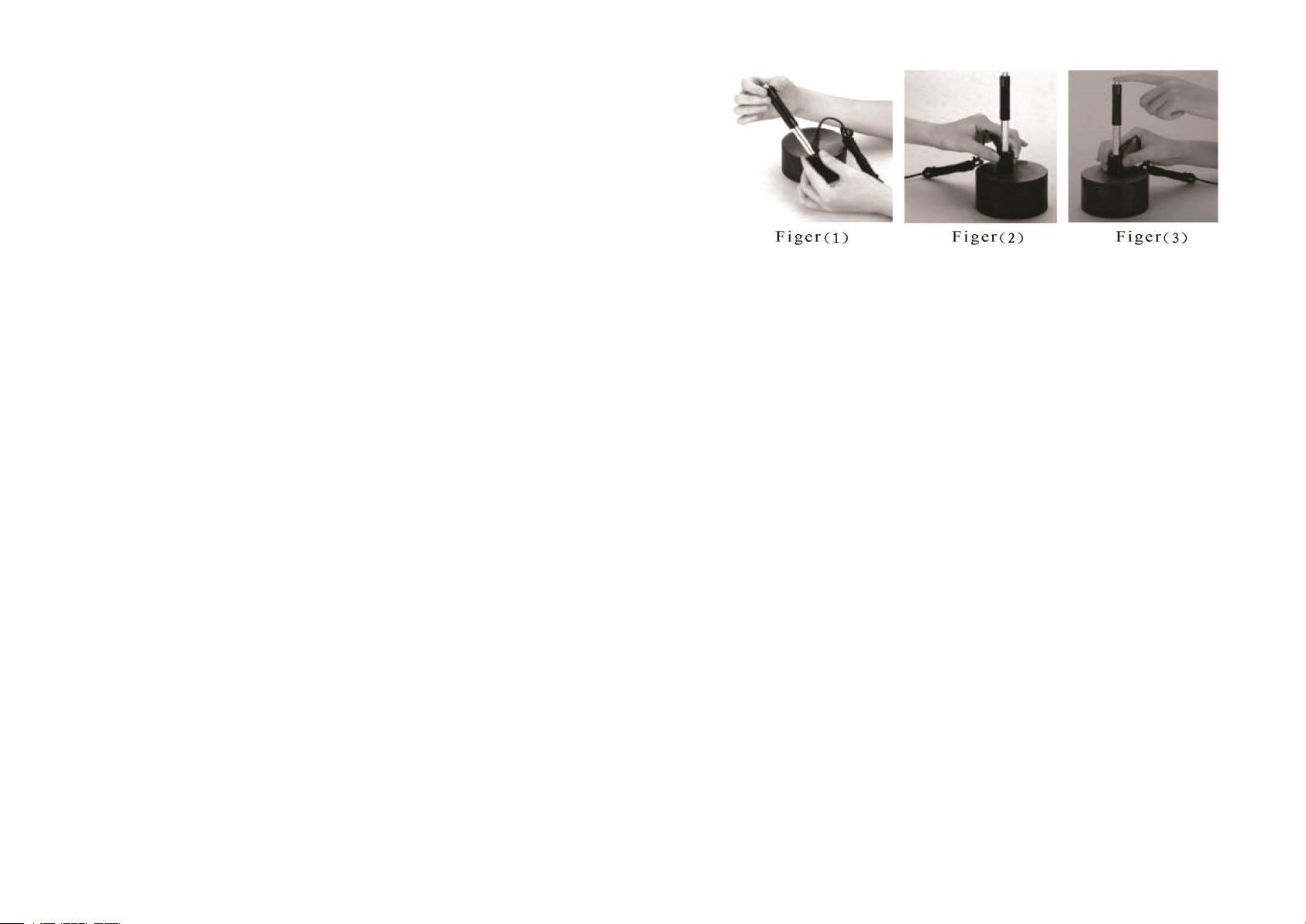

5.5 Measuring........................................................................................15

5.6 Average Value..................................................................................16

5.7Delete the Gross Error Value Manually 16

5.8 Data Save and Read Setting............................................................16

5.8.1 Storage Testing Result....................................................... 16

5.8.2 Reading................................................................................ 17

5.8.3 Delete................................................................................... 17

5.8.4 Data Transmission........................................................................17

5.9 Calibration..................................................................................... 17

6. Maintenance & Servicing........................................................... ..18

6.1 Clean the Impact Device................................................................. 18